Construction method for precision perforation drainage holes in coal mine underground roadways

A technology of underground roadway and construction method, applied in drainage, mining equipment, earthwork drilling and mining, etc., can solve the problems of long period, high cost of roadway excavation, heavy pollution, etc. The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and examples. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

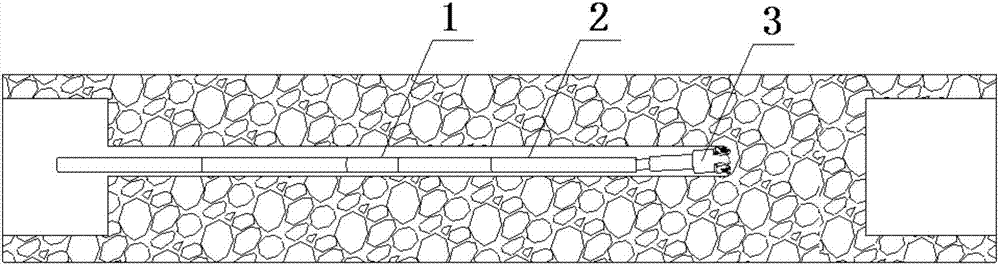

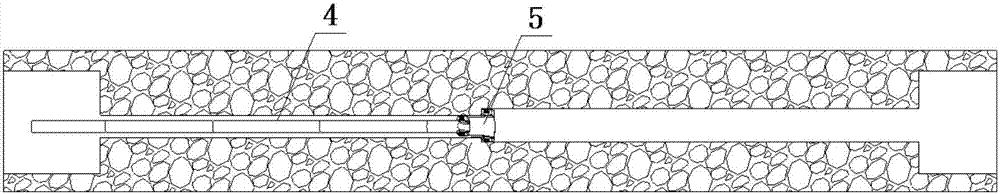

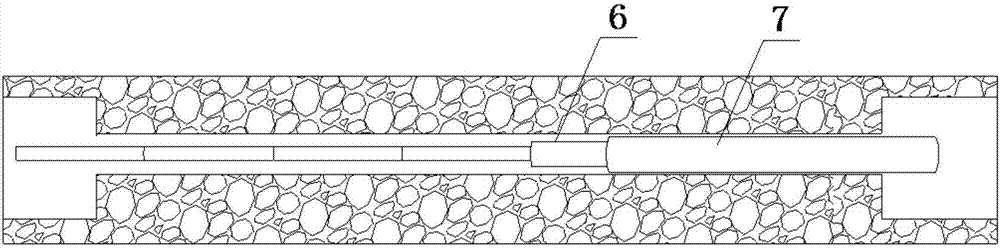

[0035] see Figure 1 to Figure 5 , shows the construction method of the coal mine underground roadway precisely crossing drainage holes of the present invention.

[0036] The method for constructing precisely opposite drainage holes in underground coal mine roadways includes the following steps:

[0037] Step 1: Drilling preparation, determine the inclination angle and azimuth angle of the drilling hole, among which, the drilling construction design can be carried out according to the drainage requirements of the working face, geological data and precise drilling hole layout requirements to determine the inclination angle and azimuth angle of the dril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com