Multi-joint accurate positioning carthamus tinctorius harvesting mechanical arm and harvesting method

A precise positioning and multi-joint technology, applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of inaccurate identification and positioning, pollution of safflower, dense and disorderly, etc., to improve harvesting efficiency and accurately align Flowers, the effect of improving the success rate of harvesting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0129] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

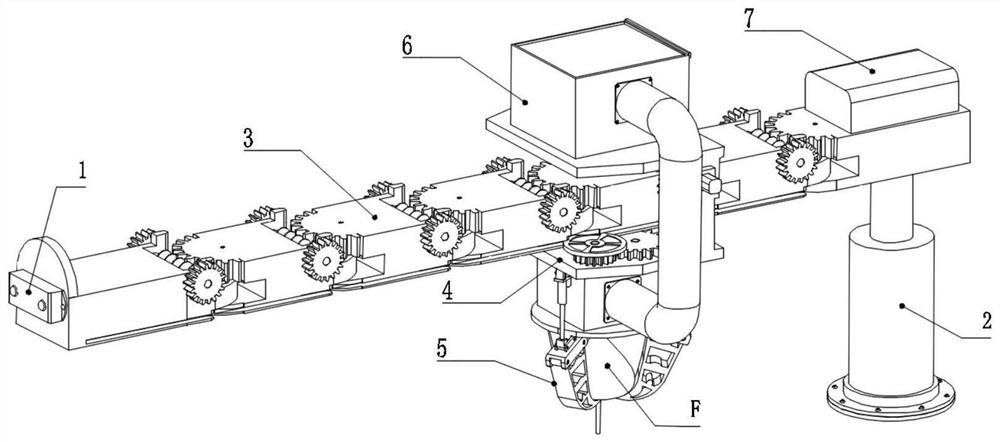

[0130] Such as figure 1 As shown, a multi-joint precise positioning safflower harvesting robot arm includes a binocular visual recognition system 1, a vertical lifting mechanism 2, a multi-joint connection module 3, a motor drive device 4, a filament harvesting mechanism 5, and a negative pressure collection mechanism 6 and controller 7.

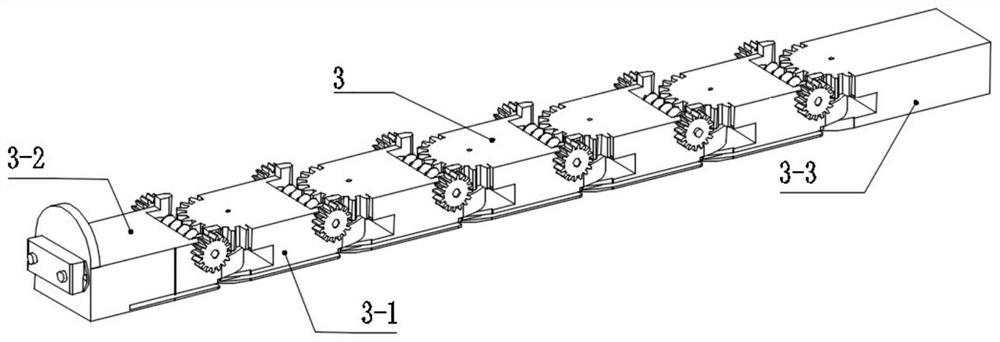

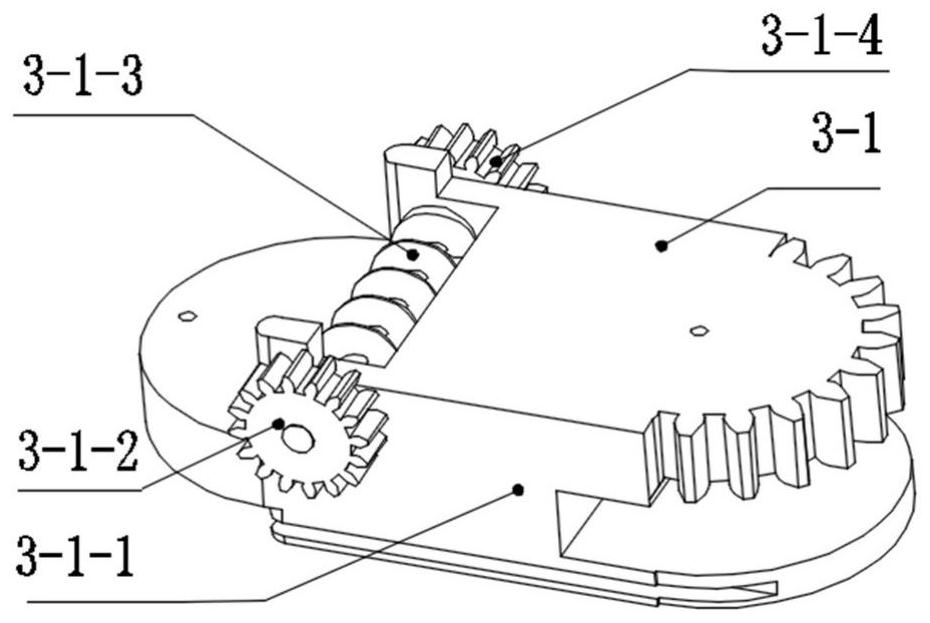

[0131] Such as figure 2As shown, the multi-joint connecting module 3 includes an intermediate connecting block 3-1, a front connecting block 3-2 and a rear connecting block 3-3; the front connecting block 3-2, a plurality of intermediate connecting blocks 3-1, the rear The end connection blocks 3-3 are connected head to tail in sequence; the rear end connection block 3-3 is affixed to the top of the vertical lifting mechanism 2, and the bottom end of the vertical elevating mechanism 2 is affixed to the harvester; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com