Patents

Literature

89results about How to "Enter fully" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

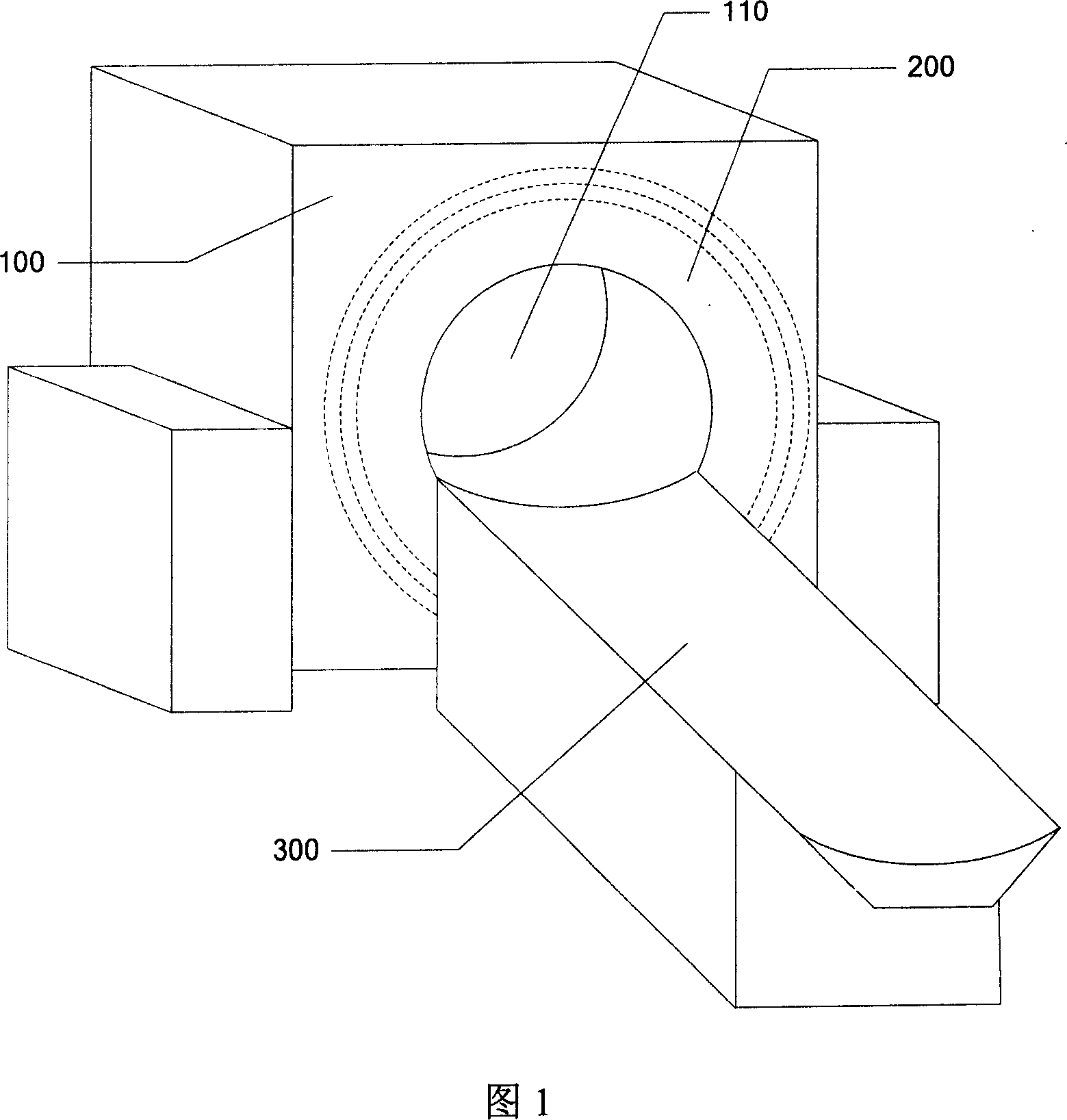

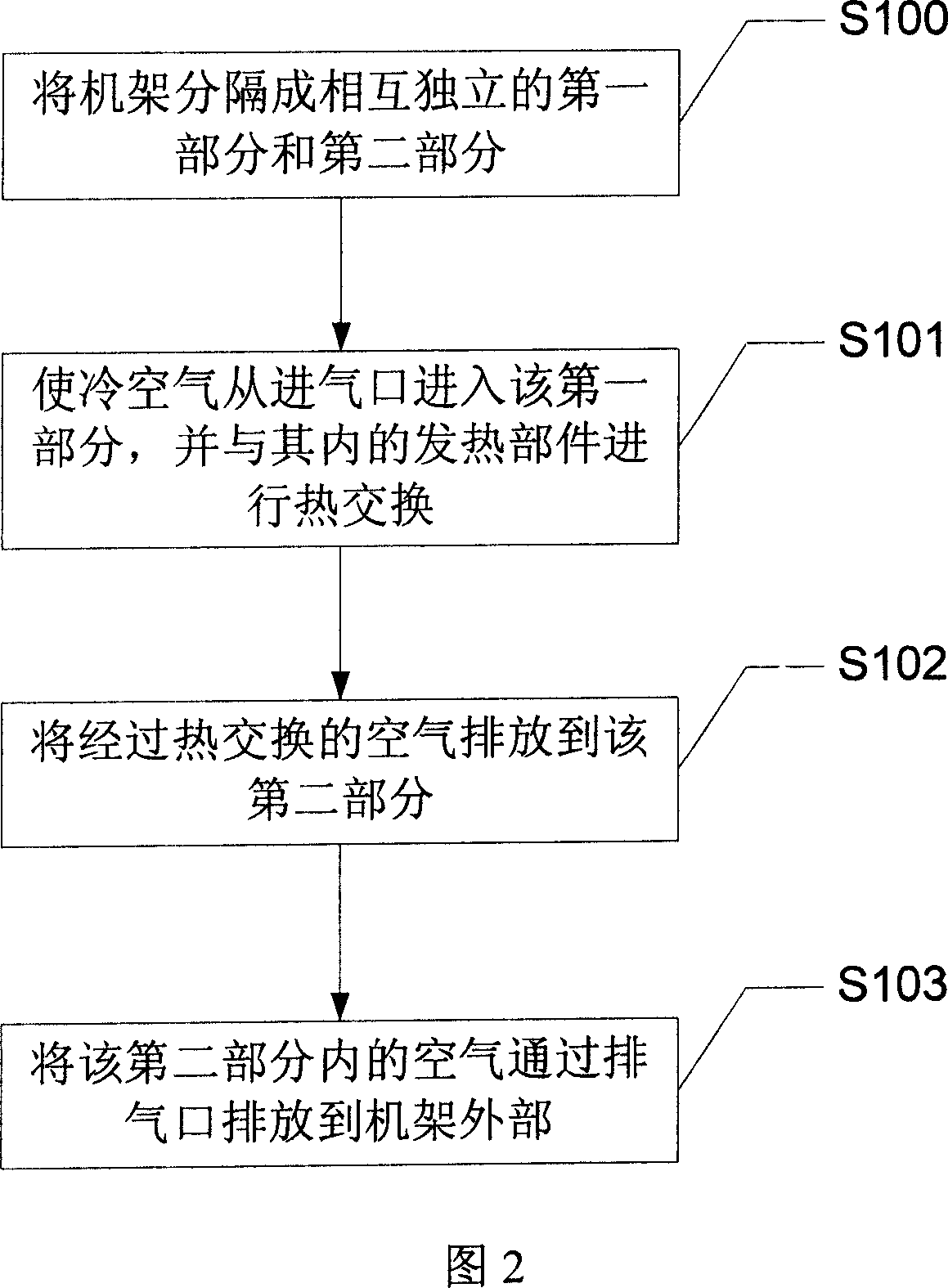

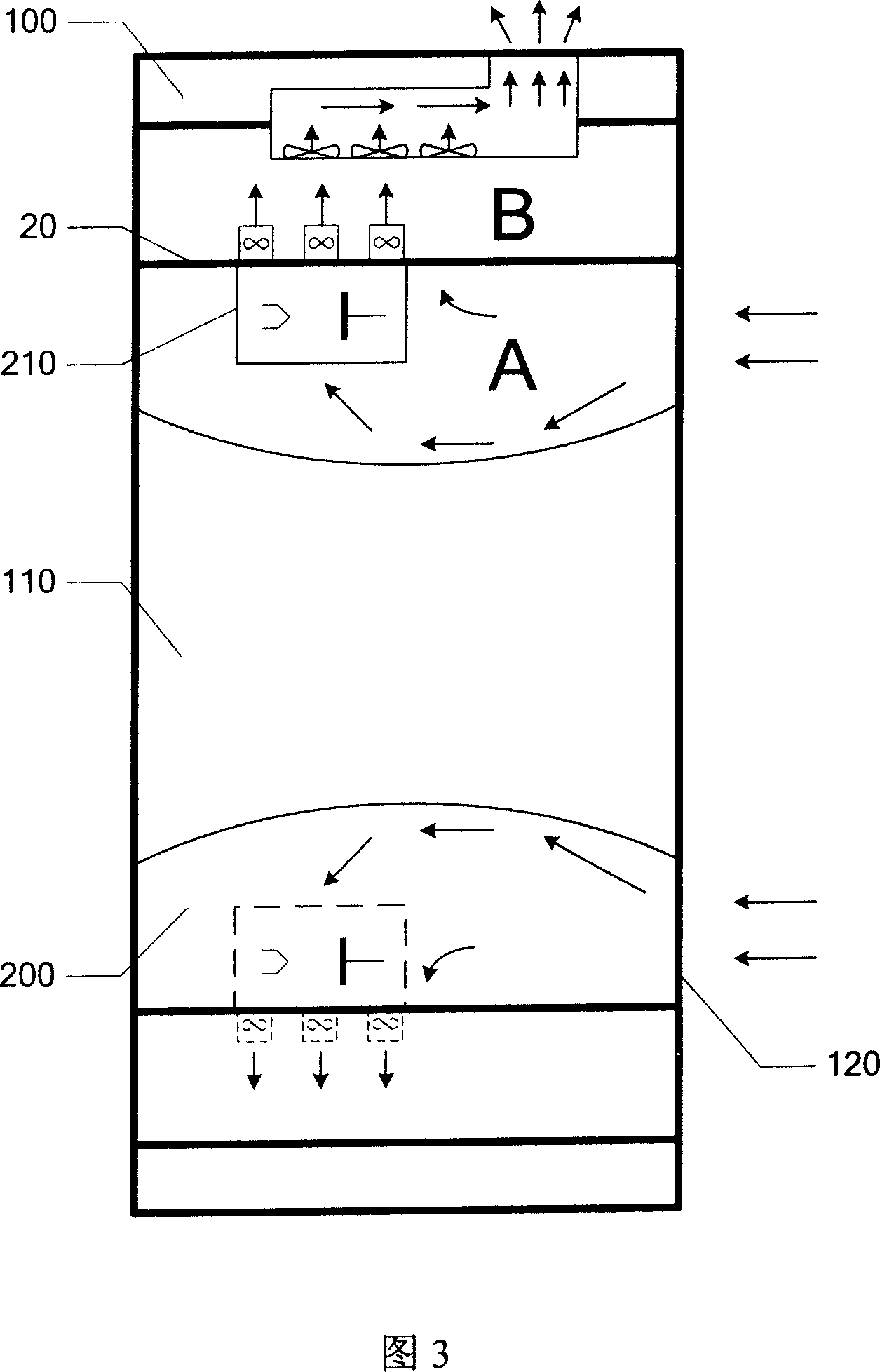

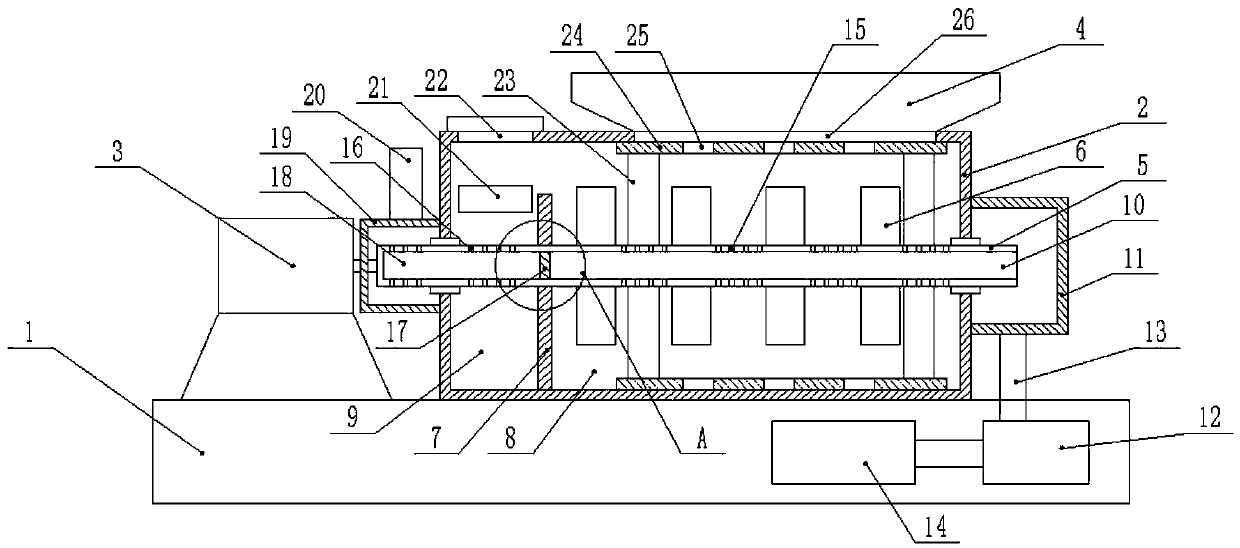

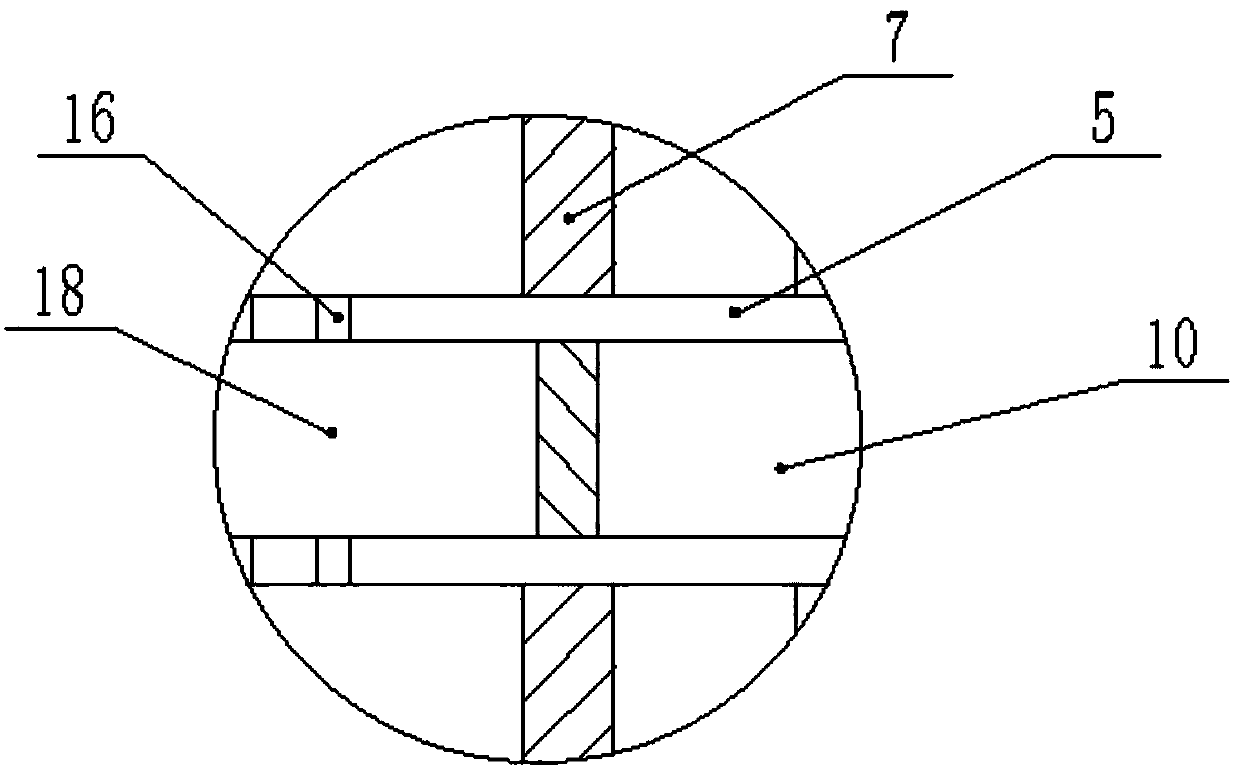

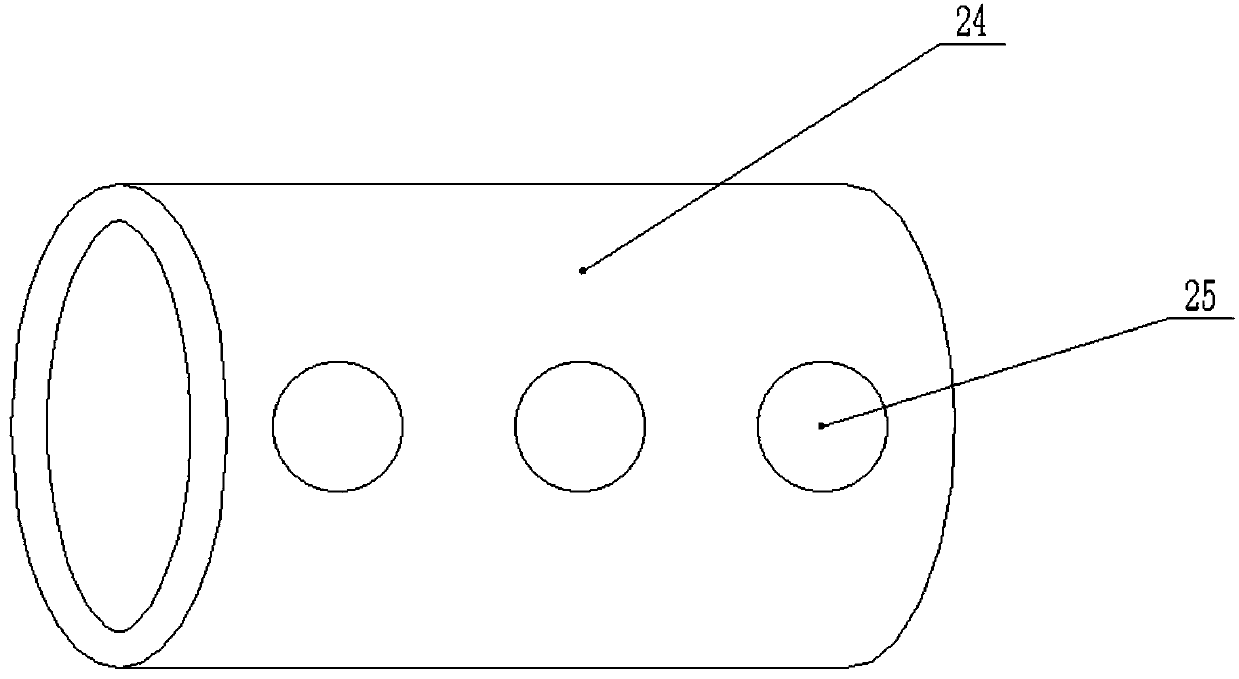

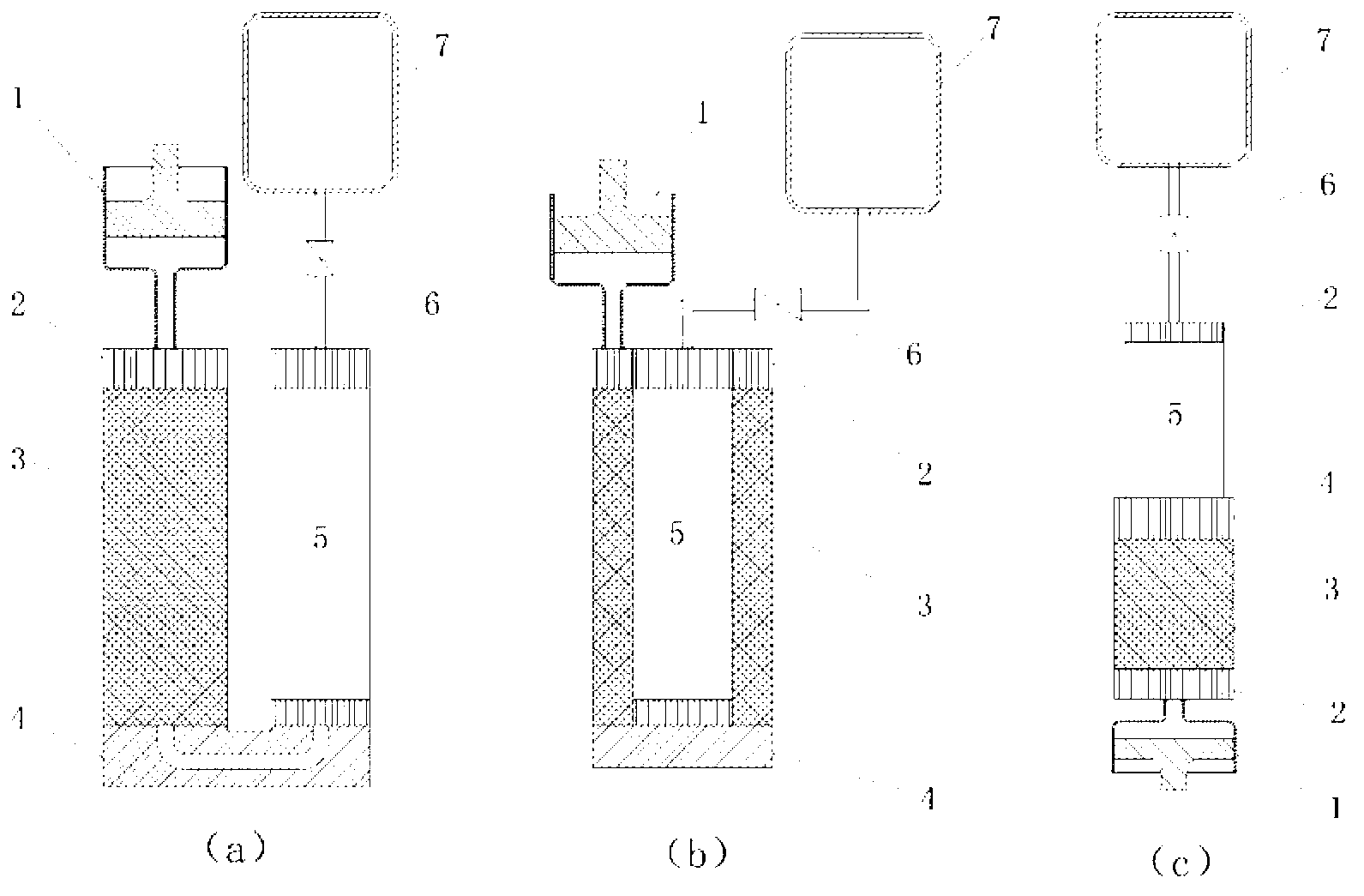

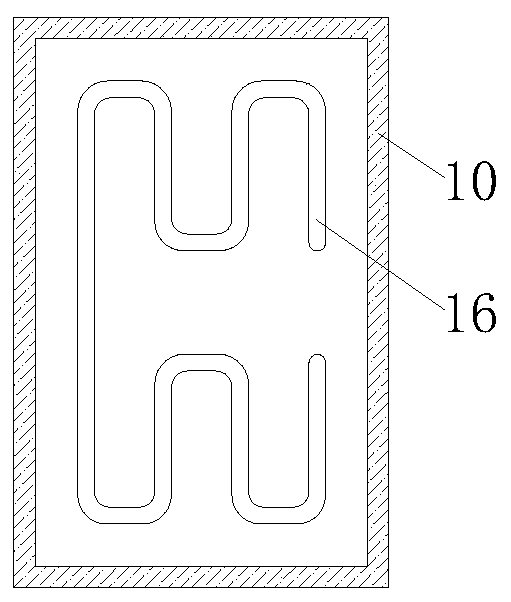

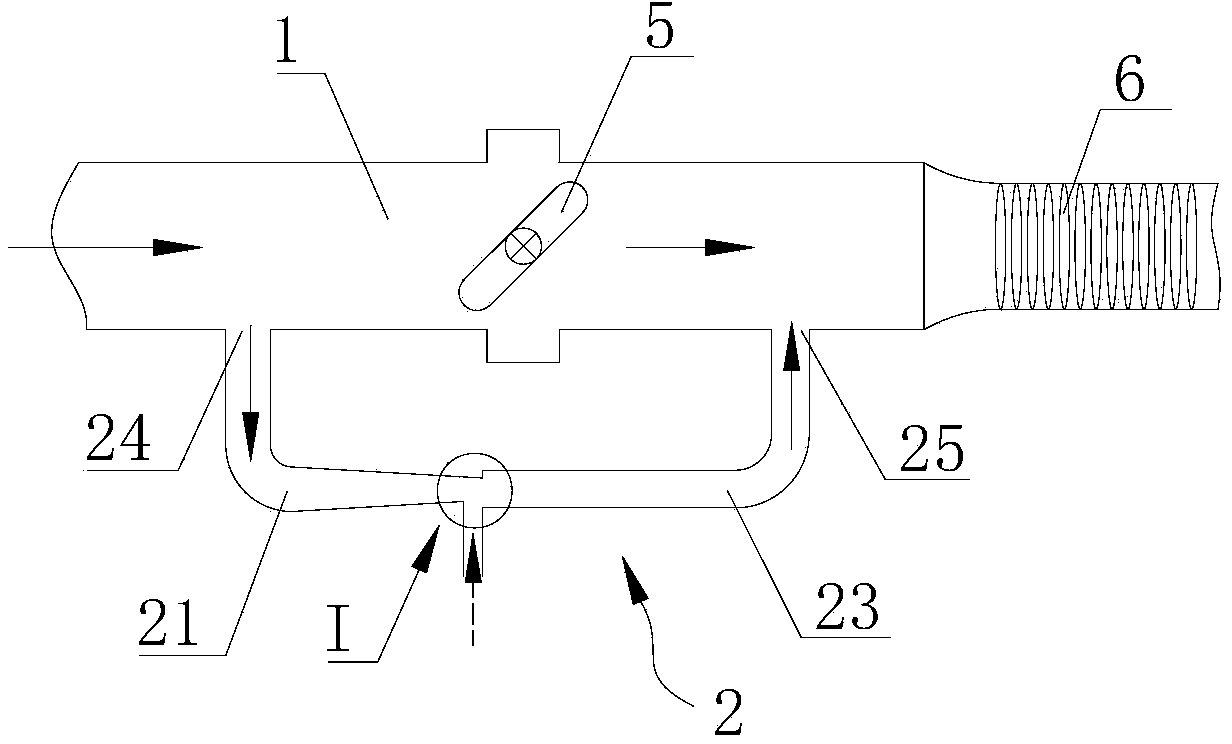

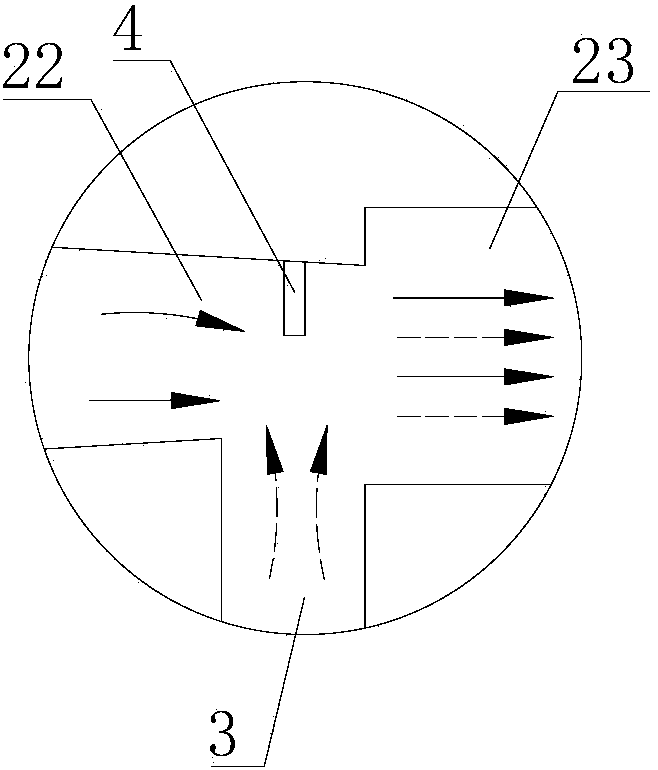

Wind-cooling heat dissipating method of CT device and the apparatus thereof

ActiveCN101061955AResolve refluxEnter fullyComputerised tomographsInstrumental cooling apparatusCold airEngineering

The invention discloses an air-cooled heat radiating method of CT device and apparatus, which is characterized by the following: entering cold air into bay from inlet port; heat-exchanging with the heating element in the bay; discharging out of the bay through outlet port; separating the bay as mutual independence first section and second section; placing the heating element in the first section; entering the cold air into the first section from the inlet port; heat-exchanging with the heating element; discharging the hot air to the second section; discharging out of the bay from the outlet port. This invention optimizes cool approach of air-cooled heat radiation effectively.

Owner:SIEMENS SHANGHAI MEDICAL EQUIP LTD

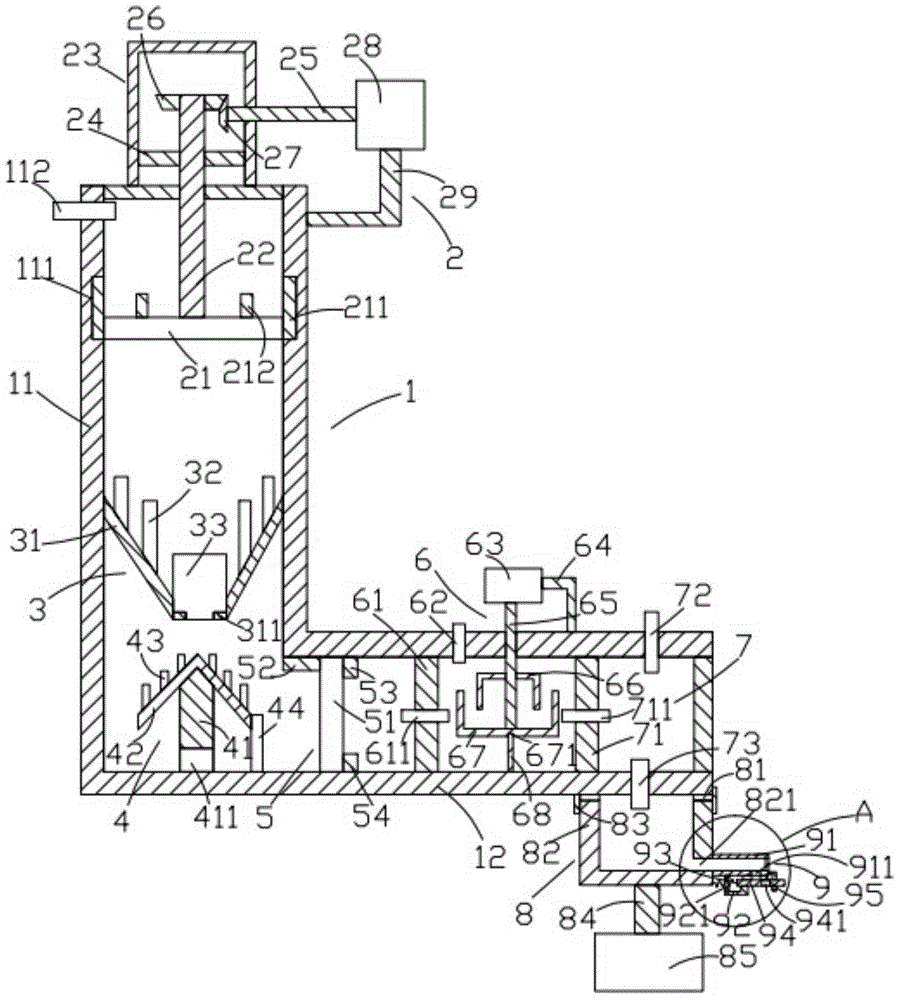

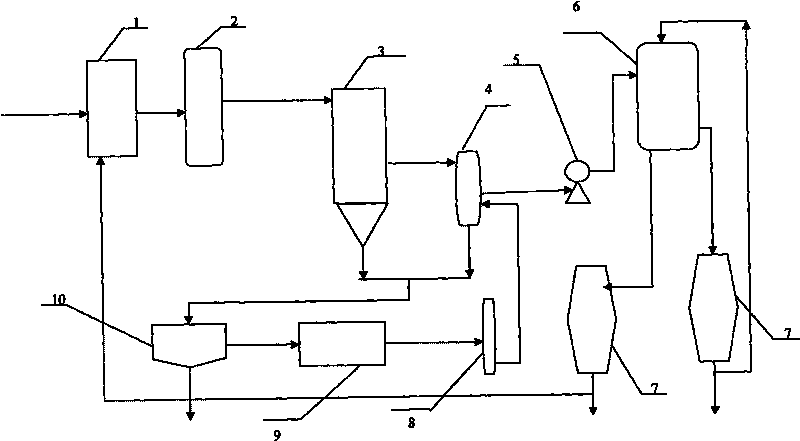

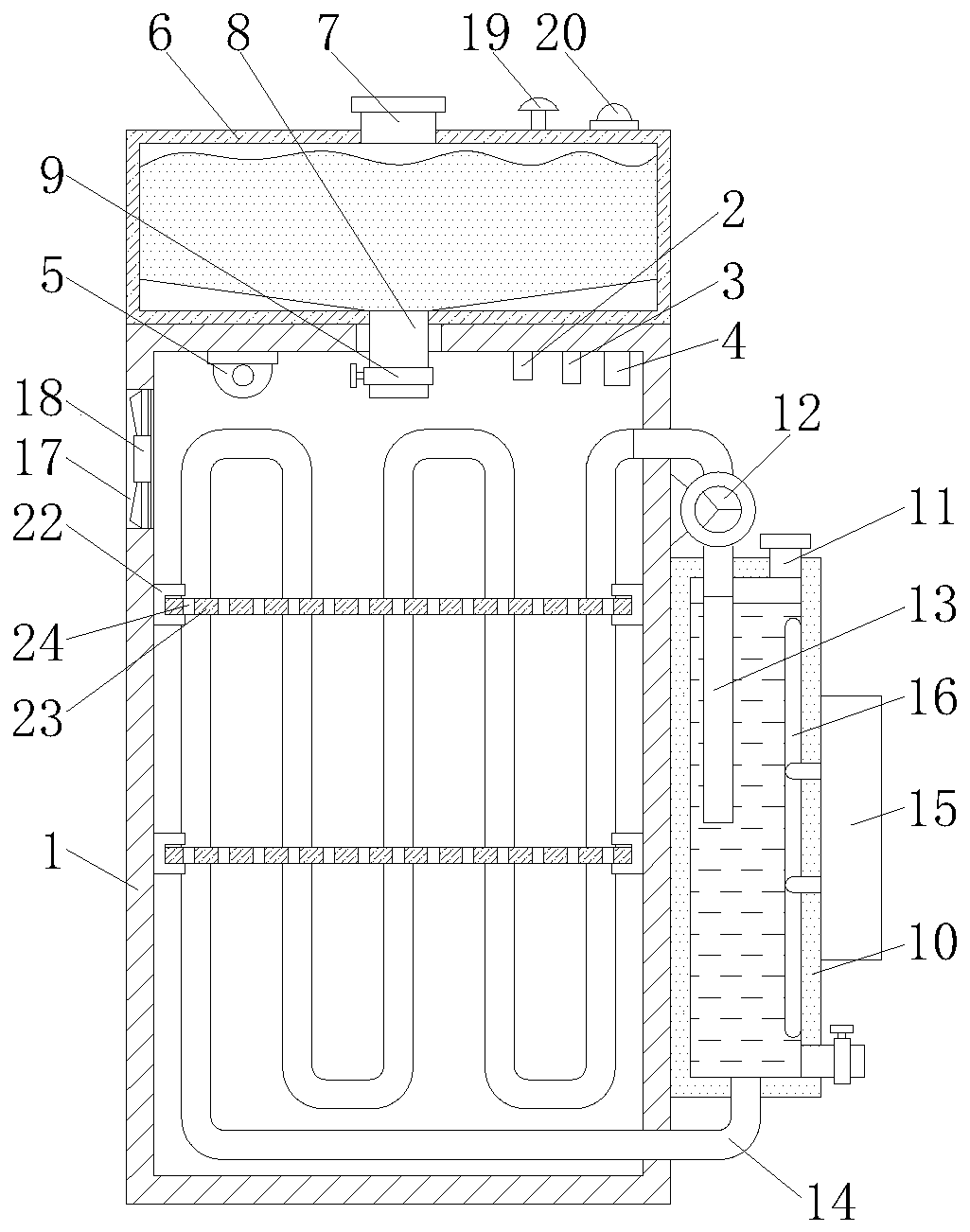

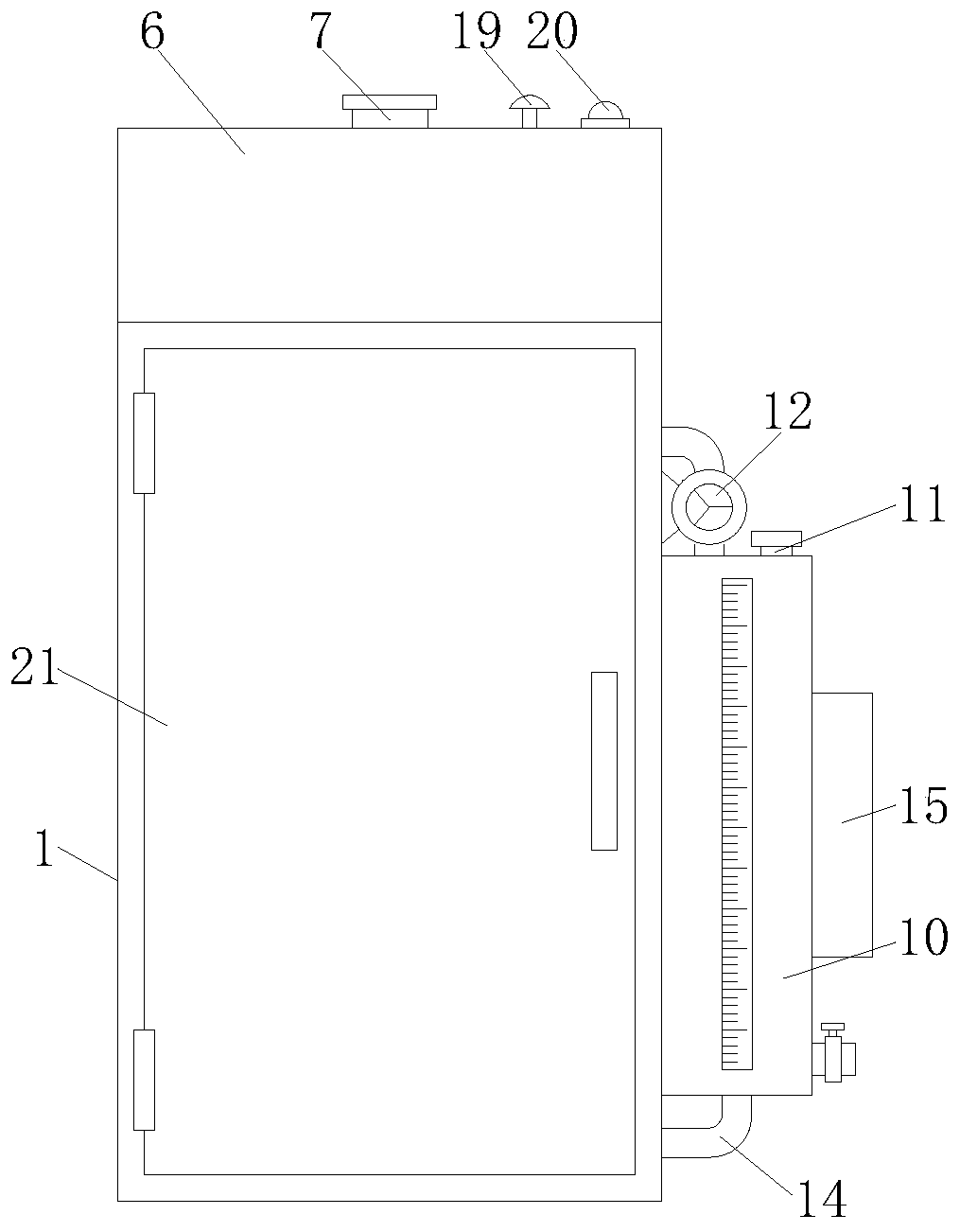

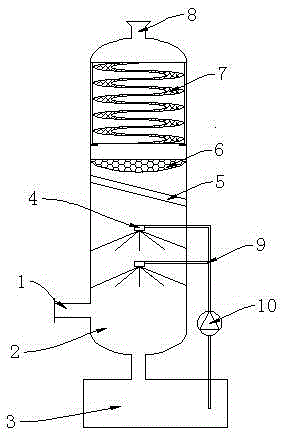

All-in-one sewage treatment machine

ActiveCN104803499ASimple structureEasy to useTreatment involving filtrationMultistage water/sewage treatmentFixed frameCentrifugation

An all-in-one sewage treatment machine comprises a frame body, a first filtering device, a second filtering device, a third filtering device, an oil absorption sponge device, a stirring device, a collection chamber, a centrifugation device and a water outlet device, wherein the frame body comprises an upper frame body and a lower frame body; a water inlet pipe and an annular groove are arranged on the upper frame body; the first filtering device comprises a first filtering screen, a first rotating shaft, a fixing frame, a positioning rod, a first gear, a second gear, a second rotating shaft, a first motor and a first support; the second filtering device comprises first inclined plates, first filtering plates and a first oil absorption sponge; a third filtering device comprises a first supporting column, second inclined plates, second filtering plates and a second oil absorption sponge; the oil absorption sponge device comprises a third oil absorption sponge, a first fixed block, a second fixed block and a third fixed block; the centrifugation device comprises an enclosed ring, a centrifugation frame, a fixing ring, a fourth rotating shaft and a third motor. The machine can completely filter impurities in sewage, and is good and obvious in decontamination effect.

Owner:NANJING LANYING ENVIRONMENTAL TECH CO LTD

Sulfur doped titanium dioxide photocatalyst with anatase structure water-heating preparation method

InactiveCN101053839AAvoid obstructionEnter fullyPhysical/chemical process catalystsThioureaVacuum drying

The invention discloses a hydrothermal preparation method for a sulfur doping titanium dioxide photocatalyst with an anatase structure, comprising the following steps: 1)preparing a nano powder precursor solution by agitating and mixing 8-12ml butyl titanate, 55-65ml deionized water, 15-25ml absolute ethyl alcohol, 5-10ml trolamine and 0.38-4.56 gthiourea at a temperature of 10-40 DEG C; 2) preparing a nano powder in a hydrothermal condition by placing the nano powder precursor solution into a reaction kettle, rising temperature at a speed of 1-5 DEG C / min to 150-240 DEG C and keeping the temperature to perform the hydrothermal reaction, stopping heating after 2-5 hours, when the reaction kettle is naturally cooled to room temperature, taking out the reactants, washing with the deionized water and the absolute ethyl alcohol for 3-4 times, and finally drying the reactants in a vacuum drying oven at 50-80 DEG C. The invention is capable of synchronous achieving processes both of the preparation of TiO2 nano particle and sulfur doping, which makes the preparation technical line of the catalyst more reasonable, be suitable to product quantity control with low energy consumption.

Owner:ZHEJIANG UNIV

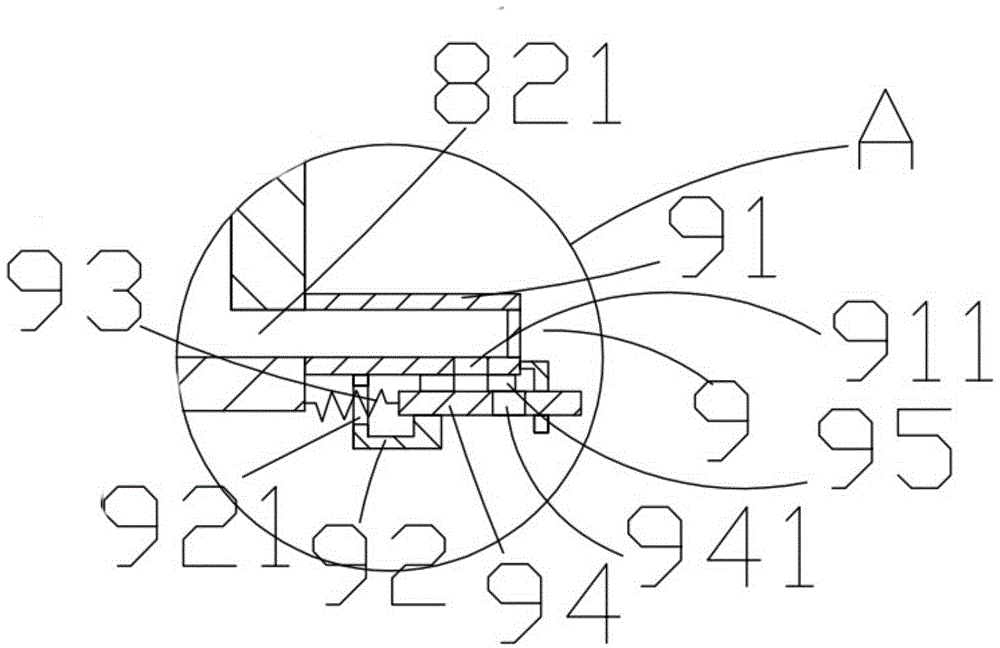

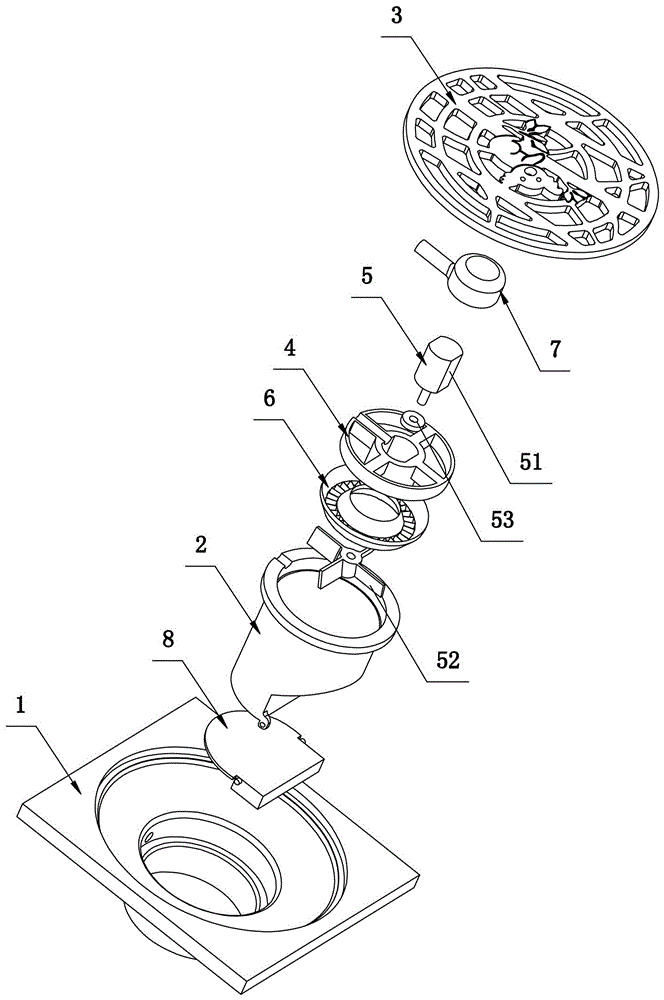

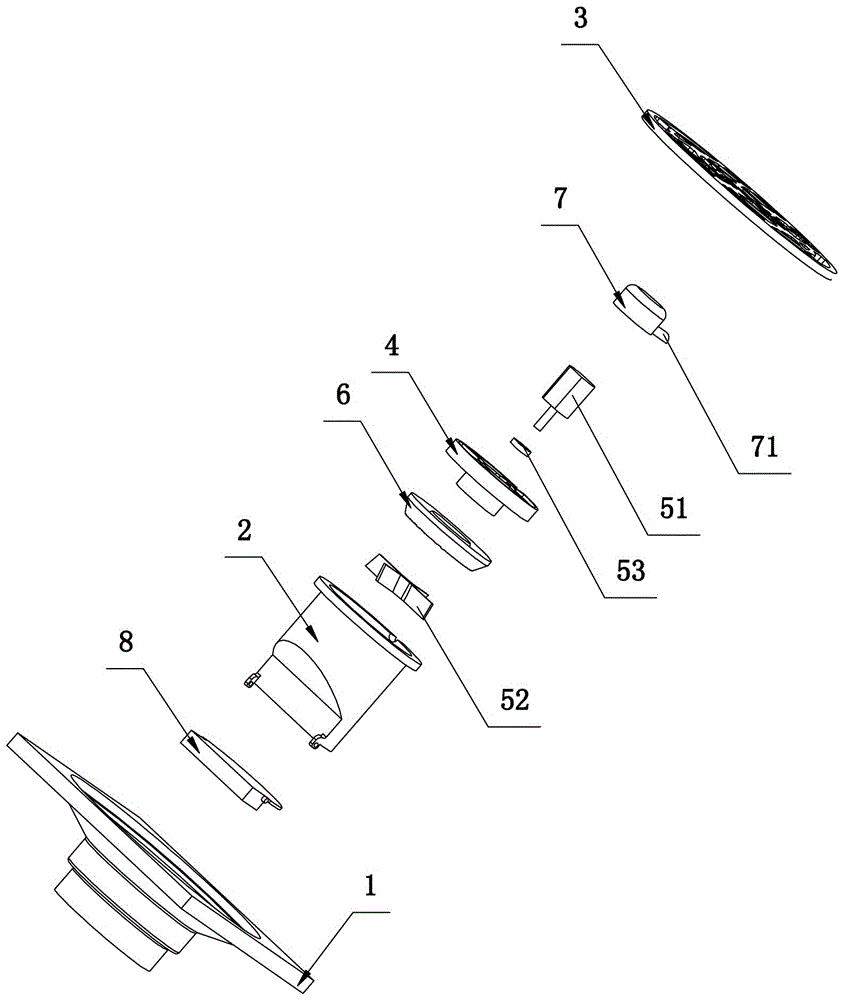

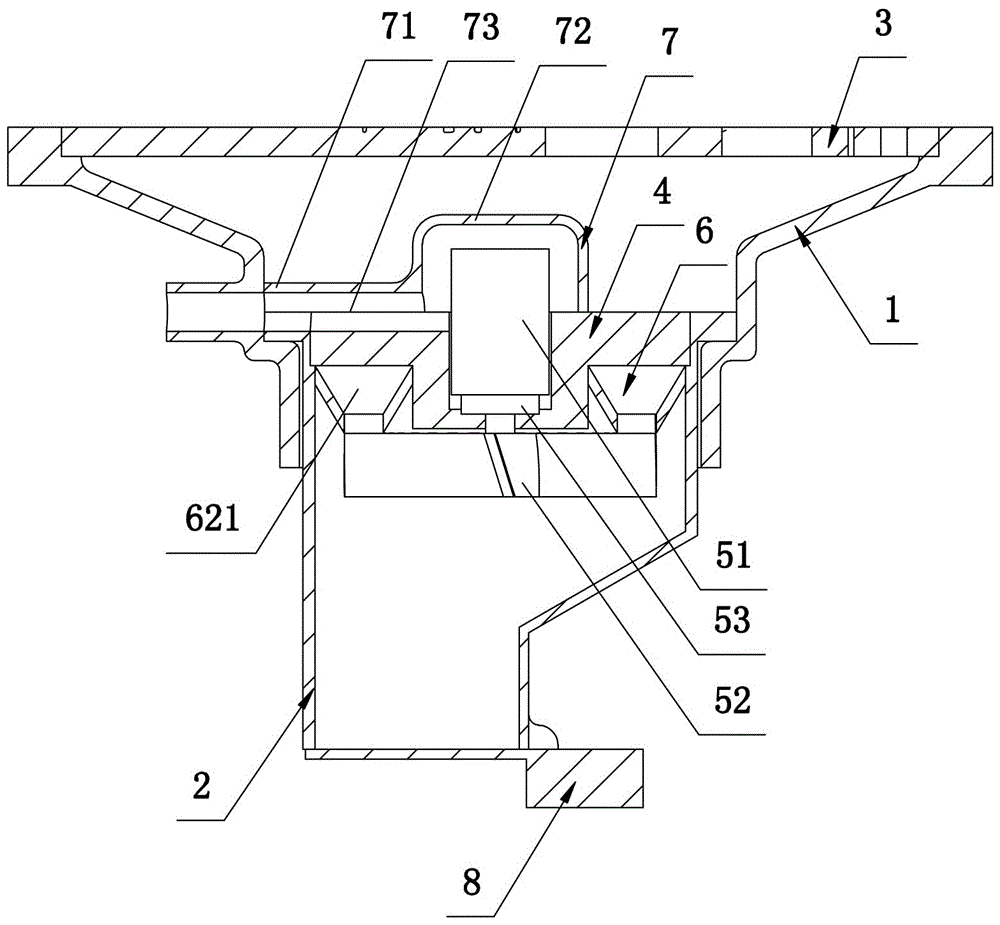

Anti-blocking floor drain for bathroom

ActiveCN106245746ASimple structurePracticalSewerage structuresDomestic plumbingHydroelectricityElectric energy

The invention provides an anti-blocking floor drain for a bathroom. The anti-blocking floor drain comprises a floor drain frame body which is used for connecting a bathroom water discharging pipeline and bathroom ground; a floor drain core body for discharging water is erected at the lower side in the floor drain frame body, and a round cover is erected at the upper side of the floor drain frame body; the anti-blocking floor drain further comprises a hydroelectric generator which is arranged in a water inlet pipeline of the bathroom; a tool rest is embedded into the upper side of the floor drain core body; the tool rest is provided with a cutting mechanism capable of cutting hairs; the cutting mechanism comprises a mini-type direct current motor and a rotary blade; and a current input end of the mini-type direct current motor is electrically connected with the hydroelectric generator, and an output shaft of the mini-type direct current motor is in transmission connection with the rotary blade. As the cutting mechanism and the hydroelectric generator are arranged, when a user utilizes water, the hydroelectric generator can generate electric energy under the action of hydraulic power, and the electric energy is transmitted to the mini-type direct current motor, so that the rotary blade is controlled to rotate and the hairs are cut off, and furthermore, the hairs can smoothly flow out from the water discharging pipeline; and the electric energy can be saved, and the blocking of the water discharging pipeline can also be effectively avoided.

Owner:SANMING CITY YIJUN MACHINERY FOUNDRY

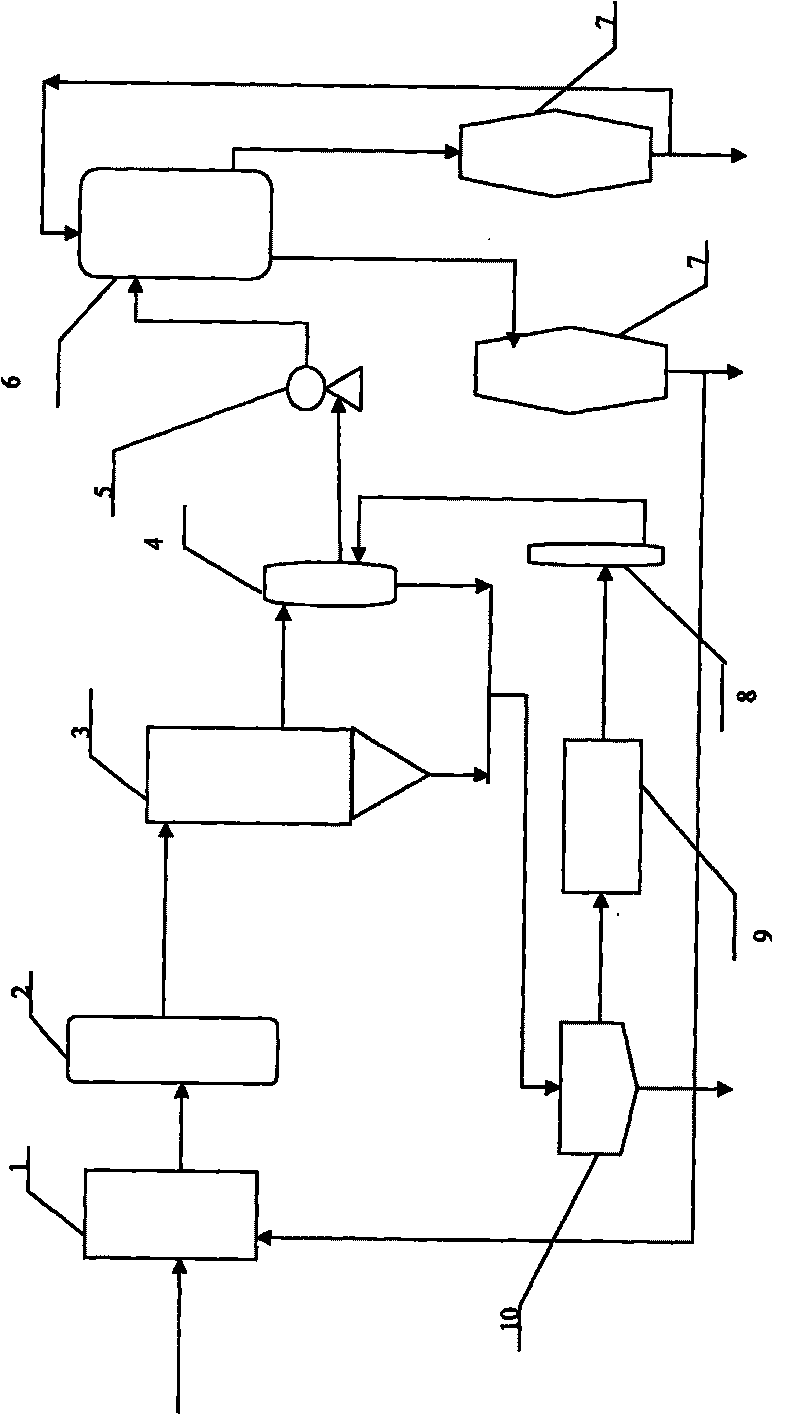

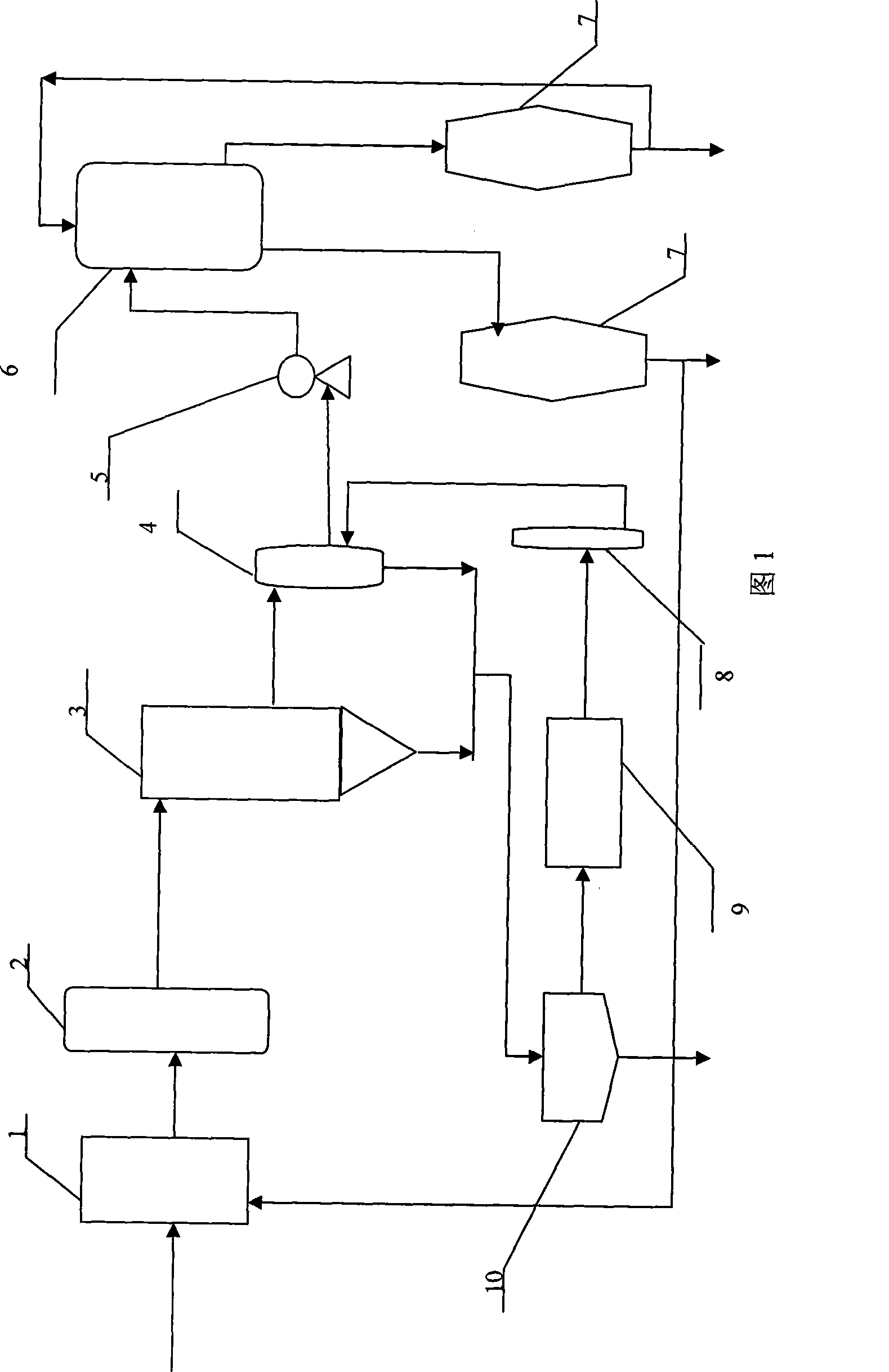

Device and method for producing acetylene by hydrogen direct current arc plasma cracking coal

ActiveCN101734995AThorough treatmentNo pollution in the processHydrocarbonsHydrocarbon preparationCoal dustProcess design

The invention relates to a device and a method for producing acetylene by hydrogen direct current arc plasma cracking coal. The method comprises the following steps: the hydrogen coal dust is fed into a plasma reactor, enters a quenching machine for quenching after the reaction, then enters a cyclone separator for preseparation between gas and solid; the gas part enters a rinsing dust removing tower for dedusting, is sent to a compressor for compression by a booster fan, then enters a pressure swing adsorption tower for adsorption and concentration, and simultaneously, the gas out of the pressure swing adsorption tower enters the compressor again and is sent to an adsorption tower for extracting hydrogen; the solid dust separated by the cyclone separator and the rinsing dust removing tower forms solution with water; a ceramic membrane device is utilized to carry out liquid and solid separation; the solid dust is sent to a power plant to be served as raw materials; and water enters therinsing tower for recycling. The invention has reasonable process design and high economic efficiency, can be used in combination or separately, and can be directly used in the processes for producing hydrogen chloride, acetylene ethane derivative, methanol and the derivatives and the like.

Owner:XINJIANG TIANYE GRP

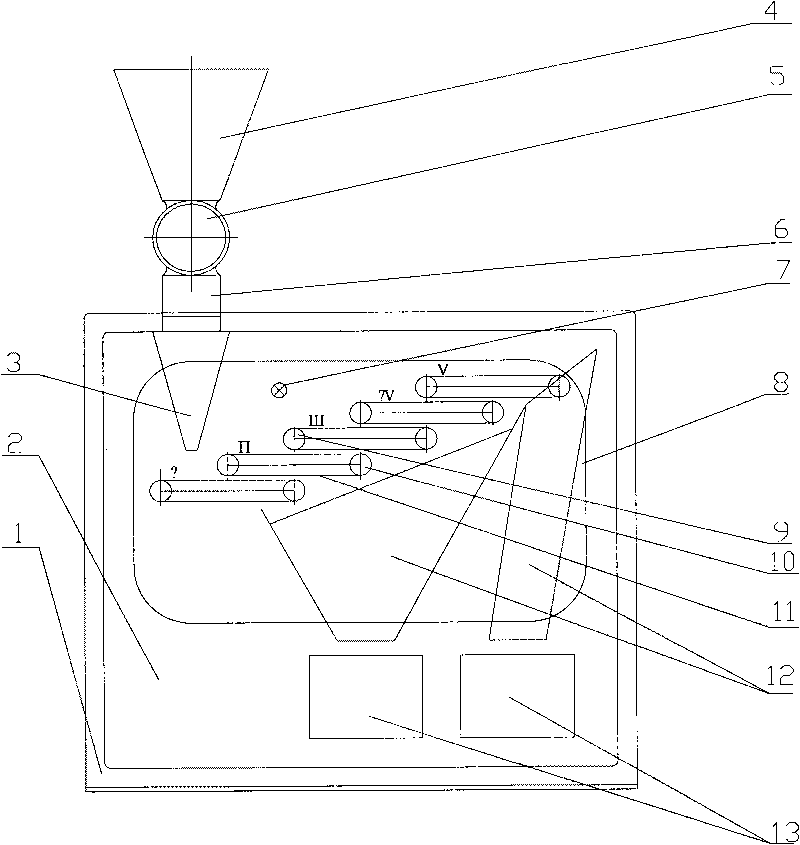

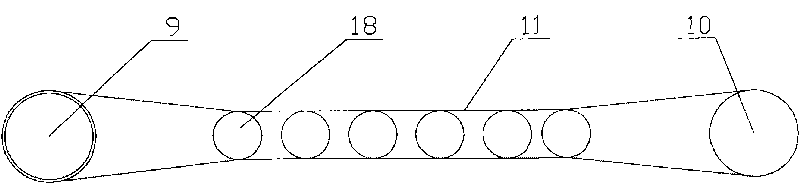

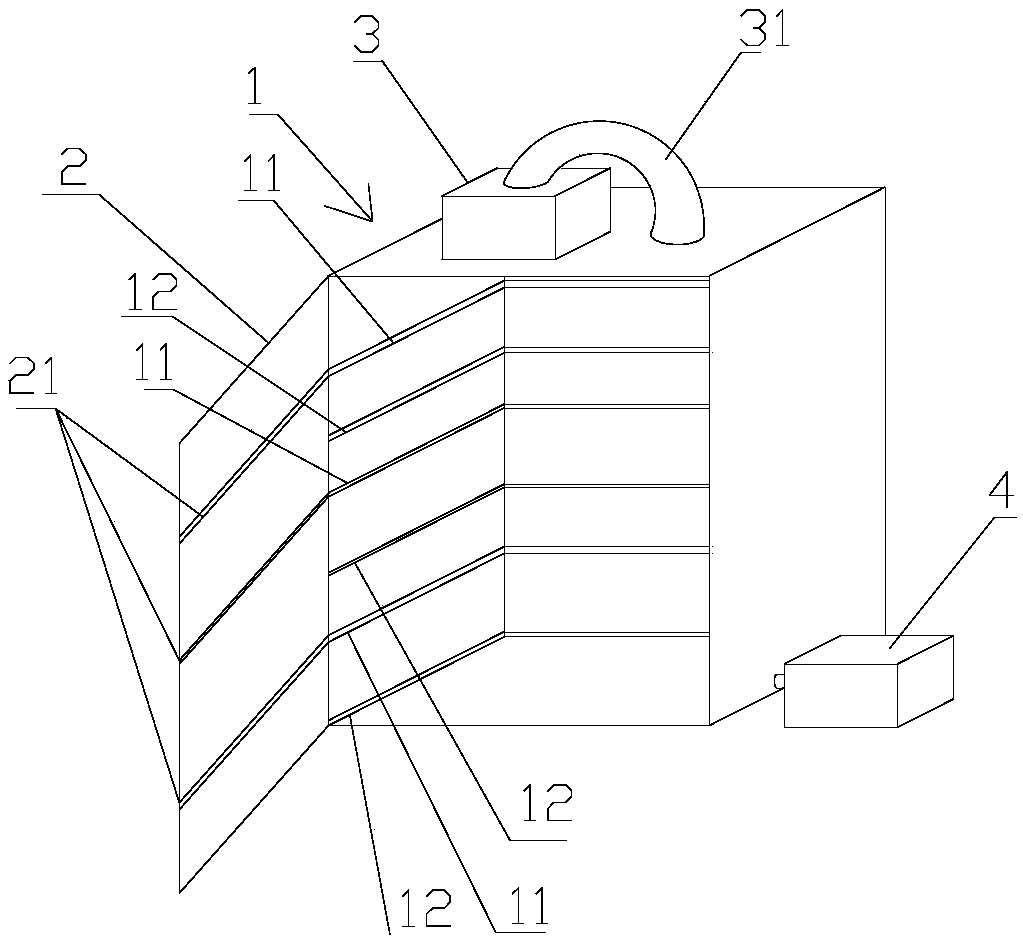

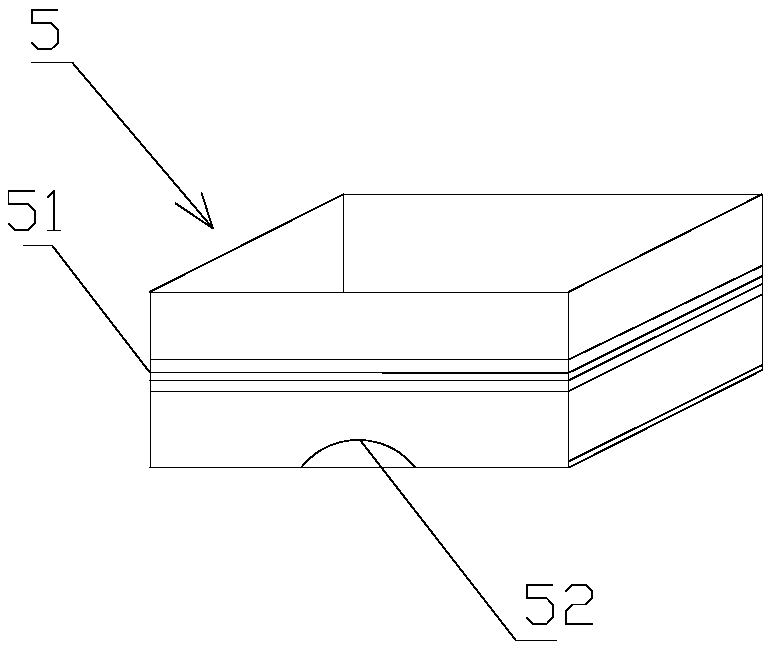

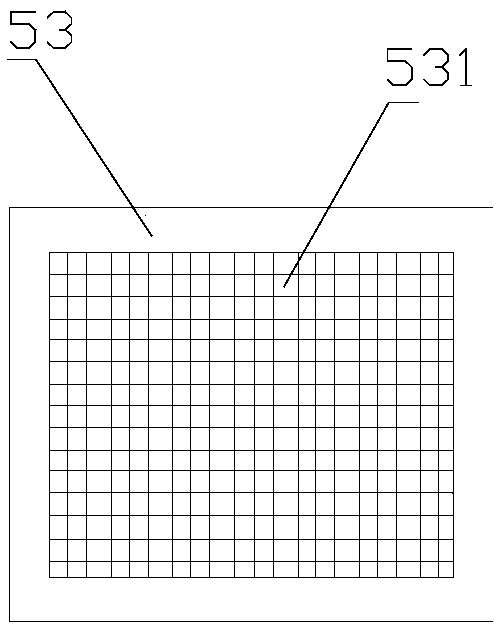

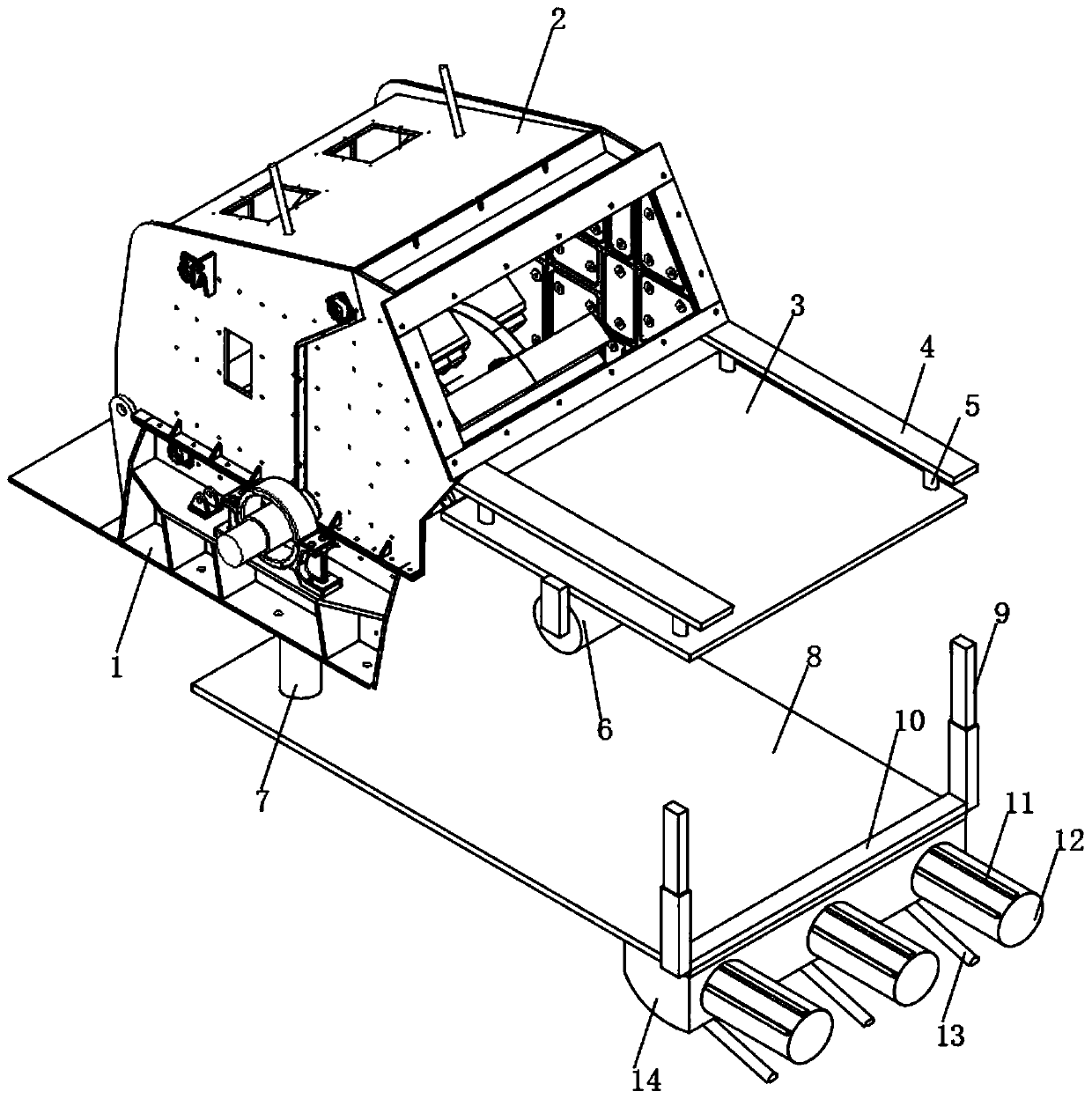

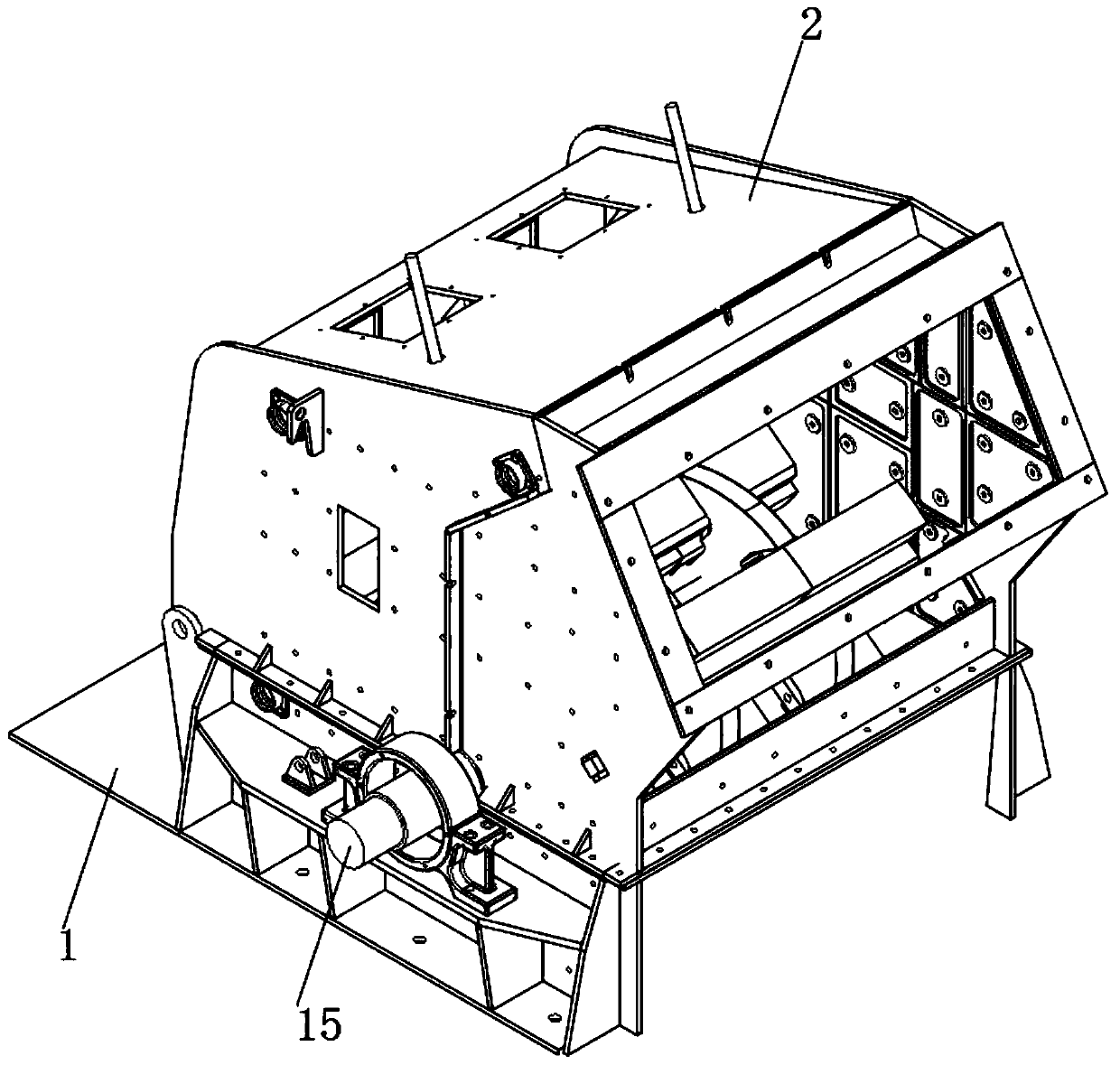

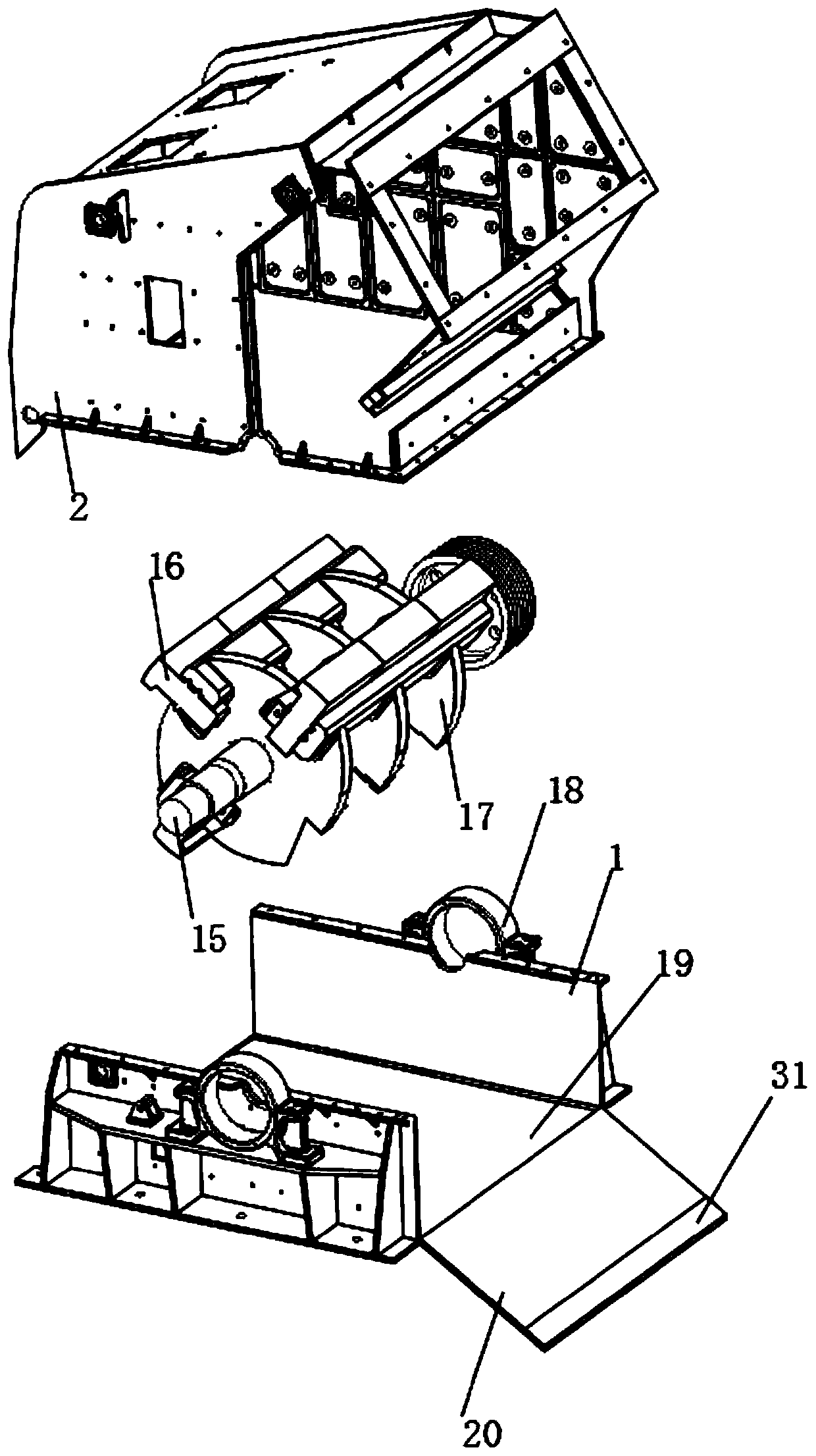

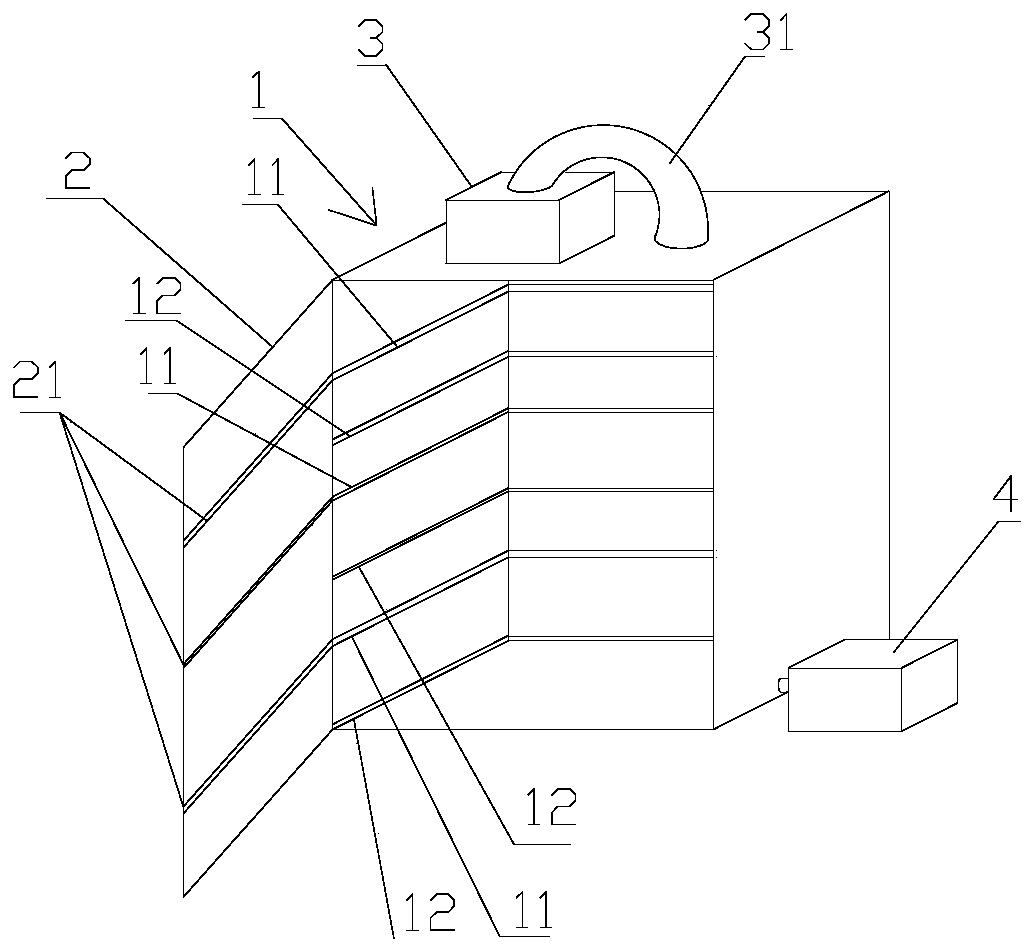

Module type permanent magnetic separation rolling machine

InactiveCN101693223AReduce wasteIncrease flexibilityMagnetic separationMechanical engineeringMagnetic separation

The invention relates to a module type permanent magnetic separation rolling machine which is characterized by comprising a stand, a belt conveyer, a feeding mechanism and a collecting hopper, wherein the belt conveyer is sequentially arranged on a plurality of layers in the stand from bottom to top in ladder type derangement and is horizontally arranged and driven by an actuating device, the feeding mechanism is arranged above the feeding end of the belt conveyer, the collecting hopper is arranged below the feeding outlet of the belt conveyer; a driving roll of every layer of the belt conveyer positioned in the feed end is of a magnetic roll structure. The complete machine is controlled by a PID control chamber which can conveniently and rapidly regulate all operation systems of the complete machine and ensure that the separation process runs continuously according to the set program, thereby realizing the automatic regulation of parameters.

Owner:HENAN POLYTECHNIC UNIV

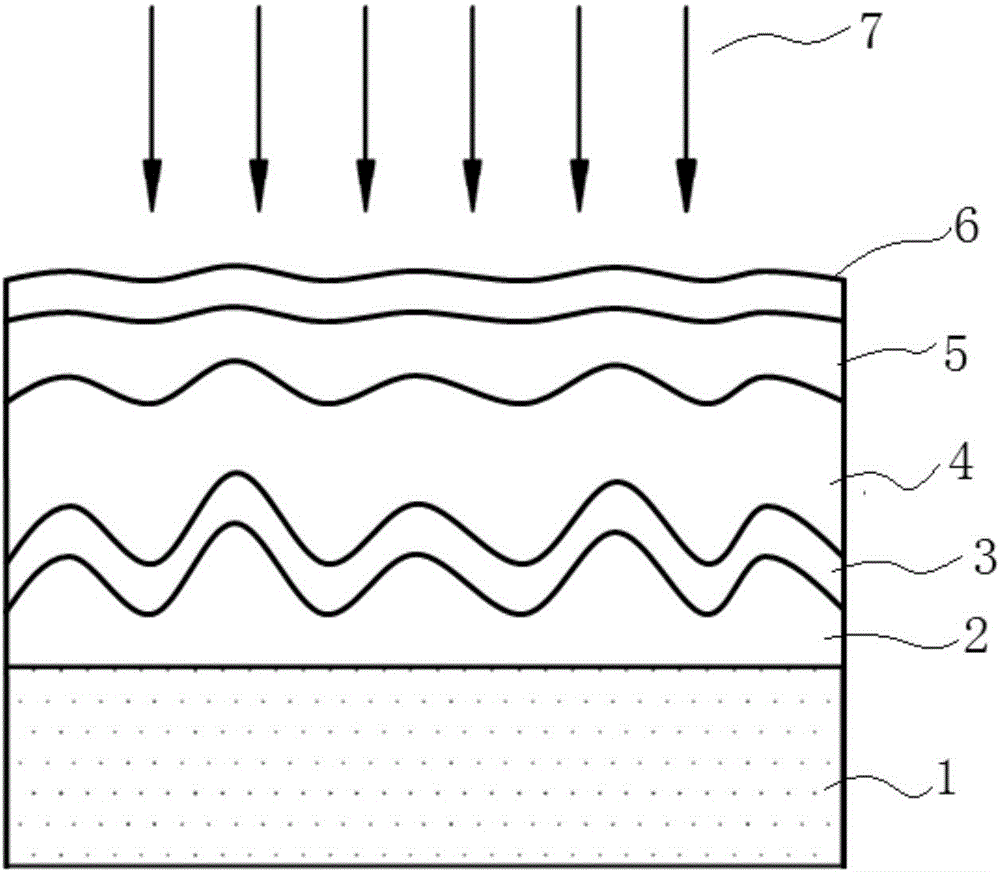

Perovskite solar cell based on suede light management structure and preparation method of solar cell

InactiveCN106252513AOptical absorption does not decreaseRealize anti-reflection functionSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellHole transport layer

The invention relates to a perovskite solar cell based on a suede light management structure and a preparation method of the solar cell. The cell comprises a substrate, a suede metal back reflection layer formed on the substrate, an electron transmission layer formed on the suede metal back reflection layer, a perovskite absorption layer formed on the electron transmission layer, a cavity transmission layer formed on the perovskite absorption layer and a transparent conductive front electrode, capable of reflection reducing, formed on the cavity transmission layer. Sunlight is input in the direction of the transparent conductive front electrode, penetrates the transparent conductive front electrode, reaches the suede of the suede metal back reflection layer at the bottom of the cell, and is reflected into the cell in certain angle, the absorption light path of light in the perovskite absorption layer is prolonged, and light management is realized. The cell is simple in structure, and optical absorption of the cell can be improved substantially.

Owner:TIANJIN POLYTECHNIC UNIV

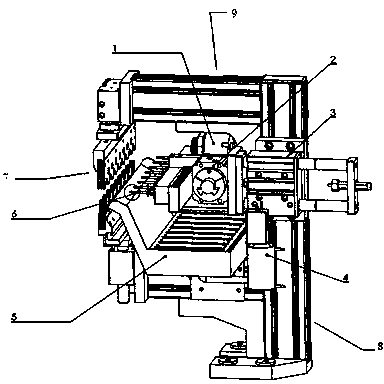

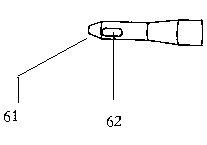

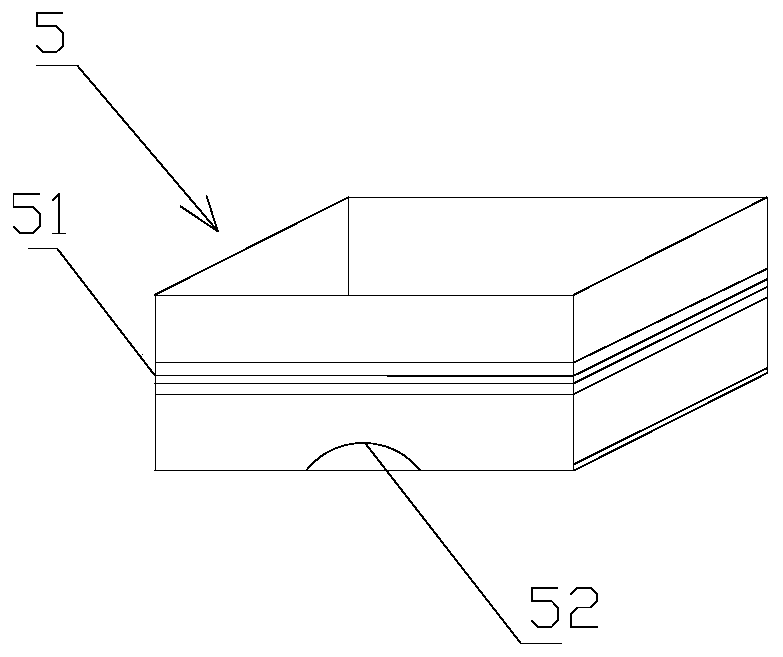

Gluing apparatus in medical-device automatic assembly equipment

InactiveCN104384071AEasy to transformEnter fullyLiquid surface applicatorsCoatingsEngineeringCatheter

At present, gluing assembling of a plurality of catheters and drip funnel assemblies is finished by means of machines, but most of automatic gluing apparatuses are unreasonable in design and easily cause nonuniform gluing phenomena. When an unevenly-gummed infusion apparatus is clinically used, a bonding position is easy to loose under a certain liquid pressure and brings great safety hidden trouble for a patient. When conventional automatic gluing equipment is designed, the assemblies are clamped only by a clamp, the soft assemblies, such as catheters, drip funnels and the like, are easy to deform, and when the to-be gummed assemblies only depend on the clamp for fixing, sometimes the purpose of enabling a gluing rod or a gluing column to completely fully enter the assemblies cannot be realized, and the gluing process is nonuniform. The invention aims at providing a gluing apparatus in medical-device automatic assembly equipment, and the gluing apparatus is characterized by comprising fixing teeth for fixing medical-device assemblies and a glue-dispensing rod with a glue storage groove. The gluing apparatus solves the problems that the flexible medical-device assemblies are easy to deform in the gluing process and gluing is nonuniform.

Owner:NANCHANG MINGFU AUTOMATION EQUIP

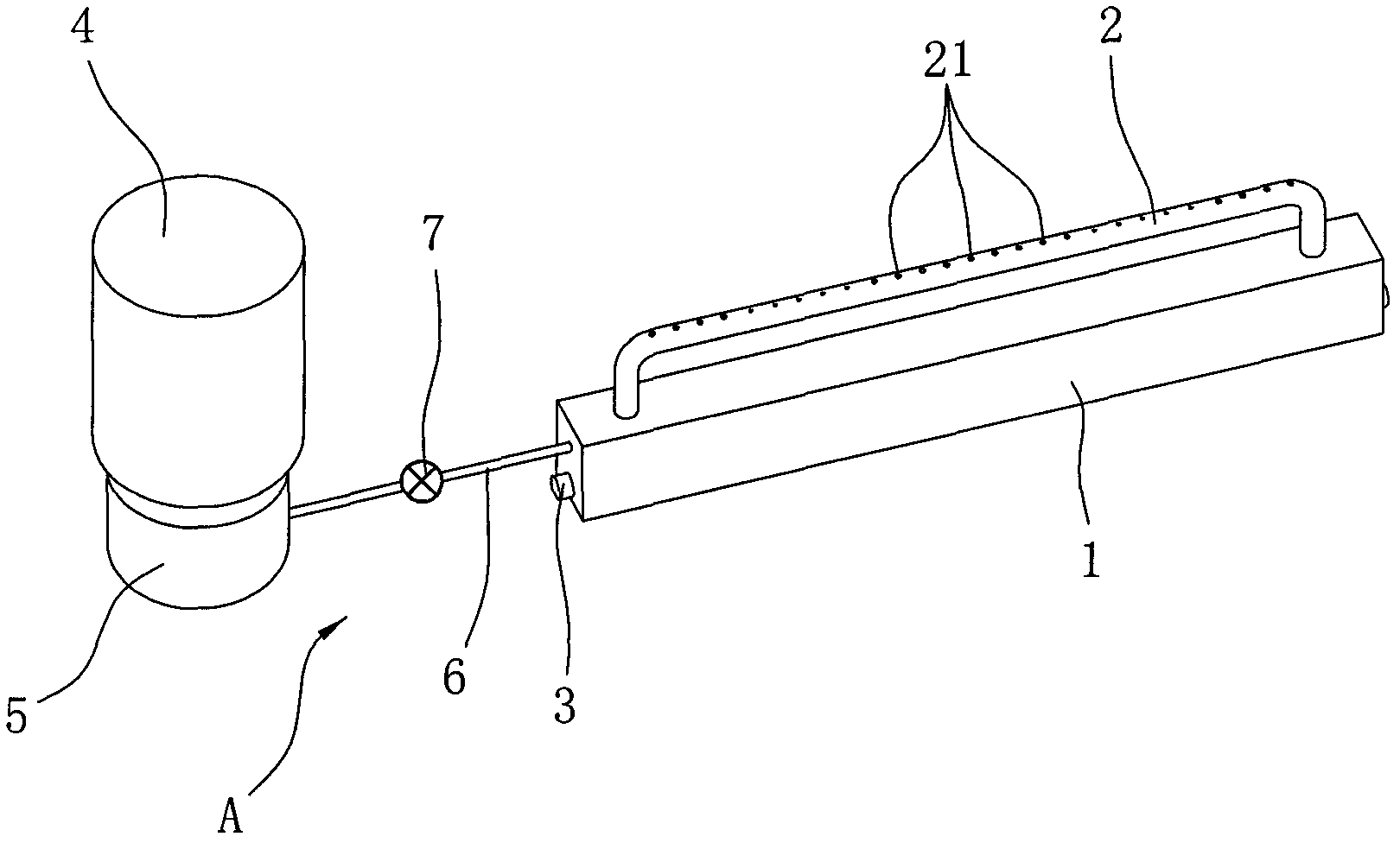

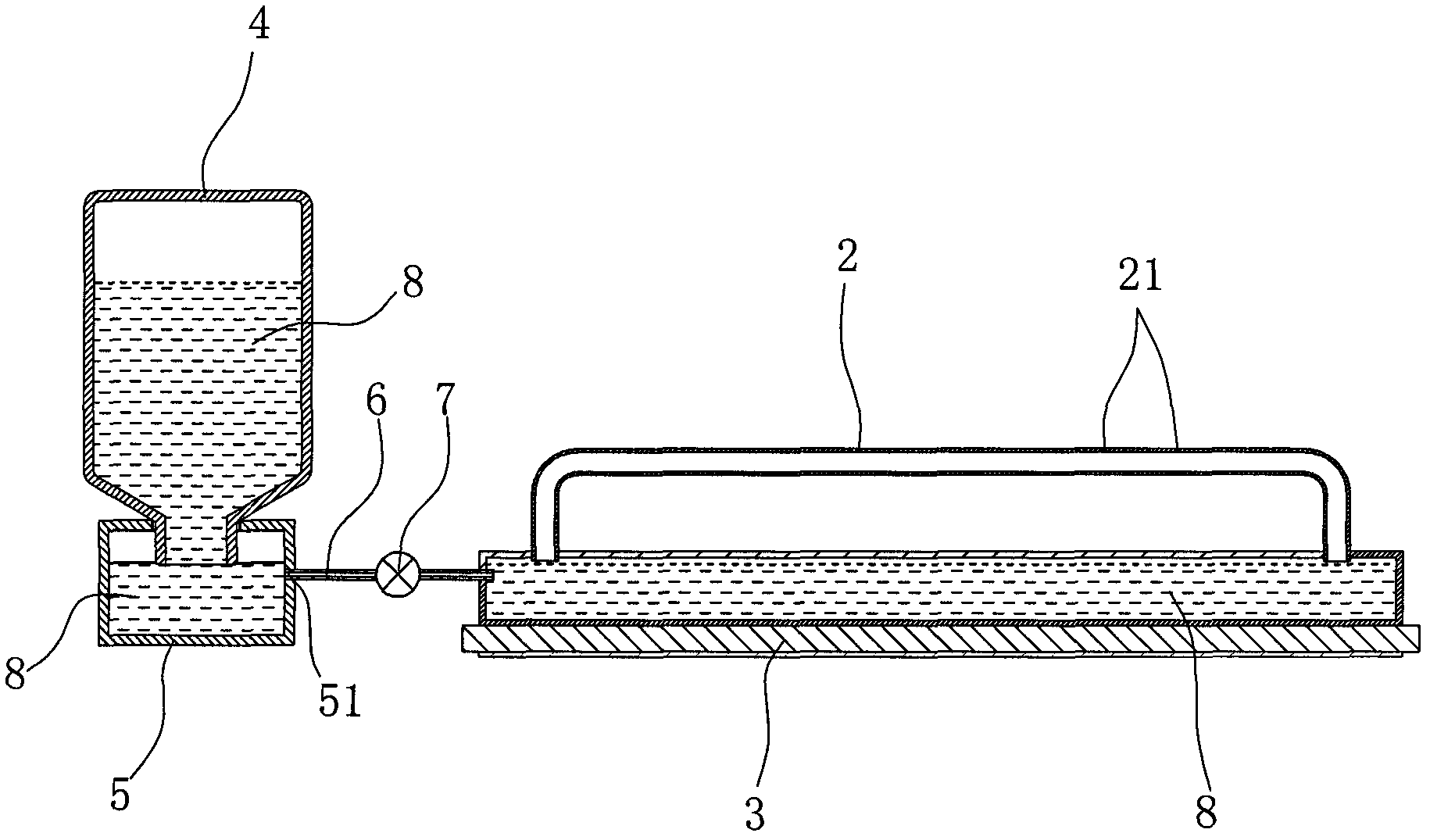

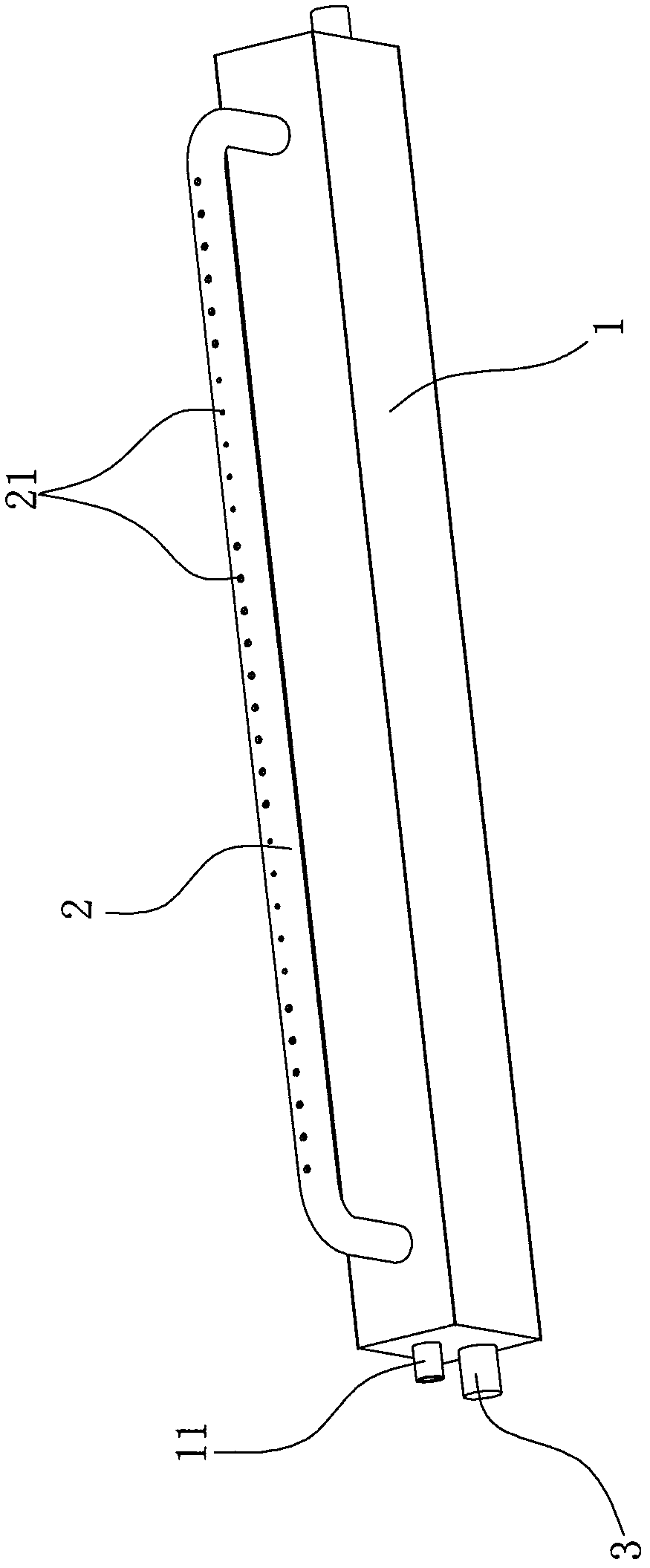

Gasifying combustion device for liquid fuel

InactiveCN102330975AThe overall structure is simpleGasification Process SimplifiedBurnersEngineeringMechanical engineering

The invention discloses a gasifying combustion device for a liquid fuel. The gasifying combustion device comprises a liquid supplying device, a gasifying chamber and a combustor, wherein the combustor is provided with a flame spraying hole. The gasifying combustion device is characterized in that: the gasifying chamber is provided with a liquid fuel inlet and an air outlet; the liquid fuel inlet of the gasifying chamber is communicated with the liquid supplying device; the air outlet of the gasifying chamber is communicated with the combustor; the main body of the combustor is arranged above a connecting port between the combustor and the gasifying chamber; and an electrical heating device for providing heat needed for gasifying the liquid fuel is arranged in the gasifying chamber. Compared with the prior art, the gasifying combustion device has the advantages that: the electrical heating device is used for directly heating the gasifying chamber, so that the fuel can be used for proving heat needed for gasifying the liquid fuel without preheating, the entire structure is simpler, and the gasifying process is simplified; and the combustor body is higher than the connecting port between the combustor and the gasifying chamber, so that the liquid fuel which is recondensed into liquid and enters the combustor can conveniently reflow into the gasifying chamber by using gravity per se, full combustion of the fuel is ensured, and the combustion efficiency is increased.

Owner:NINGBO RICHEN ELECTRIC APPLIANCE CO LTD

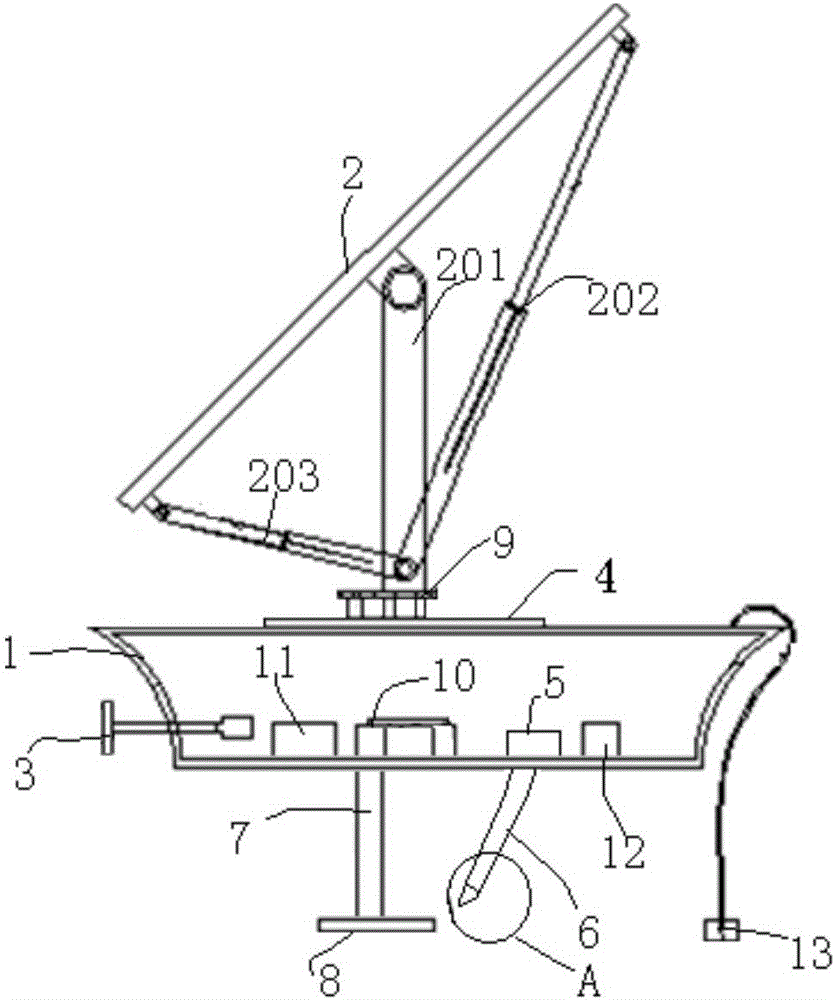

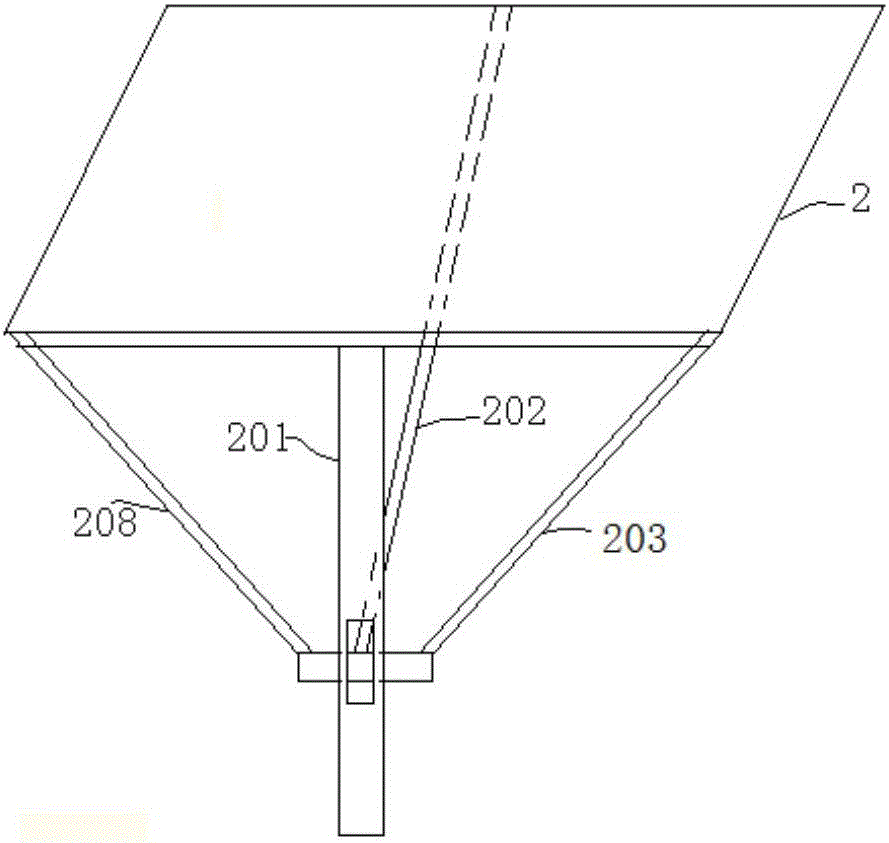

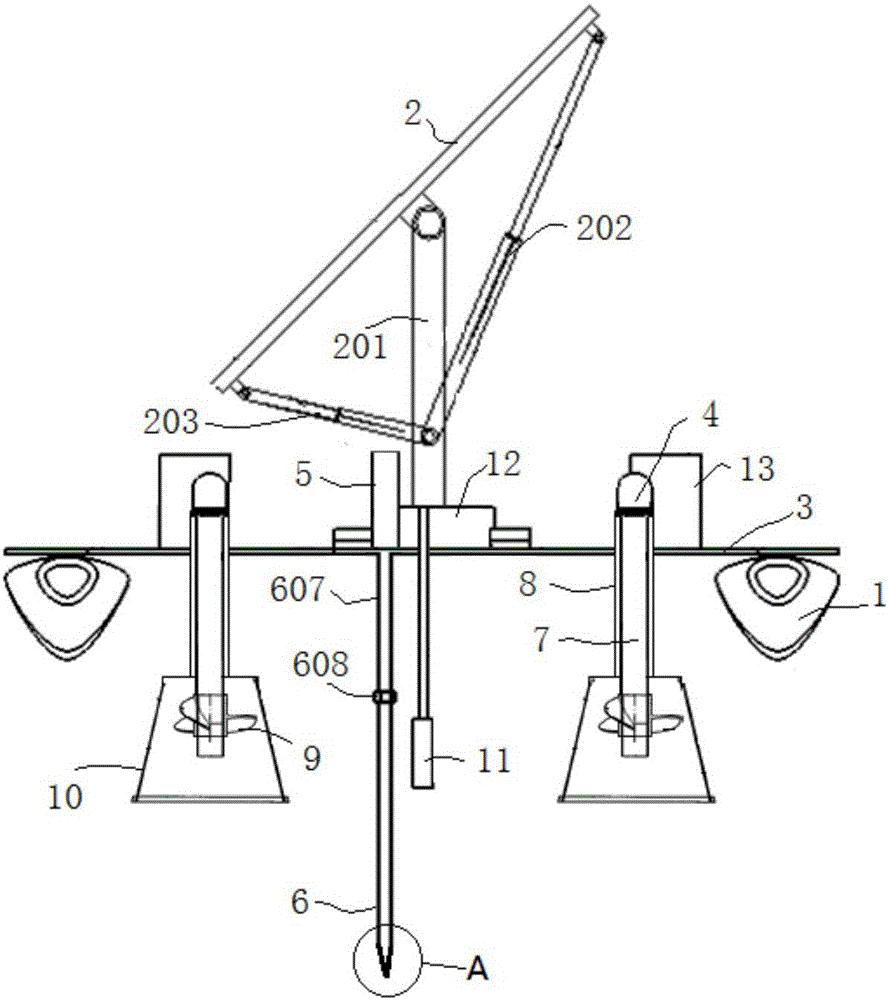

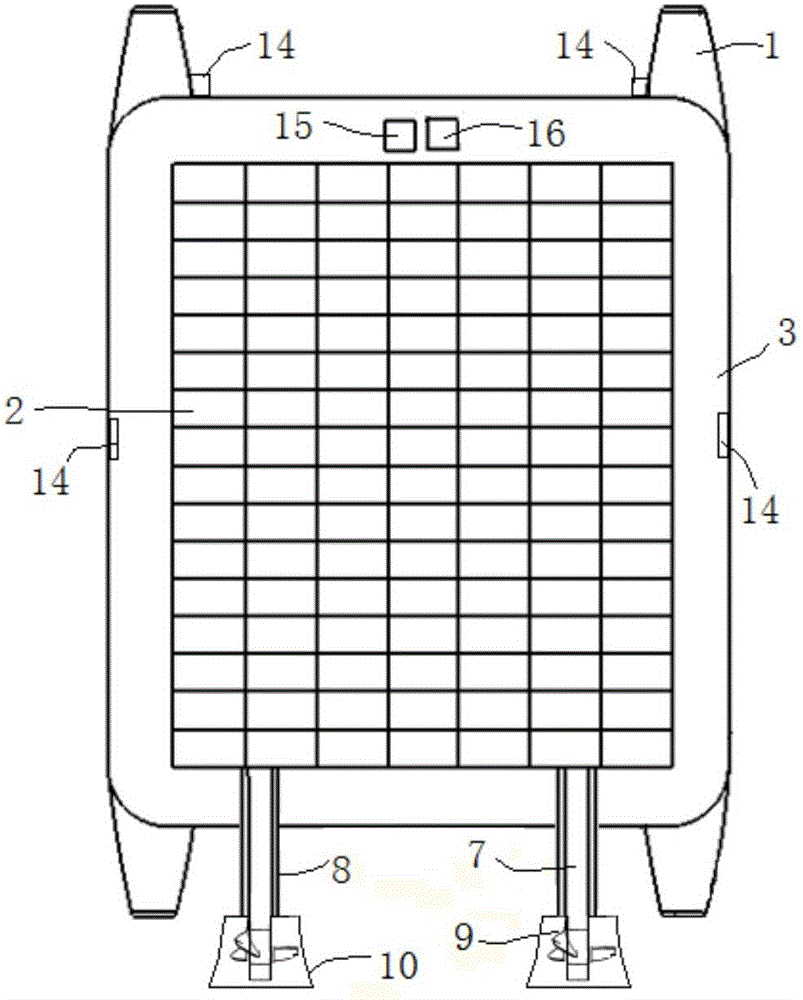

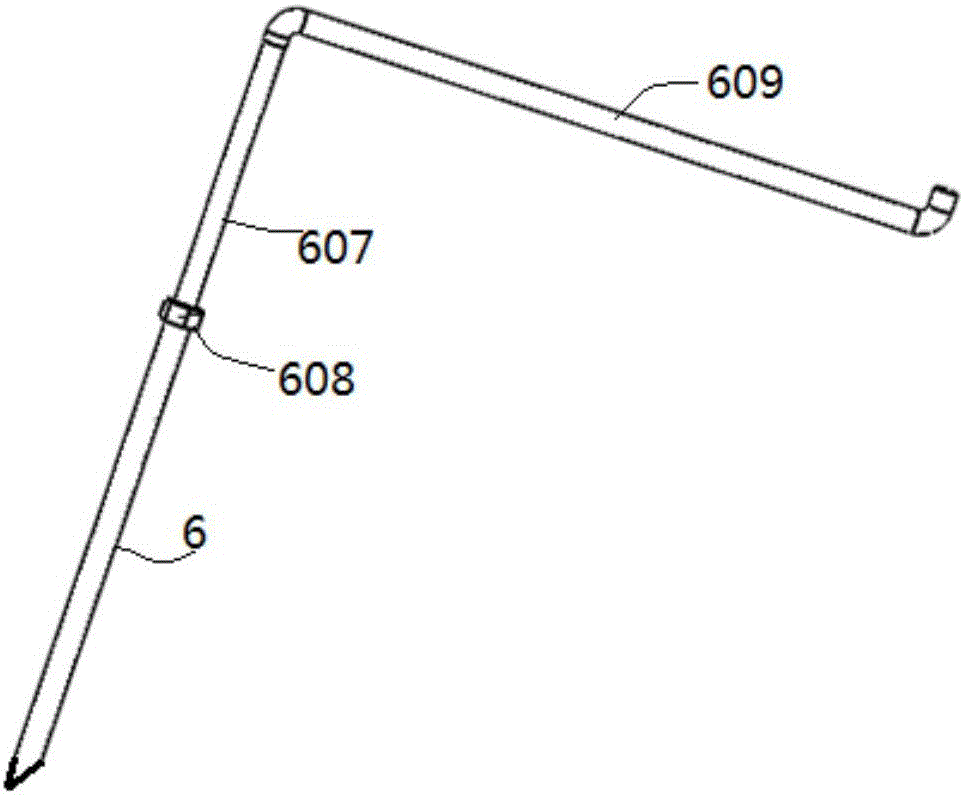

Solar aerating vessel for fishpond farming

ActiveCN106275297ARealize autonomous mobile oxygen enrichmentOxygen balancePhotovoltaic supportsEnergy supplyOxygen sensorDrive shaft

The invention discloses a solar aerating vessel for fishpond farming, and belongs to the field of fishery breeding. The solar aerating vessel comprises a hull and a deck, wherein a solar power supply mechanism is arranged on the deck; an aerating mechanism, a navigation mechanism and storage batteries are arranged in the hull; the aerating mechanism comprises a transmission shaft and an air pump; a propeller is arranged at the bottom end of the transmission shaft; thrusters are arranged at the tail part of the hull, and connected with the storage batteries; a dissolved oxygen sensor is arranged at the front end of the hull, and the dissolved oxygen situation in water is detected through the dissolved oxygen sensor; electric energy produced by a solar panel is stored in the storage batteries for providing the electric energy for the thrusters, the aerating mechanism and the navigation mechanism. The solar aerating vessel for the fishpond farming uses solar energy as a power system, is rich in resources and free of pollution, can perform mobile uniform aeration, and has a high oxygen dissolving efficiency.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Movable solar oxygenation system and oxygenation method

ActiveCN106342744AOxygen evenlyRealize mobile oxygenationPisciculture and aquariaDrive motorSolar power

The invention discloses a movable solar oxygenation system and method and belongs to the field of fishery culture. The oxygenation system comprises a buoyancy supporting mechanism, a solar power supply mechanism, a power mechanism, an oxygenation mechanism, a hoisting mechanism and a control mechanism, wherein the control mechanism comprises a central controller, and a dissolved oxygen sensor, an ultrasonic range finding module, a GPS (Global Positioning System) navigation module and an inertial navigation module, which are electrically connected with the central controller respectively; the central controller is used for controlling rotary speeds of two driving motors according to information fed back by the ultrasonic range finding module, the GPS navigation module and the inertial navigation module, so that movable oxygenation and automatic berthing are realized; electric energy generated by the solar power supply mechanism is stored in the storage battery and is used for providing the electric energy to the oxygenation mechanism, the power mechanism and the control mechanism. According to the movable solar oxygenation system and method, intelligent and flexible movement of the oxygenation system can be realized; the dissolving efficiency of oxygen in water can be effectively enhanced and the utilization performance of whole equipment is improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

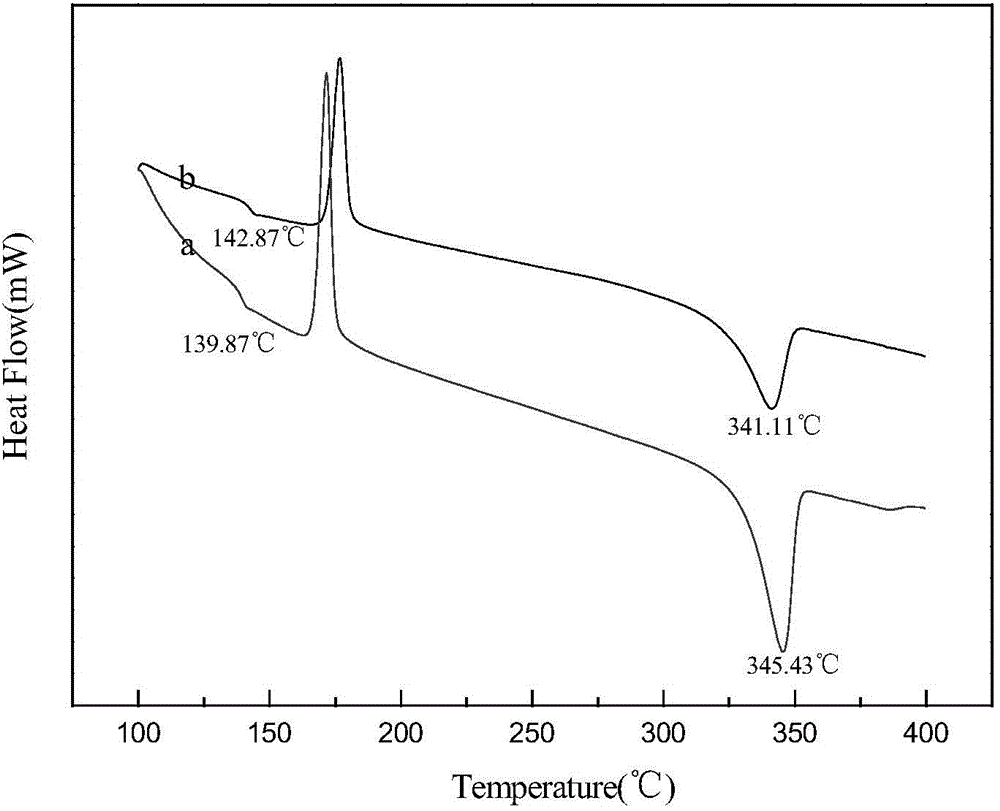

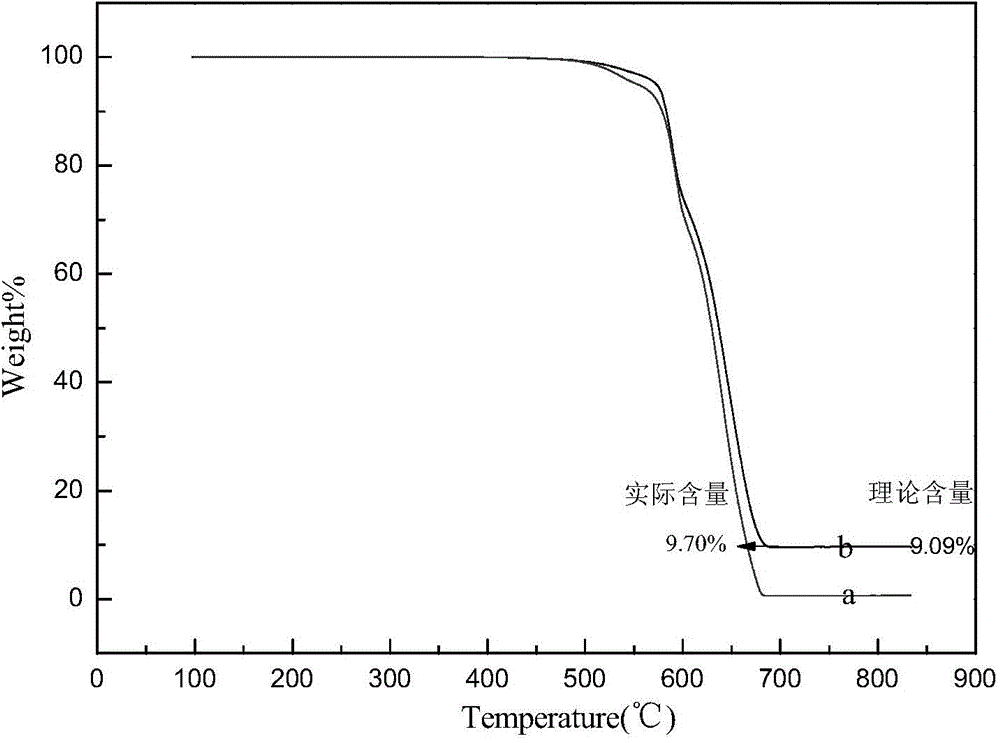

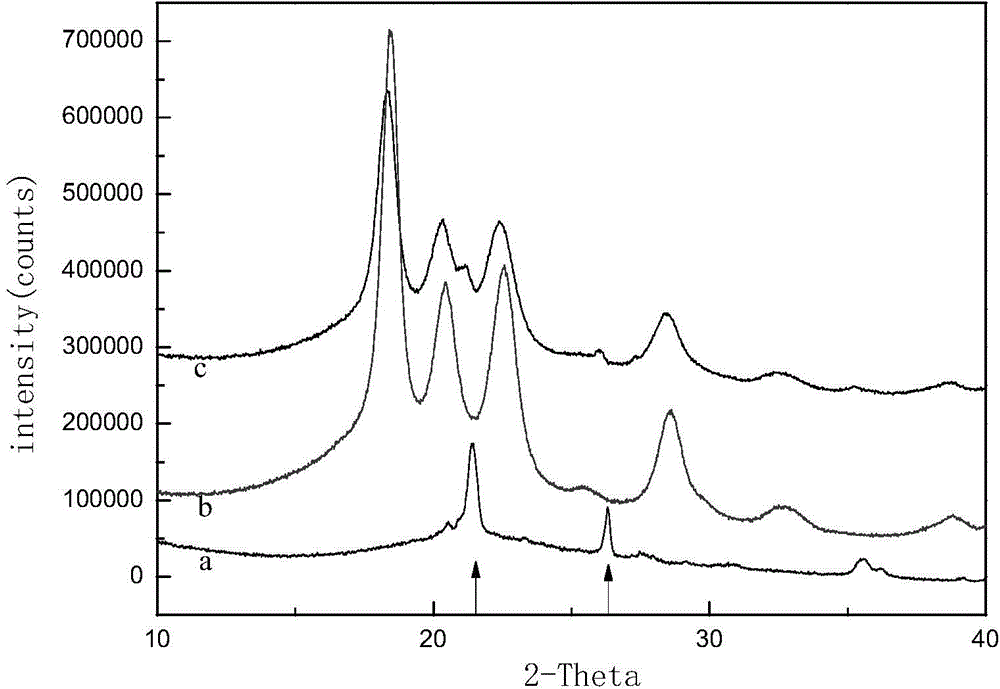

Diatomite/polyether-ether-ketone composite material and preparation method thereof

The invention relates to a diatomite / polyether-ether-ketone composite material and a preparation method thereof and belongs to the field of polymer composite materials. The preparation method comprises the following specific steps: treating diatomite with an acid solution and an alkali solution, adding the treated diatomite into a polyether-ether-ketone synthesis device, vacuumizing the polyether-ether-ketone synthesis device, displacing air with nitrogen, and carrying out polymerization reaction according to the polymerization steps of polyether-ether-ketone to obtain the diatomite / polyether-ether-ketone in-situ polymerization composite material. The diatomite which is a porous material is compounded with the polyether-ether-ketone through polymerization in situ, thus a new idea can be provided for the modification of the polyether-ether-ketone. The diatomite is a porous substance, and in-situ polymerization can ensure that the polymer enters the pores of the diatomite. The diatomite serves as the stress concentration point under stress, thus the defect that the porous substance is filled with the polymer with high melt viscosity can be alleviated, the mechanical properties of the diatomite / polyether-ether-ketone composite material can be improved significantly, and the problems that diatomite can not be dispersed uniformly into polyether-ether-ketone with high melt viscosity and the diatomite agglomerates in the polyether-ether-ketone can be well solved.

Owner:JILIN UNIV

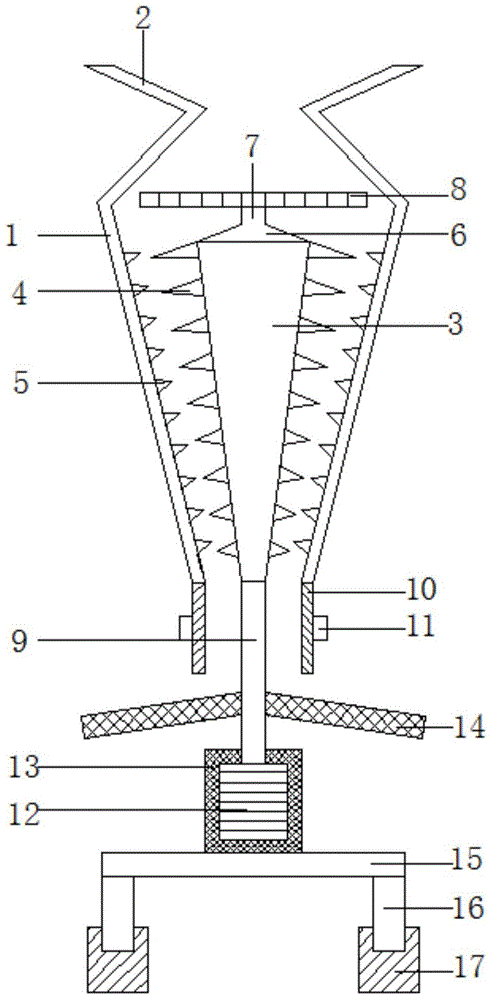

Efficient sawtooth pulverizer for ceramic production

InactiveCN104941752AGuaranteed crushing effectImprove crushing effectMagnetic separationGrain treatmentsIron removalPulp and paper industry

The invention discloses an efficient sawtooth pulverizer for ceramic production. The efficient sawtooth pulverizer comprises a pulverizer body, a pulverizing spiked roller and a pulverizing chain. A feeding hopper is arranged on the upper side of the pulverizer body, and the pulverizing spiked roller is vertically arranged on the axis of the interior of the pulverizer body; and the diameter of the top end of the spiked roller is larger than that of the bottom end of the spiked roller, and a plurality of pulverizing movable sawteeth are vertically and evenly arranged on the outer wall of the pulverizing spiked roller. According to the efficient sawtooth pulverizer for ceramic production, the pulverizing chain preliminarily pulverizes materials, and the materials enter pulverizing gaps between the pulverizing movable sawteeth and pulverizing fixed sawteeth to be pulverized; the pulverizing time is long, the pulverizing effect is good, and the pulverized materials are screened by a screen, so that the working efficiency of the pulverizer is greatly improved; electromagnets can carry out iron removal on the fallen materials, and the quality of a machined finished product is ensured; and in the pulverizing process, the vertical motion of the spiked roller is adjusted to control the size of the pulverizing gaps, so that the pulverized material is controlled, the practicability is high, and the working process of the pulverizer is low in noise.

Owner:顾广才

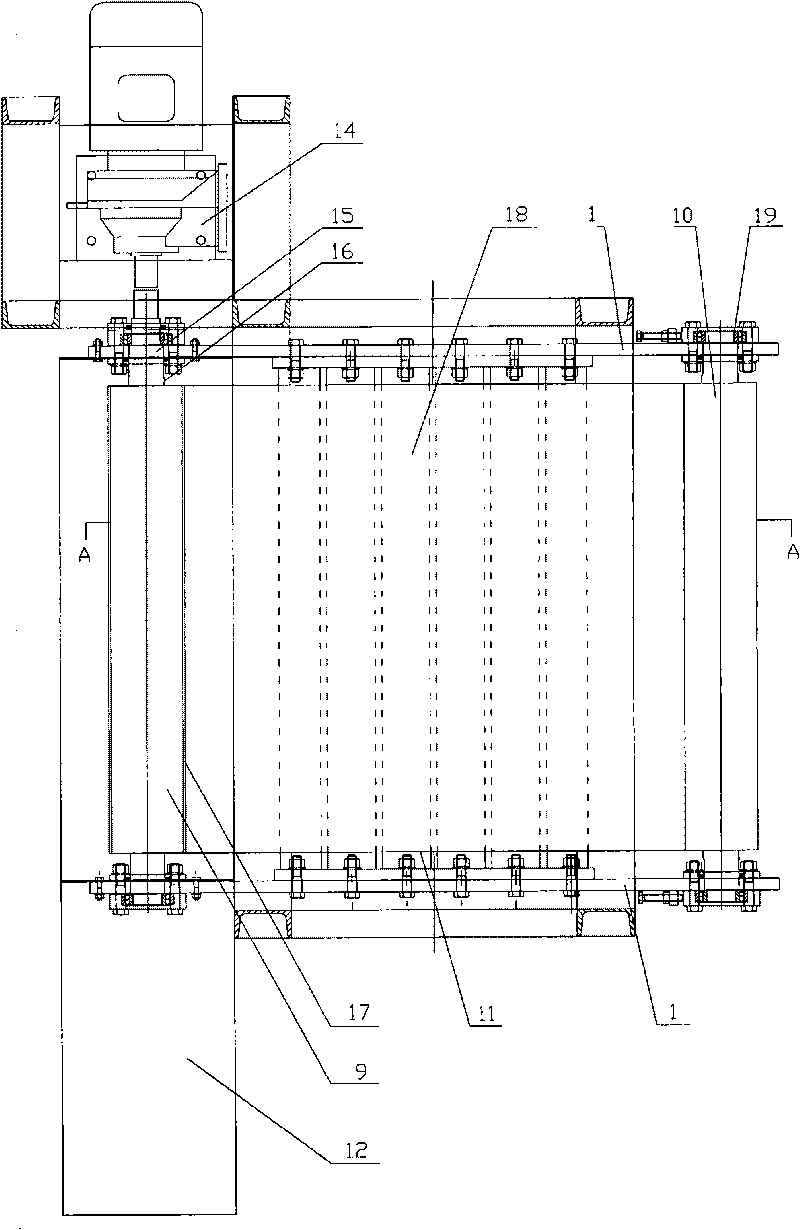

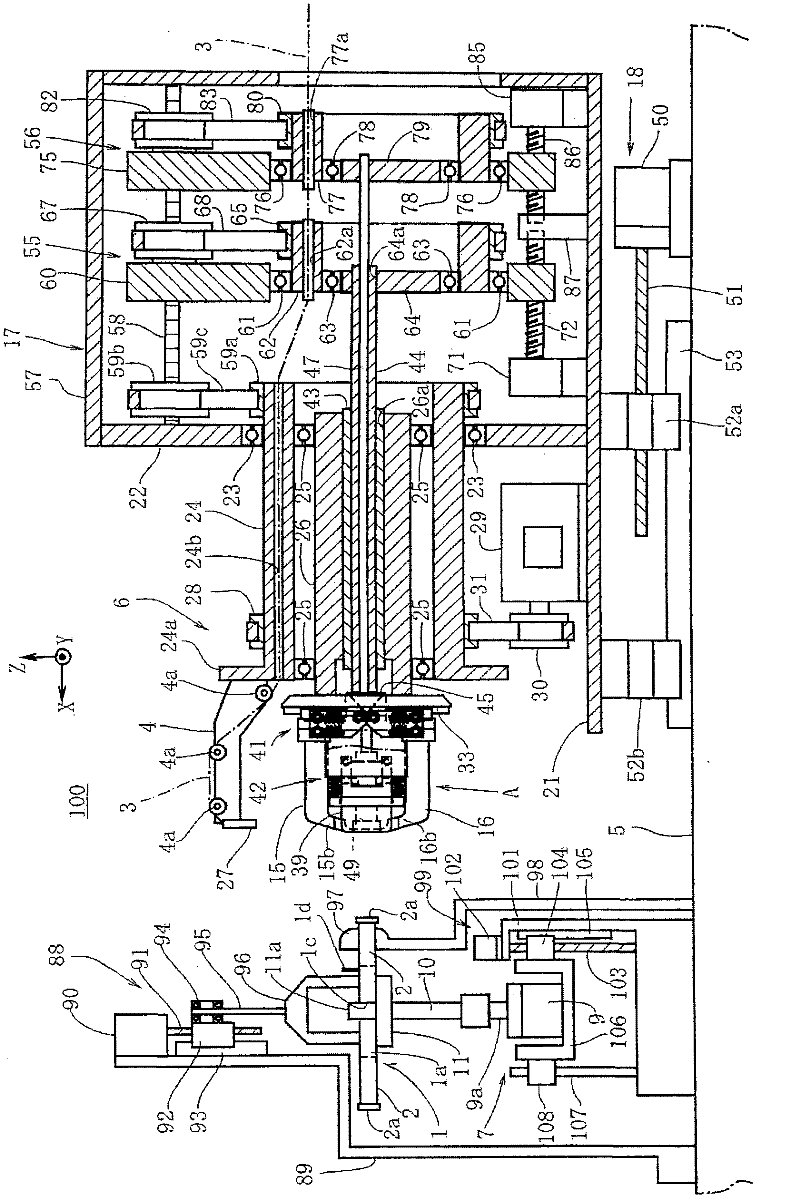

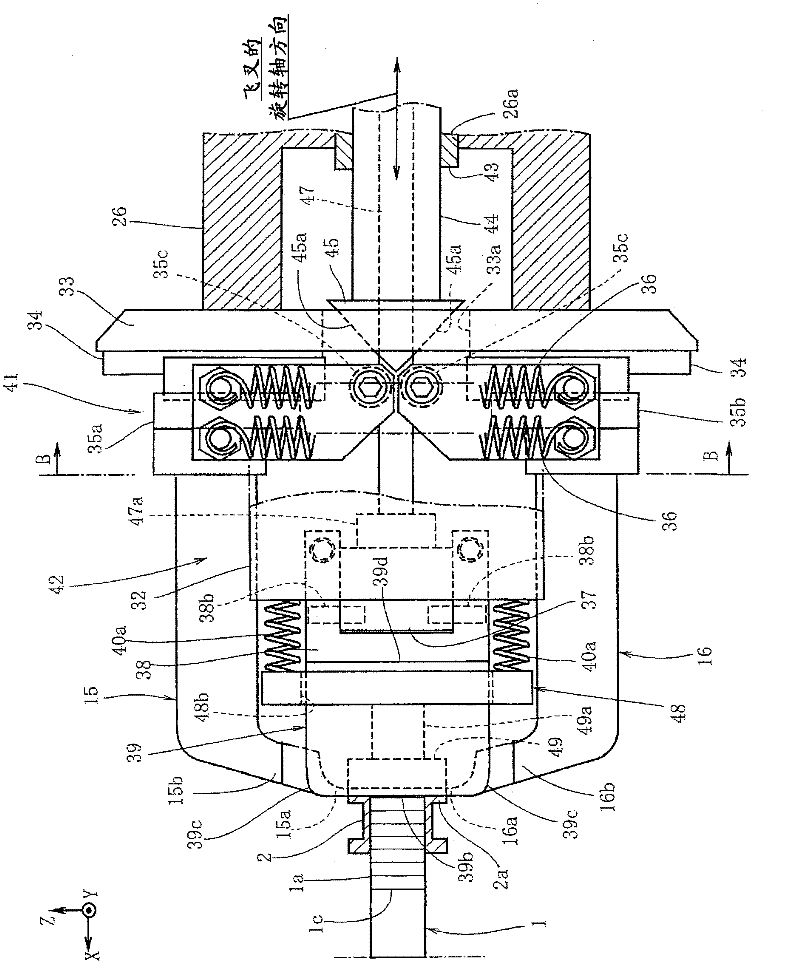

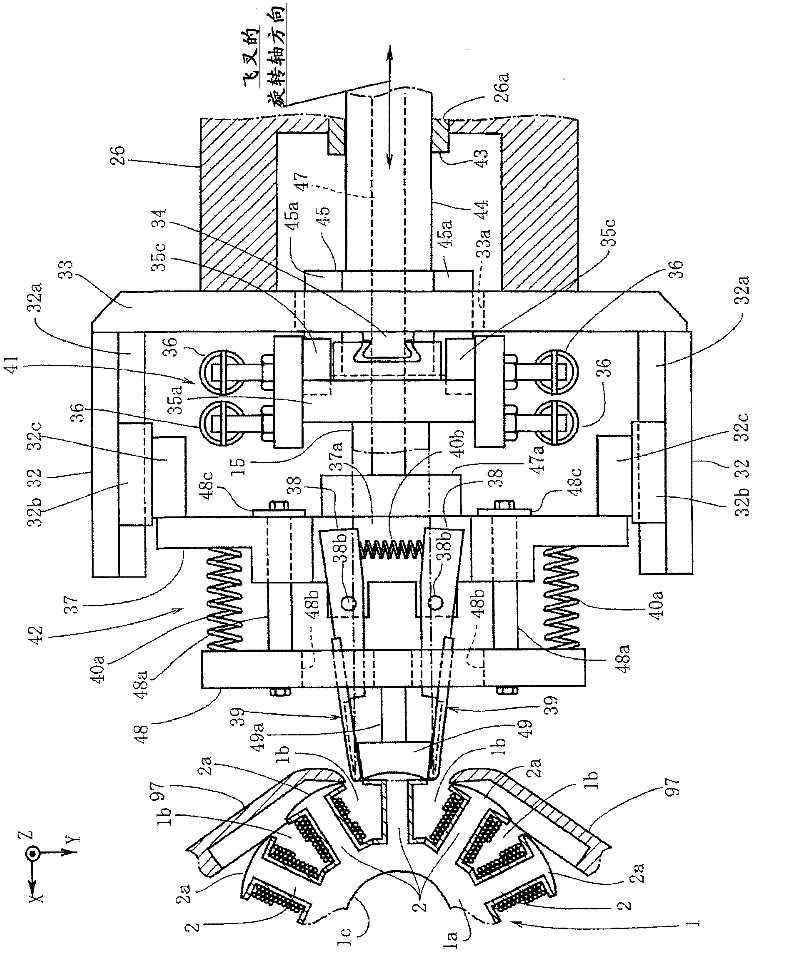

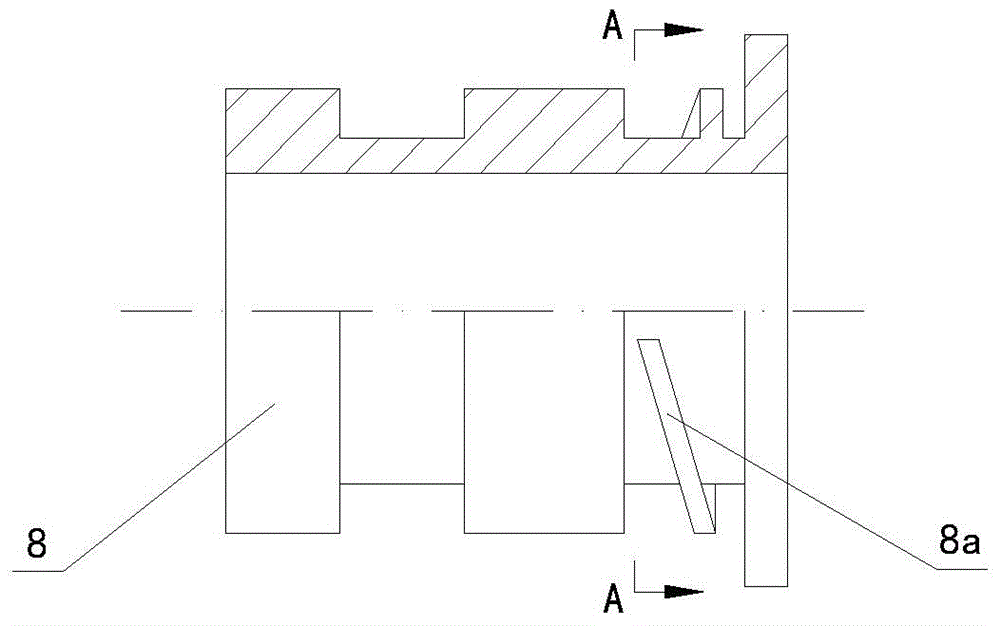

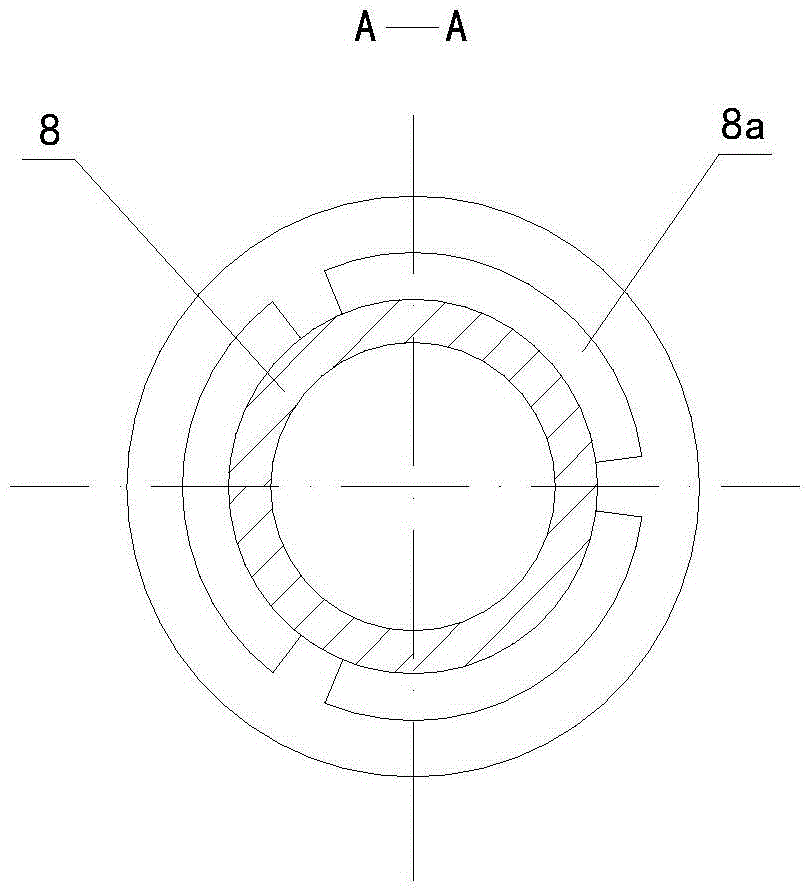

Winding machine and winding method

InactiveCN102570739AWinding firmlyEnter fullyManufacturing dynamo-electric machinesWinding machineMagnetic poles

The invention provides a winding machine and a winding method. When the winding the performed on the first layer and the second layer, a top end of a side plate completely enters into the inner circumferential side of a magnetic pole and the wire is stably and regularly wound on the magnetic pole. The winding machine comprises: a flying fork capable of rotating around the magnetic pole of multi-pole armature and simultaneously leading out the wire and winding the wire relative to the magnetic pole; a pair of central winding molds configured to axially clamp the magnetic pole from the multi-pole armature and guide the wire led out from the flying fork to the magnetic pole; a pair of side plates configured to axially clamp the magnetic pole from the multi-pole armature and guide the wire led out from the flying fork to the magnetic pole. The pair of the side plates are configured to incline relative to a rotation shaft of the flying fork in the way of closing to the inner circumferential side of the multi-pole armature and change the inclined angle relative to the rotation shaft of the flying fork, therefore the top interval between the inner circumferential side of a magnetic pole and the side plate is changed.

Owner:NITTOKU ENG CO LTD

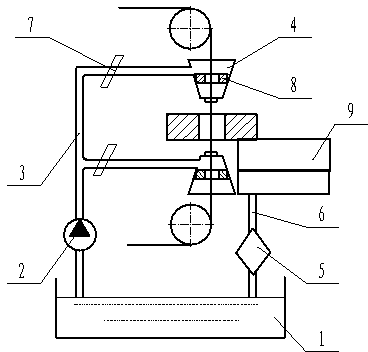

Working fluid circulation filter device of wire cut electrical discharge machine

The invention discloses a working fluid circulation filter device of a wire cut electrical discharge machine, which comprises a fluid storage tank, a hydraulic pump, a feed pipe, nozzles, a filter and a return pipe, wherein one end of the feed pipe is connected with the hydraulic pump; the other end of the feed pipe is connected with nozzles; the return pipe is located in a coordinate table and connected with the filter; the hydraulic pump draws working fluid out of the fluid storage tank and transmits to the nozzles through the feed pipe; the nozzles spray the working fluid to a machining area; and then, the working fluid enters the filter through the return pipe in the coordinate table and flows back to the fluid storage tank after filtration. With the adoption of the mode, the device is simple in structure, and can recycle the working fluid after wire cutting, thereby lowering machining cost and reducing resource waste.

Owner:SUZHOU BAOMA NUMERICAL CONTROL EQUIP

Integral ventilated drying device for fodder manufacturing

InactiveCN107606924AKeep dryImprove efficiencyDrying gas arrangementsDrying solid materialsEngineeringFodder

The invention discloses an integral ventilated drying device for fodder manufacturing. The integral ventilated drying device comprises a base, a shell, a motor and a material feeding hopper, wherein ahollow shaft is arranged in the shell in a penetrating manner; the outer side of a left end of the hollow shaft is sleeved with an air exhausting box; an output shaft of the motor horizontally extends into the air exhausting box of the base; the outer side of a right end of the hollow shaft is sleeved with an air inlet box; the inner part of the shell is divided into a drying cavity on a right side and a dedusting cavity on a left side through a separation plate; and a baffle plate is fixed on a corresponding position in the hollow shaft so as to divide the inner part of the hollow shaft intoan air inlet cavity on a right side and an air exhausting cavity on a left side. According to the integral ventilated drying device, an integral hollow shaft is arranged, and corresponding separationis arranged, so that air inlet and air exhausting can be performed at the same time; hot air entering the device is in fully contact with fodders; the drying effect and efficiency of the fodders areimproved; generated hot steam can be exhausted from the other end of the hollow shaft in time; and flowing of air in the device is ensured, so that moisture can be emitted in time.

Owner:TIANJIN KECHUANG FUXIN TECH CONSULTING CO LTD

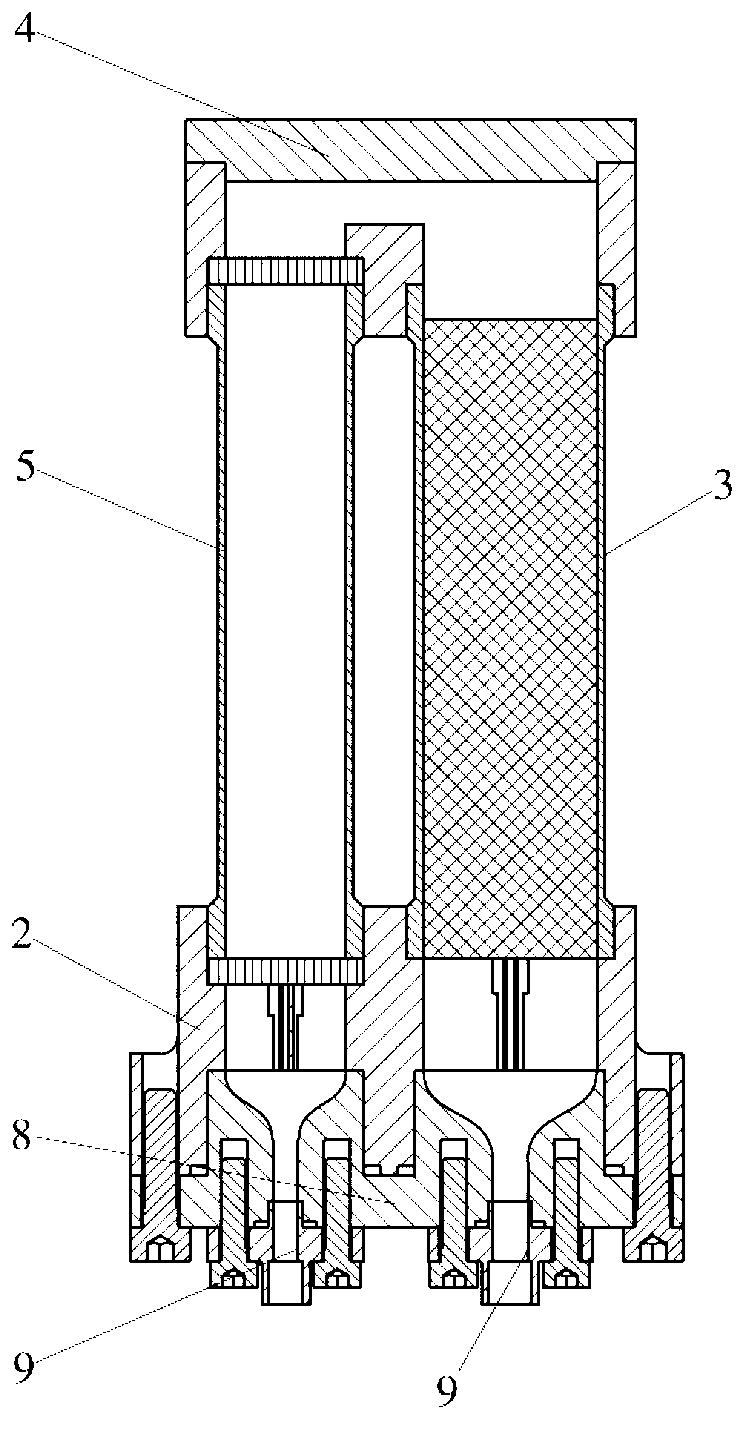

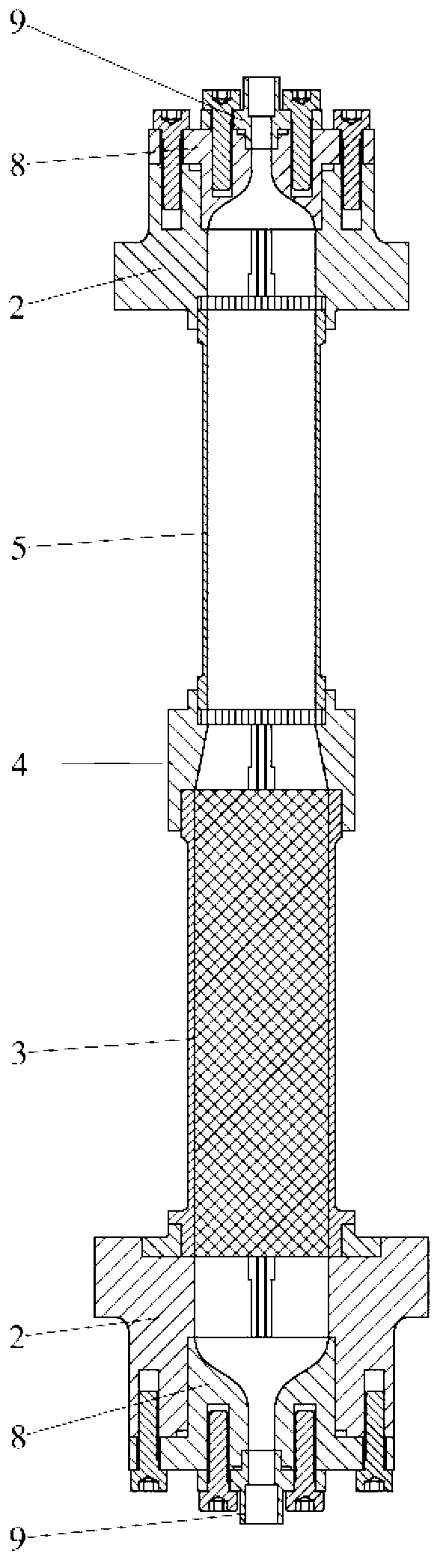

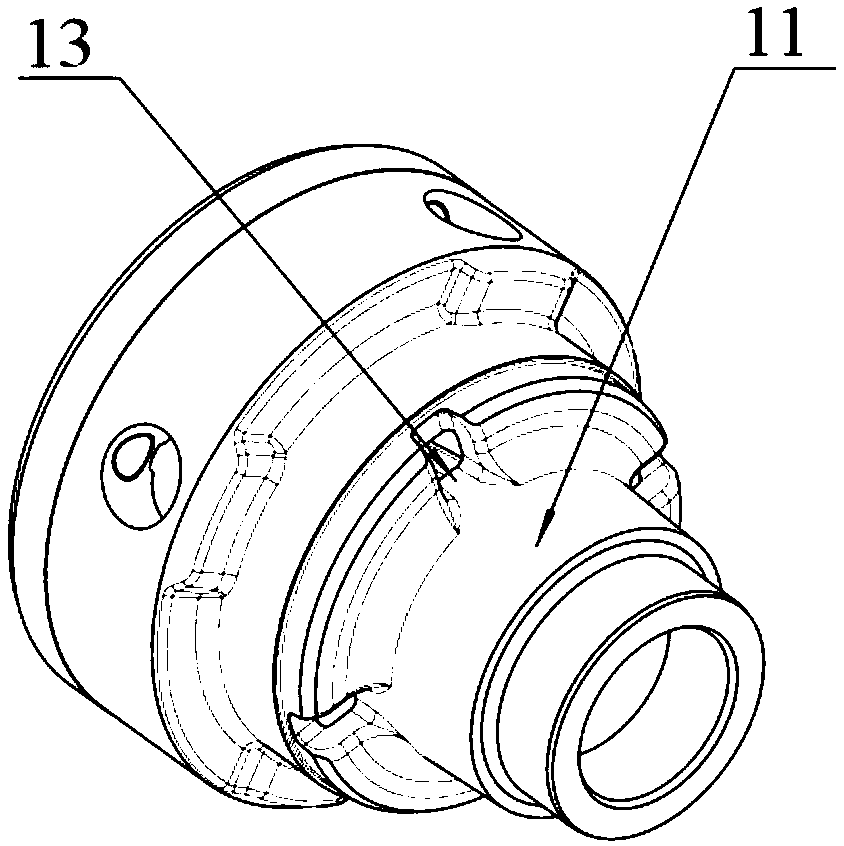

Flow guide structure inside hot end of U-type / linear pulse tube refrigerating machine and manufacturing method thereof

InactiveCN103175329AEliminate weak cornersIncrease the heat exchange areaCompression machinesGas cycle refrigeration machinesWire cuttingPulse tube refrigerator

The invention discloses a flow guide structure inside the hot end of a U-type / linear pulse tube refrigerating machine and a manufacturing method of the flow guide structure. The flow guide structure is composed of a hot end heat exchanger, a hot end plug and a flow guide core column. Cone-shaped fin structures are formed in the hot end heat exchanger in a cutting mode through the wire cutting technology and are evenly distributed around the center of the hot end heat exchanger in a ring-shaped mode. A T-shaped through hole is formed in advance in the central portion before a wire cutting process so as to eliminate a thin and weak sharp corner at the tail end of each fin. The flow guide core column which is also manufactured in a fin structure is inserted into the hot end heat exchanger, and a hole is formed in the central position of the flow guide core column in a penetrating mode. The hot end plug is inserted into the hot end heat exchanger, wherein a transition curved surface, which changes gradually in two directions inside the hot end plug is connected with slit body flow guide passageways and small hole channels, the curved surface is tangent to the surface of each of fluid passageways at two ends, and the hot end plug is tightly connected on the hot end heat exchanger through a sealing ring and screws. Through the design of the novel flow guide structure at the position of abrupt change of the cross section of a hot end gas flow passageway, loss of high-frequency oscillation gas flow at the position is enabled to be minimized, and the flow guide structure inside the hot end of the U-type / linear pulse tube refrigerating machine has important significance in improving refrigerating efficiency of the U-type / linear pulse tube refrigerating machine.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

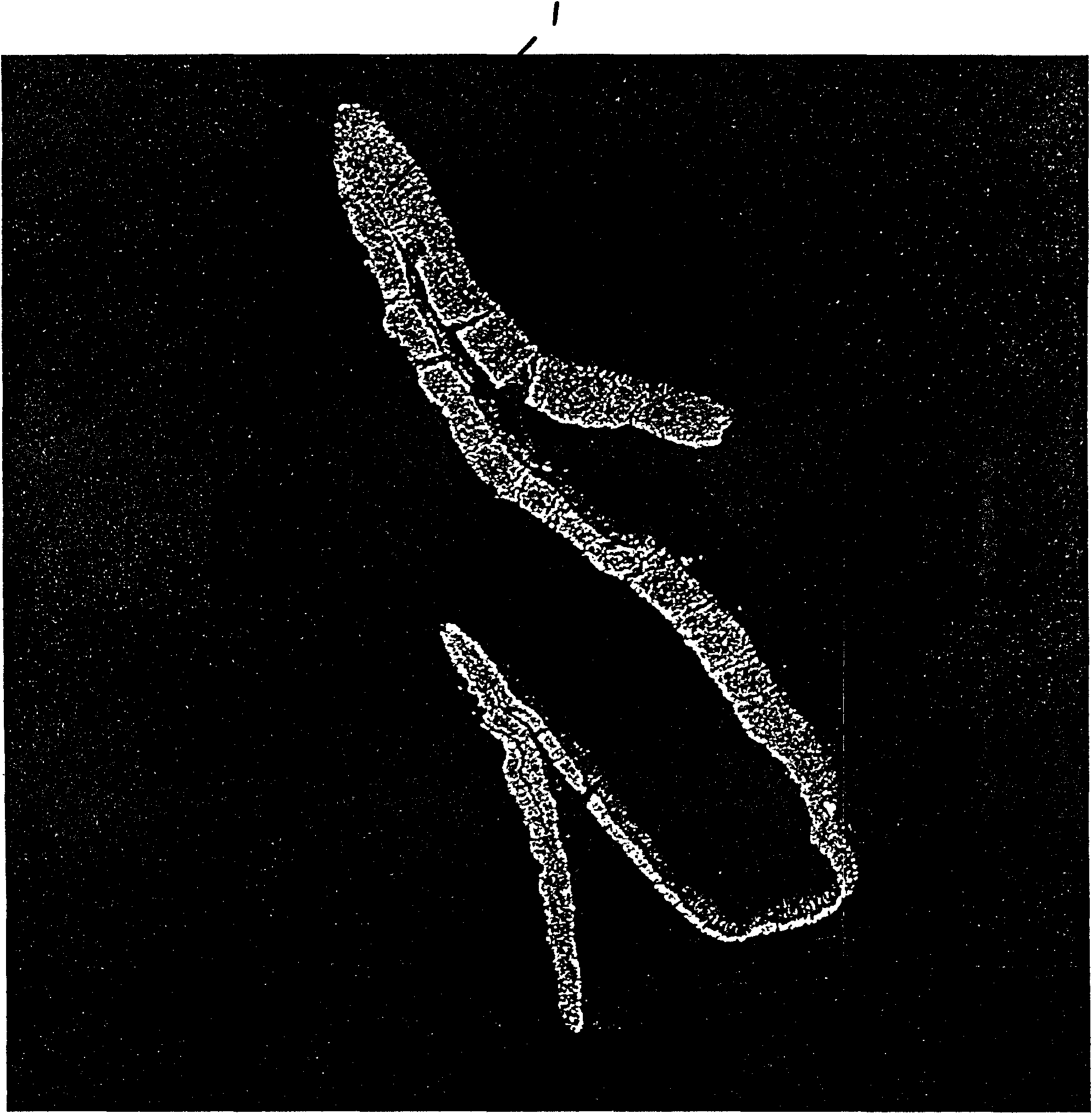

Polytetrafluoroethylene dental floss

A polytetrafluoroethylene dental floss comprises a floss body and is characterized in that the floss body is formed by the process that a polytetrafluoroethylene film provided with micropore is split by a film splitting blade and then is rolled up and stretched by a forming die and the transverse section of the floss body is in 'hi' (a Japanese hiragana) shape. The polytetrafluoroethylene dental floss of the invention is quick is the effect of degree of tightness when the floss body enters into slit between the teeth, is convenient to enter the slit between the teeth, and contact area of the floss body for cleaning teeth is large and is improved by 50-60% than that of the existing dental floss. The polytetrafluoroethylene dental floss can be used for cleaning teeth, repairing teeth and teeth health protection in hospitals and families.

Owner:SHANGHAI JINYOU FLUORINE MATERIALS

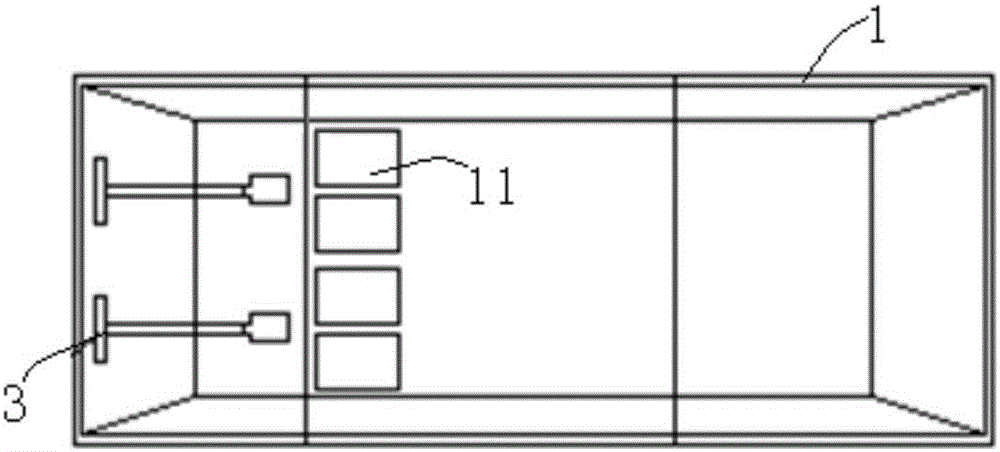

Medical disinfection cabinet

ActiveCN108992686AEnter fullyAvoid damageDispersed particle separationLavatory sanitoryEngineeringOzone

The application provides a medical disinfection cabinet. The medical disinfection cabinet comprises a cabinet body and a cabinet door. The top of the cabinet body is provided with an ozone generatingdevice. The ozone generating device is communicated with the top of the cabinet door through an ozone conveying pipe. The bottom of the cabinet body is provided with a vacuuming device for vacuuming the cabinet body. The vacuuming device vacuums the cabinet body, then the ozone generating device is started to generate ozone and the ozone is fed into the cabinet body in vacuum through the ozone conveying pipe so that the ozone fully enters stacked objects and completely disinfects the stacked clothes and towels.

Owner:石敏

Cleaning equipment for water plants

InactiveCN111328537AClean up fastSave resourcesWater cleaningHarvestersAgricultural engineeringBiology

Owner:王双炎

Monitoring device for computer network equipment

PendingCN111121865AWith fire warningEasy to placeMeasurement devicesCasings/cabinets/drawers detailsMechanical engineeringElectromagnetic valve

The invention discloses a monitoring device for computer network equipment. The monitoring device comprises a shell body, wherein a temperature sensor, a smoke sensor and a processor are fixedly connected to the right side of the top part of an inner cavity of the shell body from left to right; a camera is fixedly connected to the left side of the top part of the inner cavity of the shell body; aframe body is placed at the top part of the shell body; a sand injection pipe fixedly communicates with the top part of the frame body; a sand discharging pipe fixedly communicates with the bottom part of the frame body; the bottom part of the sand discharging pipe penetrates into the inner cavity of the shell body; an electromagnetic valve is arranged on the surface of the end, located in the inner cavity of the shell body, of the sand discharging pipe; and a cooling liquid box is fixedly connected to the right side of the shell body. The monitoring device solves the problems that an existingmonitoring device for the computer network equipment cannot effectively monitor and warn the computer network equipment, once ventilation holes are blocked or a radiator is damaged, core components of a computer can be burnt out or a fire is caused due to long-time work, and huge losses are caused.

Owner:西安世锐软件有限责任公司

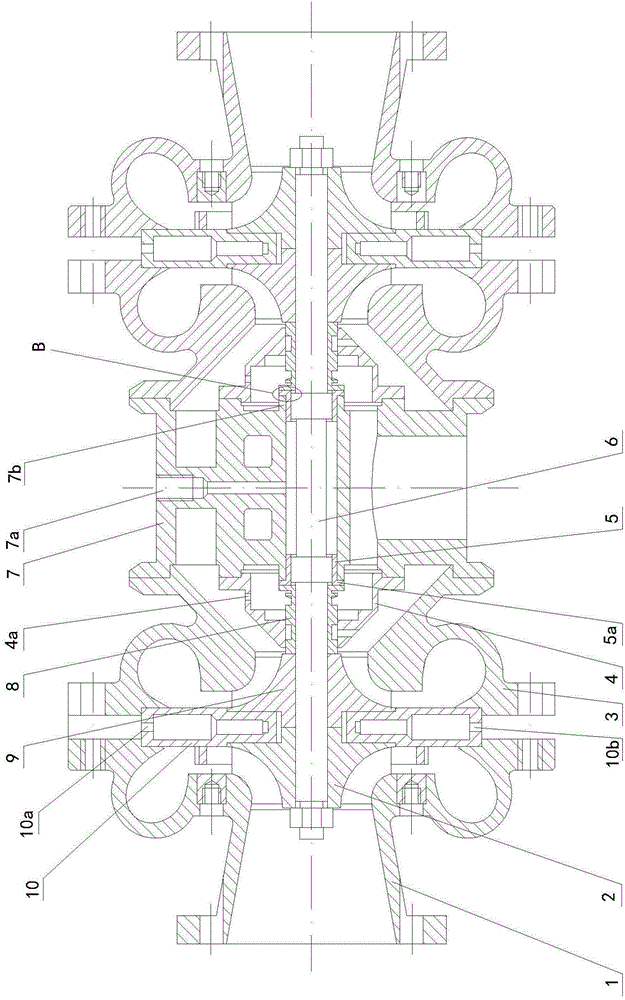

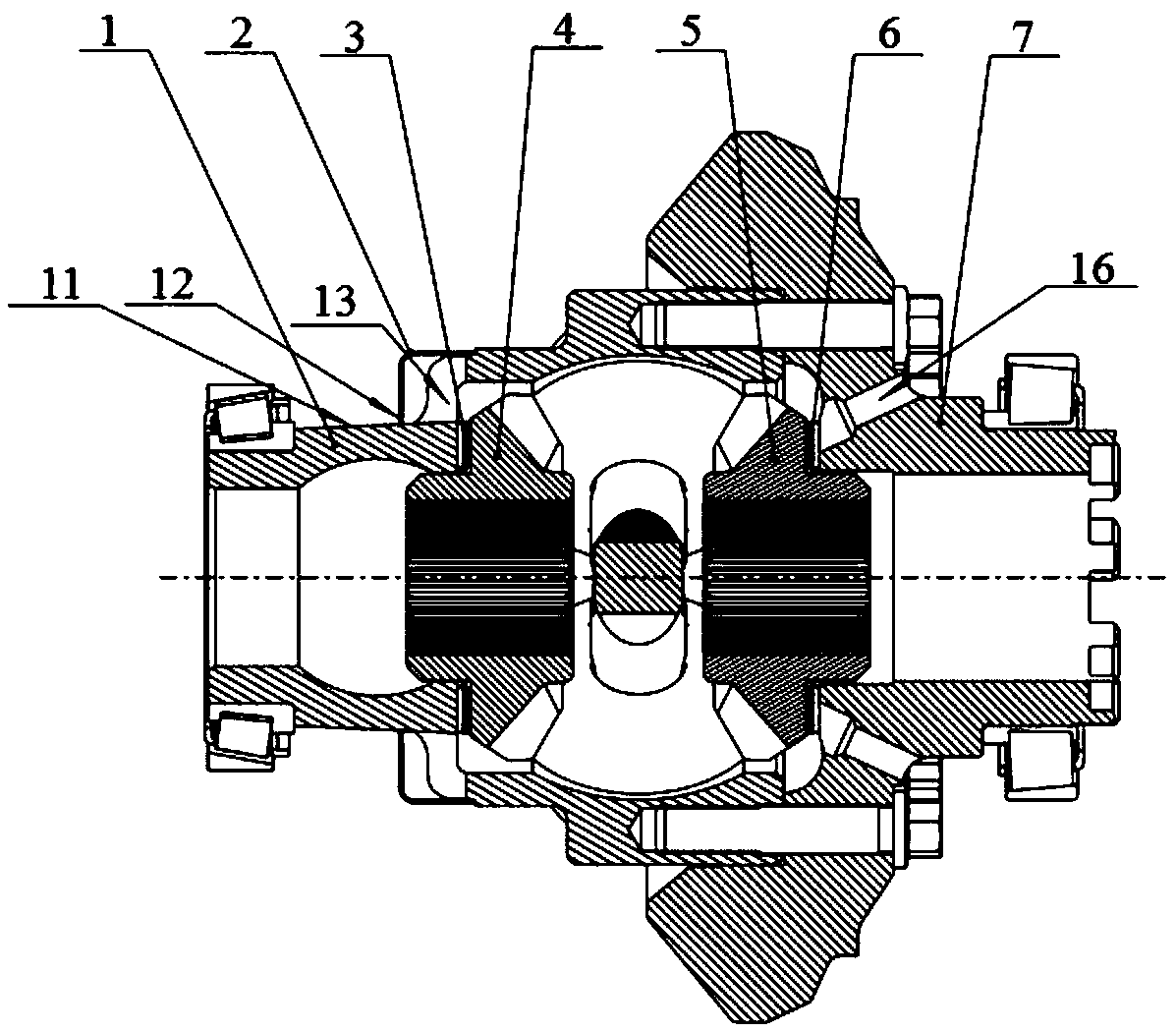

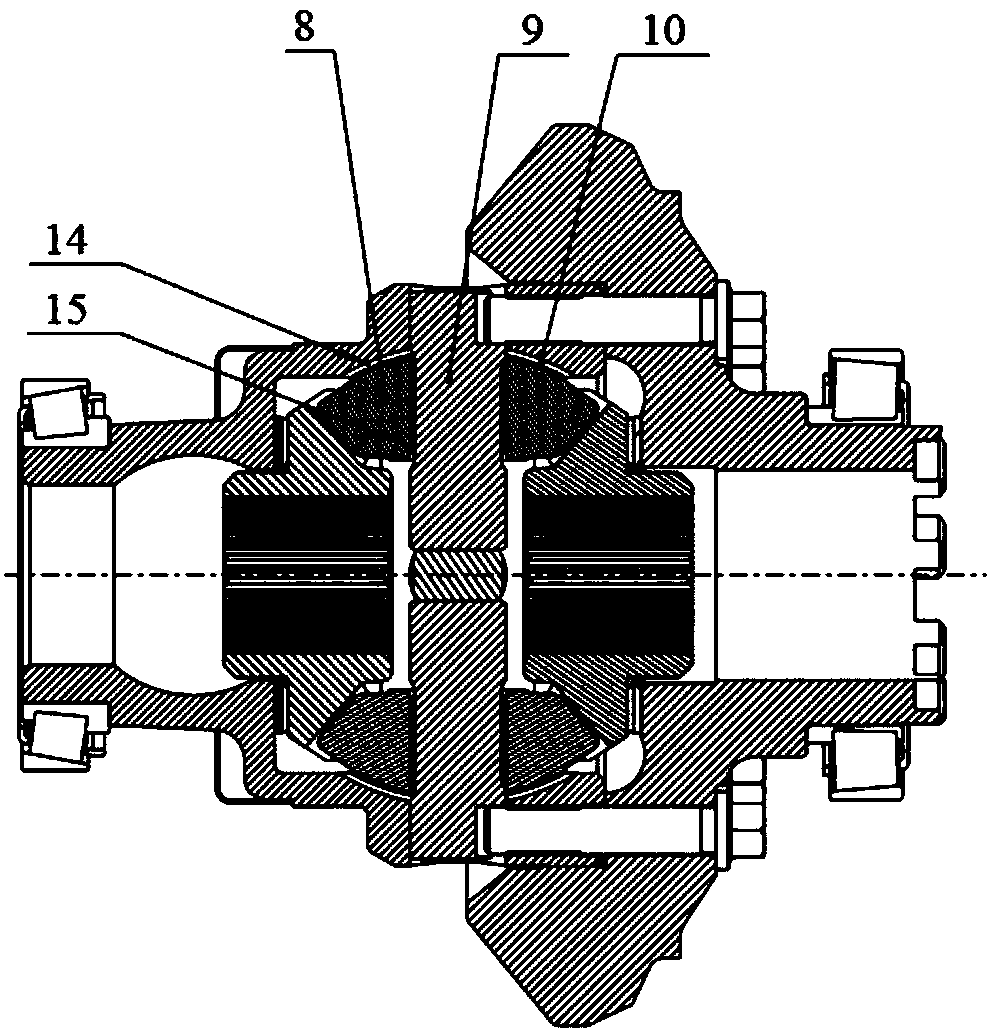

One-shaft two-unit horizontal turbocharger for vehicle

InactiveCN104696062ASimple structureStable jobInternal combustion piston enginesEngine componentsImpellerLubrication

Provided is a one-shaft two-unit horizontal turbocharger for a vehicle. Both sides of a bearing shell are connected to compressor casings respectively connected to a turbine housing. A rotating shaft is mounted in the bearing shell in a penetration mode. A compressor impeller and a turbine impeller are mounted on the rotating shaft. Bearing caps are mounted at both ends of the bearing shell. An oil slinger is arranged between the bearing caps and the rotating shaft. Both end openings of an inner opening of the bearing shell are respectively provided with a floating bearing with a blocking shoulder. The floating bearings are in clearance fit with the rotating shaft and the bearing shell. Both end openings of the bearing shell are provided with bosses. The blocking shoulder of each of the floating bearings is arranged between the boss at one end of the bearing shell and one of the oil slingers. The bearing shell is provided with an oil inlet. The lubricating oil enters the bearing shell from the oil inlet and then enters the portion between the floating bearings and the rotating shaft and the bearing shell to achieve axial oil feeding, so that the floating bearings are in an ideal suspension state in the work to achieve the ideal lubrication effect. Furthermore, the floating bearings play a role of thrust bearings as well as floating bearings, so that the structure is greatly simplified.

Owner:费传华

Spiral flue gas desulphurization apparatus

InactiveCN106512690AAvoid poisoningIncrease concentrationDispersed particle separationCeriumLanthanum

The invention discloses a spiral flue gas desulphurization apparatus. The spiral flue gas desulphurization apparatus comprises a gas inlet pipe and a desulphurization tank, wherein the gas inlet pipe is located at the lower part of the desulphurization tank; an ammonia water atomization nozzle is arranged at the central part of the desulphurization tank; a flue gas discharge outlet is formed in the top of the desulphurization tank; a demisting device and spiral wind guiding vanes are arranged in the desulphurization tank; the demisting device is arranged above the ammonia water atomization nozzle; the wind guiding vanes are located above the demisting device; and the wind guiding vanes are sprayed with at least one element selected from a group consisting of praseodymium, lanthanum, cerium, nickel, zinc and titanium or a compound of the elements selected from the group. The spiral flue gas desulphurization apparatus provided by the invention has the advantages of more thorough desulphurization, recoverable byproducts, no secondary pollution, etc.

Owner:CHONGQING HUAXU ENERGY TECH

Lubricating structure of drive axle differential mechanism and drive axle differential mechanism assembly

PendingCN111089154AEasy dischargeReduce the temperatureGear lubrication/coolingDifferential gearingsOil canEngineering

The invention relates to a lubricating structure of a drive axle differential mechanism and a drive axle differential mechanism assembly. The lubricating structure comprises an oil baffle cover, the oil baffle cover is fixedly arranged on the circumferential outer side of a tooth surface side differential mechanism shell of the differential mechanism, an outer conical surface is arranged at the axial joint between the tooth surface side differential mechanism shell and a half axle of the differential mechanism, the rotation diameter of the end, facing the half axle, of the outer conical surface is increased, a gap is formed between the oil baffle cover and the outer conical surface, so that lubricating oil flows inwards, and an oil inlet leading to an inner cavity is formed in the inner side, at the gap, of the tooth surface side differential mechanism shell. According to the lubricating structure of the drive axle differential mechanism and the drive axle differential mechanism assembly, the oil can be promoted to be fed and discharged, oil circulation of oil in the inner cavity of the differential mechanism shell and oil outside the differential mechanism shell is achieved through feeding and discharging of the oil, impurities and heat generated inside the differential mechanism can be brought out, the impurities in the inner cavity of the differential mechanism shell are reduced, the inner temperature of the differential mechanism is reduced, meanwhile, oil microcirculation is formed in the inner cavity, and the lubricating effect is improved, and therefore, internal abrasion of the differential mechanism can be remarkably reduced, and service lives of the differential mechanism and the whole axle are greatly prolonged.

Owner:SHAANXI HANDE AXLE CO LTD

Device and method for producing acetylene by hydrogen direct current arc plasma cracking coal

ActiveCN101734995BThorough treatmentNo pollution in the processHydrocarbonsHydrocarbon preparationCoal dustDust control

The invention relates to a device and a method for producing acetylene by hydrogen direct current arc plasma cracking coal. The method comprises the following steps: the hydrogen coal dust is fed into a plasma reactor, enters a quenching machine for quenching after the reaction, then enters a cyclone separator for preseparation between gas and solid; the gas part enters a rinsing dust removing tower for dedusting, is sent to a compressor for compression by a booster fan, then enters a pressure swing adsorption tower for adsorption and concentration, and simultaneously, the gas out of the pressure swing adsorption tower enters the compressor again and is sent to an adsorption tower for extracting hydrogen; the solid dust separated by the cyclone separator and the rinsing dust removing tower forms solution with water; a ceramic membrane device is utilized to carry out liquid and solid separation; the solid dust is sent to a power plant to be served as raw materials; and water enters therinsing tower for recycling. The invention has reasonable process design and high economic efficiency, can be used in combination or separately, and can be directly used in the processes for producing hydrogen chloride, acetylene ethane derivative, methanol and the derivatives and the like.

Owner:XINJIANG TIANYE GRP

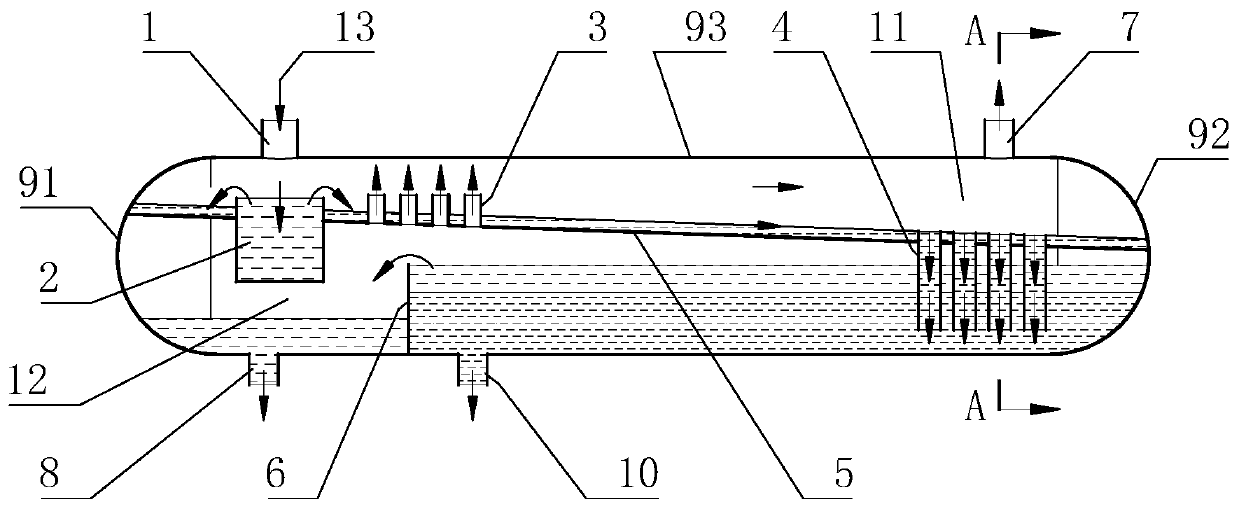

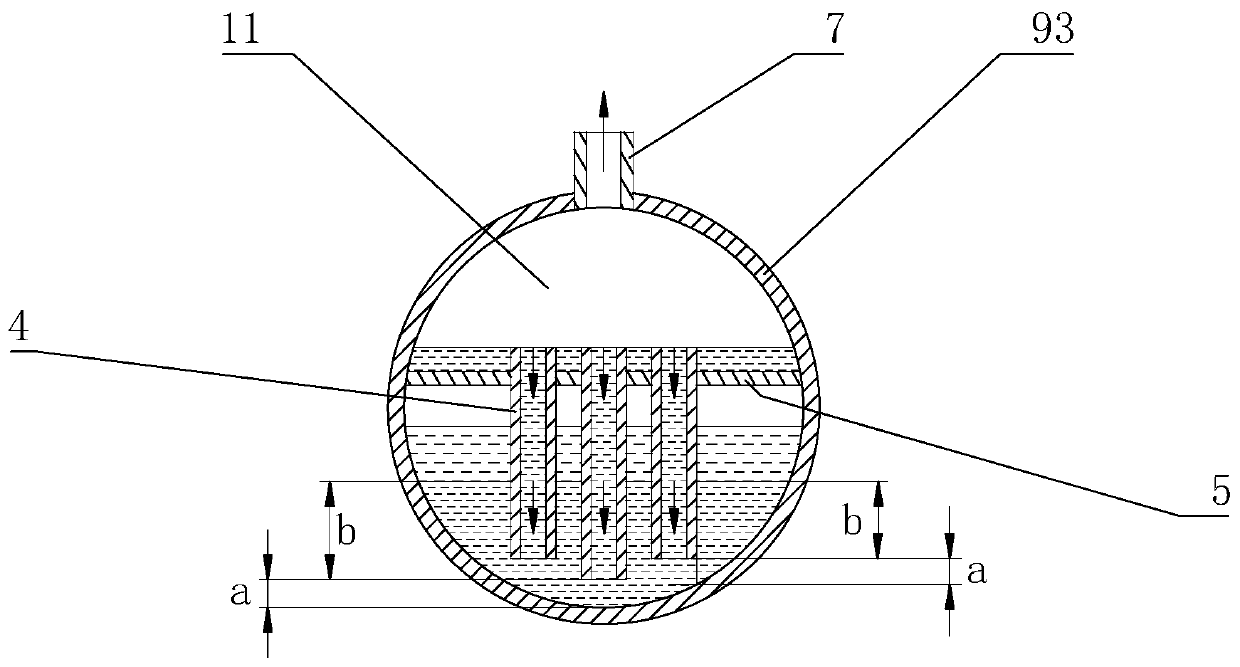

A kind of oil-gas-water horizontal three-phase separator and oil-gas-water separation method

ActiveCN107737466BEasy to separateFully isolatedLiquid degasificationNon-miscible liquid separationLiquid layerVapor liquid

Owner:SINOPEC GUANGZHOU ENG CO LTD +1

Efficient mixing device for ozone and water

ActiveCN103861485AIncrease the ozone contentGuaranteed bactericidal effectFlow mixersMixing methodsOzoneEnvironmental engineering

The invention provides an efficient mixing device for ozone and water. The efficient mixing device is used for solving the problem of bad sterilizing effect caused by low content of ozone in irrigation water in the prior art. The efficient mixing device for the ozone and the water comprises a main pipe and a by-pass pipe, wherein one end of the main pipe is used for connecting a water pump and the other end of the main pipeline stretches in a farmland for irrigation; the radial size of the by-pass pipe is smaller than that of the main pipeline, the by-pass pipe is connected with the main pipeline in parallel and is communicated with the main pipeline, and an ozone inlet is formed in the by-pass pipe. The efficient mixing device for the ozone and the water is simple in structure and convenient to use, the content of the ozone in the water can be effectively improved, and the water is irrigated in the farmland, so that the efficient mixing device has the good sterilization effect.

Owner:北京田缘农业科技发展有限公司

A medical disinfection cabinet

ActiveCN108992686BEnter fullyAvoid damageDispersed particle separationLavatory sanitoryEngineeringOzone

Owner:石敏

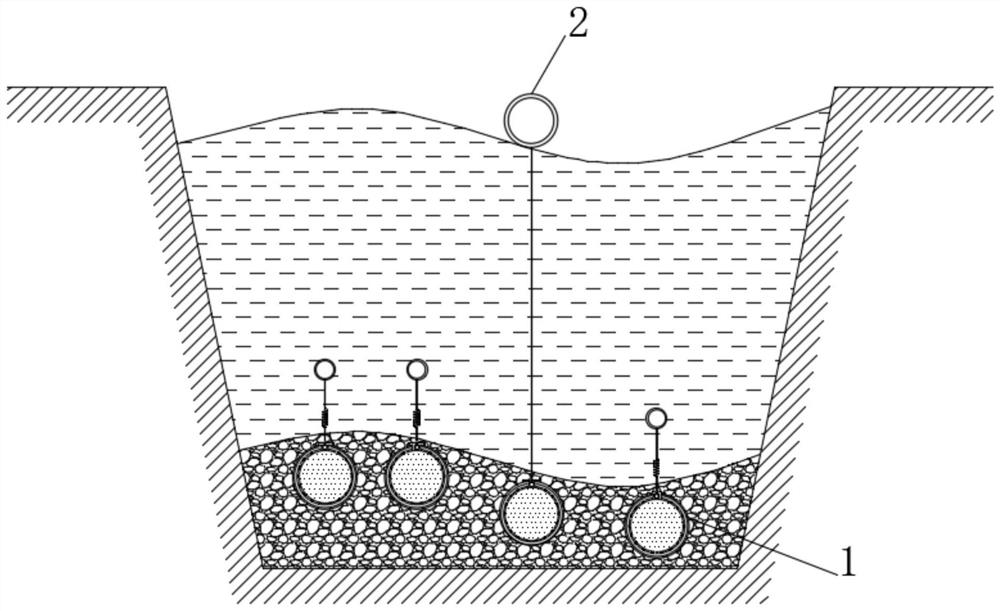

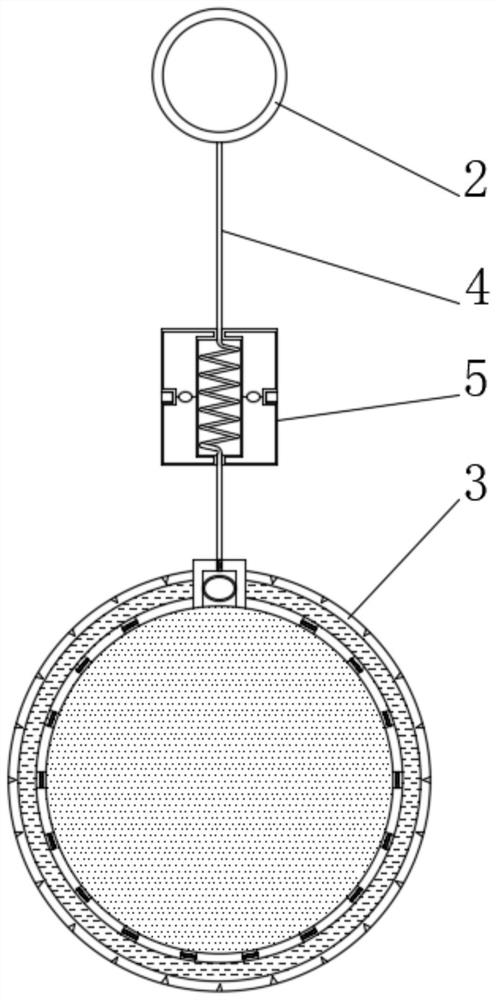

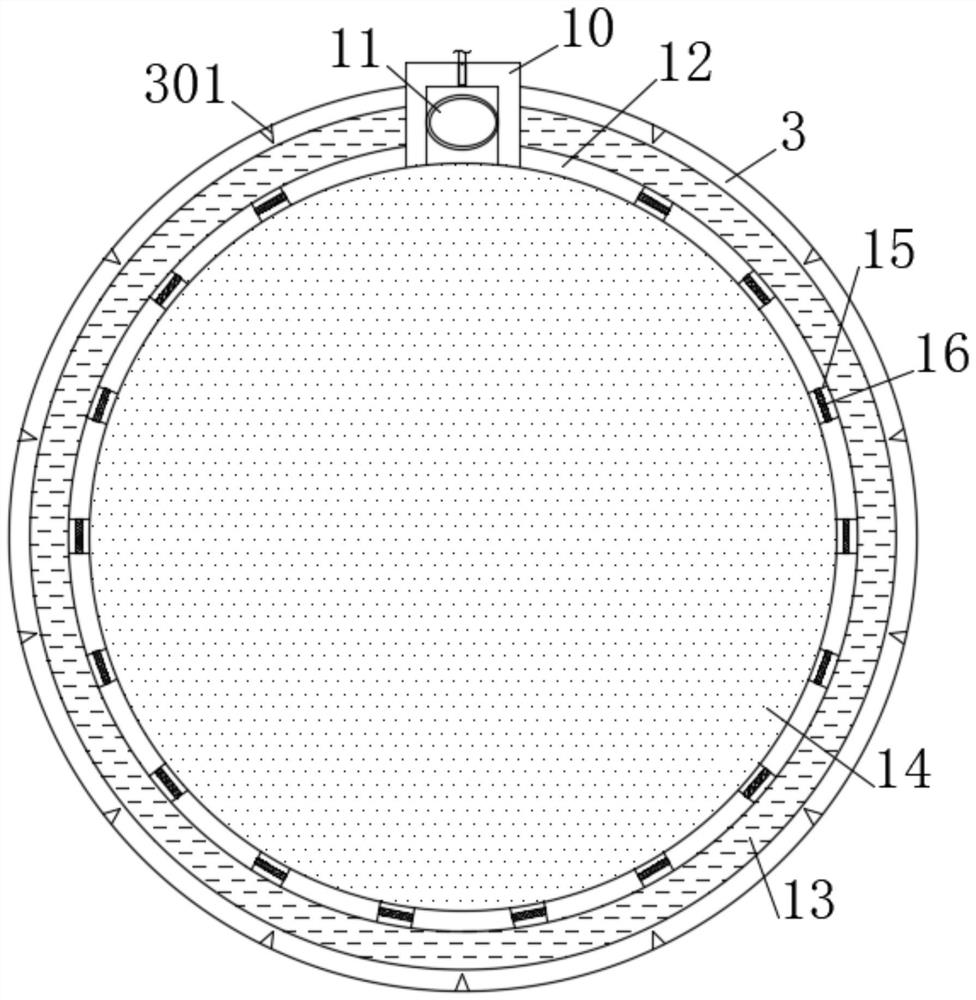

Automatic floating type restoration ball for underwater sludge in small watershed

ActiveCN111718090AEasy to removePromote decompositionWater treatment compoundsBiological treatment apparatusSludgeNitrifying bacteria

The invention discloses an automatic floating type restoration ball for underwater sludge in a small watershed. The invention belongs to the technical field of water body restoration. According to thescheme, sludge throwing balls are thrown into river water; extrusion between a closing air bag and a lemon ball is utilized so that the inner wall of the collecting air bag is exploded when being incontact with juice extruded by the lemon ball, and the release of transmission hoses in the closing air bag is promoted; nitrifying bacteria in a nitrifying bacteria culture solution generate heat through the vital movement of the nitrifying bacteria so that hydrogen peroxide decomposition and oxygen generation can be promoted and the nitrifying bacteria are massively propagated; a lower repair ball bag is dissolved, then a magnet ring can move downwards and pull a dredging plug bag to flow downwards, a reaction ball is pressed into the hydrogen peroxide, most oxygen generated by decompositionof the hydrogen peroxide is discharged into an upper traction ball bag, a small part of oxygen is blown out through a waterproof breathable film to blow away bacterial colonies into sludge and blow away the sludge, and the upper traction ball bag and the inner release bag can be recycled conveniently after the upper traction ball bag floats upwards.

Owner:江苏拓丰环保科技有限公司

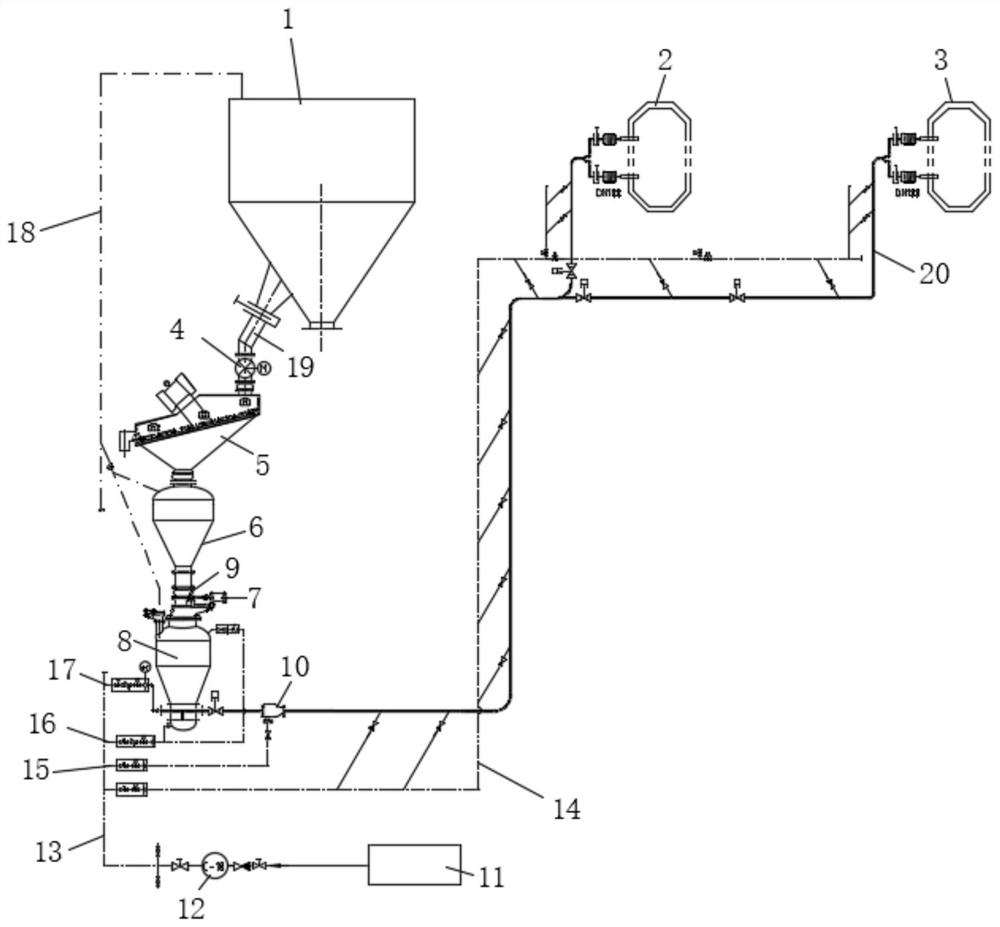

Automatic bed material adding system

PendingCN112747310AReduce washoutFully fluidizedFluidized bed combustionApparatus for fluidised bed combustionProcess engineeringAir compressor

The invention belongs to the technical field of circulating fluidized bed boilers, and particularly relates to an automatic bed material adding system. The automatic bed material adding system comprises a slag bin, a first boiler, a second boiler, a variable-frequency electric feeder, a vibrating screen, a surge bin, a sending device and a conveying pipeline, a discharging pipe is fixed to the bottom of the slag bin, the variable-frequency electric feeder is mounted at the bottom of the discharging pipe, vibrating screen is connected to the bottom of the variable-frequency electric feeder, the surge bin is assembled at bottom of the vibrating screen, the sending device is arranged below the surge bin, a gas inlet pipe is connected to one end of a gas pipeline, a gas storage tank is mounted at the lower end of the gas inlet pipe in a matched mode, an air compressor is connected to one end of the gas storage tank, a gas inlet pipe is connected to the end, away from the air compressor, of the gas storage tank, a first air supplementing pipe is connected between the gas inlet pipe and an ash-air mixer, and a second air supplementing pipe is connected to the gas inlet pipe and the lower end of the conveying pipeline. The pressure difference can be met to the maximum extent, it is ensured that materials enter the pipeline after being fully fluidized, instantaneous pressure relief cannot be formed, and the fluidization effect cannot be reduced.

Owner:JIANGSU JIUSHENG ENVIRONMENTAL PROTECTION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com