Polytetrafluoroethylene dental floss

A technology of polytetrafluoroethylene and dental floss, which is applied in the fields of dental floss, dentistry, and tooth cleaning. It can solve the problems of slow elastic effect of dental floss, small cleaning surface, and insufficient strength of dental floss, and achieve rapid elastic effect and clean surface. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

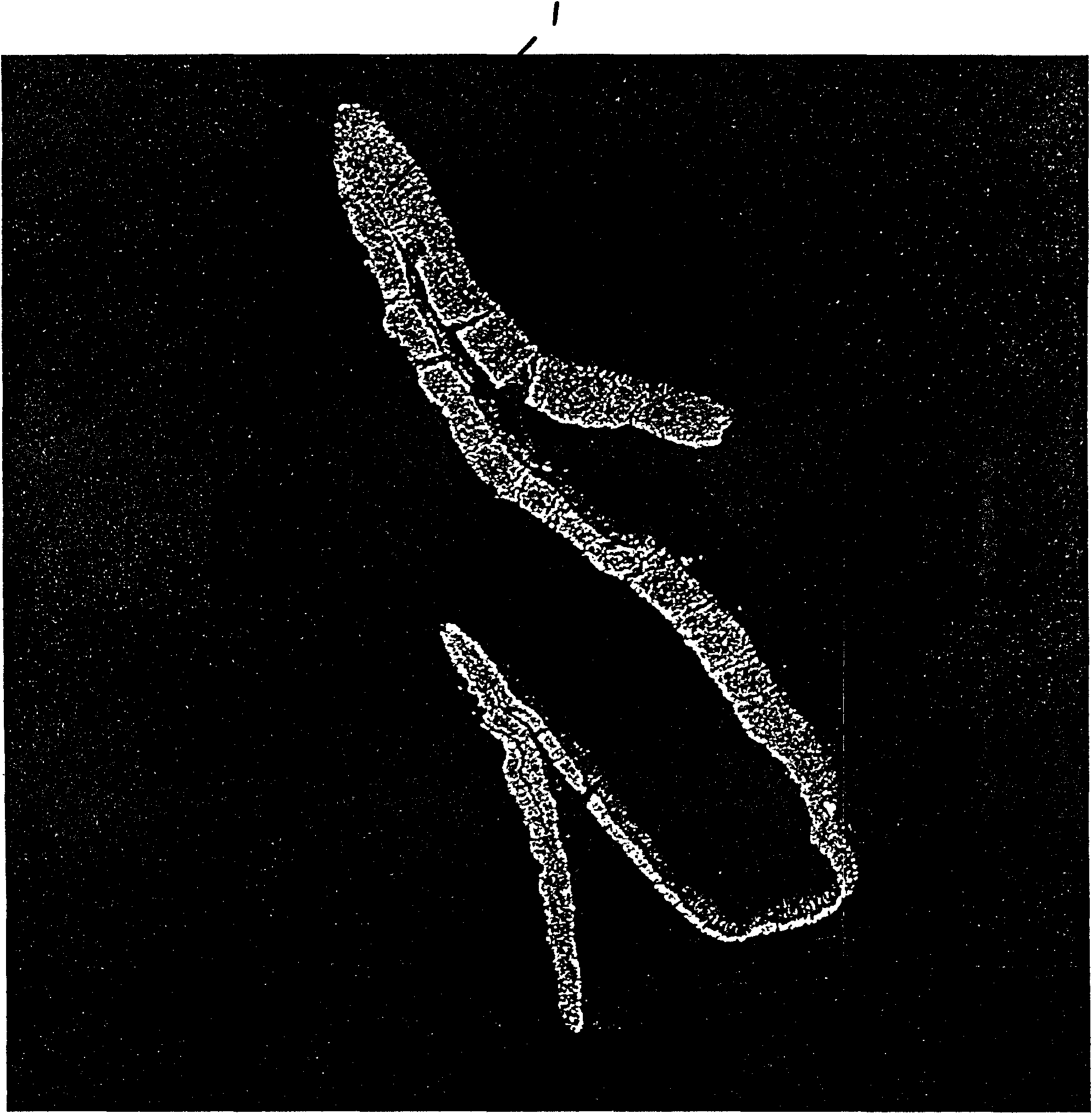

[0016] A polytetrafluoroethylene dental floss of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] see figure 1 , a polytetrafluoroethylene dental floss of the invention comprises a thread body 1, the thread body 1 is a microporous polytetrafluoroethylene film cut by a film splitting blade and then formed by a "V" shaped groove The forming die is rolled up and stretched to form a "ひ" shaped wire body in cross section, which is cut by a microporous polytetrafluoroethylene film through a film splitting blade and then formed by a "V" shaped groove. The width of the wire body formed in the shape of "ひ" is 2.0-2.2 mm in cross-section after being rolled up and stretched by the forming die. The thickness of the wire body formed in the shape of "ひ" in the cross section after being rolled up and stretched by the forming die with "V" shape groove is 50-65 μm. The polytetrafluoroethylene film with micropores is passed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com