A kind of oil-gas-water horizontal three-phase separator and oil-gas-water separation method

A technology for three-phase separator and oil-water separation, which is applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problem that the oil phase contains large-diameter water droplets, etc., so as to facilitate oil-water separation, promote oil-water separation, and improve The effect of the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

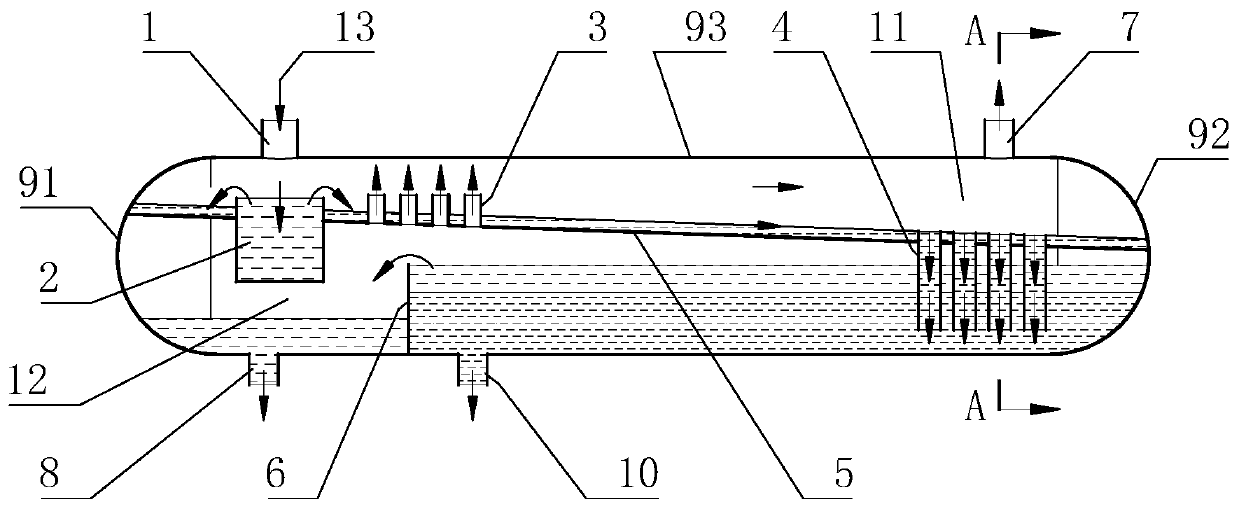

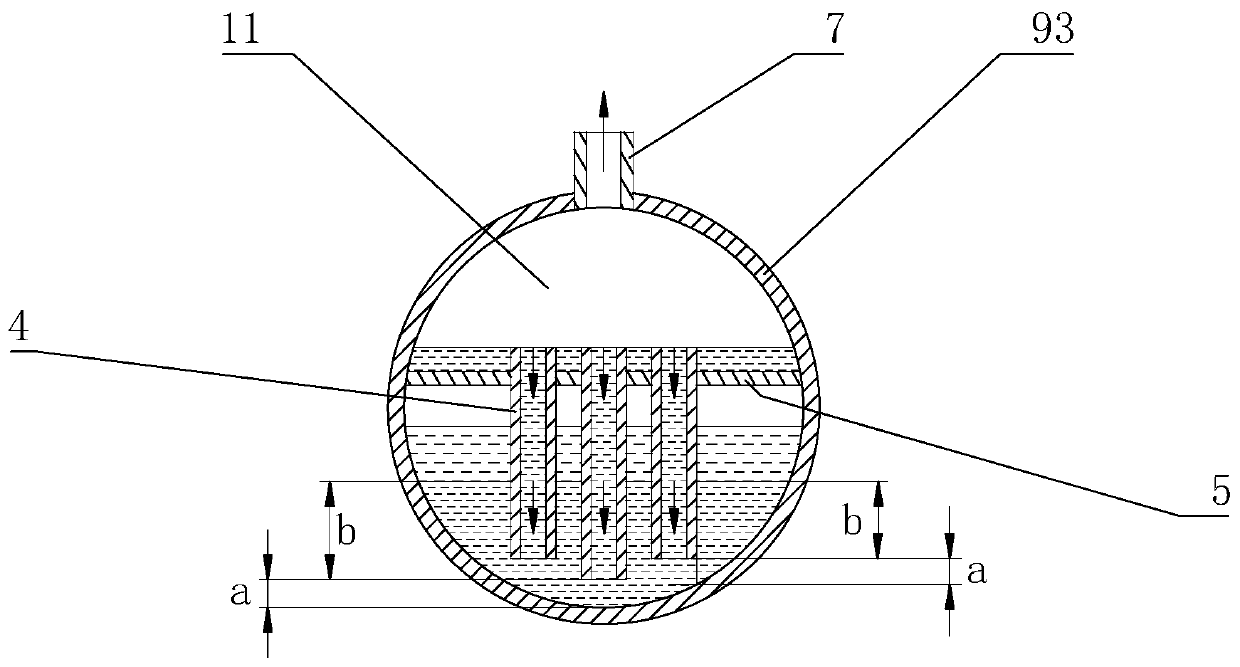

[0012] see figure 1 and figure 2 , the oil-gas-water horizontal three-phase separator (abbreviated as separator) of the present invention is provided with a horizontal tank body, the horizontal tank body includes a cylindrical body 93 and a first sealing head 91 and a second sealing head 92, two The heads are generally hemispherical. The bottom of the inner cavity of the cylindrical body 93 is vertically provided with an overflow plate 6, and the top of the cylindrical body 93 is provided with an inlet pipe 1 near the first head 91 and an outlet pipe 7 near the second head 92. The bottom of the cylindrical body 93 is provided with an oil outlet pipe 8 between the overflow plate 6 and the first head 91, and an outlet pipe 10 is provided between the overflow plate 6 and the second end head 92. The outlet pipe 10 is usually Close to overflow plate 6. The various pipes mentioned in the present invention generally have a circular cross-sectional shape.

[0013] The inner cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com