Lubricating structure of drive axle differential mechanism and drive axle differential mechanism assembly

A lubricating structure and differential technology, applied in the direction of differential transmission, gear lubrication/cooling, transmission, etc., can solve the problem of reducing the service life of the differential assembly and drive axle, internal heat cannot be discharged, and parts are abnormal Wear and other problems, to achieve the effect of lowering temperature, improving life and reducing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

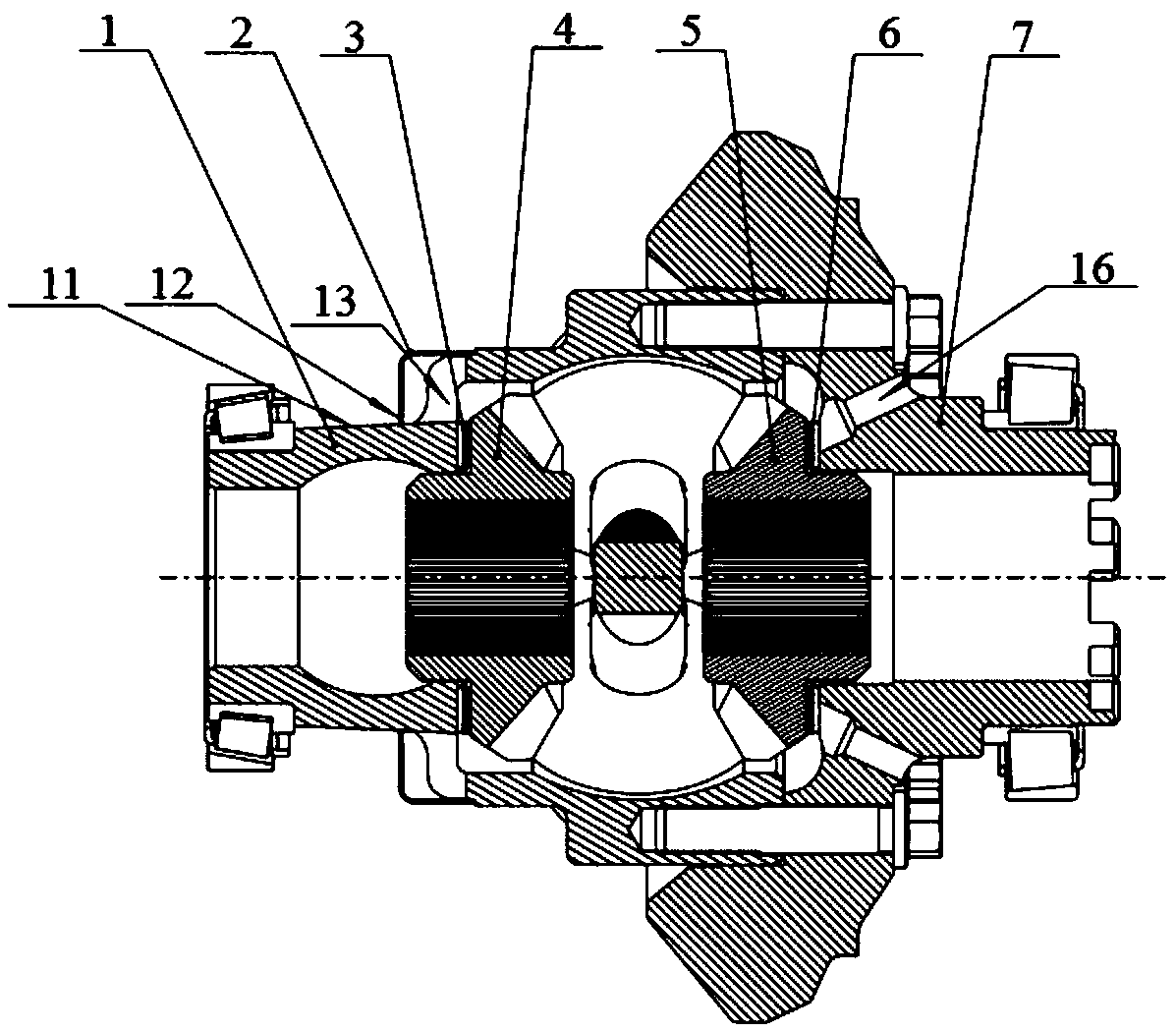

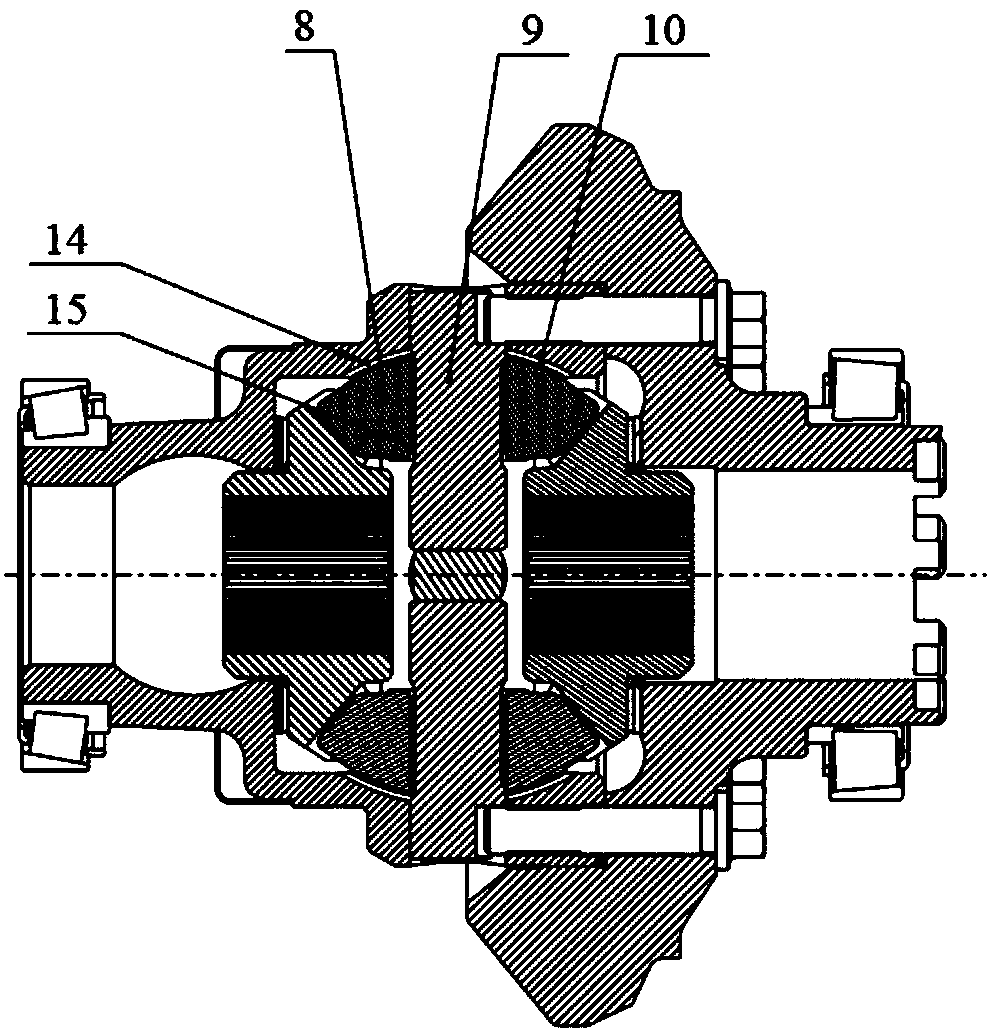

[0045] Such as figure 1 , 2 As shown, the transaxle differential adopting the new lubrication method in this embodiment includes a tooth side differential case 1, an oil deflector cover 2, a left side gear spacer 3, a left side gear 4, and a right side gear 5 , Right side shaft gear spacer 6, tooth back side differential case 7, planetary wheel 8, cross shaft 9, planetary wheel spacer 10. Its features and functions are as follows:

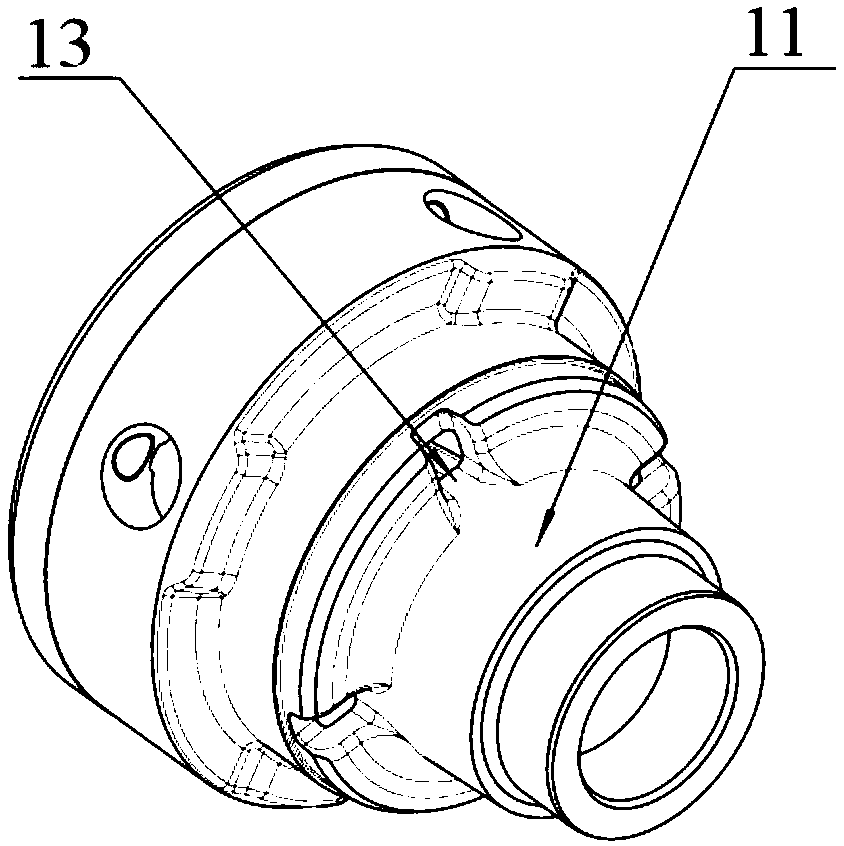

[0046] The outer cone surface 11 of the gear side differential case 1 is a rotary conical surface with a certain draft angle. The oil adhering to the conical surface enters the differential cavity through the oil inlet 12 of the oil retaining cover and the oil inlet 13 of the differential housing on the tooth side under the action of centrifugal force. There is a certain gap between the oil retaining cover 2 assembled on the tooth surface side differential case 1 and the conical surface of the differential case to form the oil retaining cover oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com