Wind-cooling heat dissipating method of CT device and the apparatus thereof

A technology of heat dissipation device and heat dissipation method, which is applied to the cooling of instruments, radiation safety devices, and parts of instruments, etc., and can solve problems such as noise pollution, noise increase, and negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

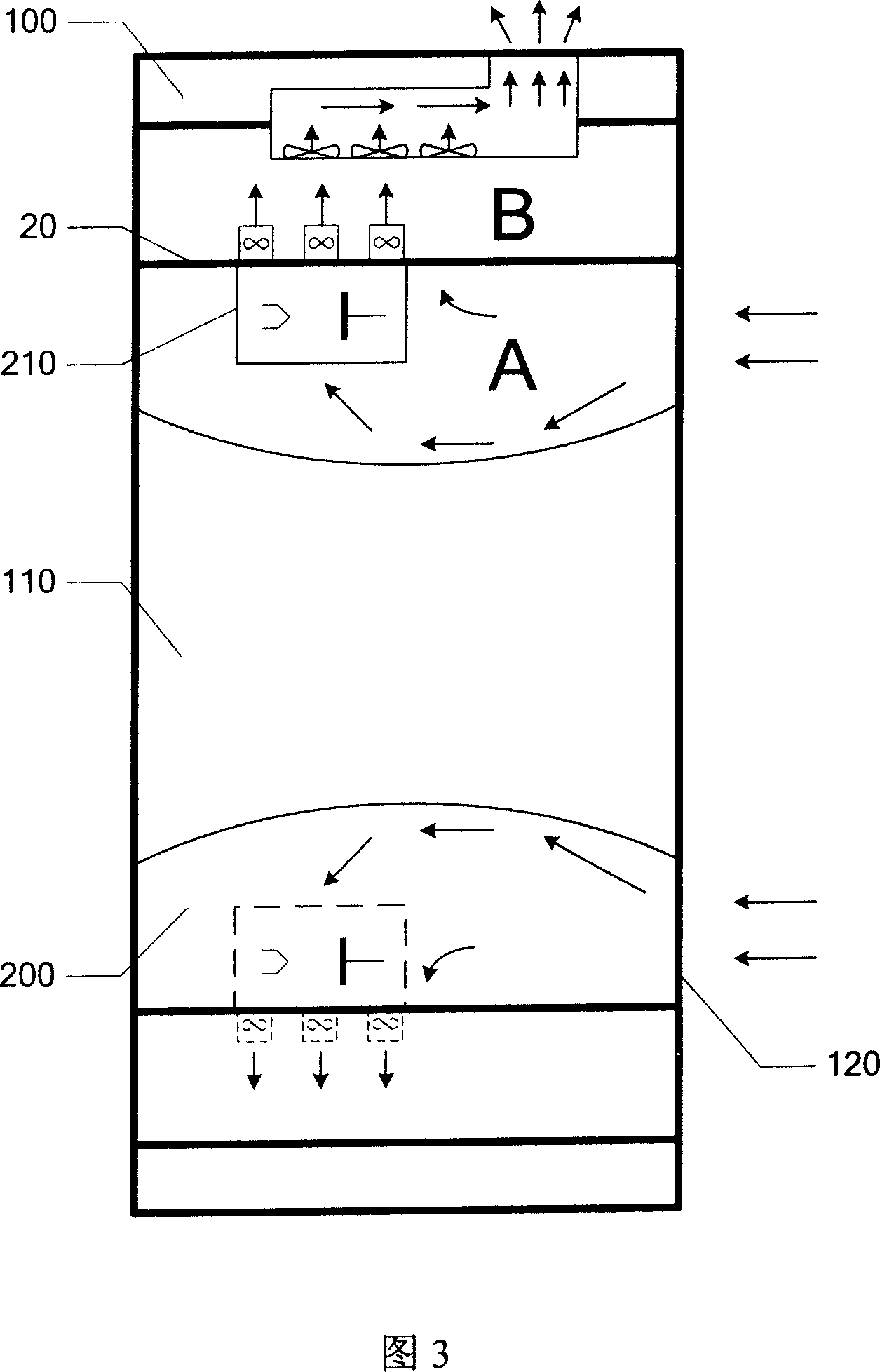

[0022] The air-cooled heat dissipation method and device of the present invention are described by taking the application on CT equipment as an example, but its application is not limited to this, and other medical imaging equipment that needs heat dissipation, such as nuclear magnetic resonance equipment, etc., can also be applied All or part of the design points of the present invention are used to realize the purpose of heat dissipation and noise reduction.

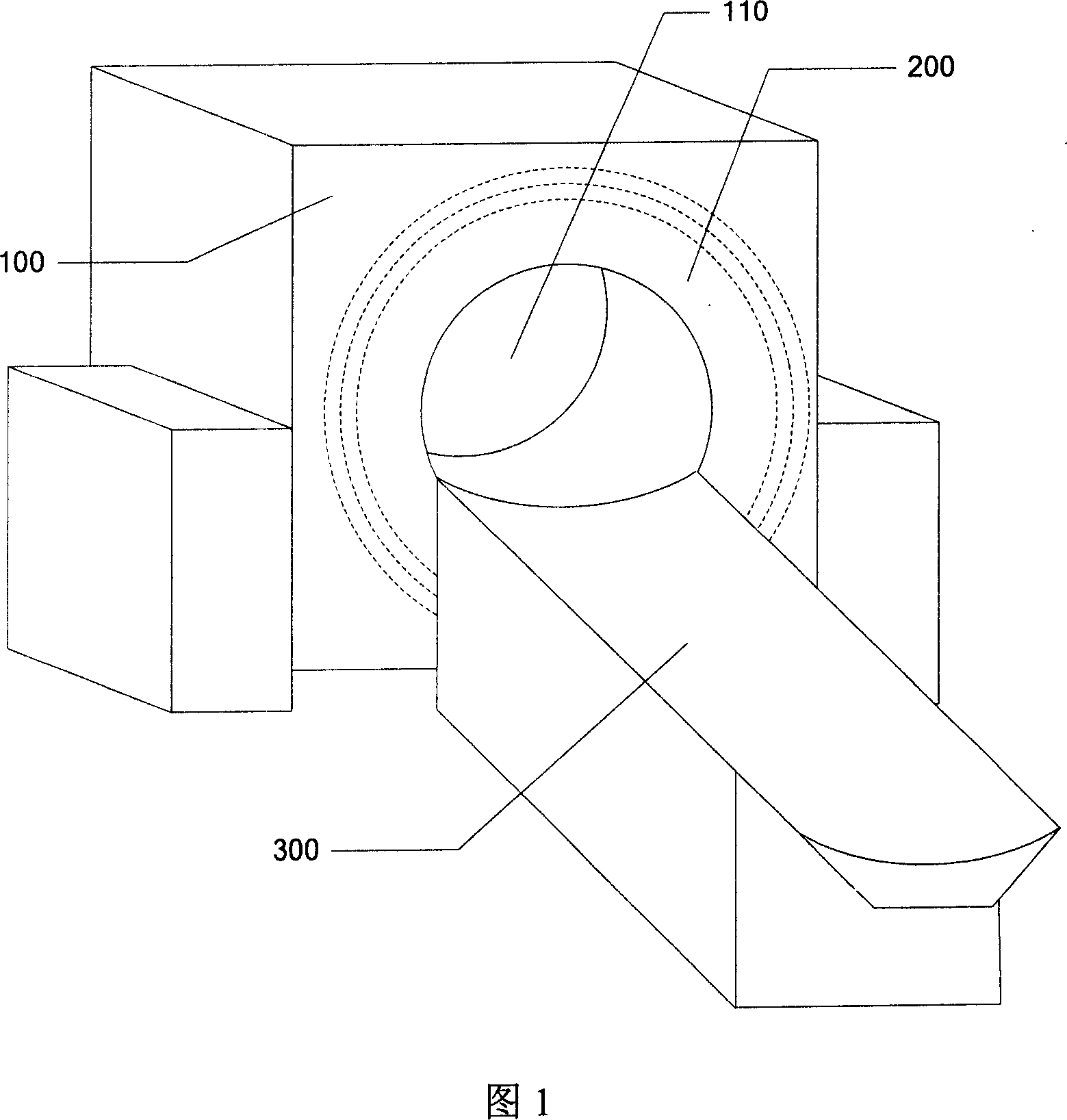

[0023] Referring to Fig. 3, a typical CT equipment includes a frame 100, and a turntable 200 rotating in the frame 100 for scanning inspection, wherein a frame hole 110 is set in the frame 100, and the turntable 200 surrounds the frame The hole 110 is rotated. The patient lies on a hospital bed arranged in front of the frame 100 and enters the hole 110 of the frame to be scanned.

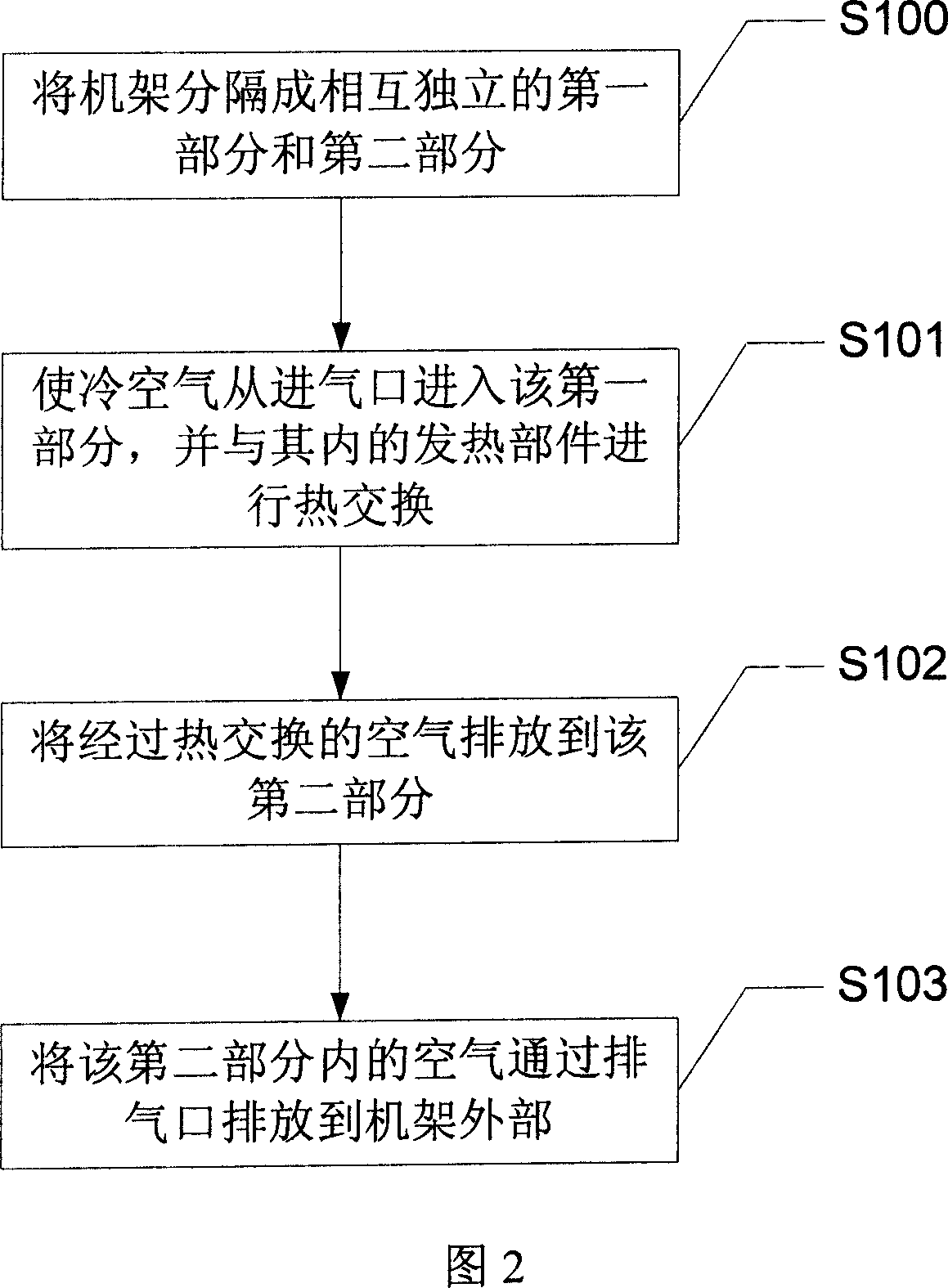

[0024] The air-cooled heat dissipation method and device of the CT equipment of the present invention will be described in detail below in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com