Spiral flue gas desulphurization apparatus

A desulfurization equipment and spiral technology, applied in the field of spiral flue gas desulfurization equipment, can solve the problems of secondary pollution of ammonia water and incomplete desulfurization by blending method, achieve complete desulfurization, prevent poisoning of active substances, and increase concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

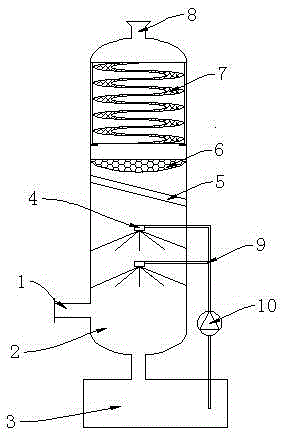

[0016] Such as figure 1 As shown, the spiral flue gas desulfurization equipment of the present invention includes an air inlet pipe 1 and a desulfurization tank 2, the air inlet pipe 1 is located at the bottom of the desulfurization tank 2, and an ammonia water atomizing nozzle 4 is arranged in the middle of the desulfurization tank 2, and the desulfurization The top of the tank 2 is provided with a flue gas discharge port 8, and the demisting device (5, 6) and the spiral air guide vane 7 are also provided in the desulfurization tank 2, and the demisting device (5, 6) is located above the ammonia atomization nozzle 4 , The spiral air guide vane 7 is located above the demisting device (5, 6), and the spiral air guide vane 7 is sprayed with at least one element of praseodymium, lanthanum, cerium, nickel, zinc, titanium or a compound thereof. The spiral air guide vane 7 loaded with at least one element of praseodymium, lanthanum, cerium, nickel, zinc, titanium or their compounds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com