Construction waste reinforced embankment under sandy soil

A construction waste and embankment technology, which is applied in construction, embankment, sea area engineering, etc., can solve the problems of water seepage, low garbage utilization rate, high porosity, etc., to improve the anti-seepage performance and strength, improve utilization rate, and improve use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

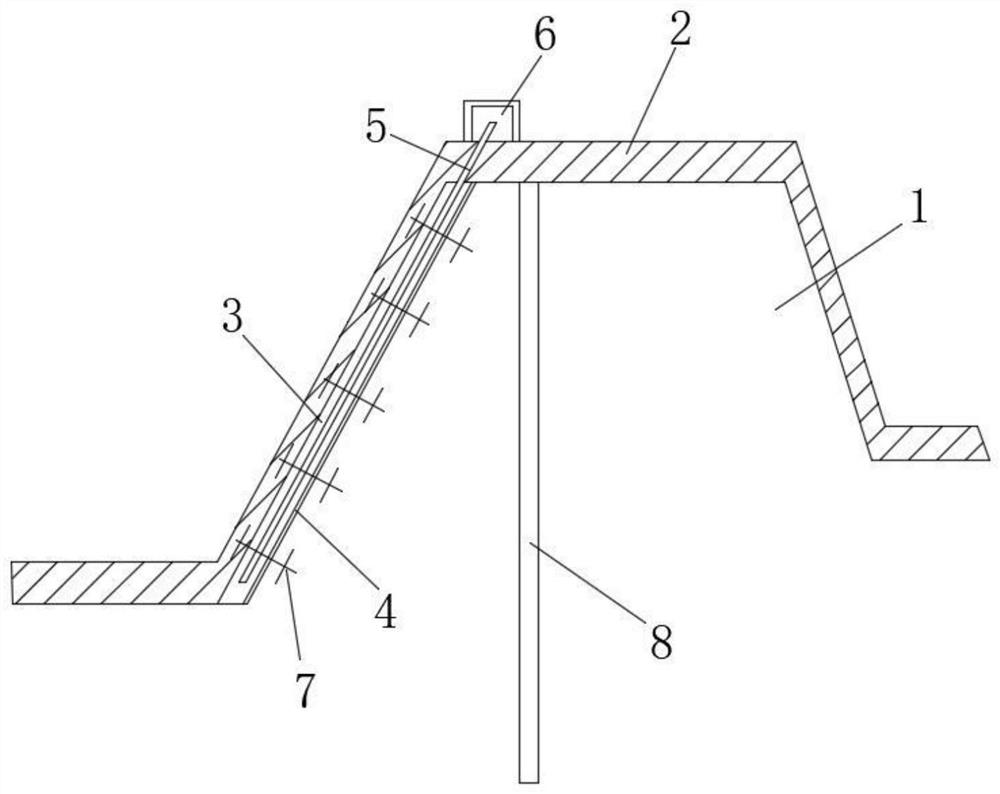

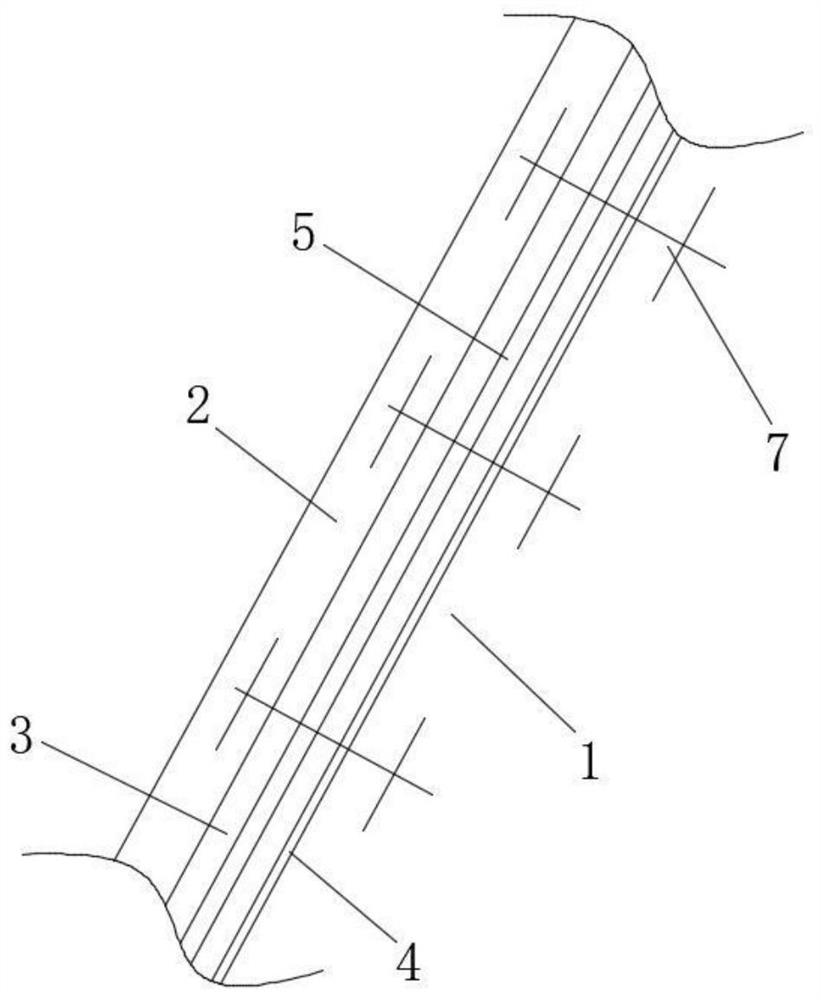

[0053] like figure 1 with 2 As shown, the construction waste in the shequo, including the river embankment, including the river embeid of the sand, and the cement concrete layer 2 poured onto its surface, in the cement concrete layer 2 welcomes surface and There is a modified waterproof layer 3 between the river embankment, the modified waterproof layer 3 is a fine particle construction waste and a particle size of 15-30 mm from a fine particle construction waste and a particle diameter of 10 mm. Particle construction garbage is compared to the mass of 1.5: 1: 3.5: 2.5: 1.5.

[0054] In the present embodiment, the thickness of the modified waterproof layer 3 is generally 20-50 cm, which is freely selected according to the actual situation.

[0055] The above is the basic embodiment of the present invention, and further improvement, optimization, and defined on the above basis, thereby obtaining the following examples:

Embodiment 2

[0057] This embodiment is an improvement scheme according to the first embodiment, and the main structure is the same as in Example 1, and the improvement point is: figure 1 with 2 As shown, the modified waterproof layer 3 is disposed between the river embankment 4, and the geotextile 4 generally uses at least two layers, preferably waterproof material.

Embodiment 3

[0059] In this example, another improvement scheme is made based on the first embodiment, and its main structure is the same as in Example 1, and the improvement point is: figure 1 with 2 As shown, the modified waterproof layer 3 is distributed along the river bank extension, and the top of the seepage column 5 extends to the concrete sealing box 6 provided in the top of the river bank, filled in the concrete seal 6 Cement and moisture loess are mixed with a mixture of 4: 1.

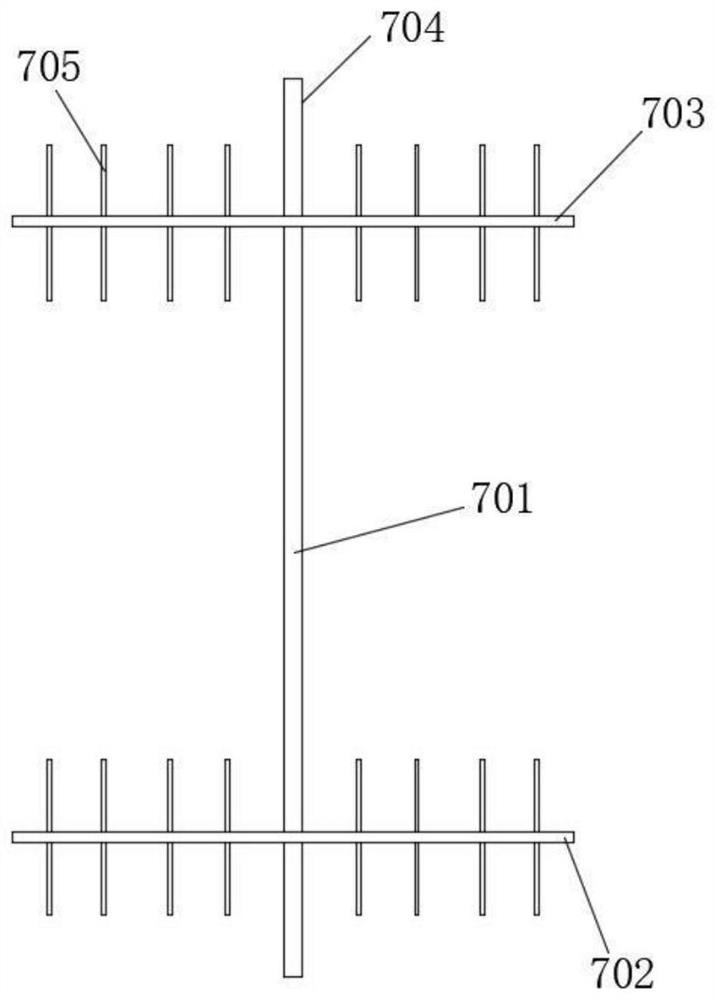

[0060] The construction method of the seepage column 5 is:

[0061] 1) Select the PC tube having a diameter of 2 mm through the surface of the surface, and the PC tube is placed in advance when the construction expansion soil modified waterproof layer 3 is used, and the top of the PC tube is protected from the top surface of the river embankment. And when the cement concrete layer is poured, the top of the PC is exposed to the top of the river embankment;

[0062] 2) Inject the mortar into the PC tube, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com