Patents

Literature

61results about How to "Ensure thorough cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

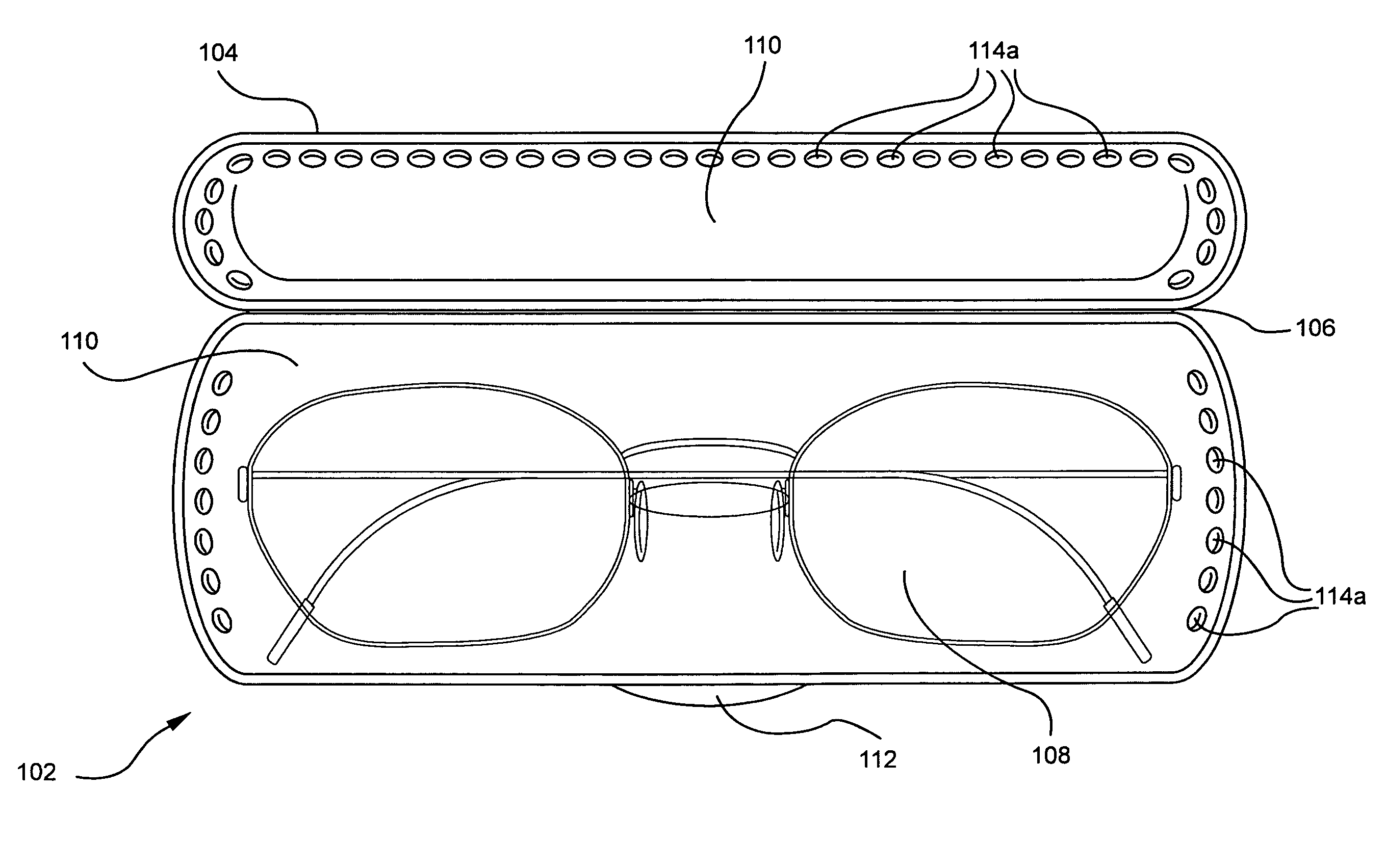

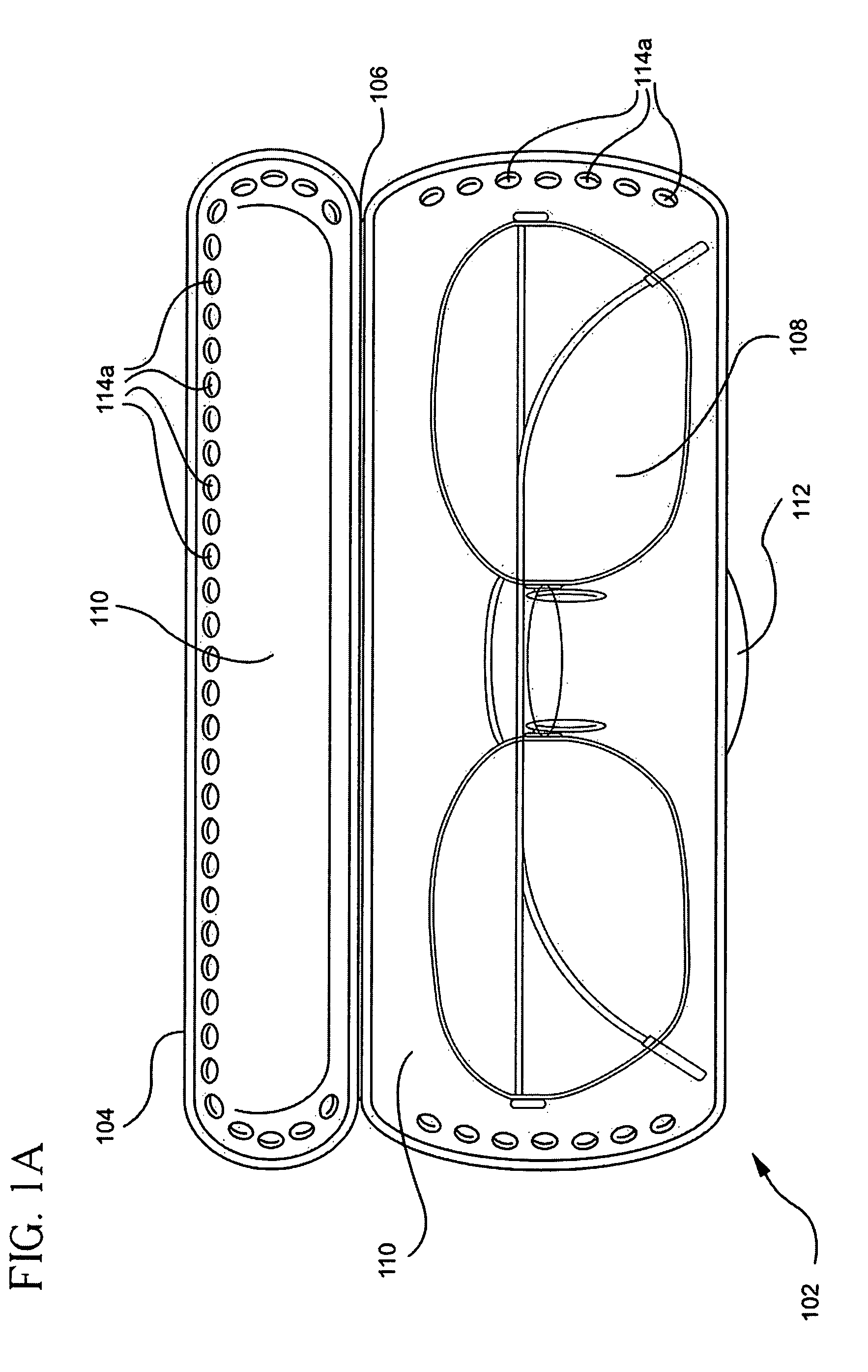

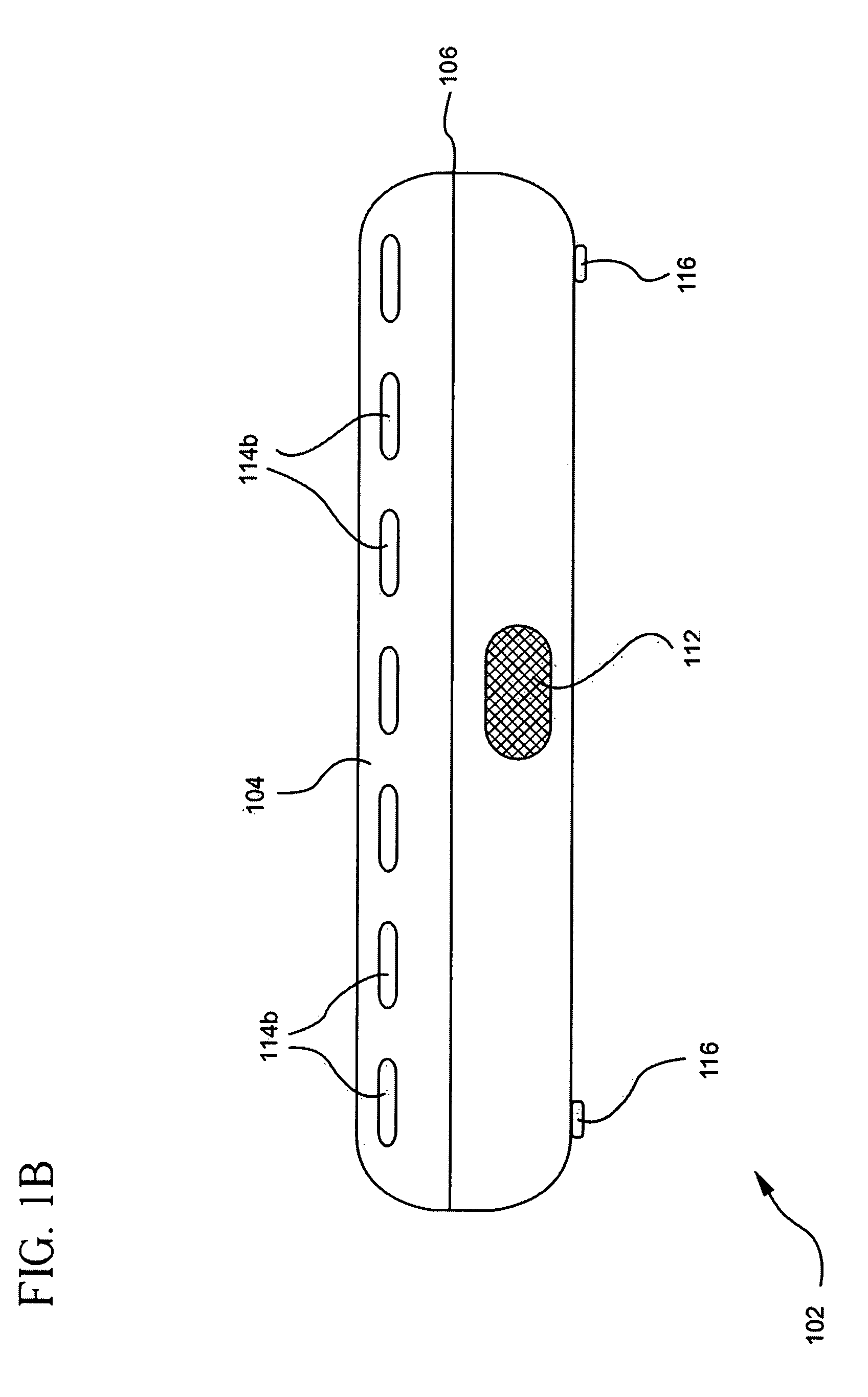

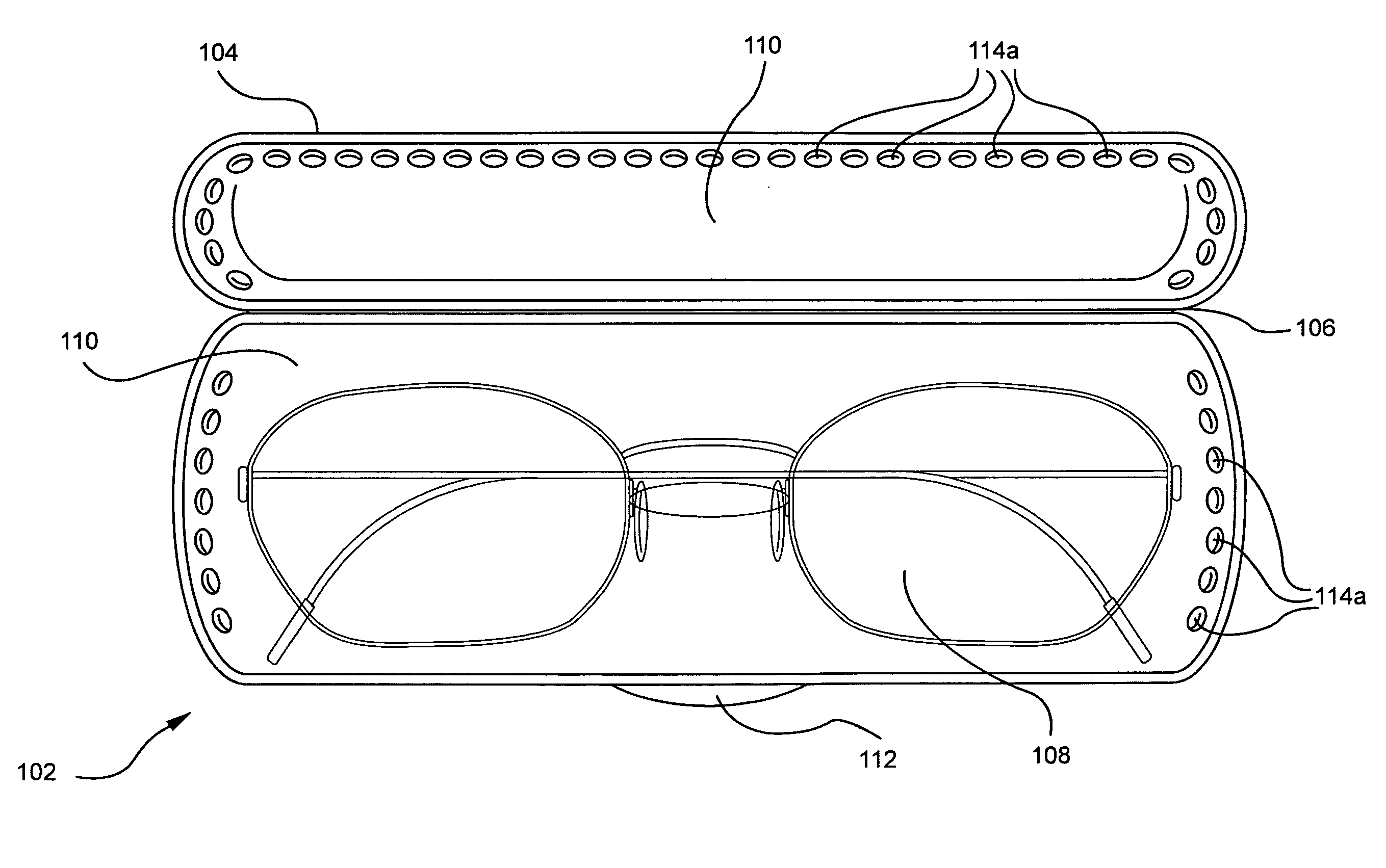

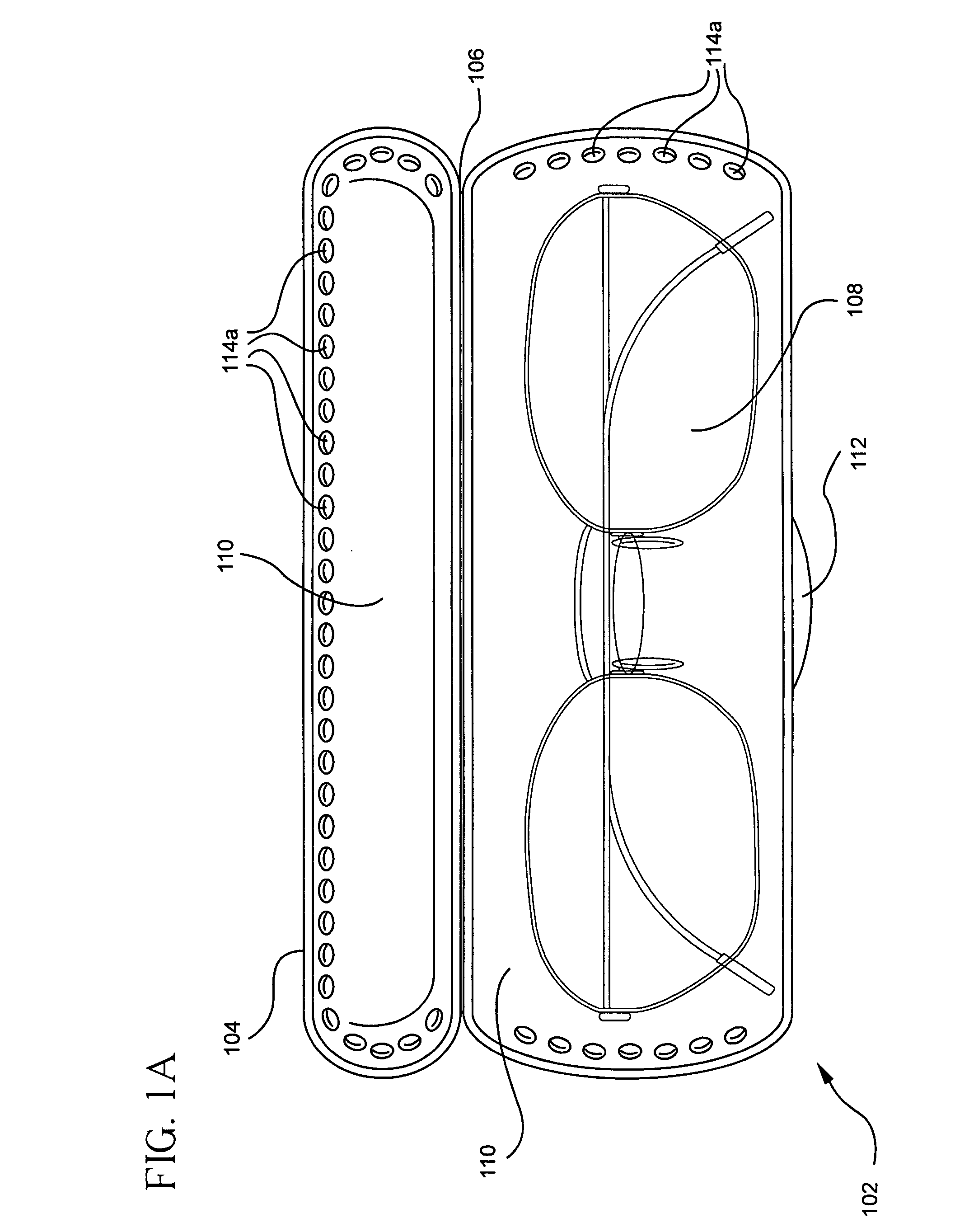

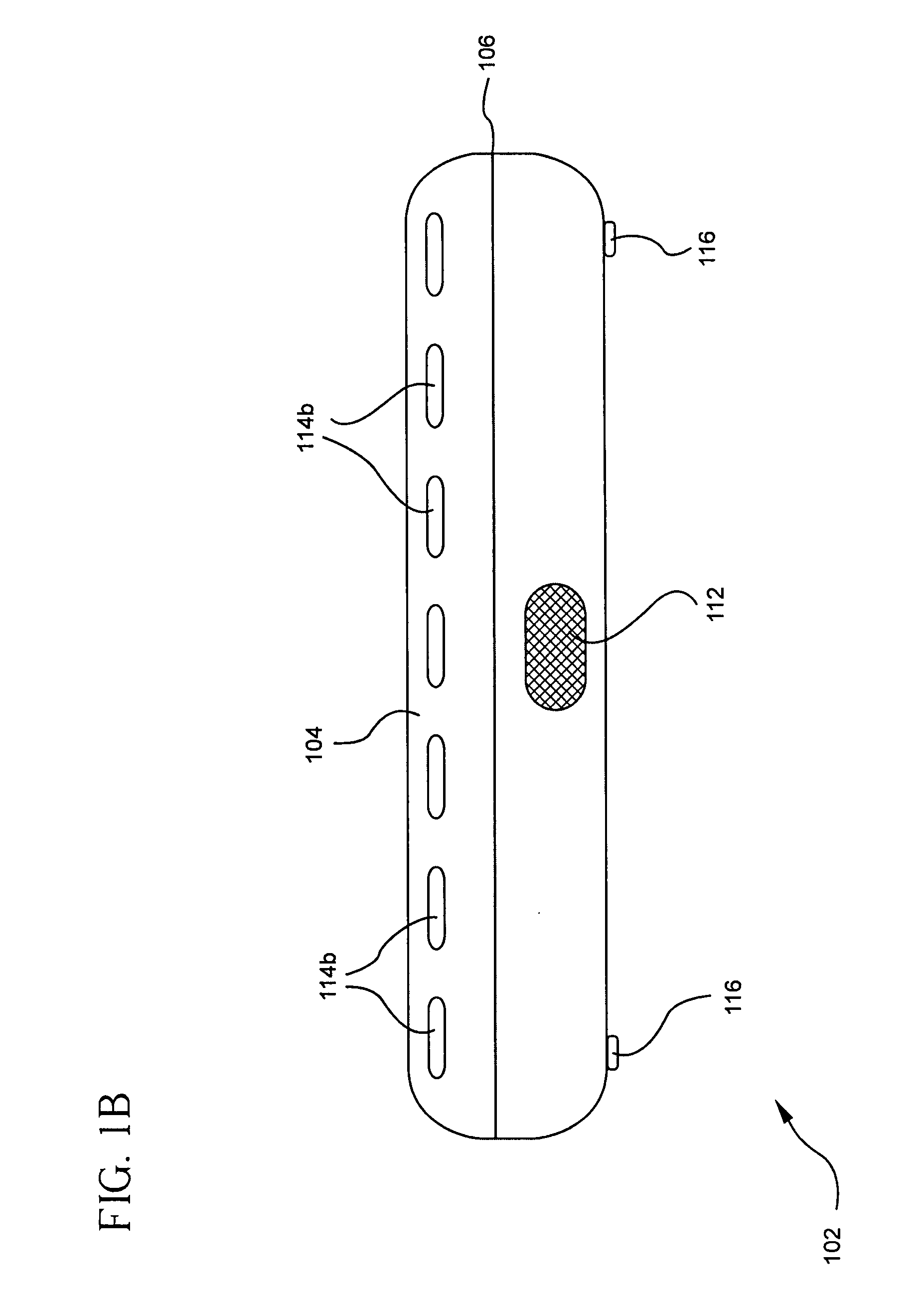

Eyeglasses case

ActiveUS7775675B2Precise positioningReliable lockingElectric circuit arrangementsLighting elementsMotion detectorEyewear

A container having a compartment for retaining personal objects such as eyeglasses comprises a transducer which activates the container in response to a specified user action in proximity to the container. In some embodiments, the transducer is a motion detector and is activated in response to user motion. In other embodiments, the transducer comprises a speech recognition module and is activated in response to the user's voicing a specified utterance. Some embodiments become illuminated upon activation. Some embodiments produce a sound upon activation, enabling the user to locate the container. Some embodiments have a normally closed lid which opens upon activation. Some lidded embodiments are normally locked and become unlocked upon activation. Some embodiments of the container further normally provide low level lighting, thereby enabling the container to serve as a night light. Some embodiments further provide for an individual clean tissue prior to each time an object is placed in the case, to assure cleanliness of the container for each use when it is used by multiple users in a location accessible to the public, such as places of business serving the public where removing eyeglasses is common.

Owner:S & D INNOVATIONS

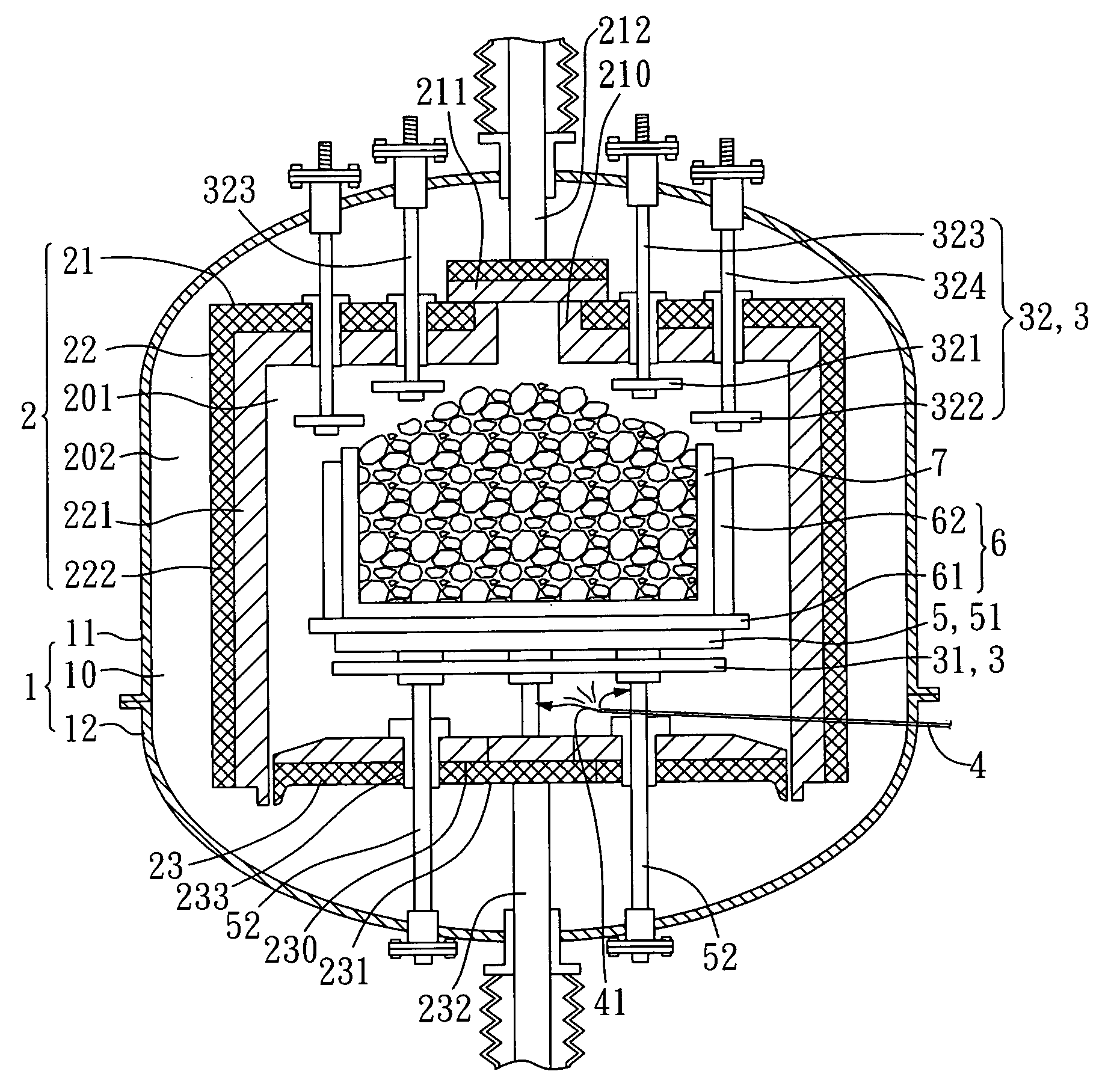

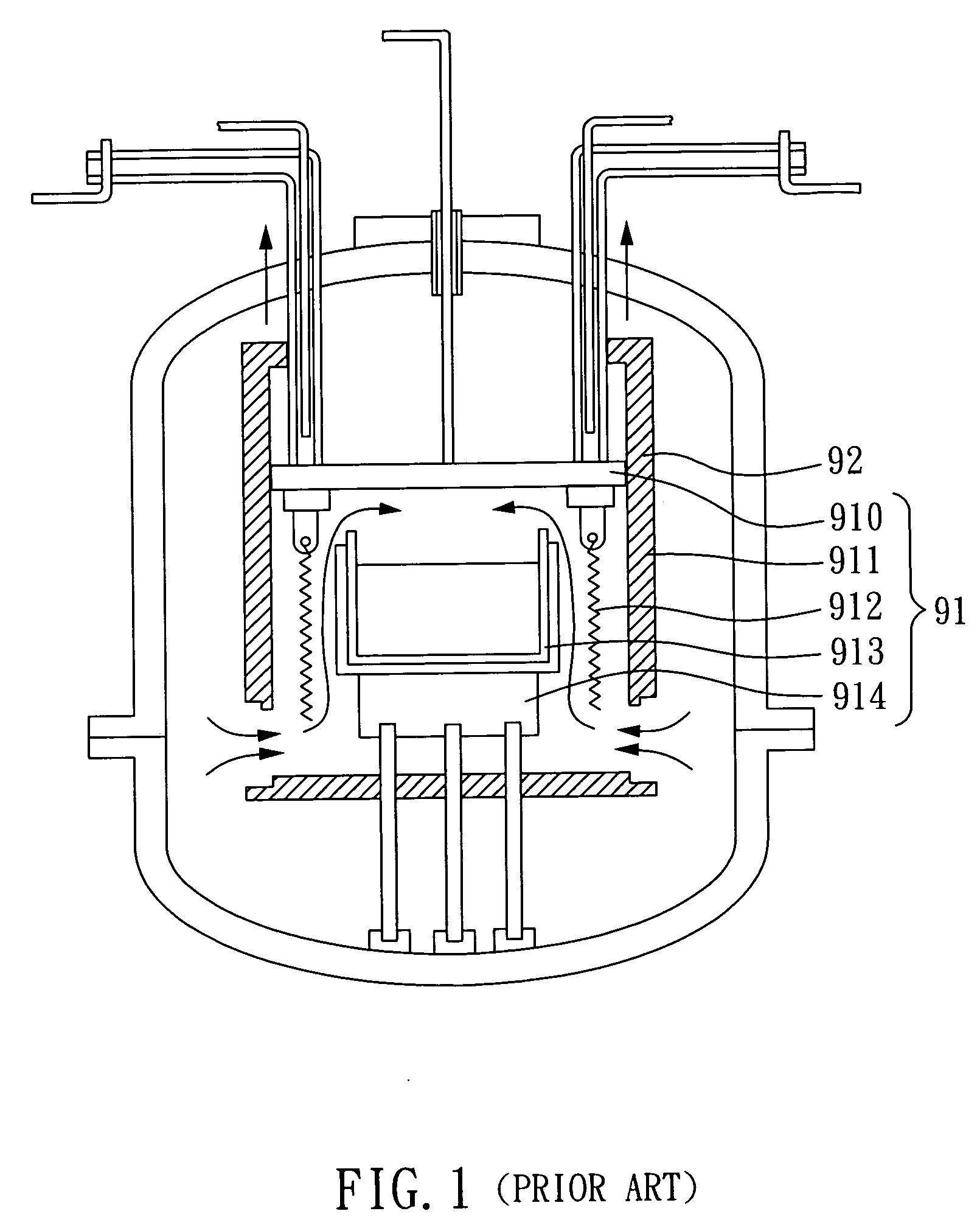

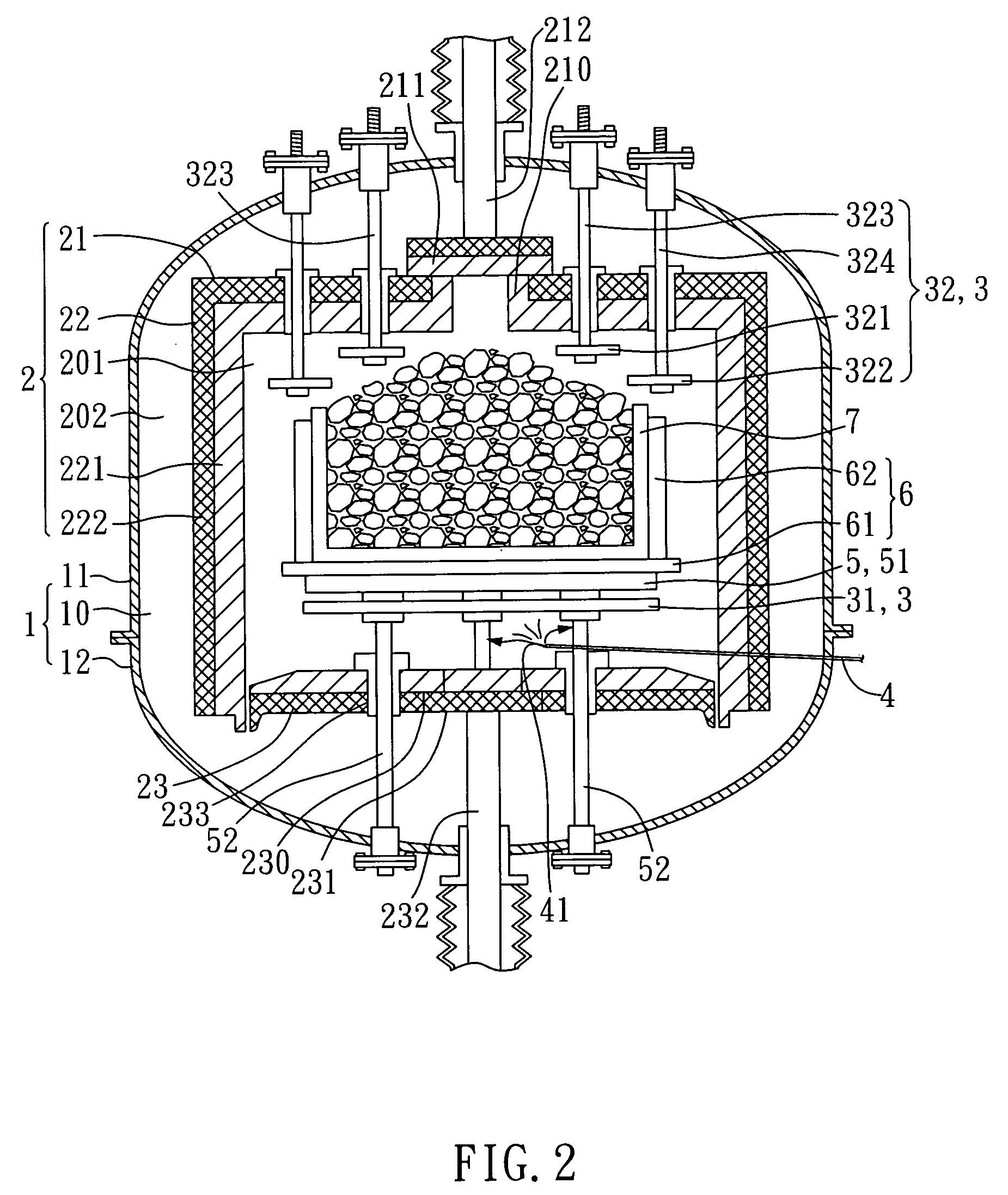

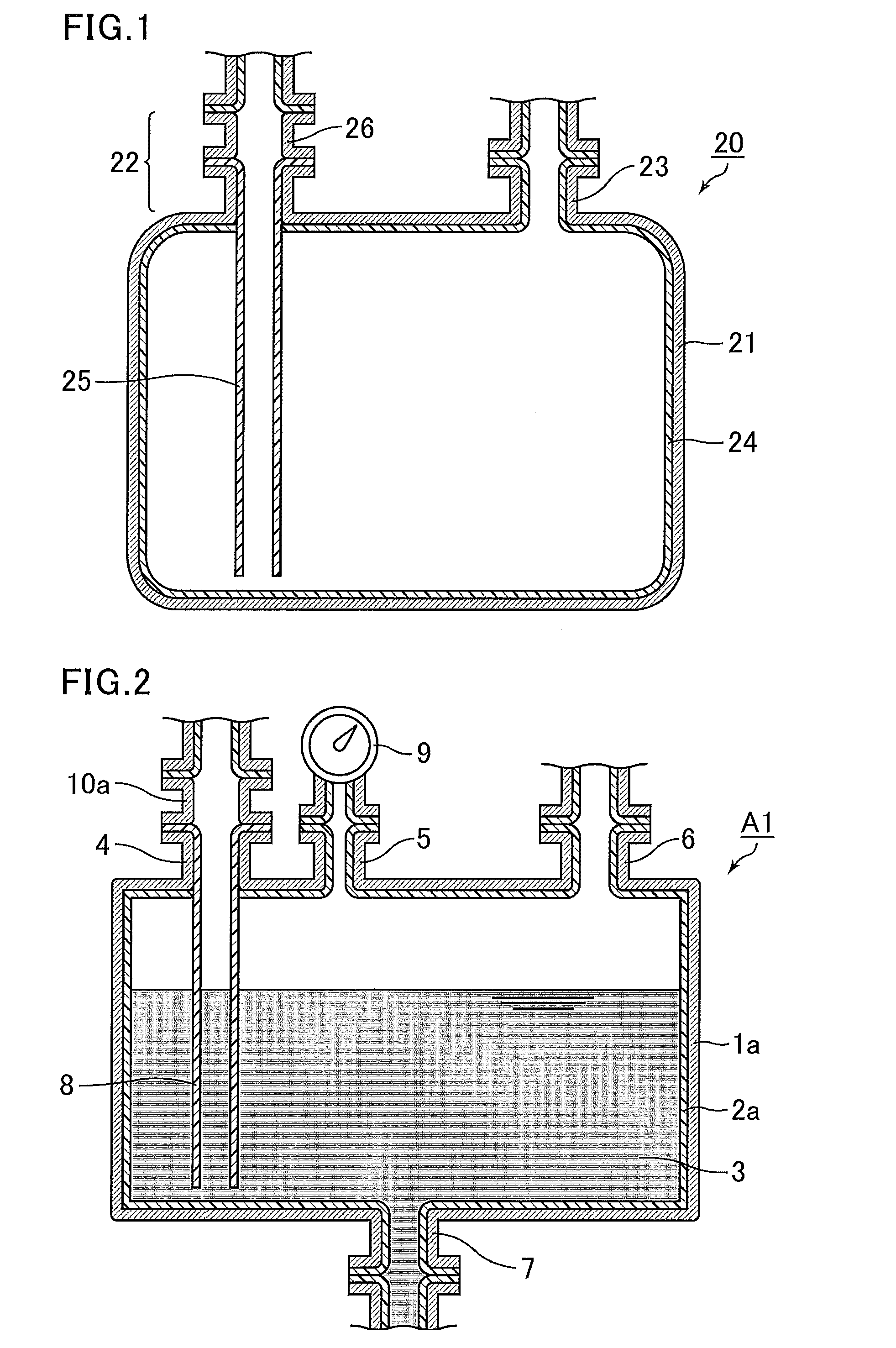

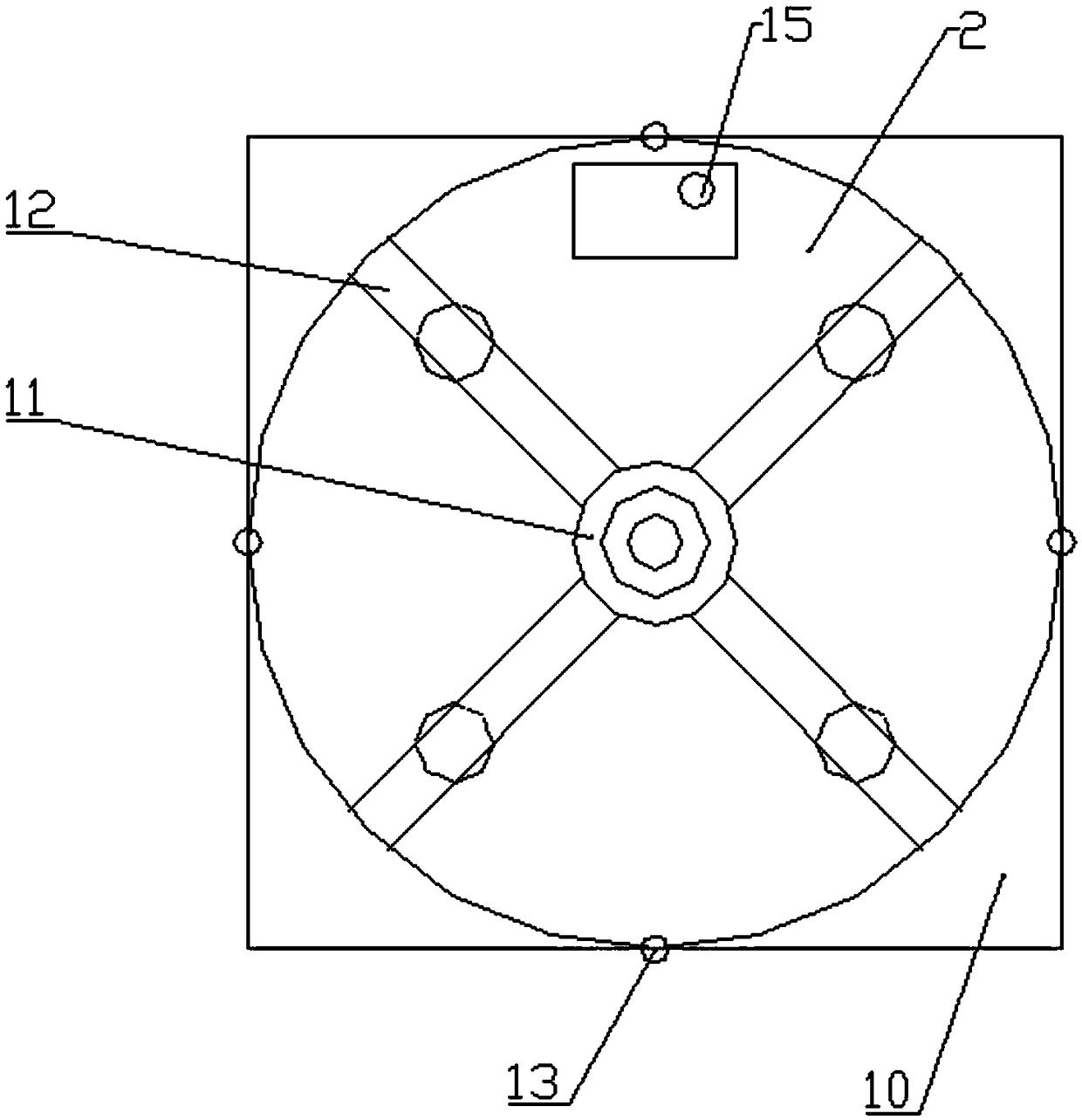

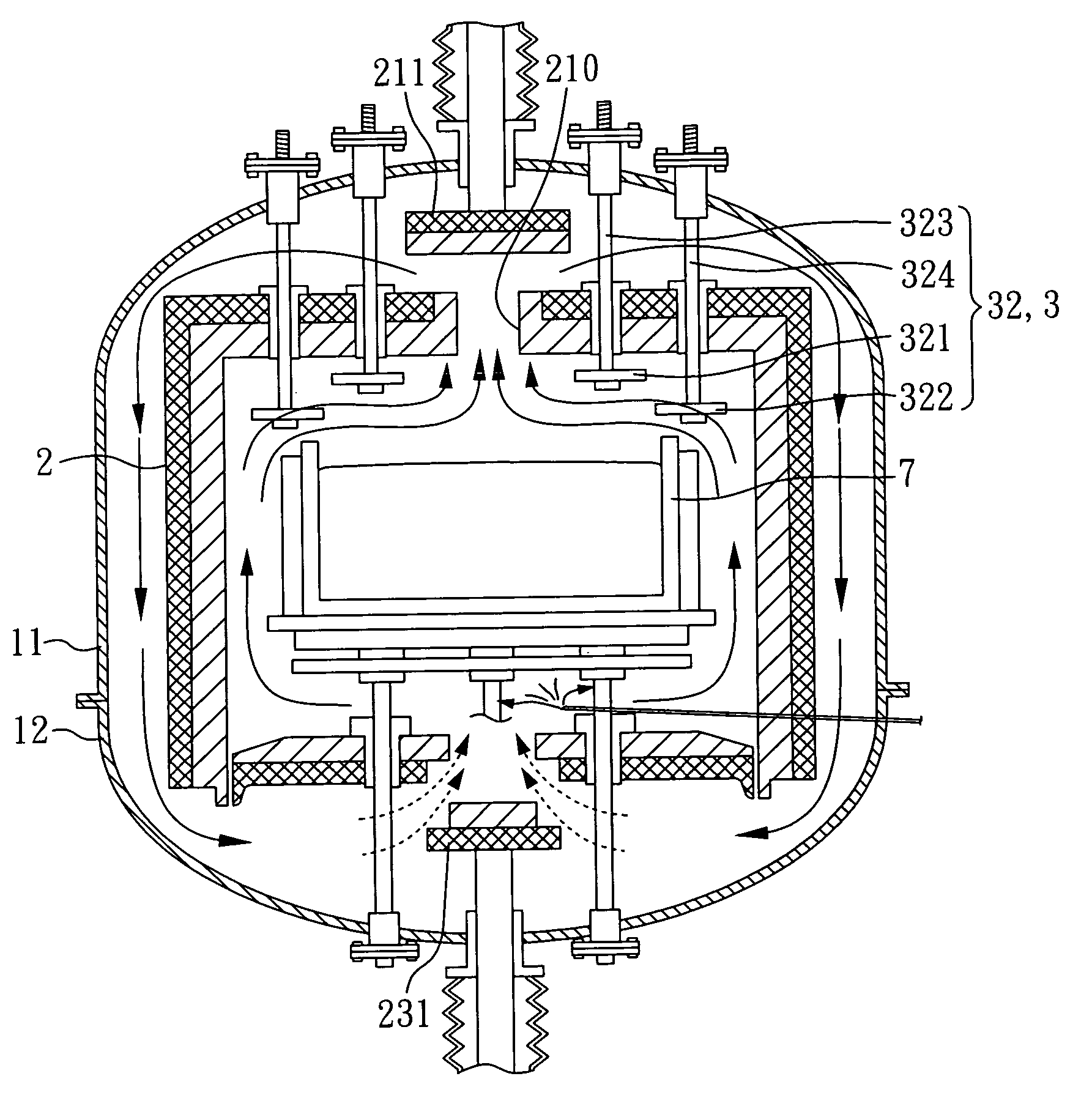

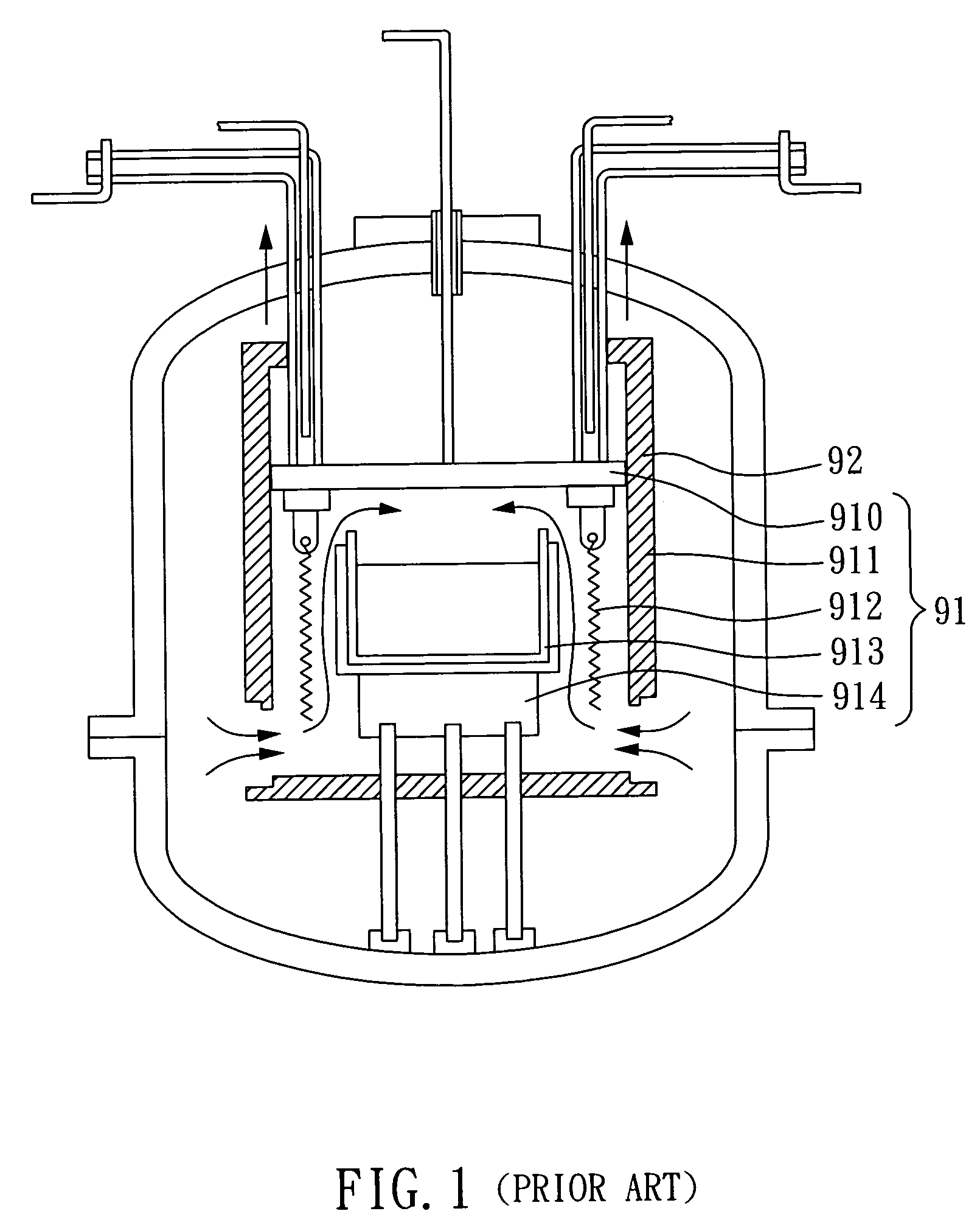

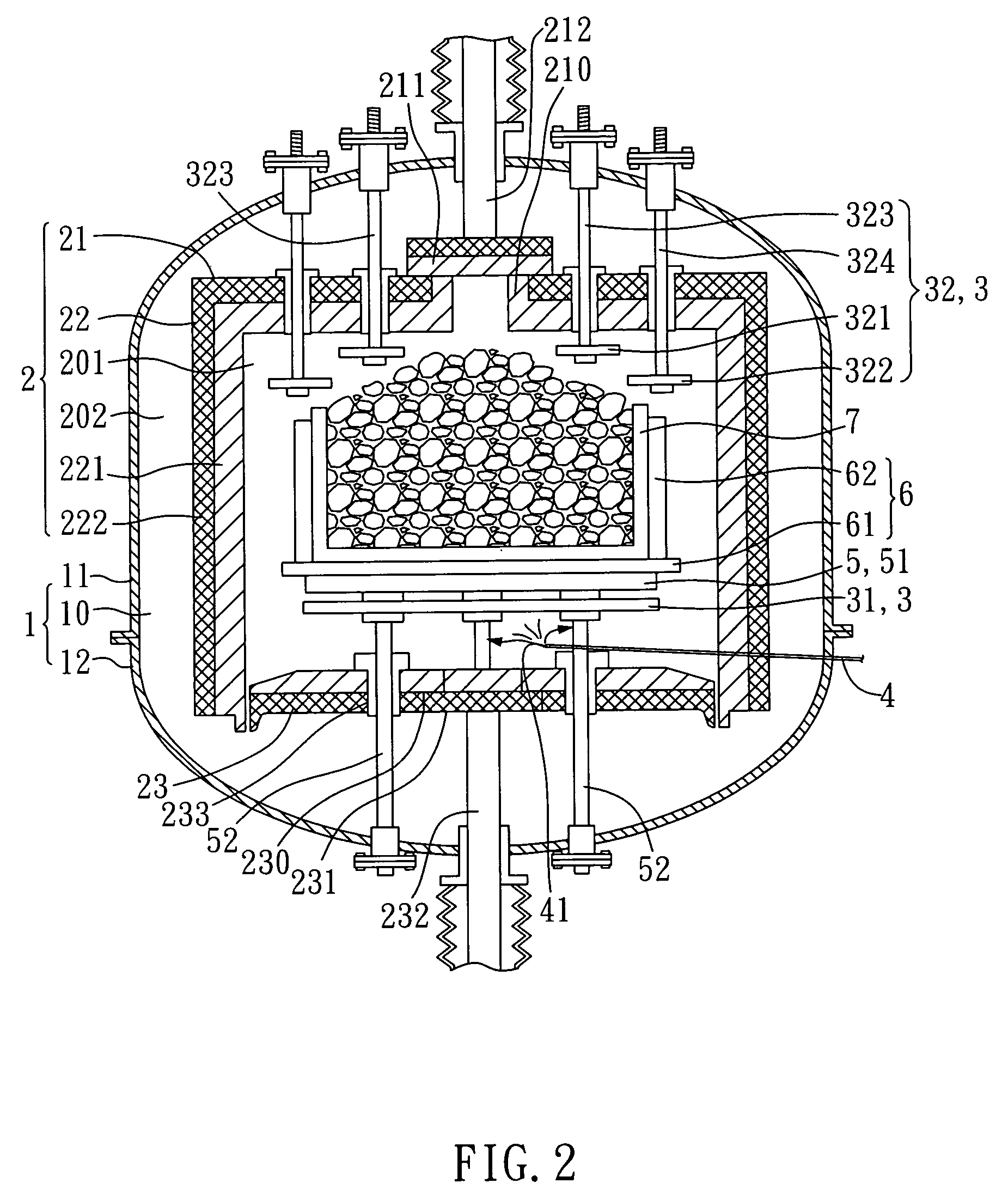

Crystal-Growing furnace with convectional cooling structure

InactiveUS20090158995A1Rapid coolingShorten the timeAfter-treatment apparatusPolycrystalline material growthStream flowIngot

A crystal-growing furnace with a convectional cooling structure includes a furnace body, a heating room, and at least one heater. The heating room is accommodated in the furnace body, and includes an upper partition, a plurality of side partitions, and a lower partition. The upper partition is provided with an upper opening, and the lower partition with a central opening. Further, the heating room is provided with an upper door, a lower door, an upper driver, and a lower driver. When silicon slurry is to be cooled and solidified, cooling gaseous stream flows into a lower portion of the heating room through the central opening. Then the upper opening is opened by the upper door which is driven by the upper driver, so that heated gaseous stream is discharged from the upper opening and flows downward along furnace inside wall, and flows back to the heating room from the central opening. Therefore, an automatic convectional circulating cooling flow field can be formed, such that the silicon slurry can be cooled quickly with time saved and production efficiency improved. Further, in the process of cooling and crystal growing from the silicon slurry, solidification and crystallization start from bottom to upward of the silicon slurry, such that inner stress and corner fracture may not be occurred to the silicon crystal ingots, and that a desirable quality of the silicon crystal ingots can be obtained.

Owner:GREEN ENERGY TECH

Eyeglasses case

ActiveUS20080083627A1Precise positioningReliable lockingElectric circuit arrangementsLighting elementsMotion detectorTransducer

A container having a compartment for retaining personal objects such as eyeglasses comprises a transducer which activates the container in response to a specified user action in proximity to the container. In some embodiments, the transducer is a motion detector and is activated in response to user motion. In other embodiments, the transducer comprises a speech recognition module and is activated in response to the user's voicing a specified utterance. Some embodiments become illuminated upon activation. Some embodiments produce a sound upon activation, enabling the user to locate the container. Some embodiments have a normally closed lid which opens upon activation. Some lidded embodiments are normally locked and become unlocked upon activation. Some embodiments of the container further normally provide low level lighting, thereby enabling the container to serve as a night light. Some embodiments further provide for an individual clean tissue prior to each time an object is placed in the case, to assure cleanliness of the container for each use when it is used by multiple users in a location accessible to the public, such as places of business serving the public where removing eyeglasses is common.

Owner:S & D INNOVATIONS

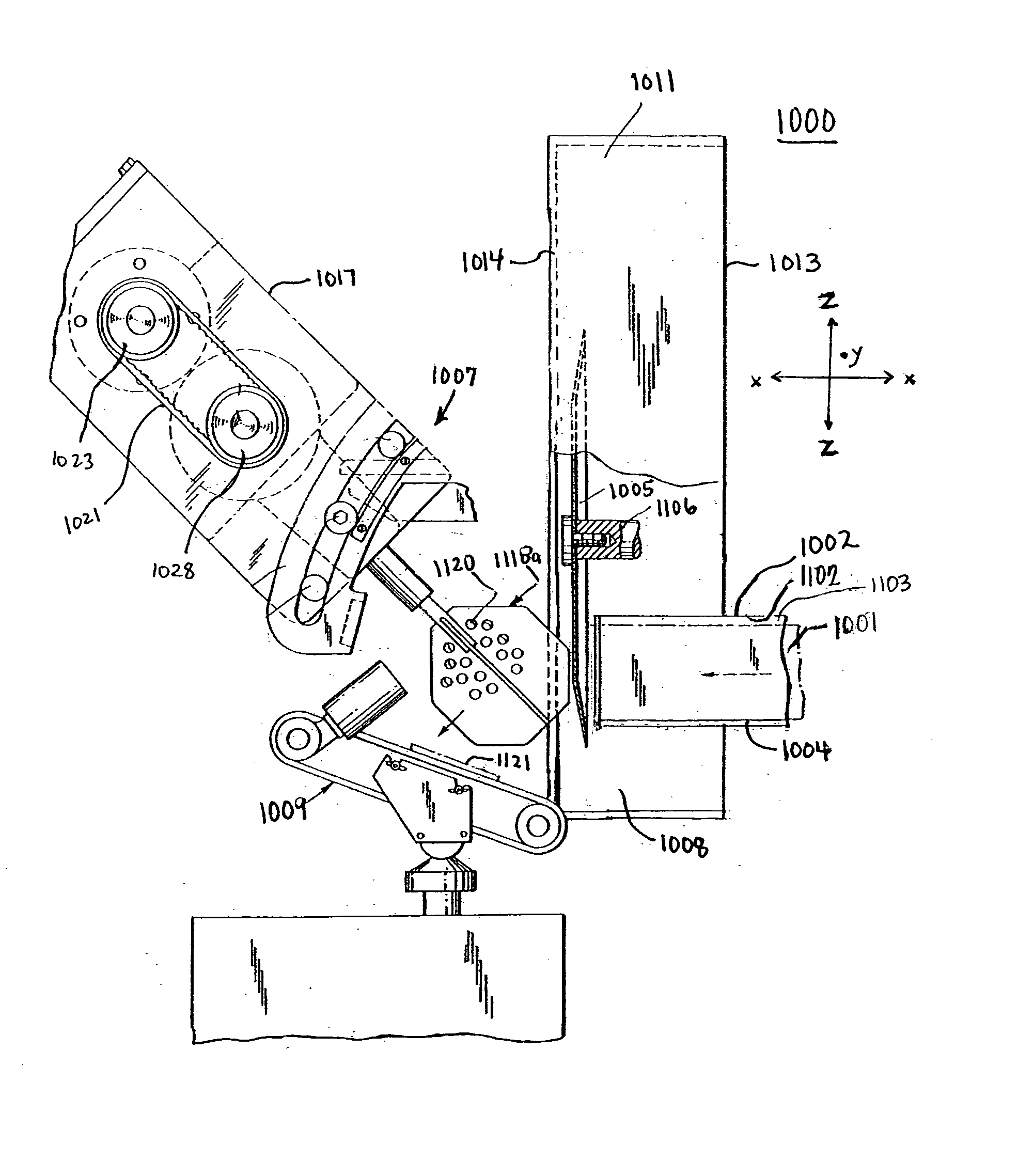

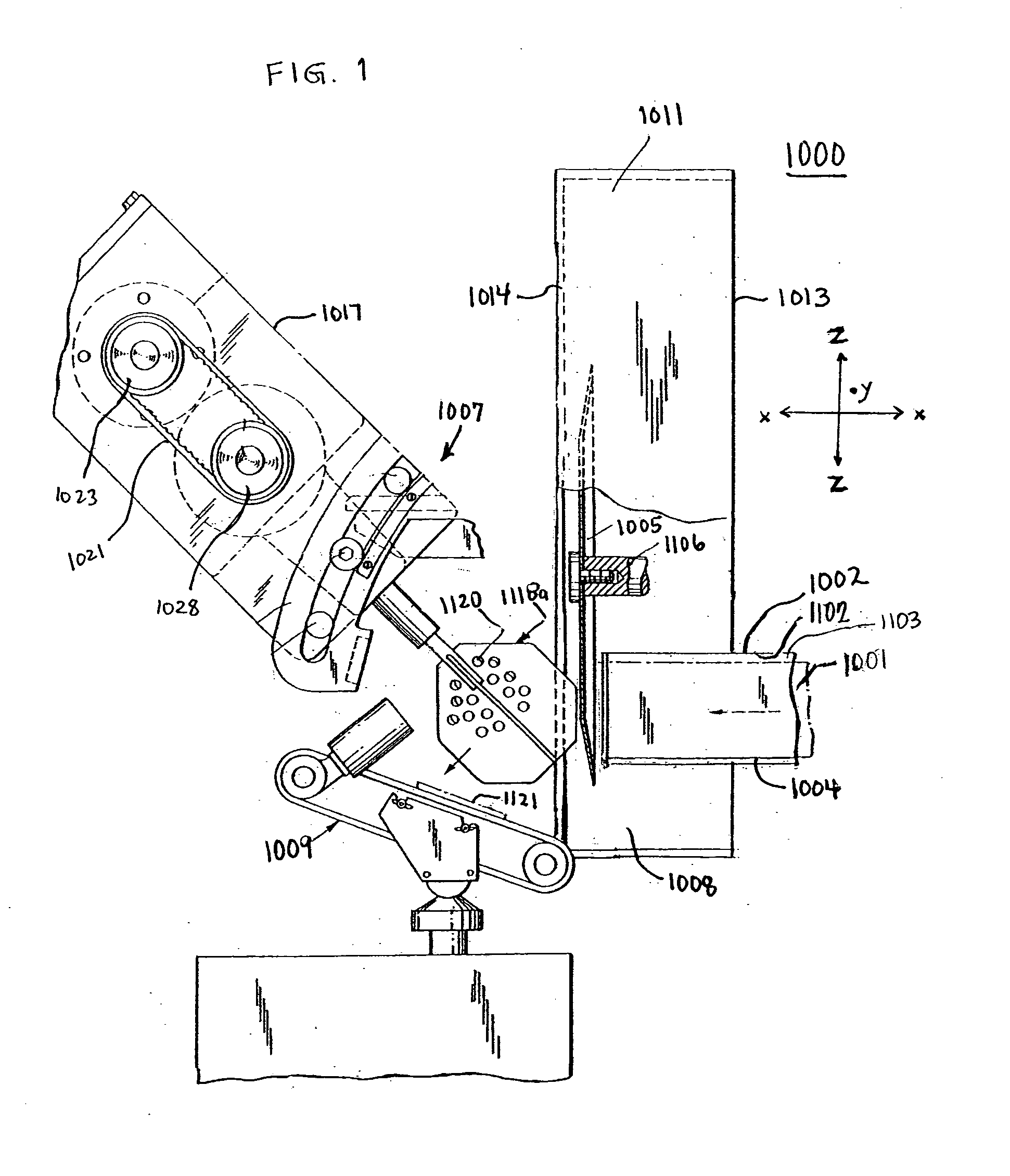

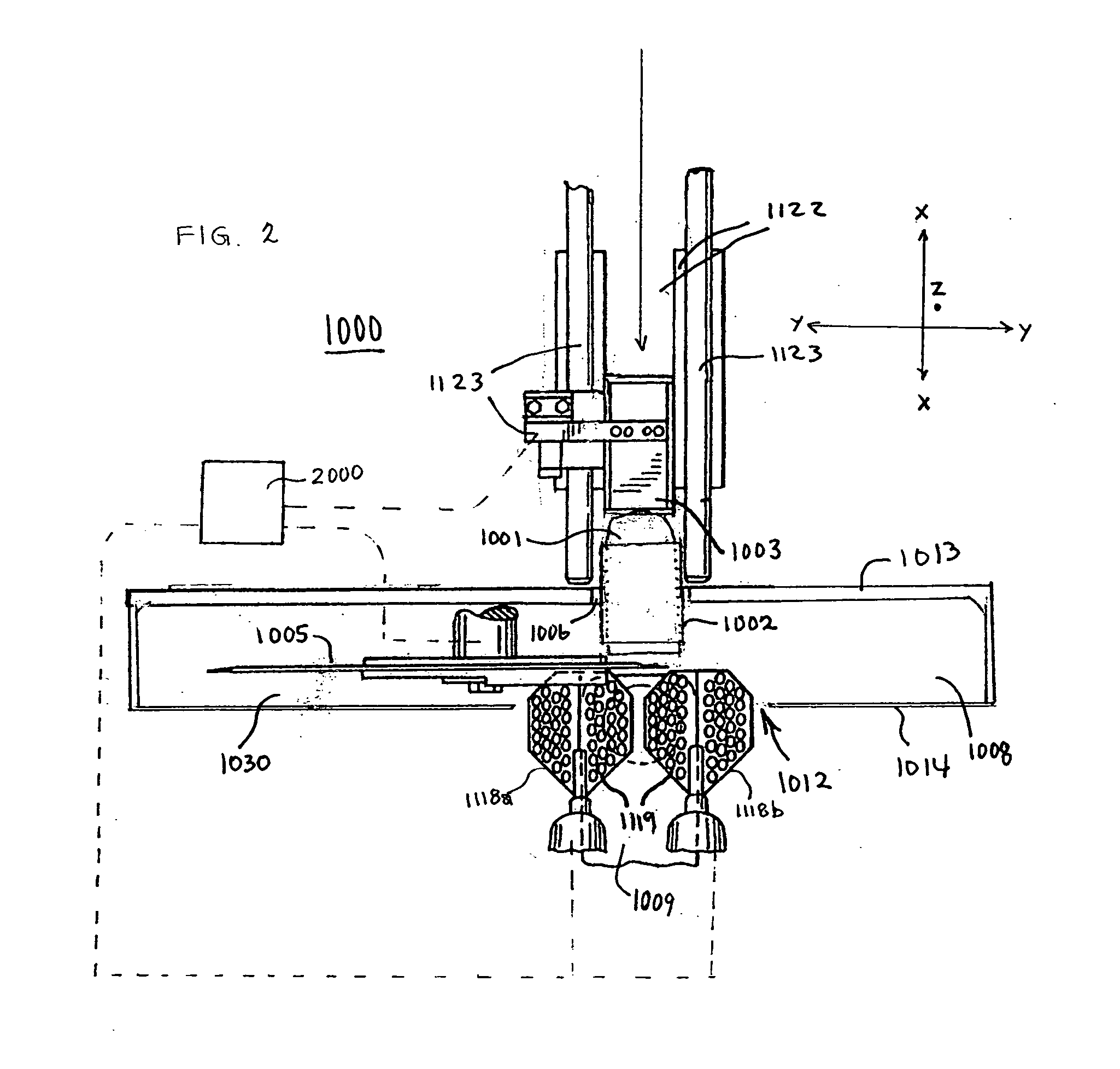

Food product slicing apparatus and method

InactiveUS20060219069A1Reliable and accurate continuous clean slicing capabilityMaintenance conditionMetal working apparatusHEPASurface finish

An apparatus, and method of its use, for slicing food products, particularly elongated food products, in which the apparatus has a housing enclosing a rotatable slicing blade, and a sleeve which is mounted in a housing sidewall. The sleeve provides a passageway through which a food product passes and receives a treatment along its outer surface. Other additional and / or alternative features for enhancing or sustaining the cleanliness within the slicing housing also are provided, which include use of overpressure within the housing interior, introduction of HEPA-filtered gas or air therein, delivery of an antimicrobial agent therein, and / or providing interior housing wall surfaces having a surface finish (RMS) not exceeding 32 microinches. The slicing apparatus, and its method of operation, provides reliable, accurate continuous slicing capability while requiring less cleaning.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

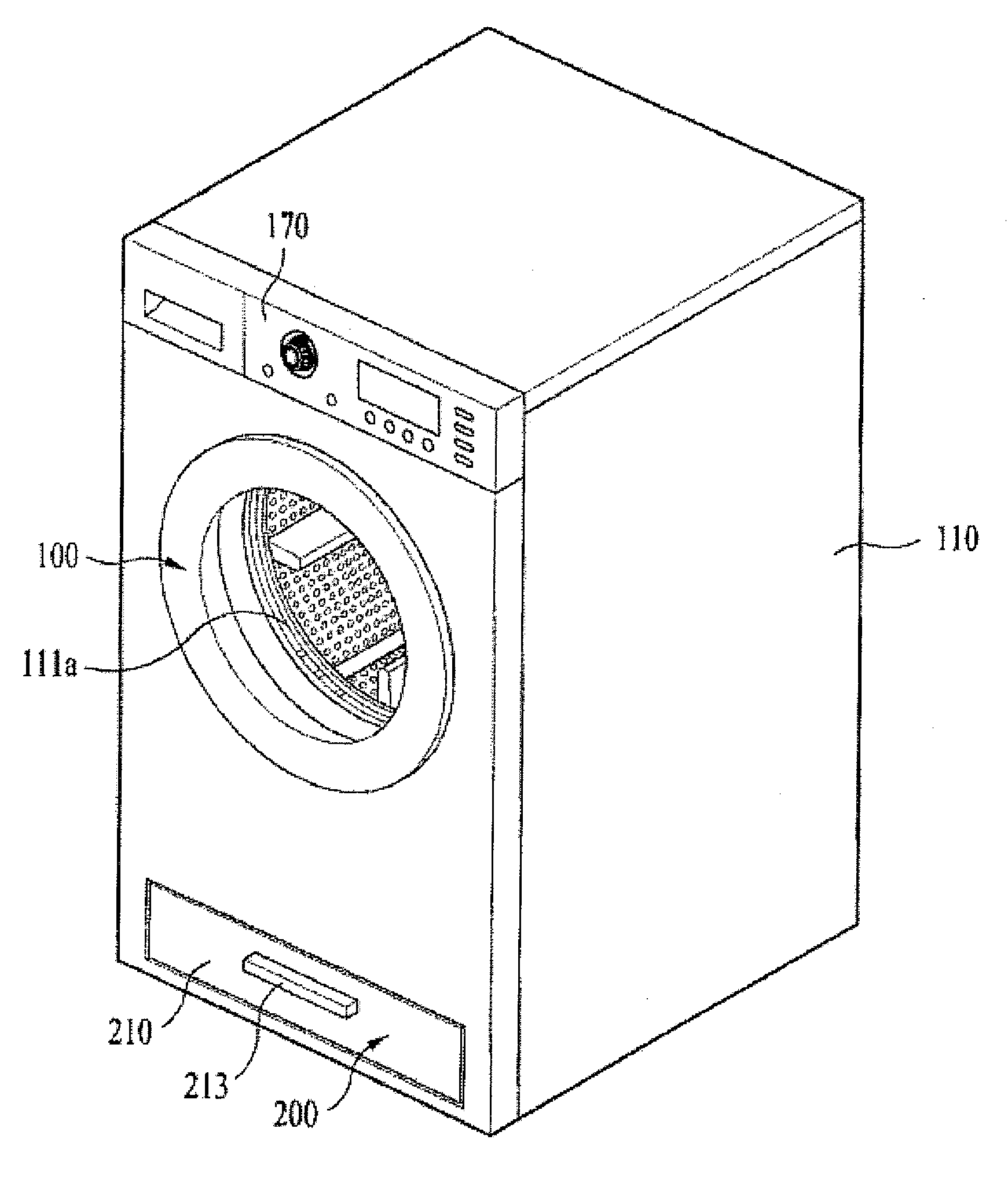

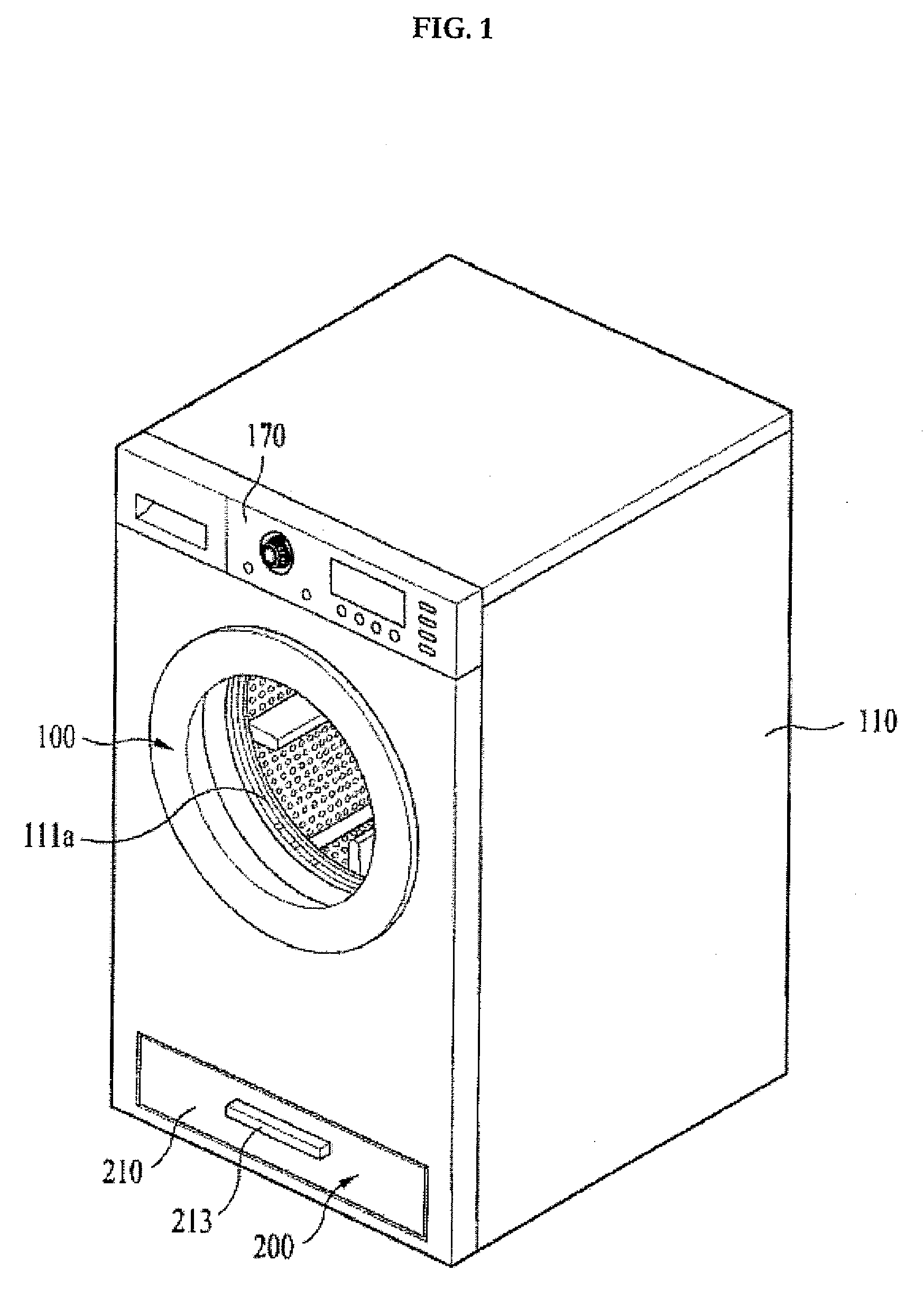

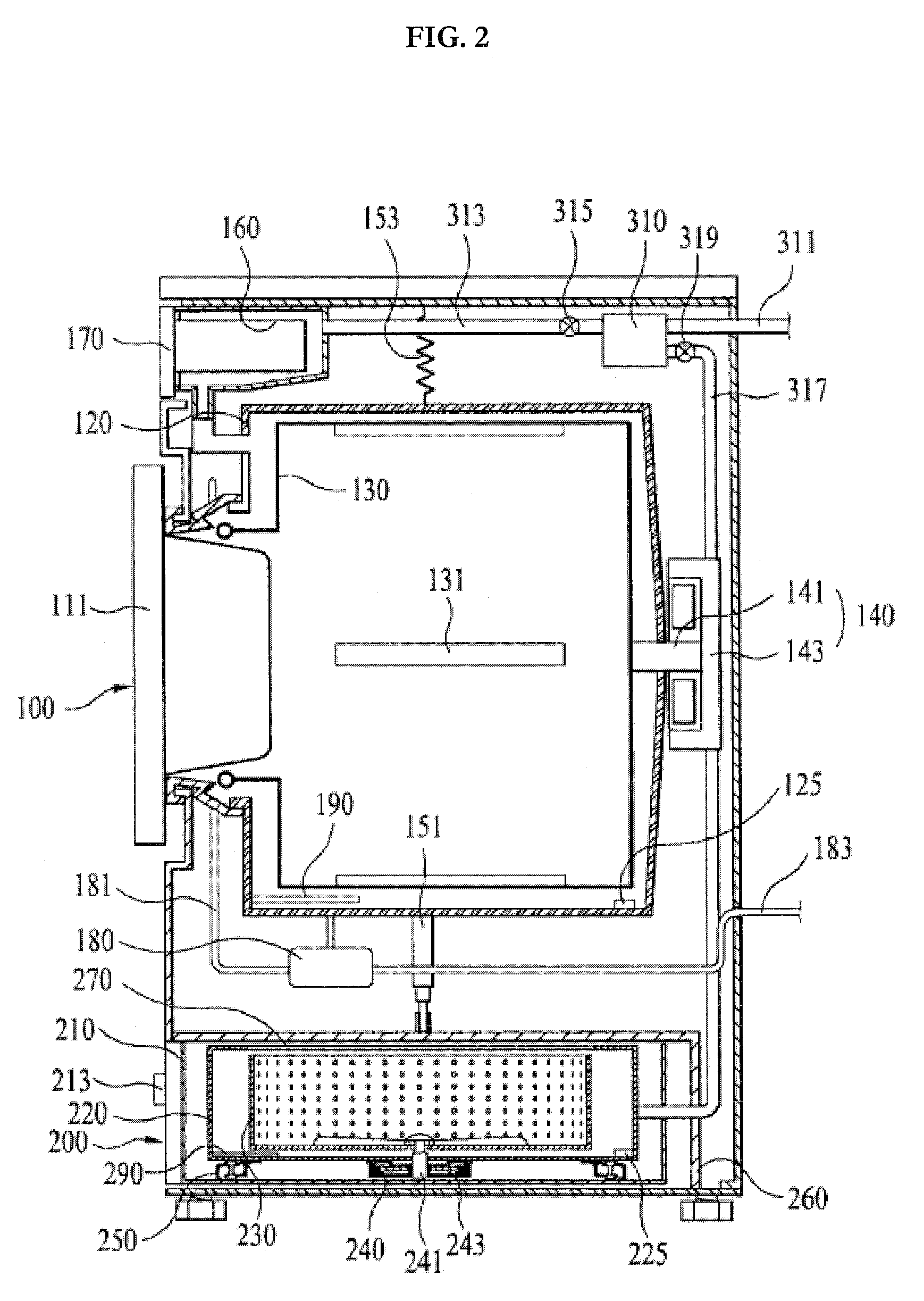

Laundry treating device and method of controlling the same

ActiveUS20090133197A1Reduce consumptionEnsure thorough cleaningOther washing machinesControl devices for washing apparatusBiomedical engineering

A laundry treating device includes a first laundry treating device and a second laundry treating device adjacent to the first laundry treating device. A first heater provided in the first laundry treating device and a second heater provided in the second laundry treating device can be selectively and alternatively operated to heat washing water.

Owner:LG ELECTRONICS INC

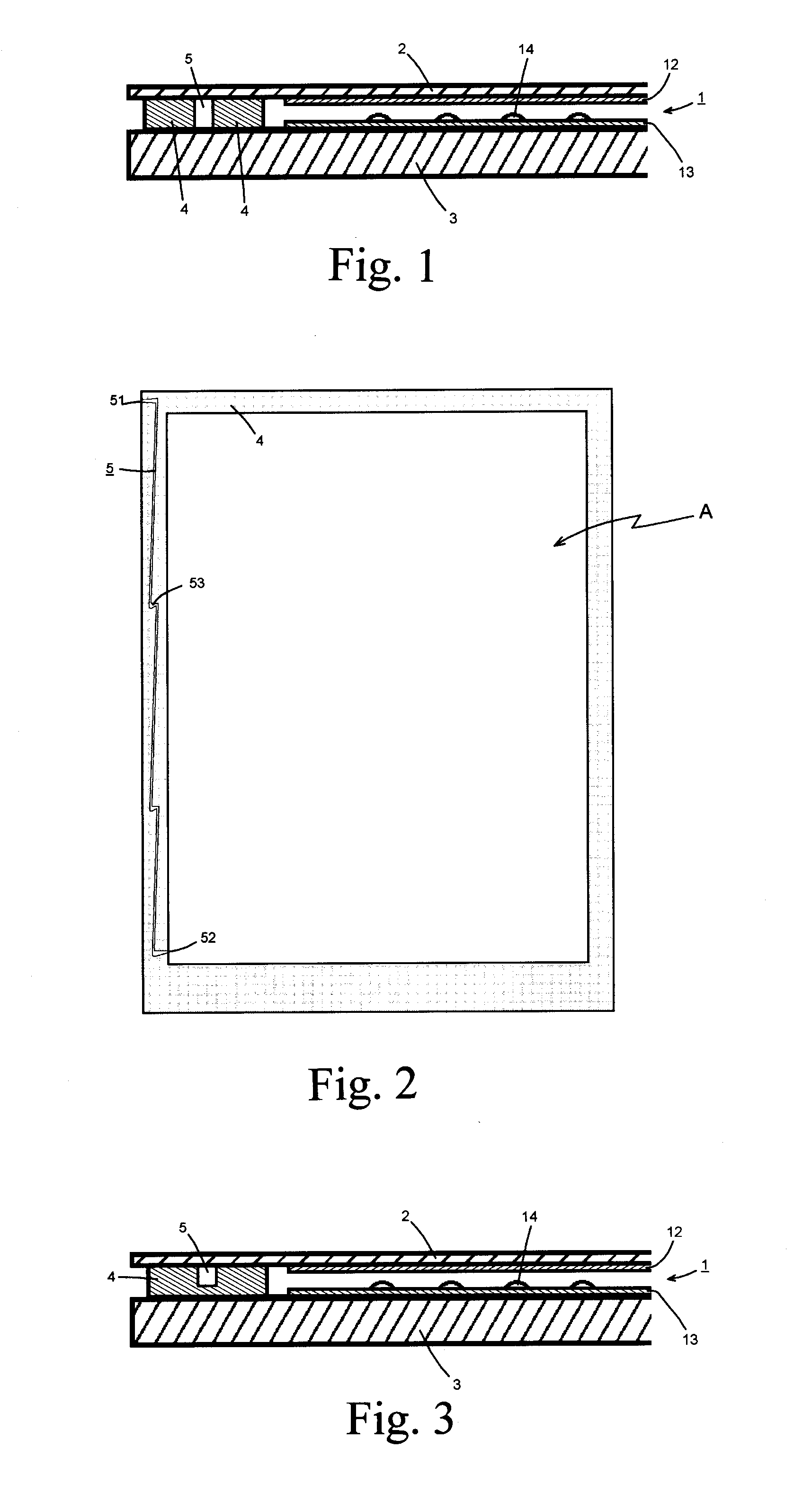

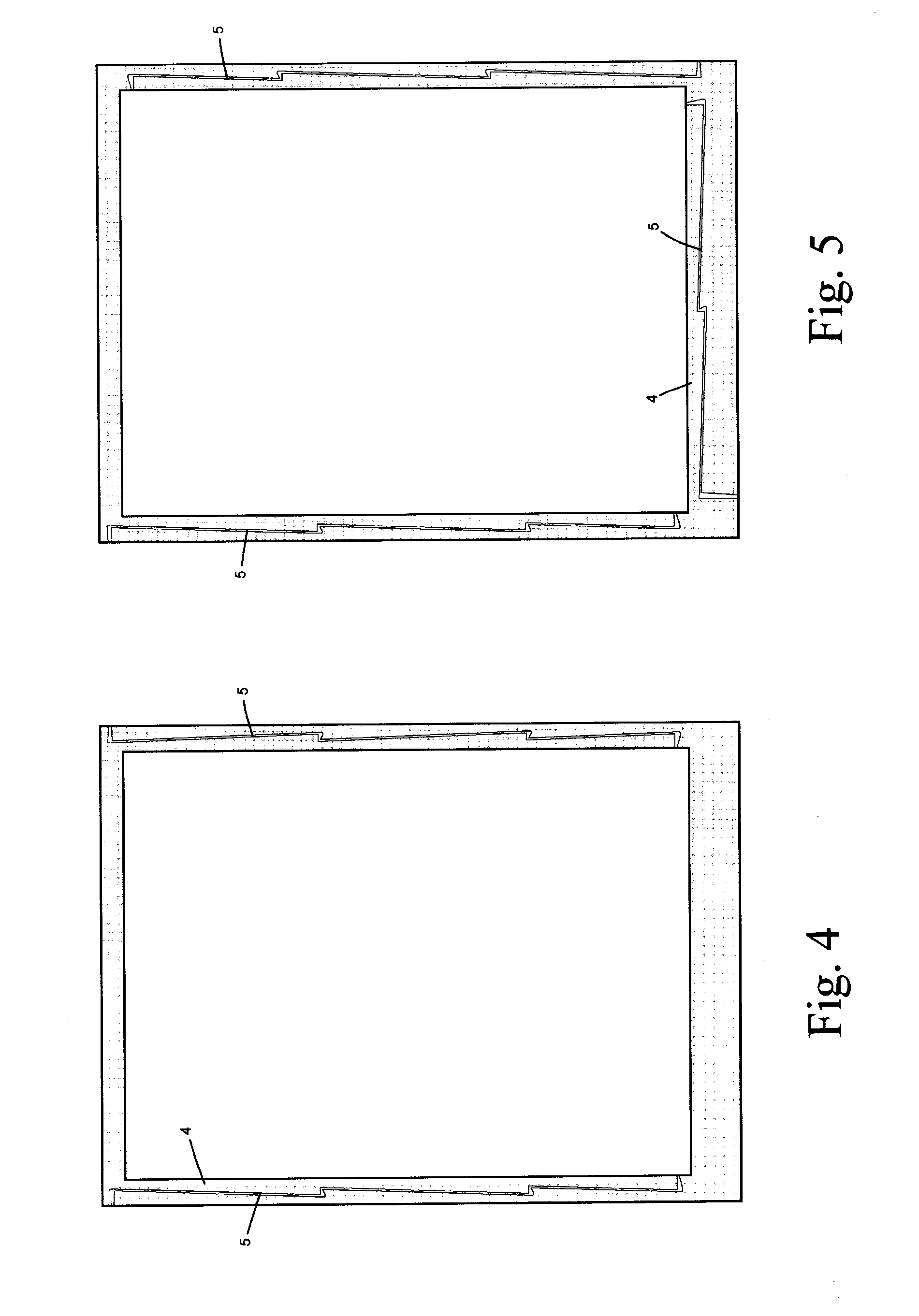

Air pressure balance structure for touch panel

InactiveUS20110193789A1Ensure thorough cleaningPrevent a damage caused by pressure differenceInput/output processes for data processingInterior spaceAtmospheric pressure

An air pressure balance structure for touch panel has at least one long narrow ventilating tunnel formed vertically to a gluing frame of a resistive touch panel. The ventilating tunnel communicates an inner space of the touch panel with the outside of the touch panel so as to prevent a damage caused by difference of air pressure. By the long narrow ventilating tunnel and the adhesive material of the gluing frame, moisture and dust will be prevented from coming into the touch panel so that an inner cleanliness of the touch panel will be ensured. The ventilating tunnel also has a turning portion, the turning portion has large containing space so as to buffer the air flow and capture the moisture and dust.

Owner:LIN TEH ZHENG

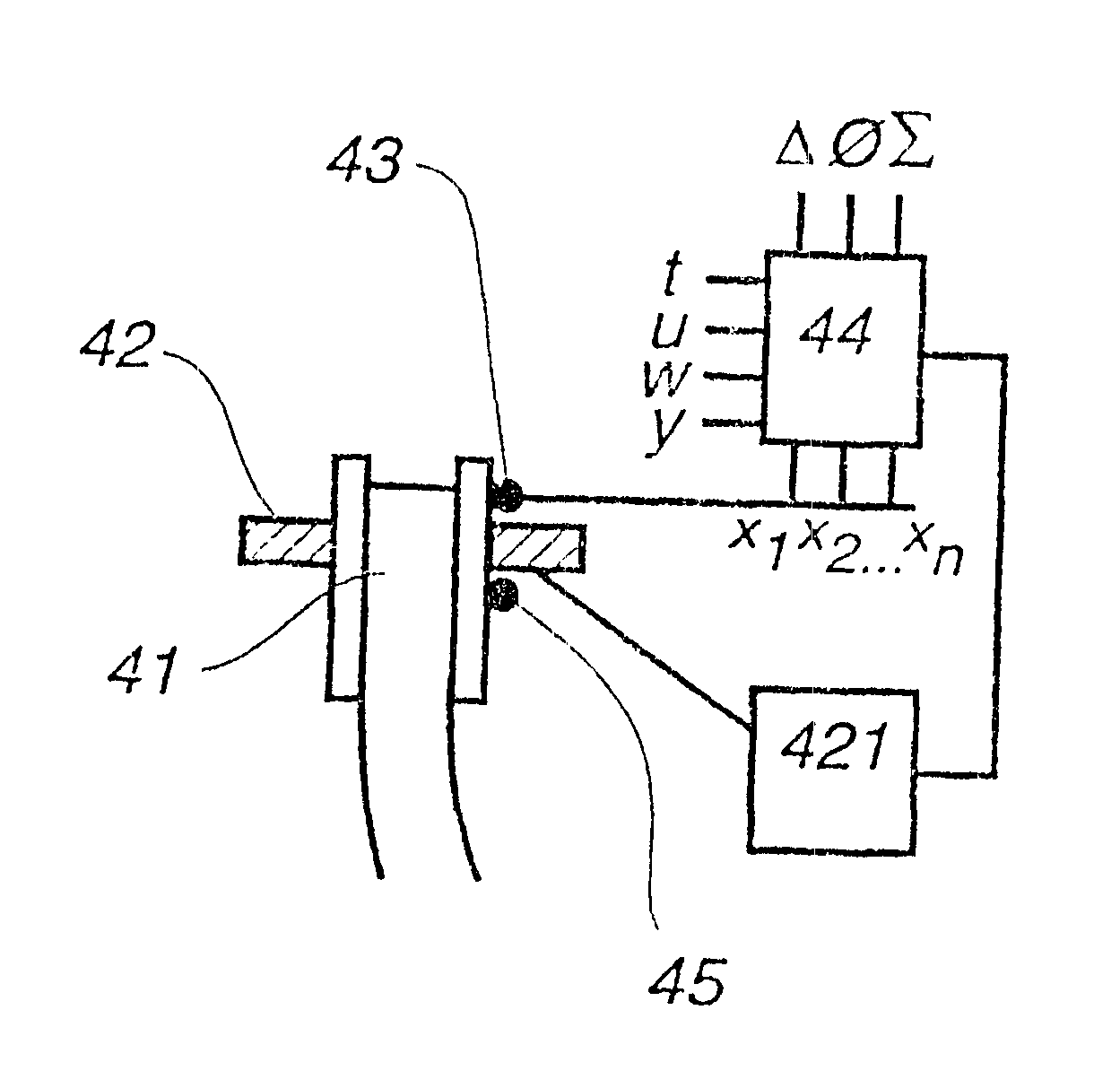

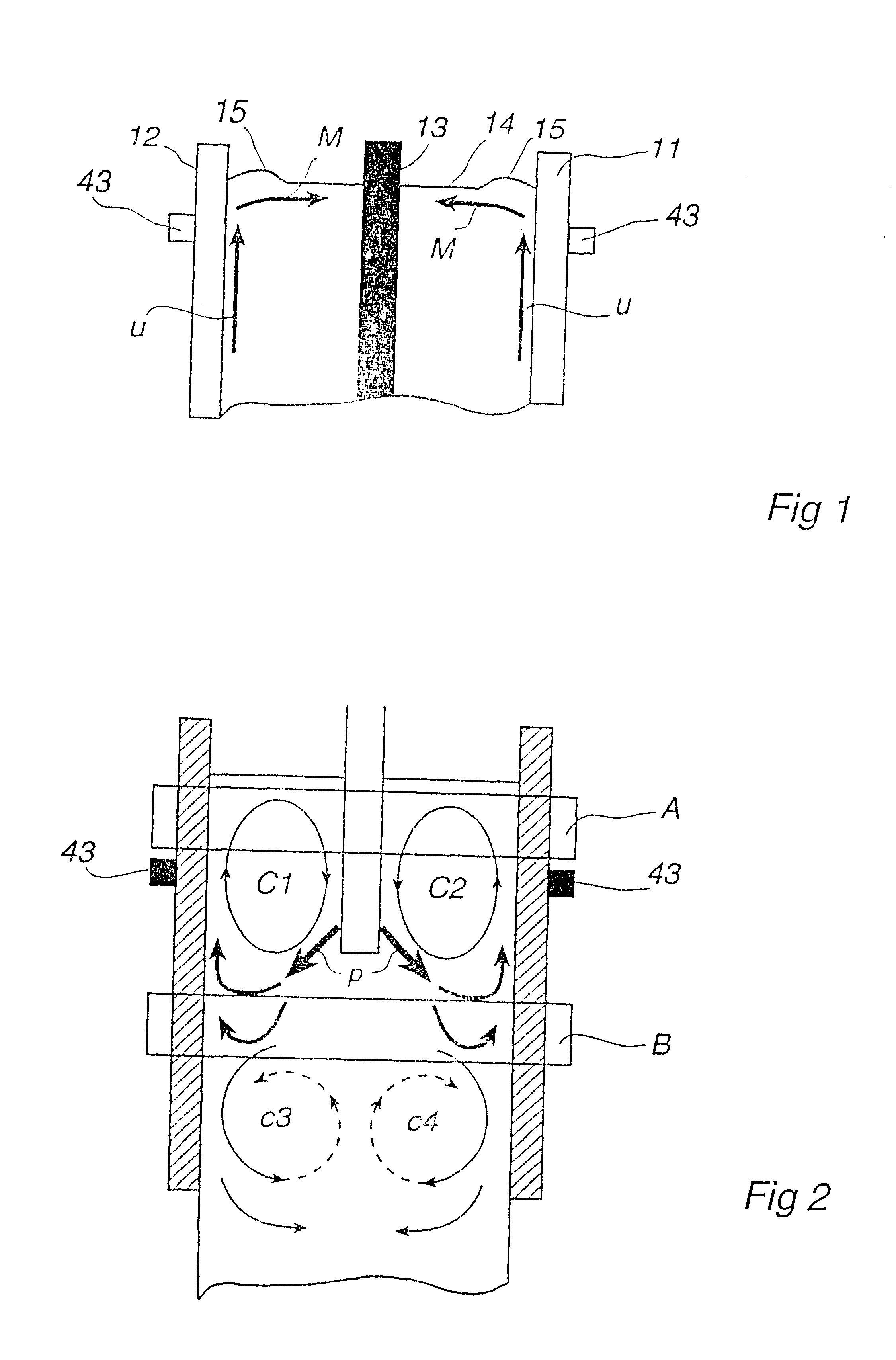

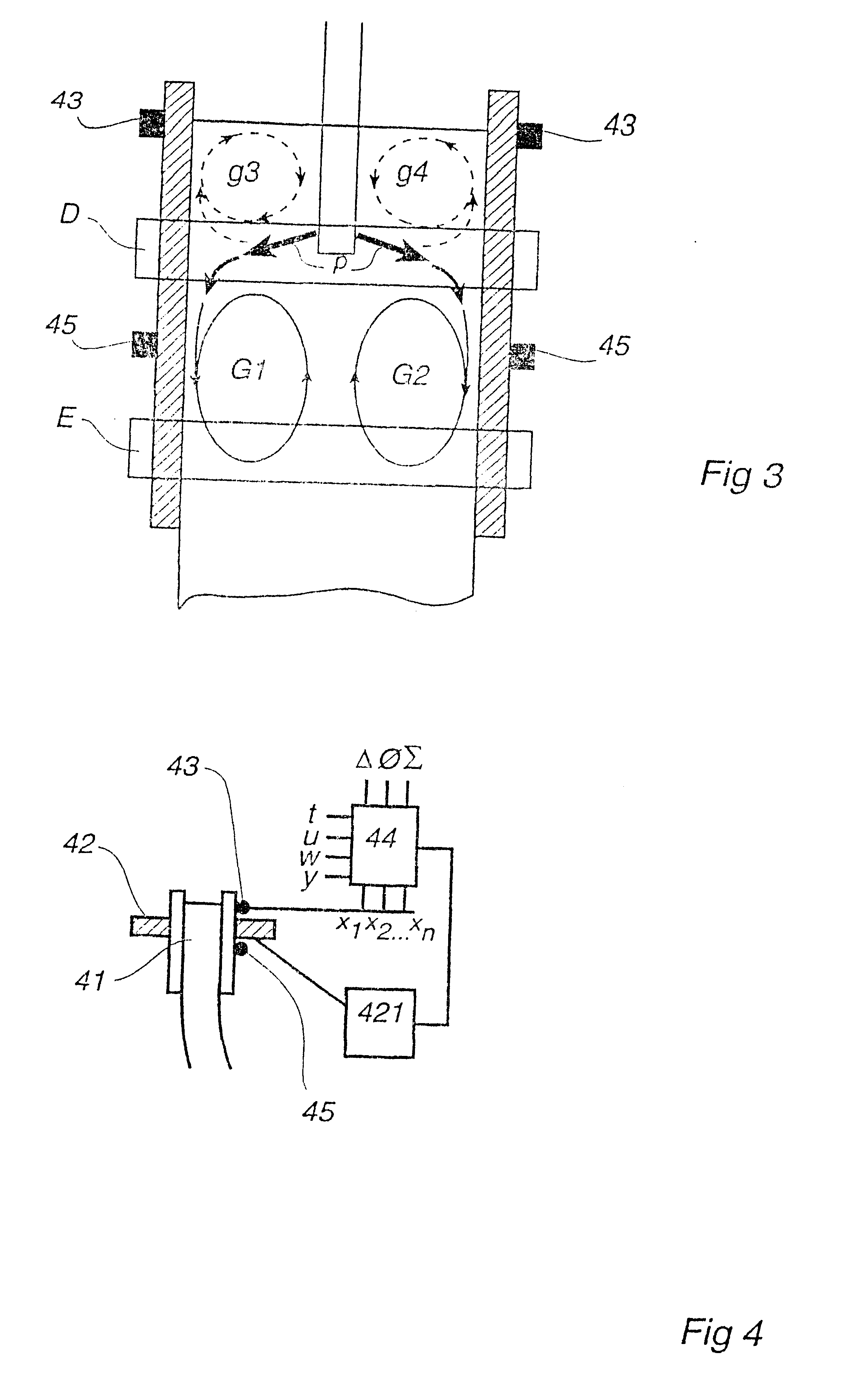

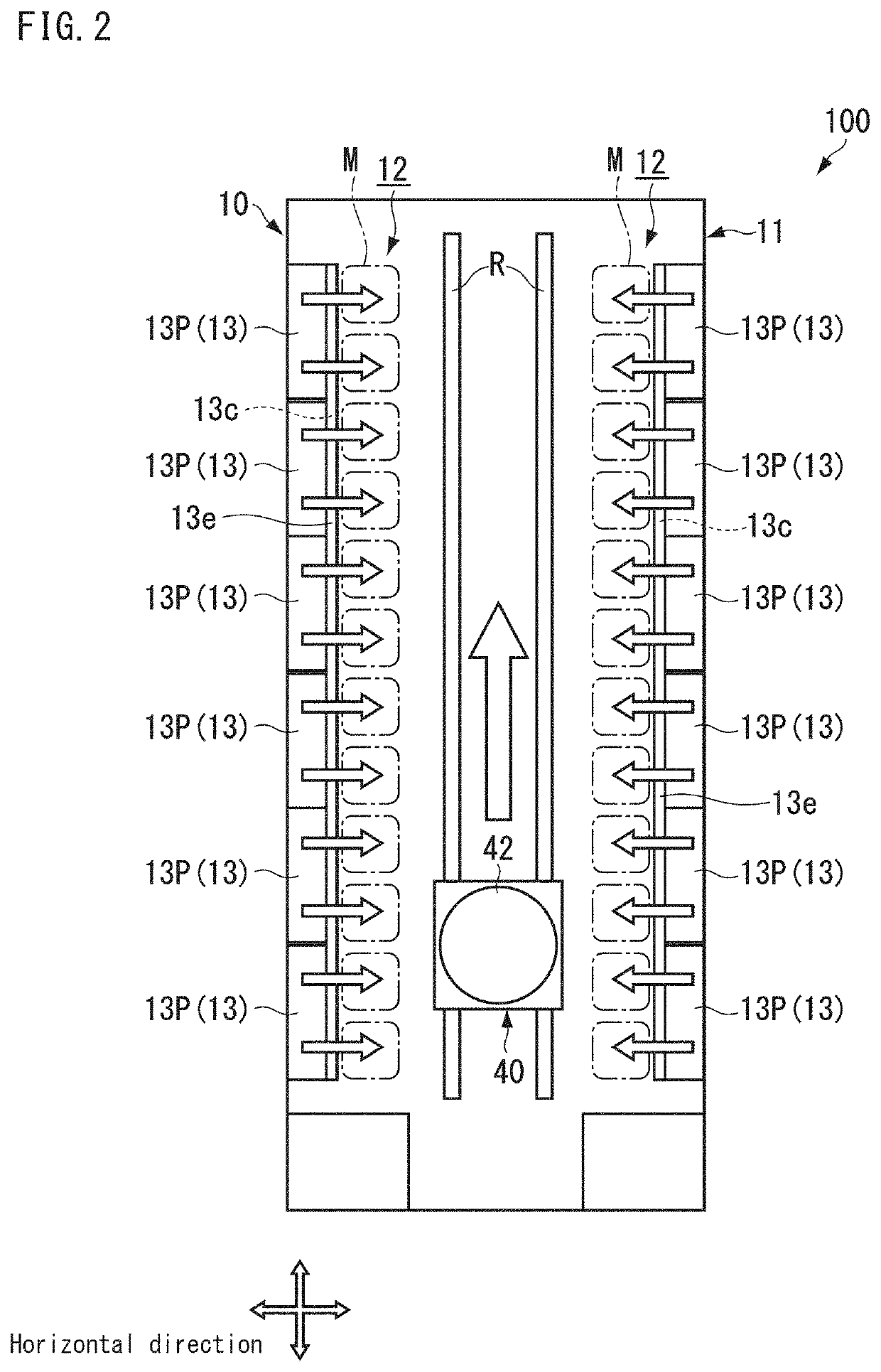

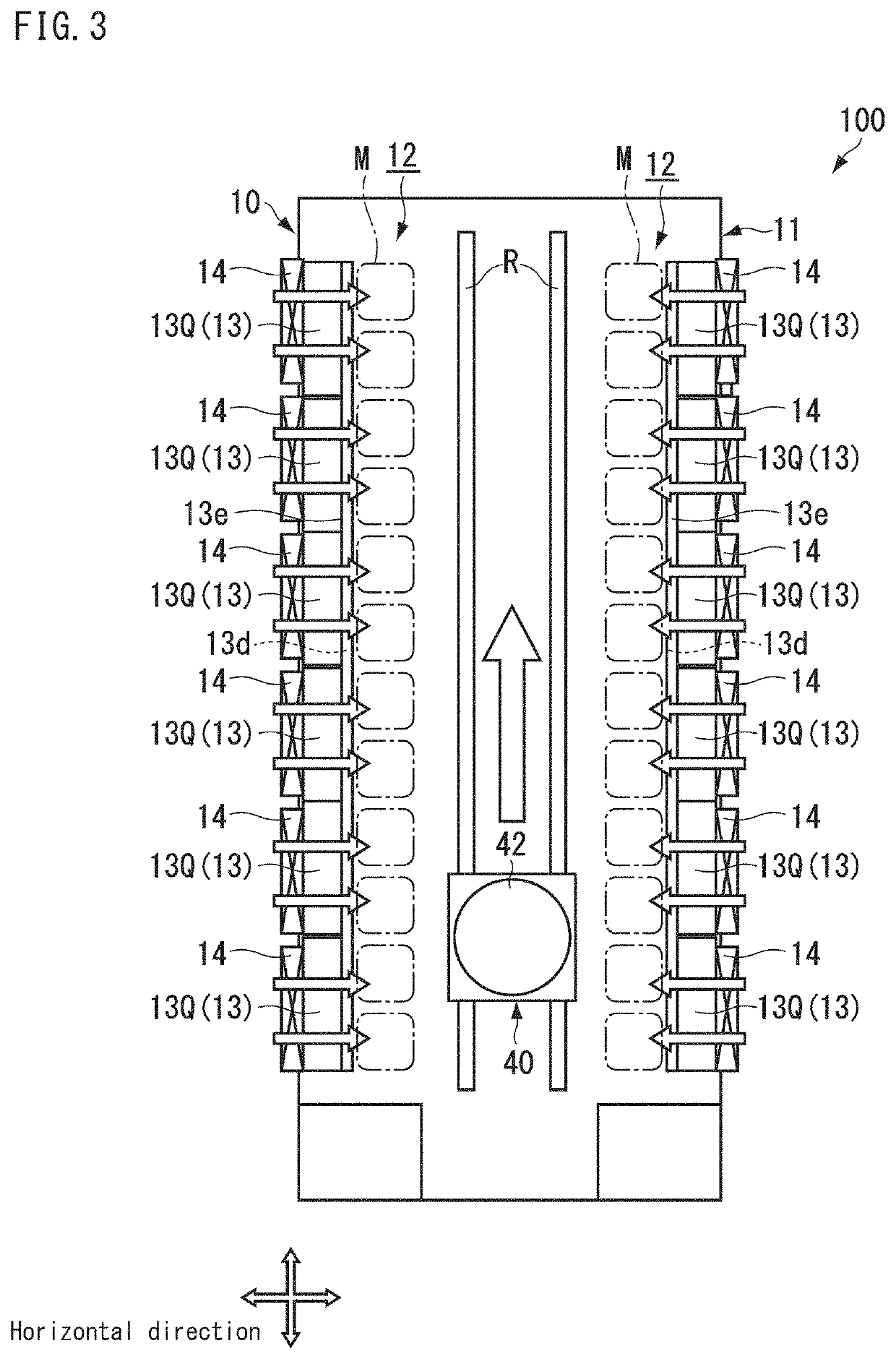

Method and device for control of metal flow during continuous casting using electromagnetic fields

InactiveUS6494249B1Improve productivityImprove abilitiesCasting safety devicesMould controlling devicesVolumetric Mass DensityElectromagnetic field

A method and a device for continuous or semi-continuous casting of metal. A primary flow (P) of hot metallic melt supplied into a mold is acted upon by at least one static or periodically low-frequency magnetic field to brake and split the primary flow and form a controlled secondary flow pattern in the non-solidified parts of the cast strand. The magnetic flux density of the magnetic field is controlled based on casting conditions. The secondary flow (M, U, C1, C2, c3, c4, G1, G2, g3, g4, O1, O2, o3, o4) in the mold is monitored throughout the casting and upon detection of a change in the flow, information on the detected change monitored flow is fed into a control unit (44) where the change is evaluated and the magnetic flux density is regulated based on this evaluation to maintain or adjust the controlled secondary flow.

Owner:ABB (SCHWEIZ) AG

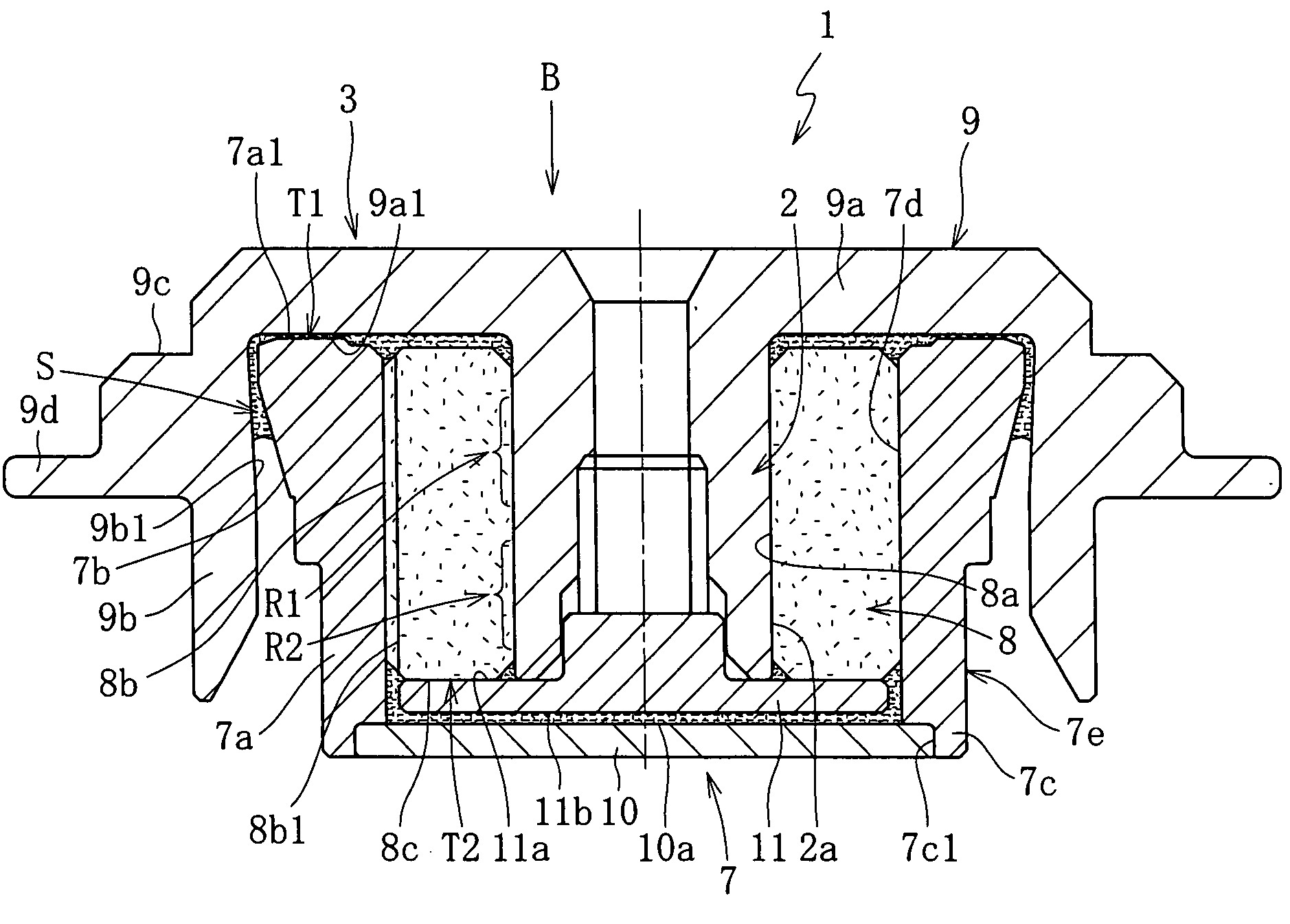

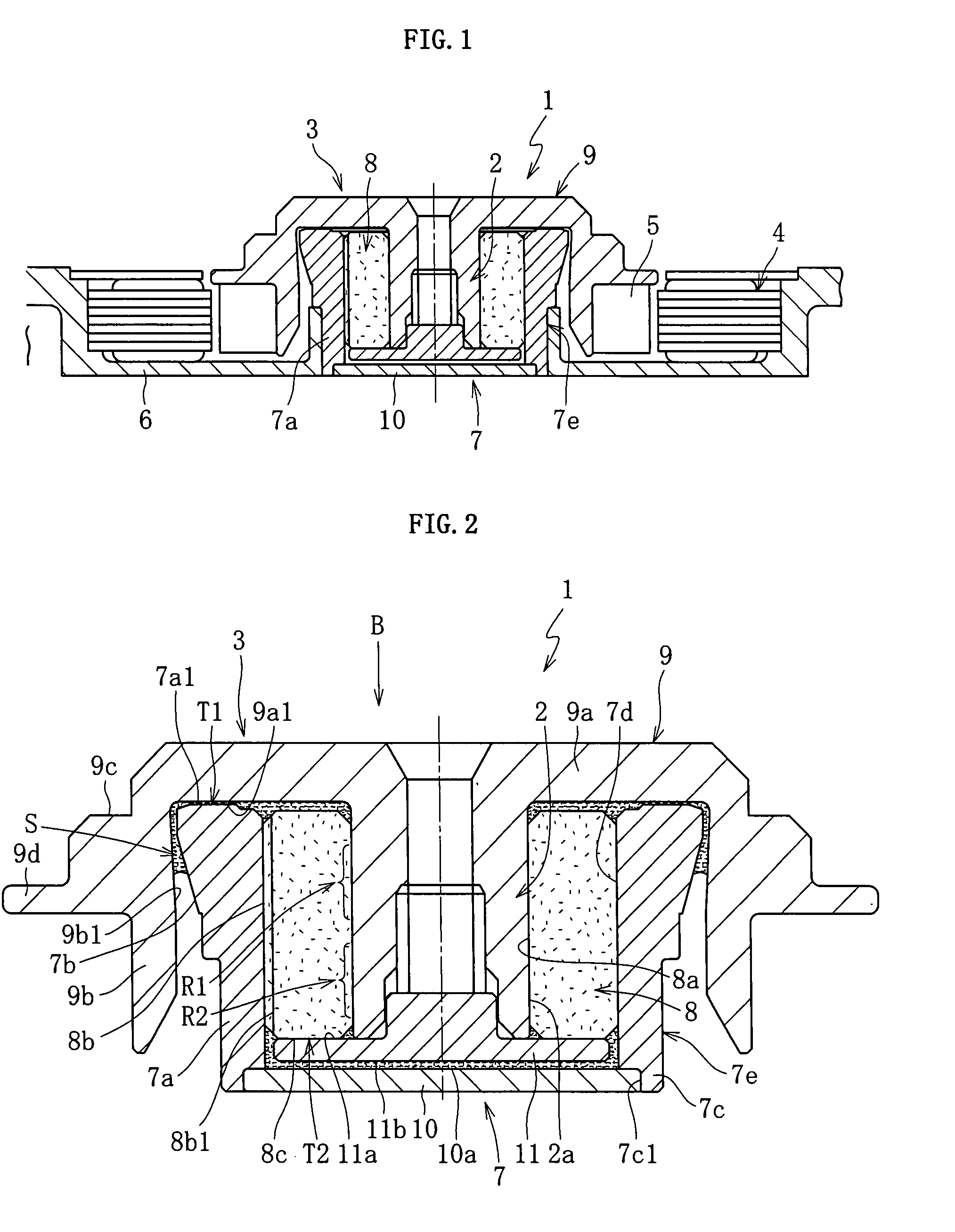

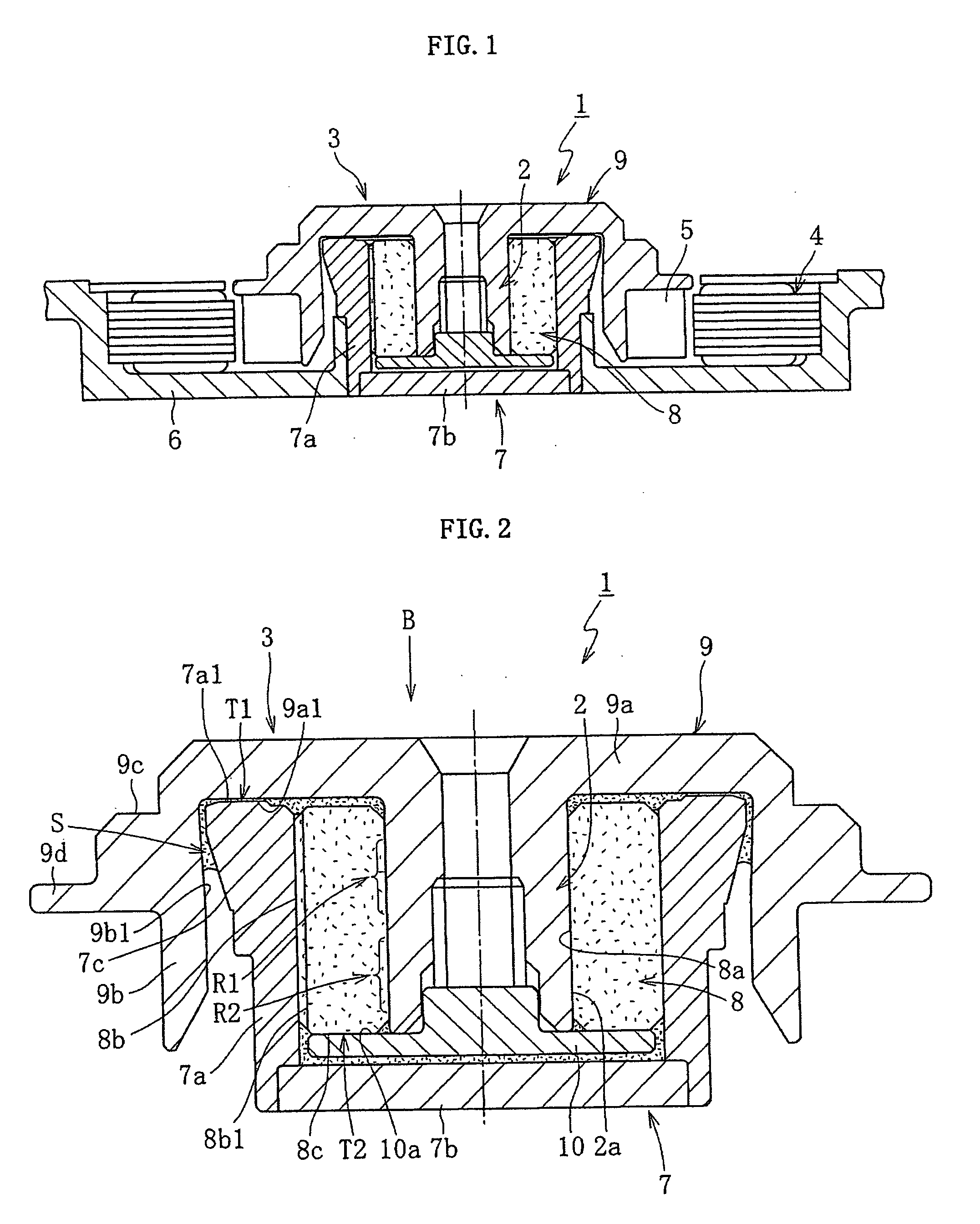

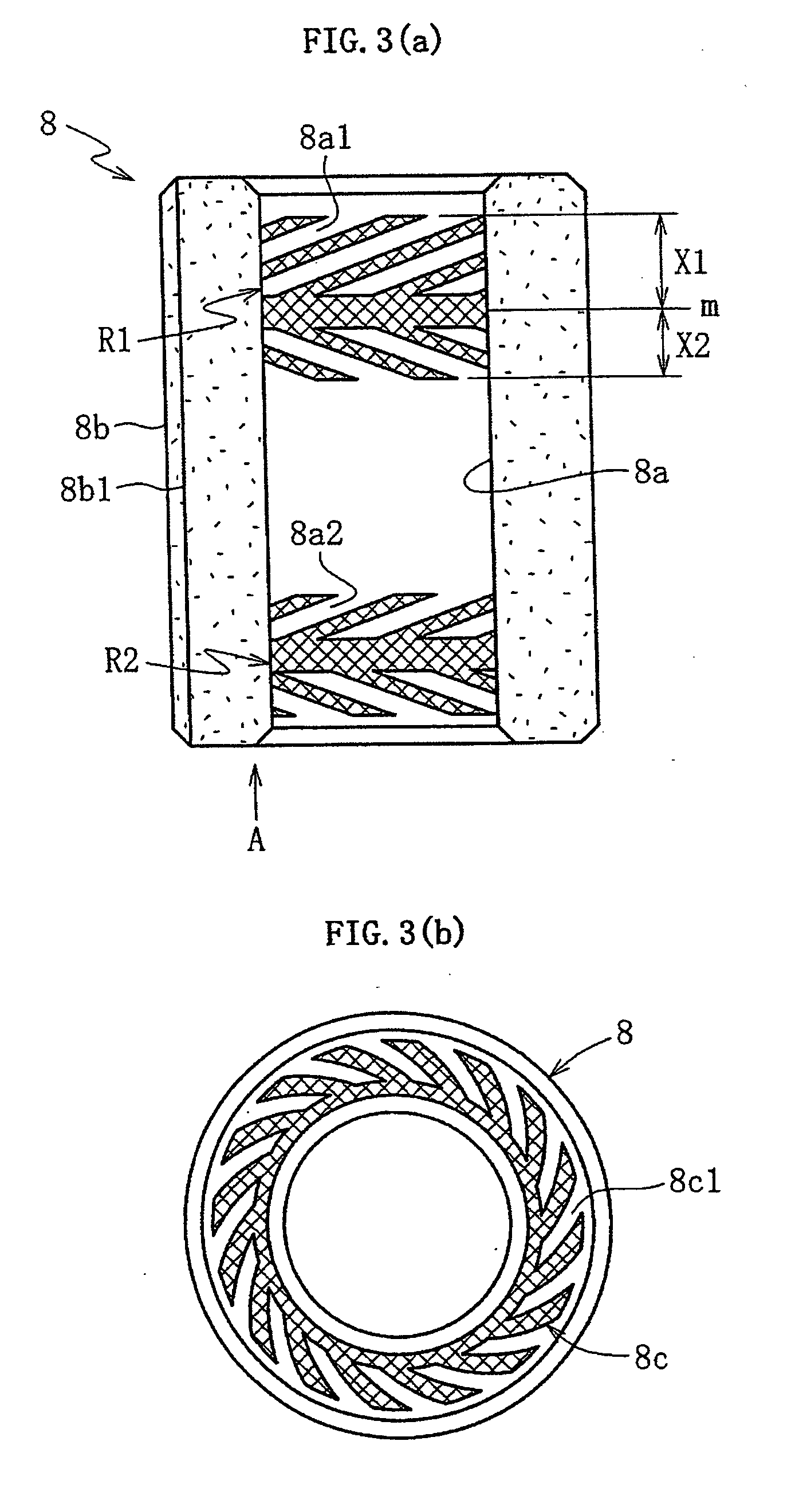

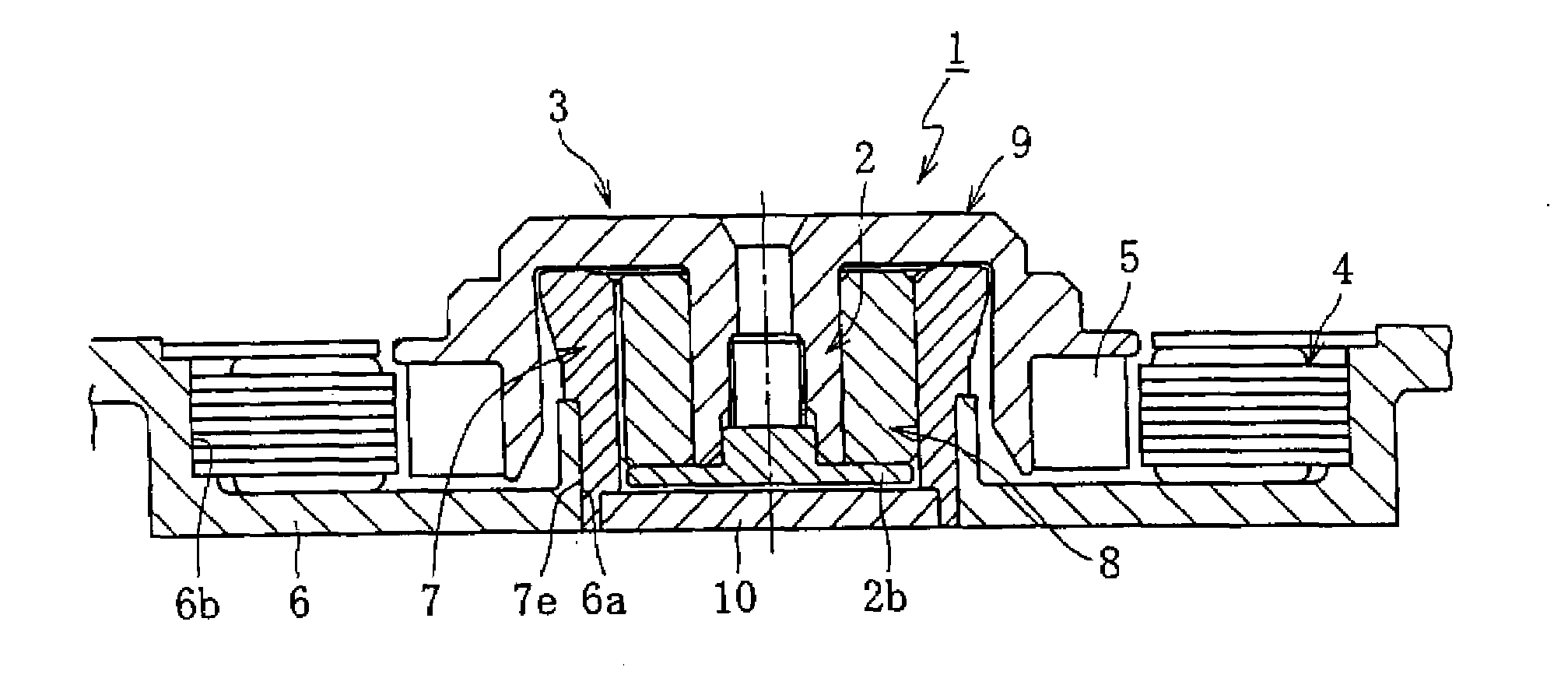

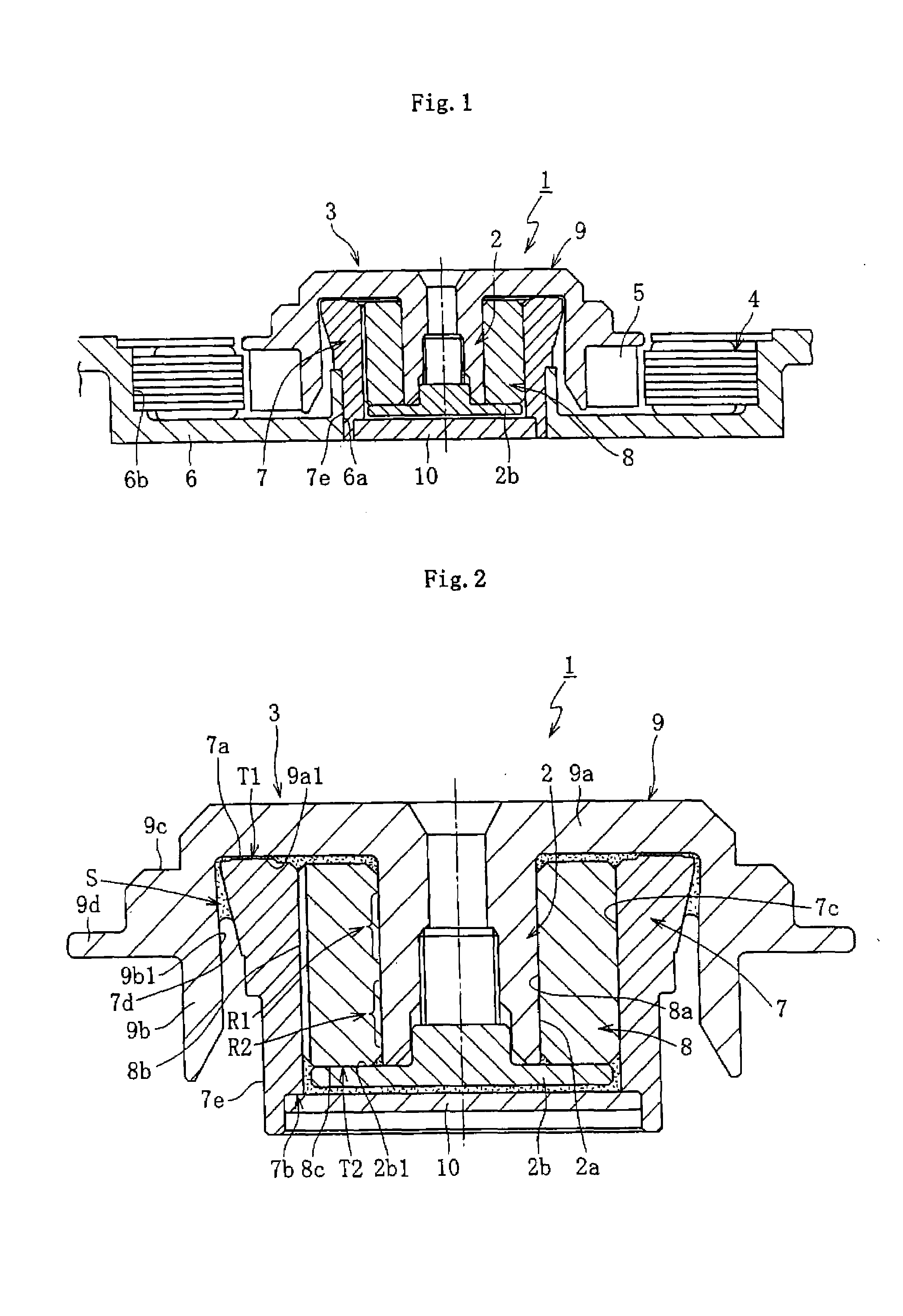

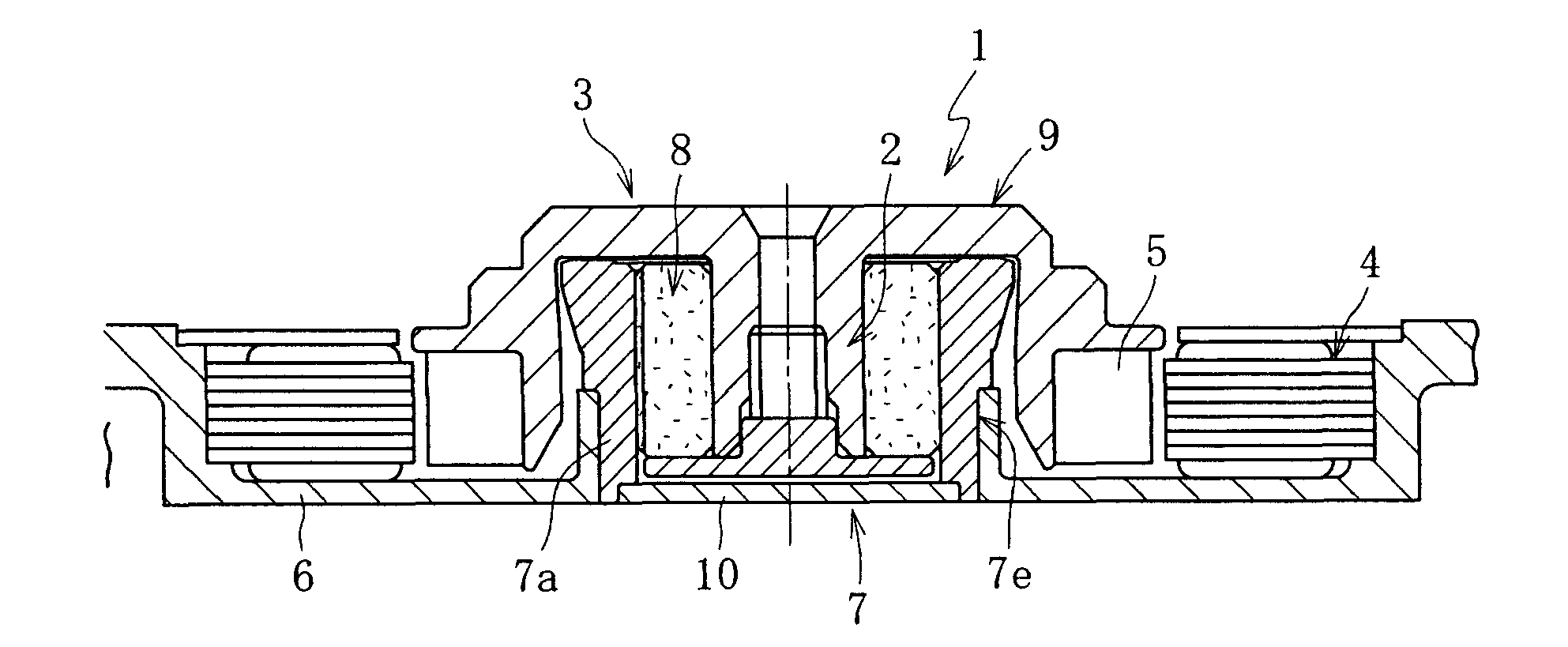

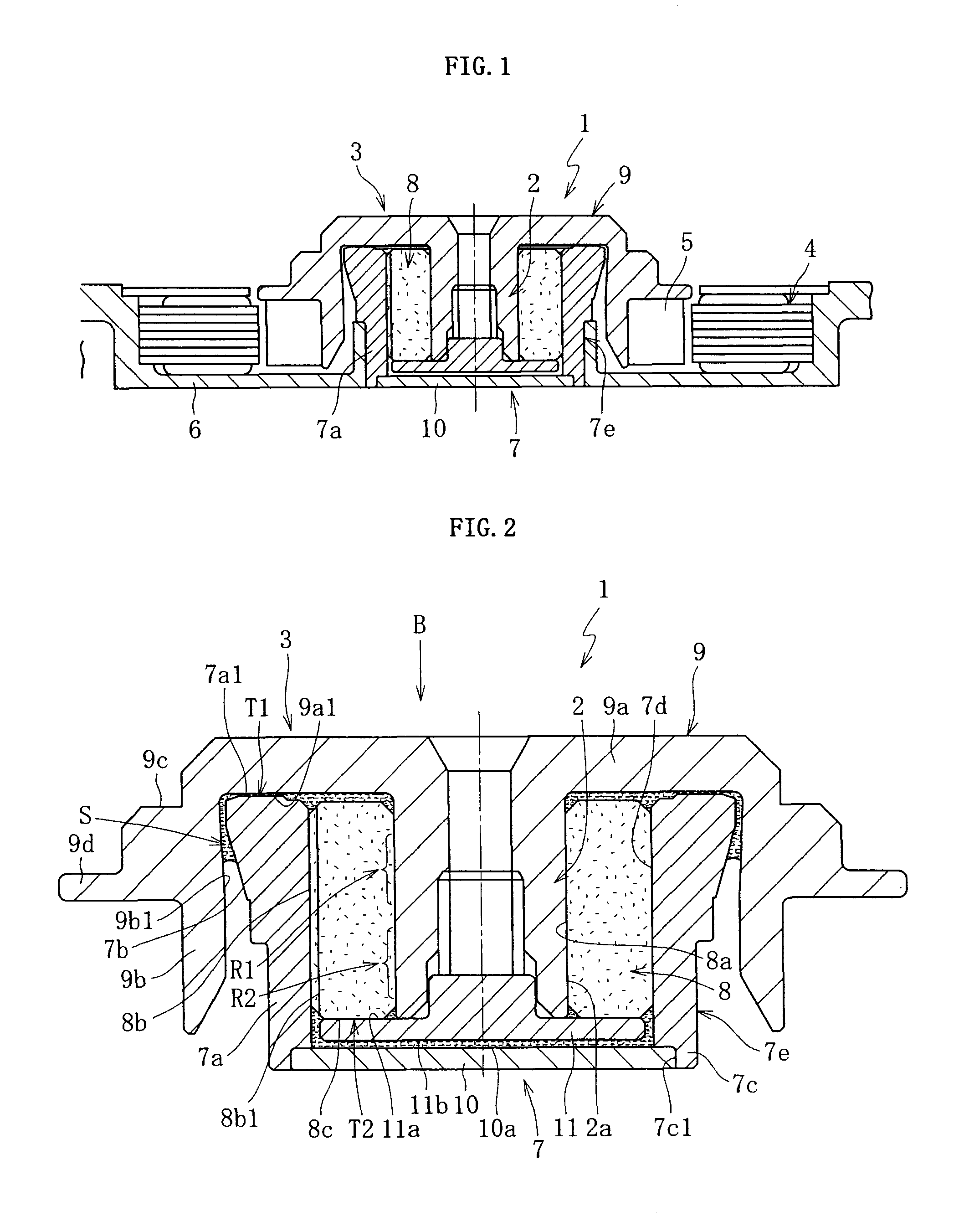

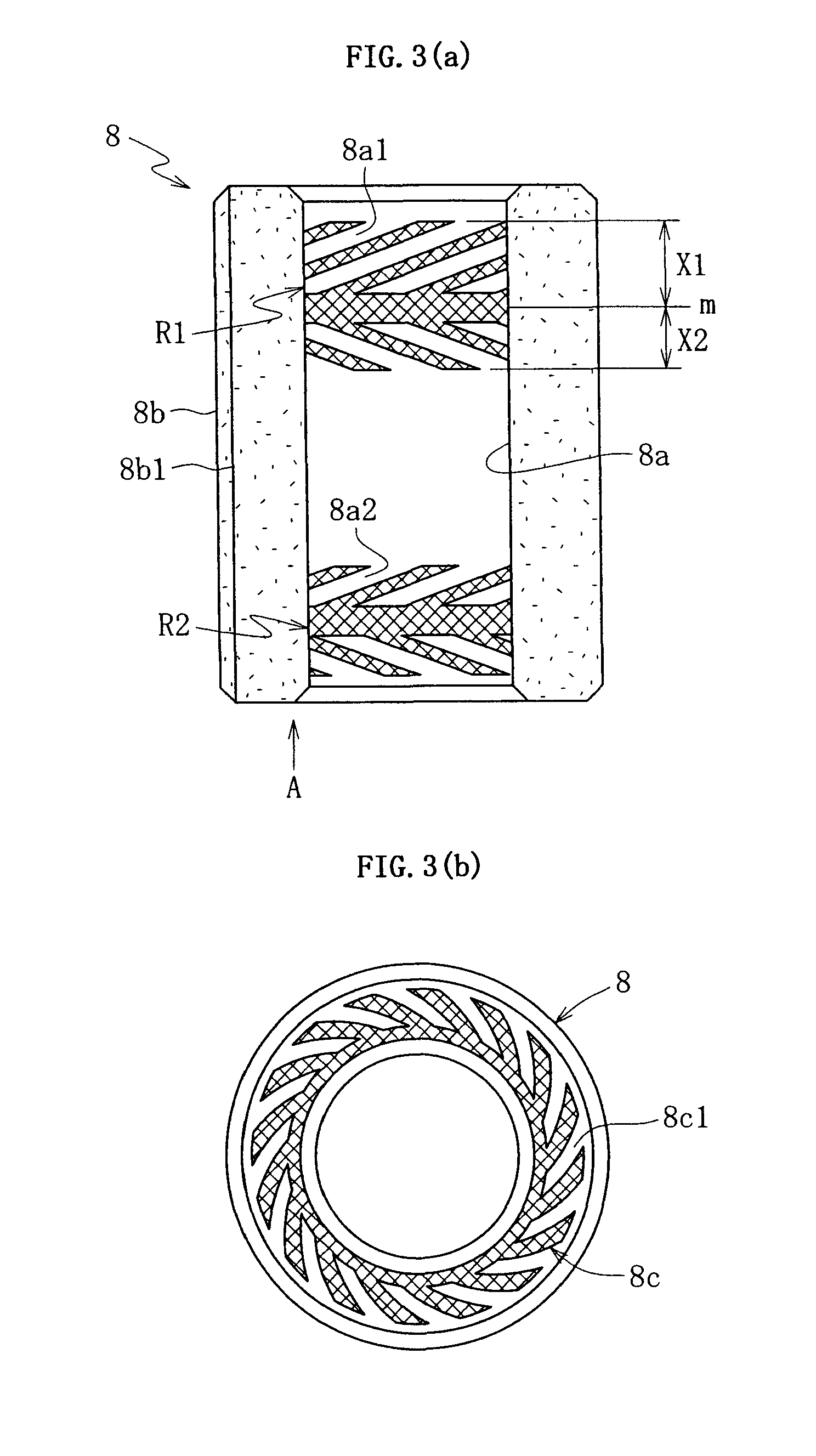

Dynamic Bearing Device

Disclosed is a dynamic bearing device which allows production of a smaller housing at low cost and which suppresses ion elution from the resin portion to thereby maintain cleanliness in the dynamic bearing device and exert a desired bearing performance. A dynamic bearing device 1 is equipped with a bearing sleeve 8 fixed to the inner periphery of the housing 7, and a rotary member rotatable relative to the bearing sleeve 8 and the housing 7, in which the rotary member is supported in the radial direction and the thrust direction in a non-contact manner by a dynamic pressure action of a lubricant fluid generated in a bearing clearance. The housing 7 is formed by injection molding of a resin composition containing polyphenylene sulfide (PPS) as the base resin and PAN type carbon fibers as a filler.

Owner:NTN CORP

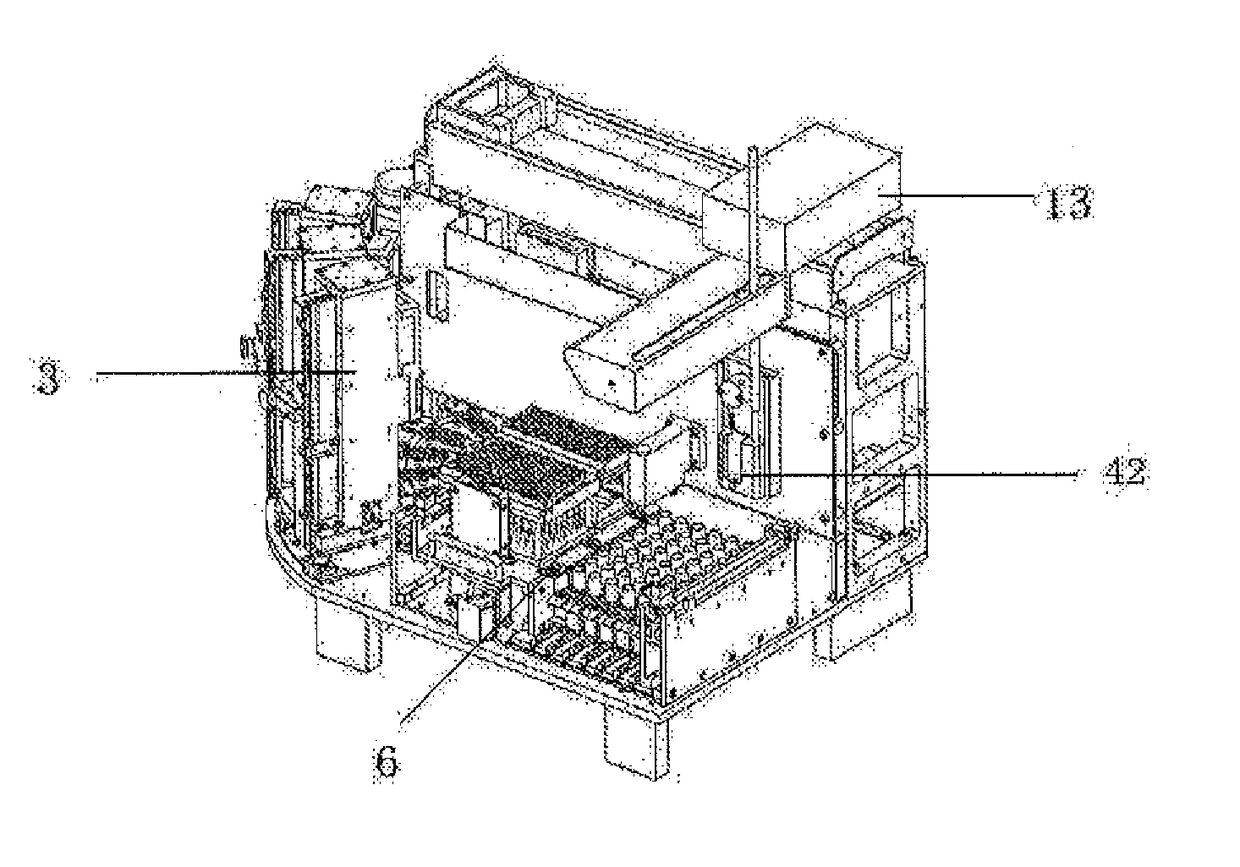

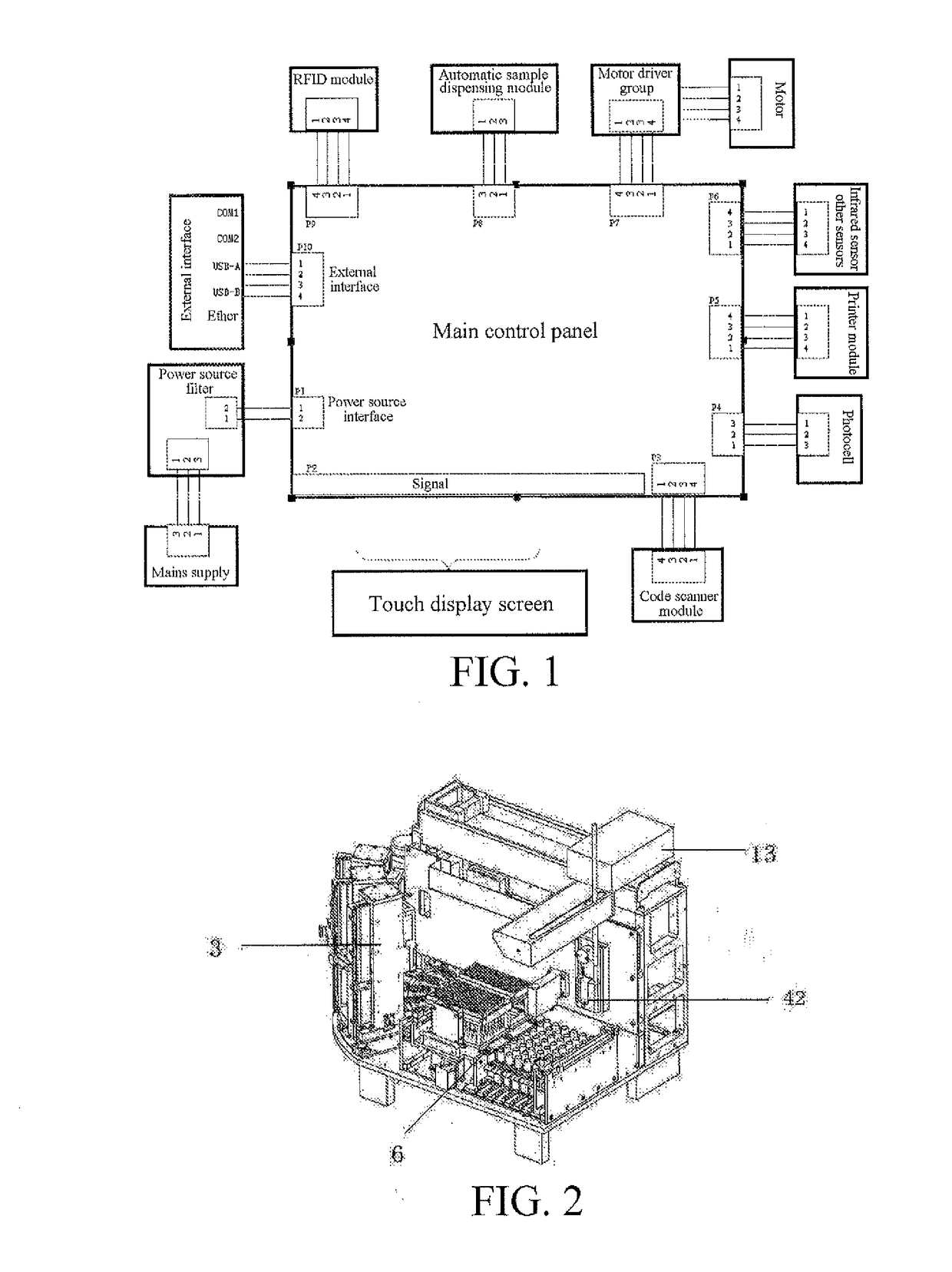

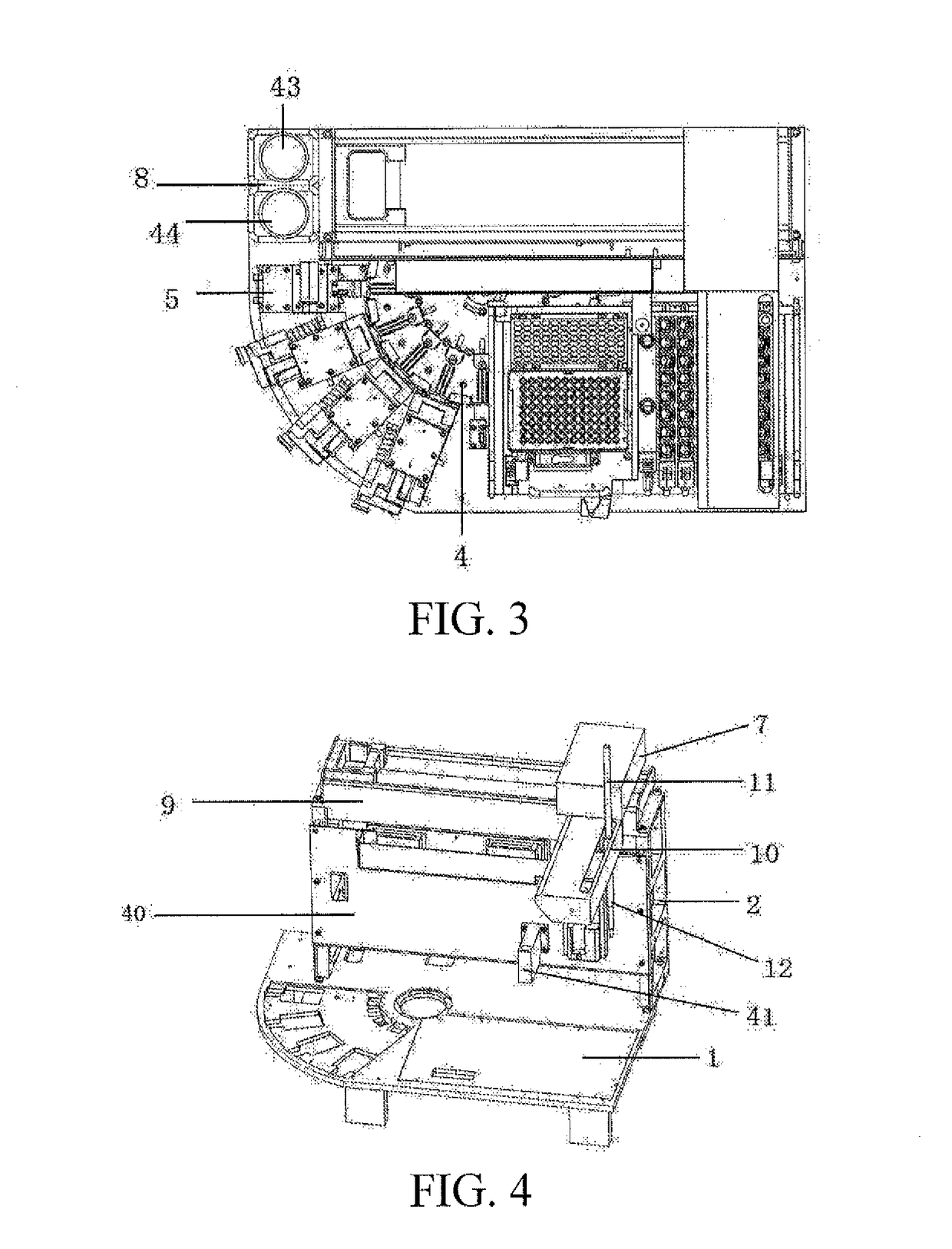

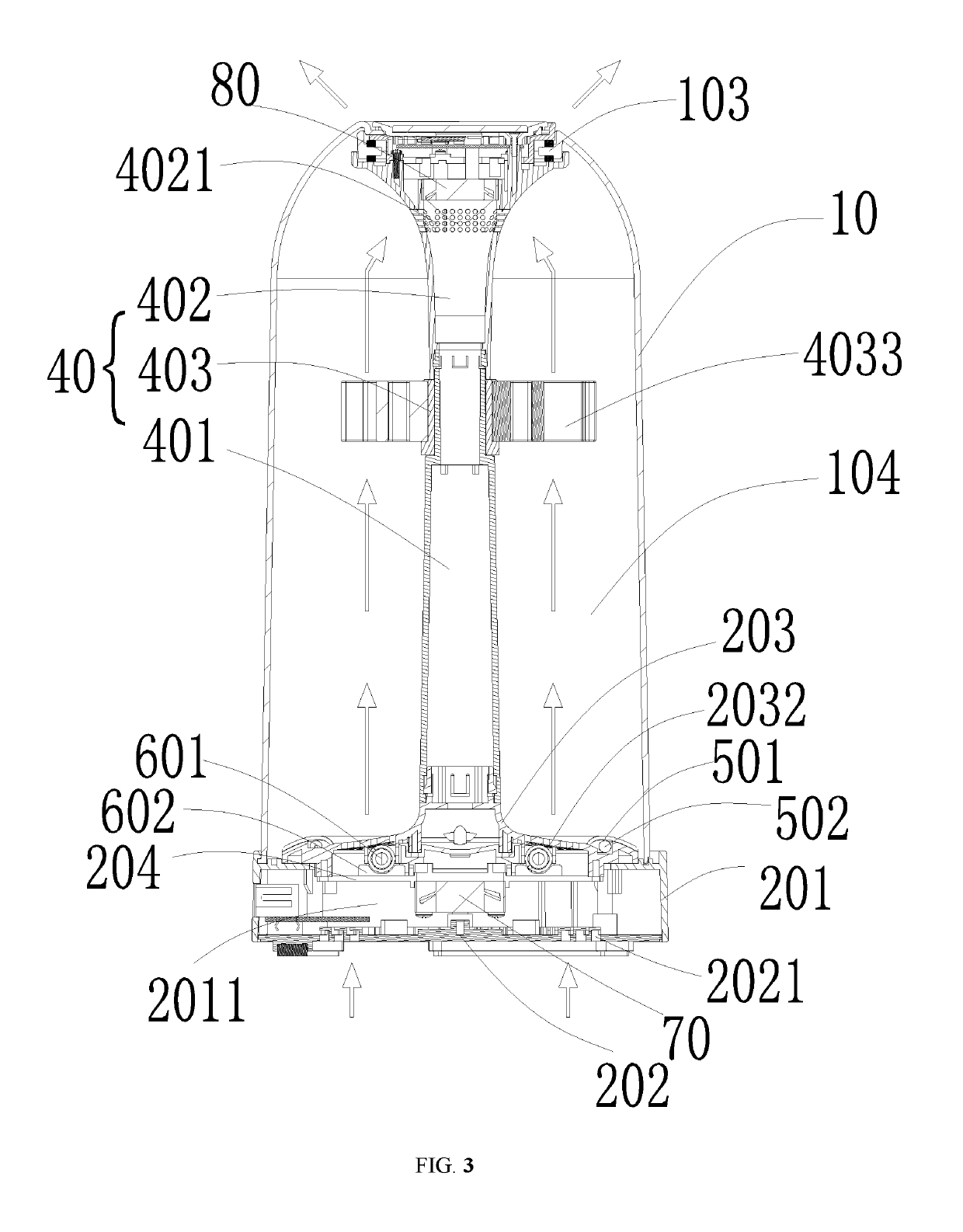

Fully-automatic immunofluorescence quantitative analysis apparatus and detection method

A fully-automatic immunofluorescence quantitative analyzing apparatus and detection method belong to the field of quantitative immunofluorescence analysis and detection. The immunity quantitative analyzing apparatus includes a support baseplate, a reagent strip storage and automatic loading module, a cuvette ring module, a detection module, a sample module, a sample dispensing module, a washing module and a control system, the reagent strip storage and automatic loading module, the cuvette ring module, the detection module, the sample module, the sample dispensing module, the washing module being sequentially arranged on the support baseplate. The reagent strip storage and automatic loading module provides a reagent strip for the cuvette ring module, and the sample dispensing module dispenses the sample on the sample module to the cuvette ring module and performs a reaction, and the sample enters the detection module to complete the detection after the reaction is complete.

Owner:GETEIN BIOTECH

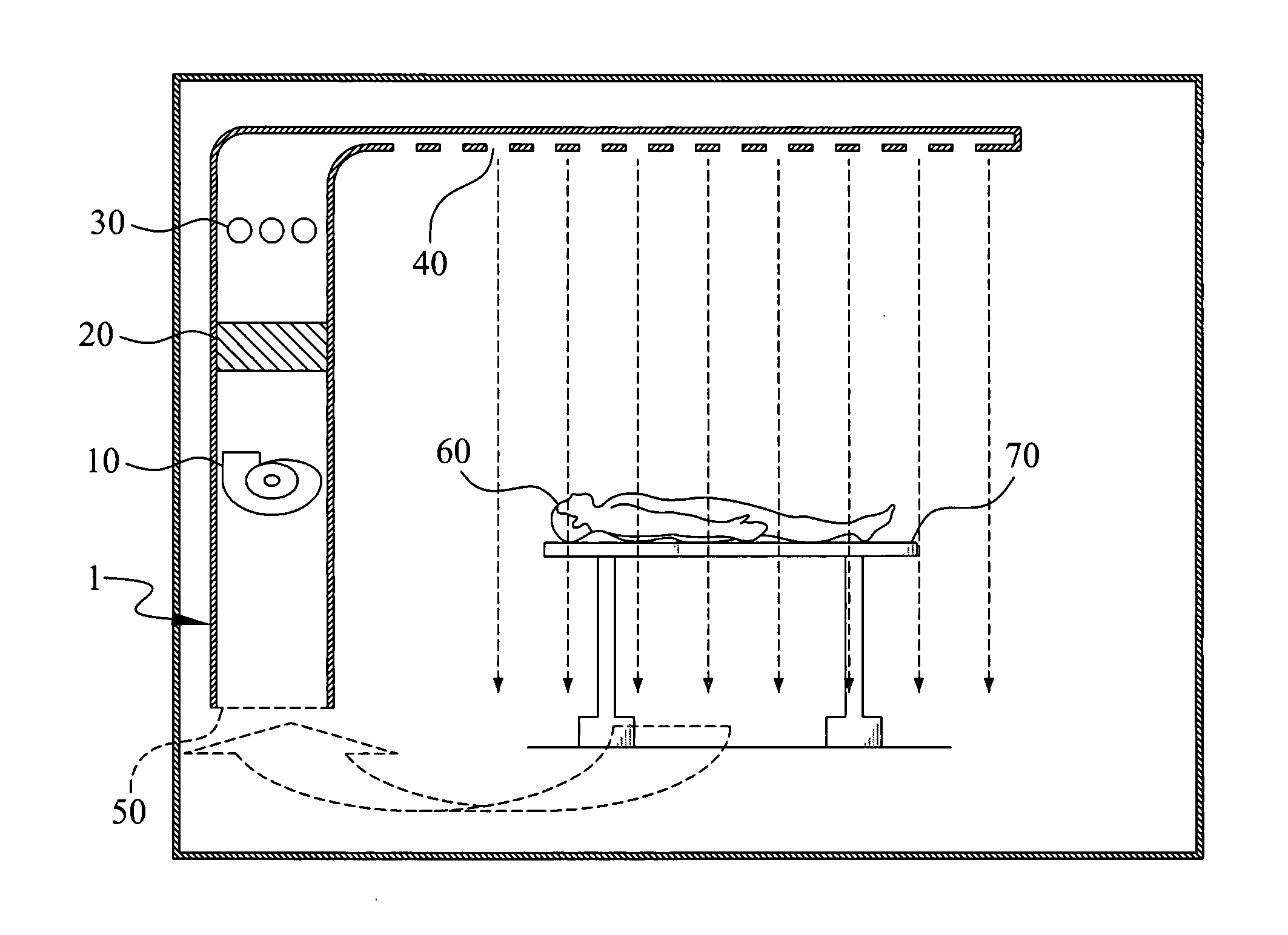

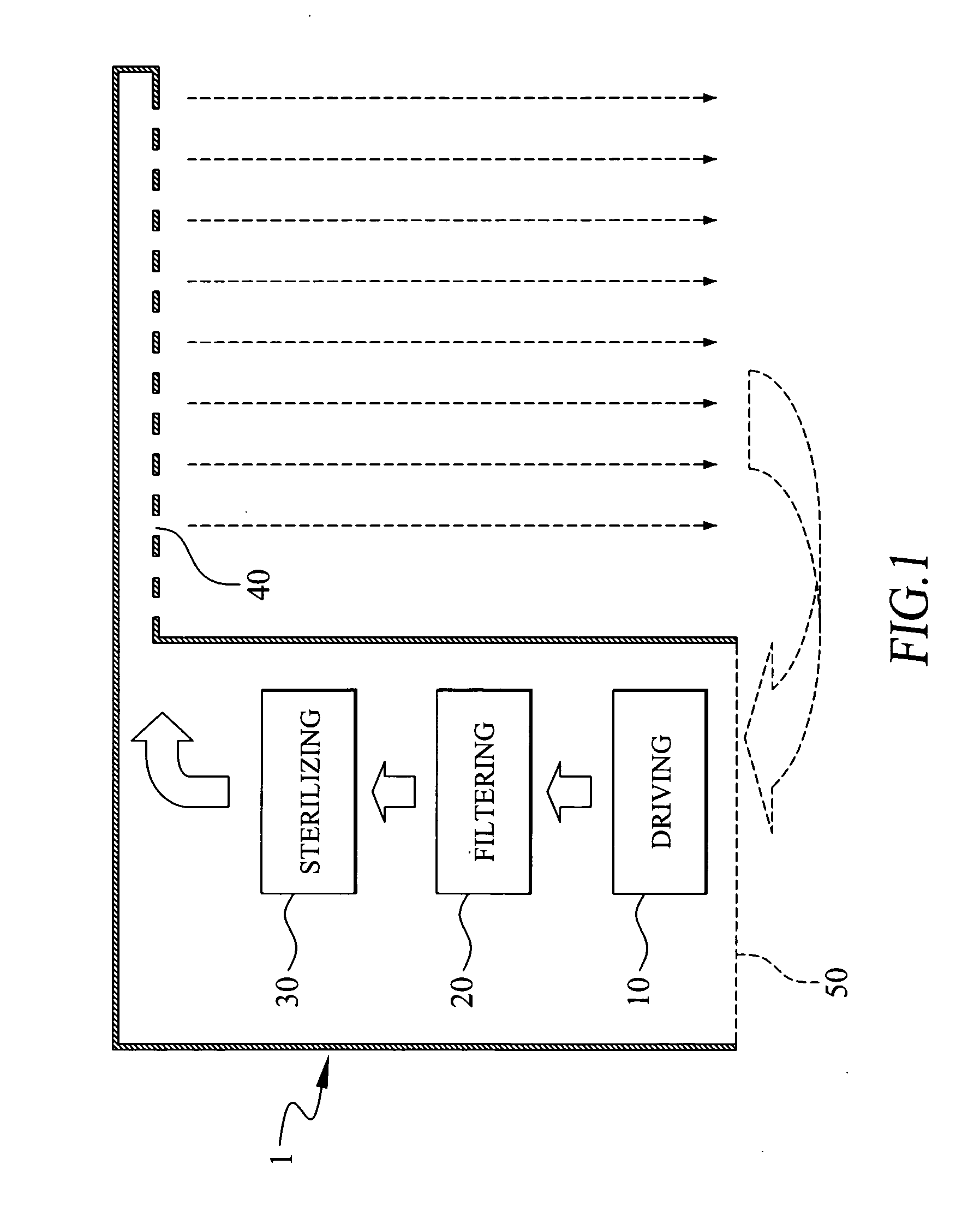

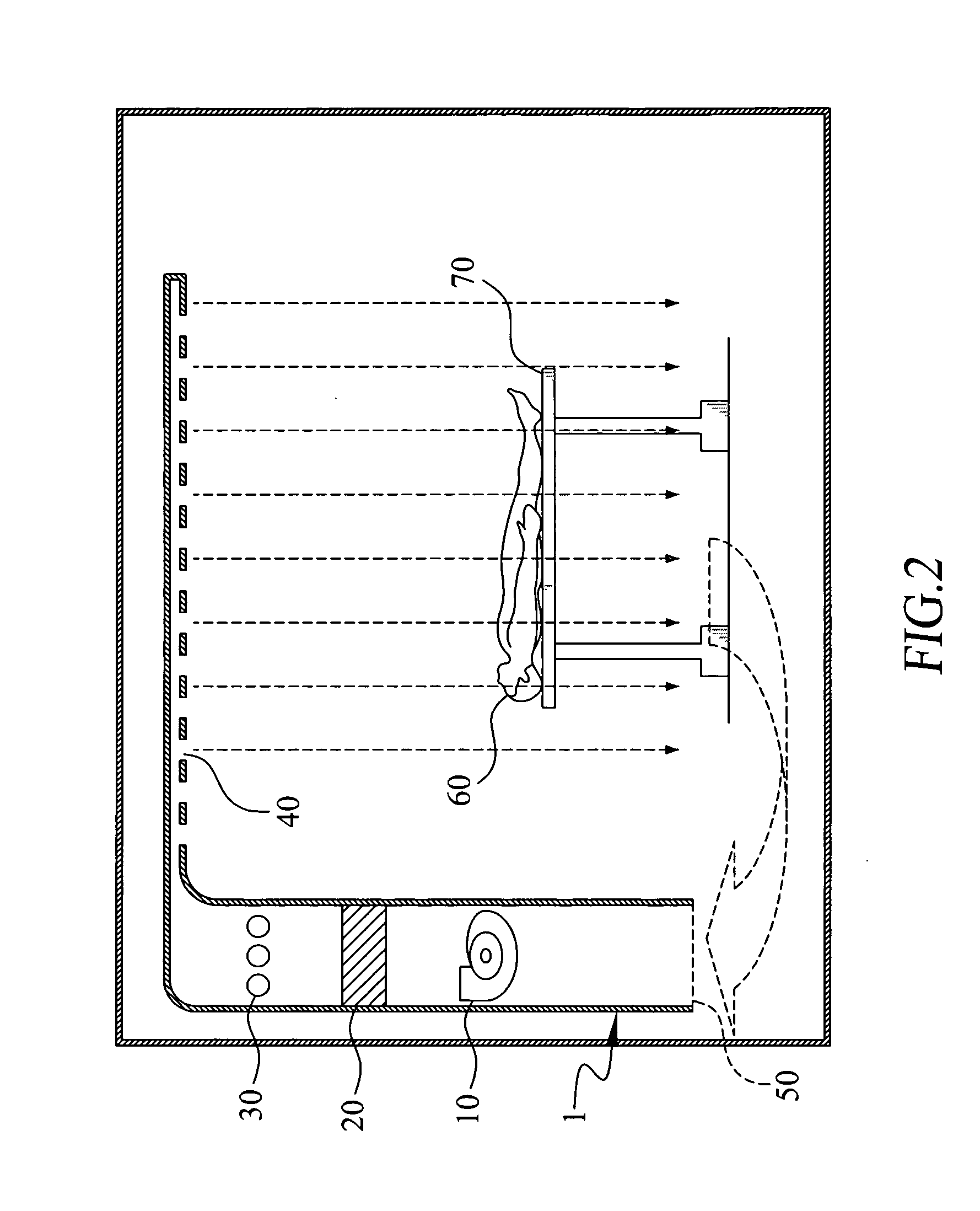

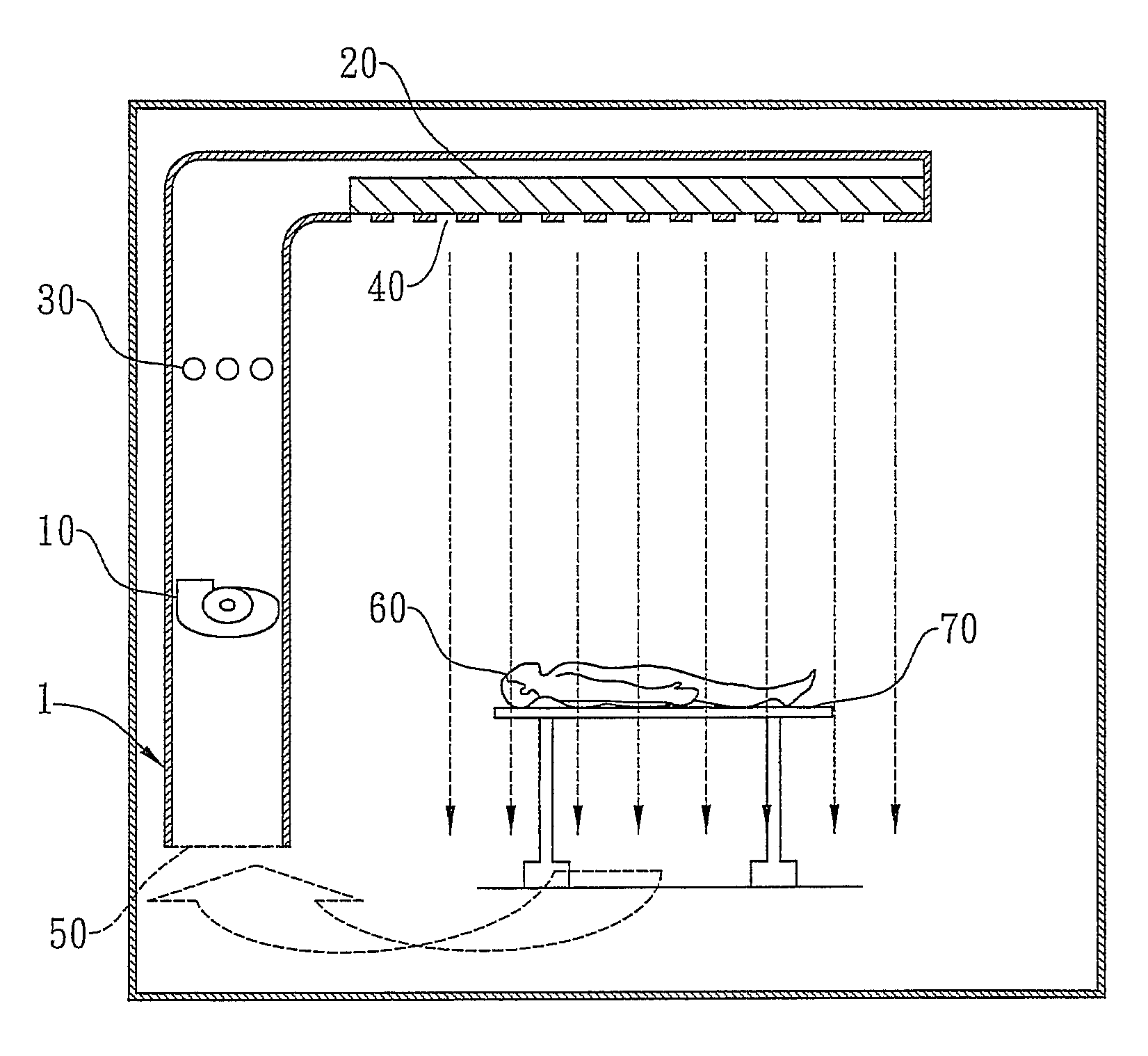

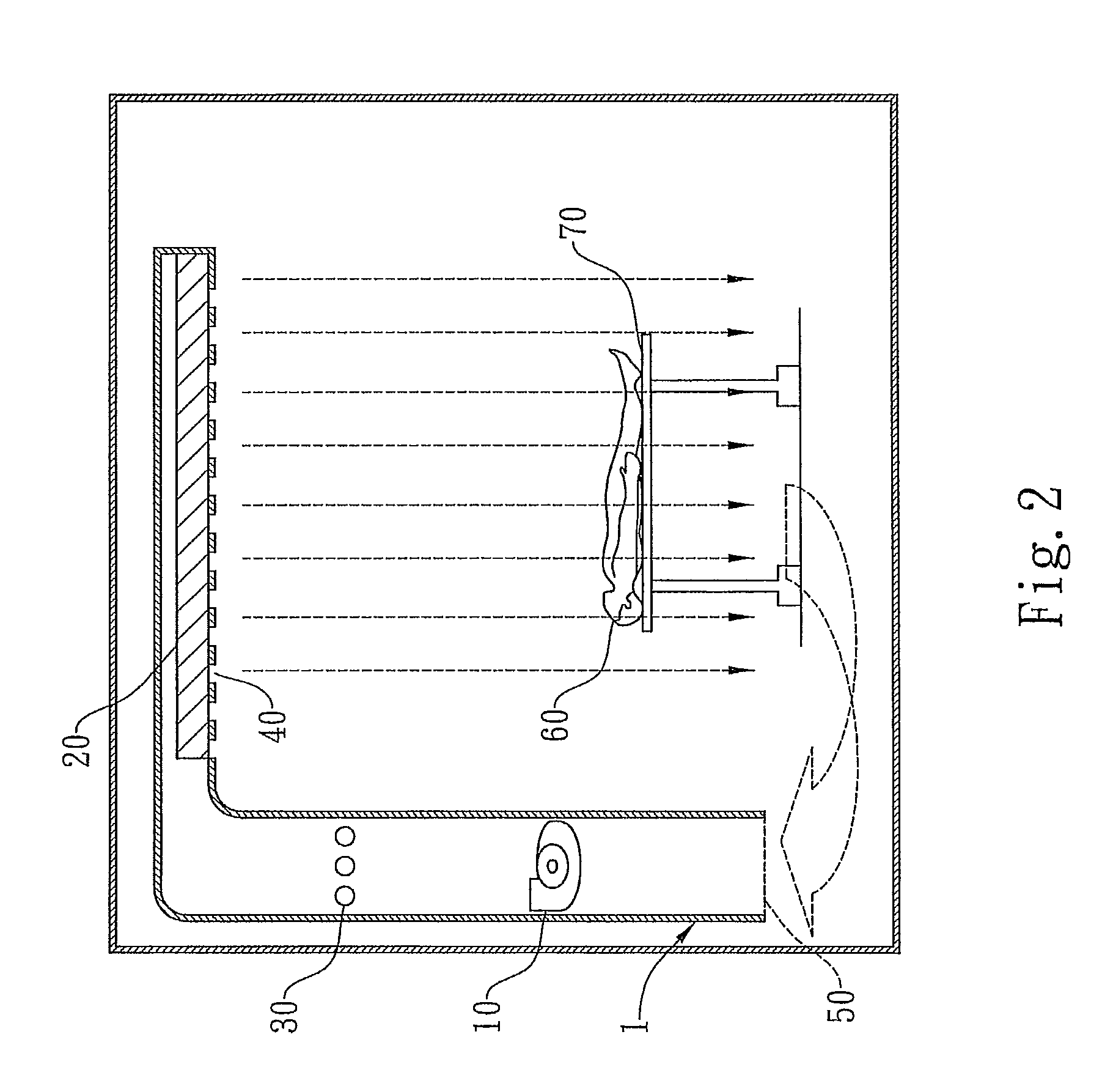

Medical mini-environment device

InactiveUS20070042702A1Assure air qualityAssure cleanlinessGas treatmentMechanical apparatusBiomedical engineeringMedical treatment

Owner:IND TECH RES INST

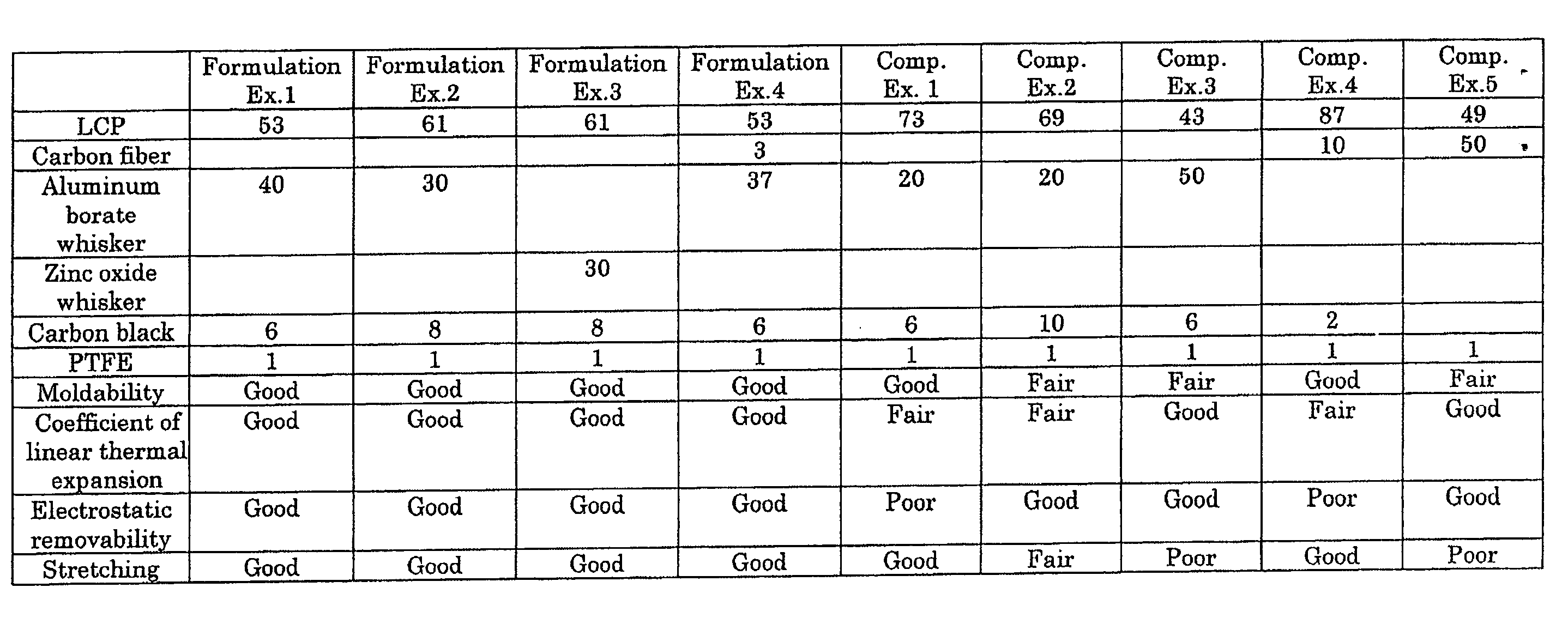

Hydrodynamic bearing unit

ActiveUS20090034888A1High oil resistanceLow outgassing propertyShaftsRecord information storageEngineeringHigh resistance

A housing for a hydrodynamic bearing unit of this type is formed from a resin material having high oil resistance and low outgassing property to ensure the cleanliness of the bearing unit. An ester-based lubricating oil is used as a lubricating oil filled inside the hydrodynamic bearing unit 1, and the housing 7 is formed from an LCP-based resin material.

Owner:NTN CORP +1

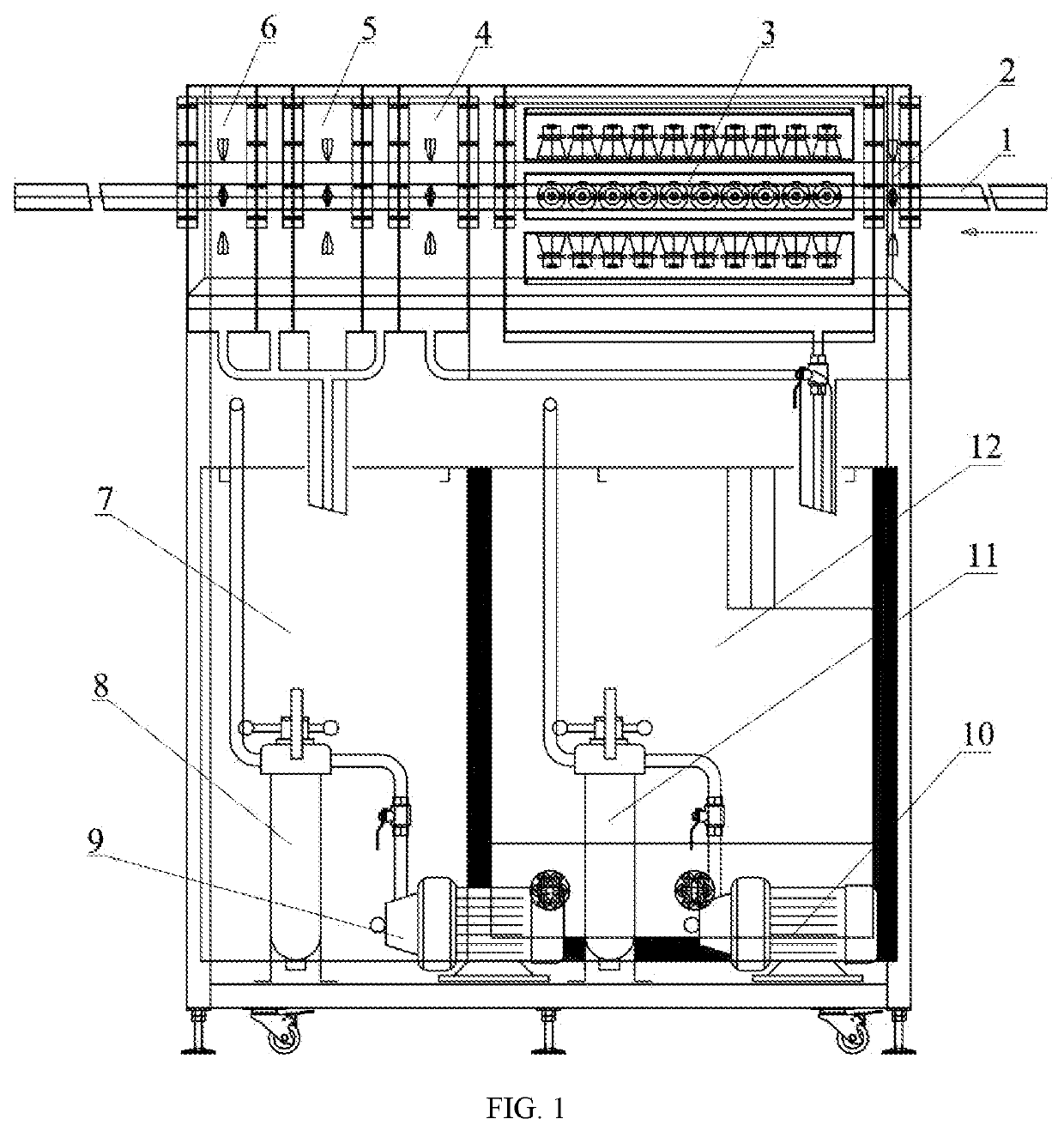

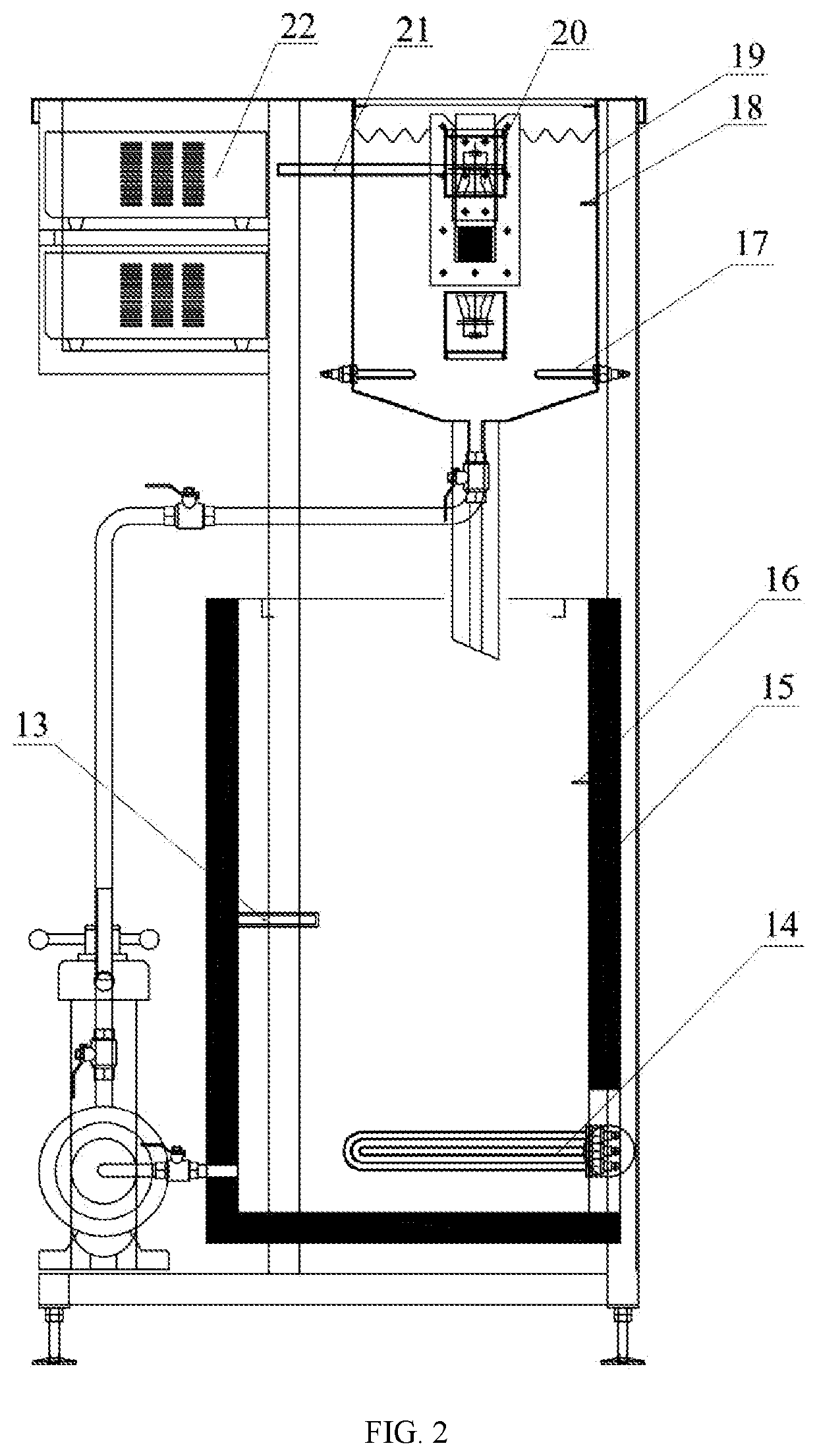

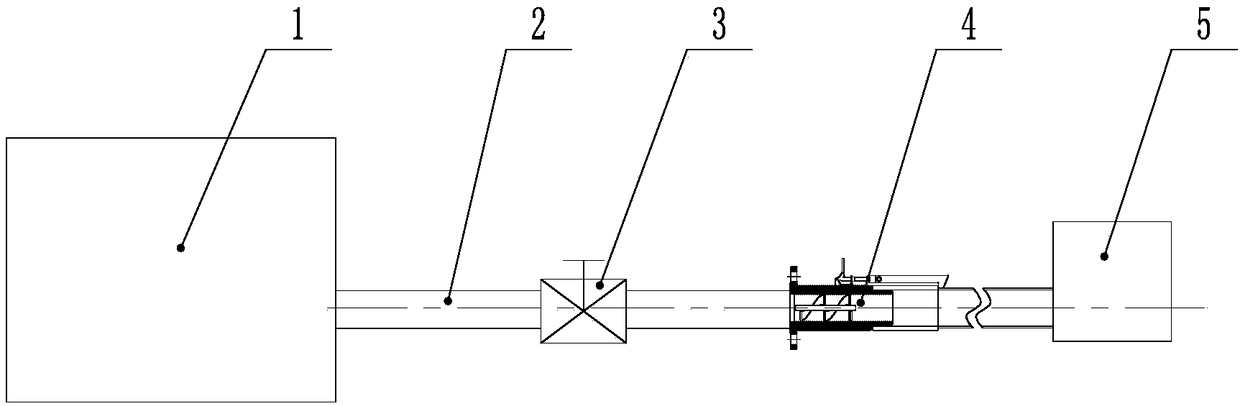

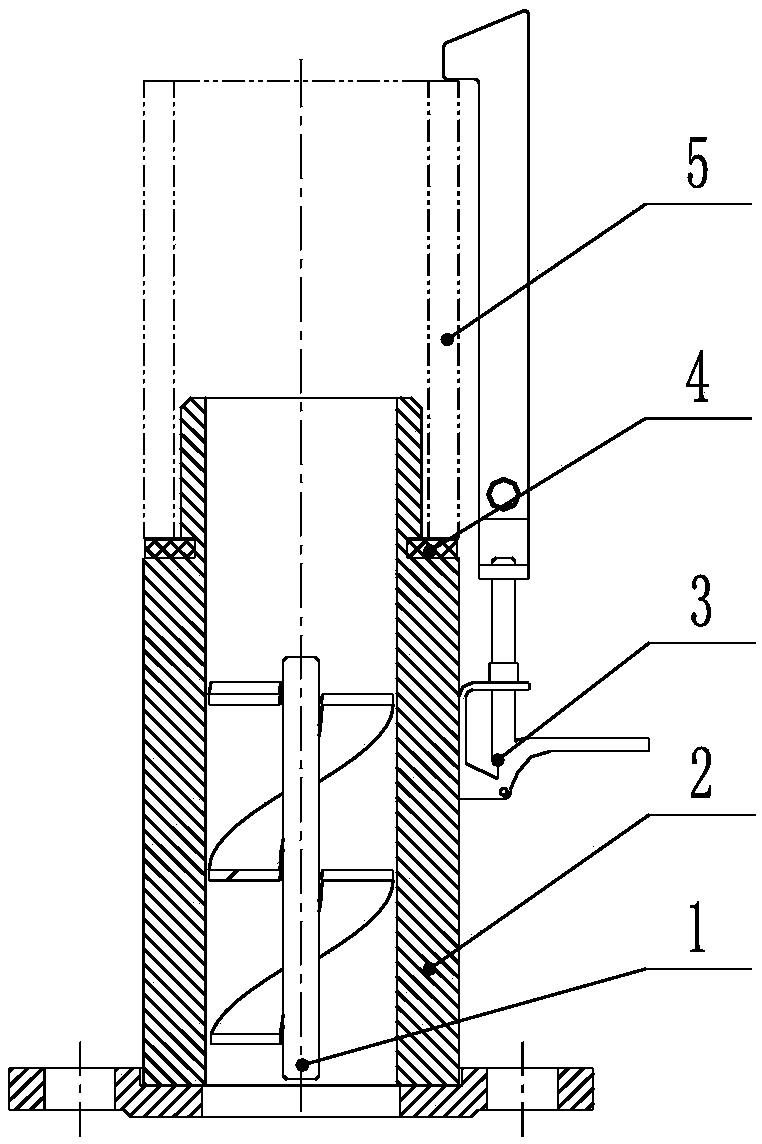

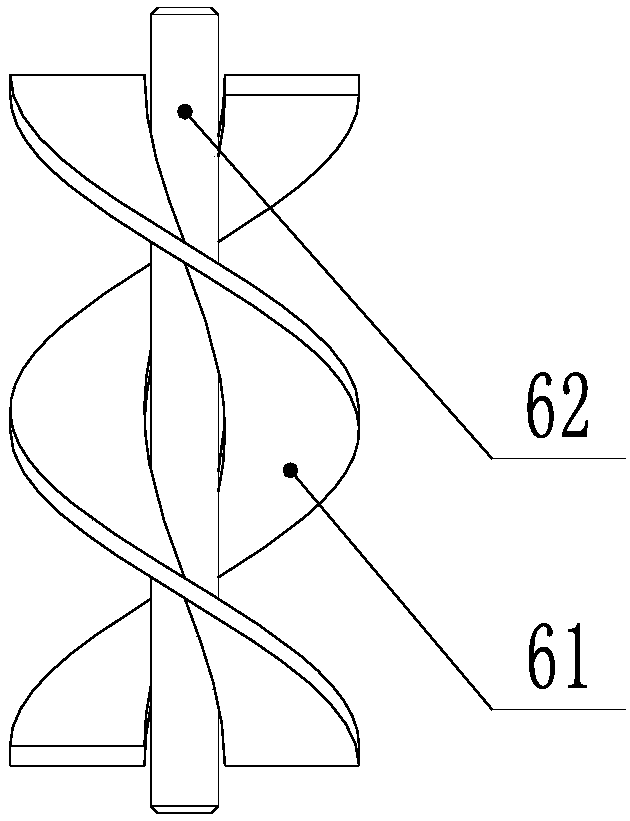

Feed-through ultrasonic cleaning system for winding of large-sized superconducting coils

ActiveUS20190366392A1Ensure cleanlinessQuality improvementDrying solid materials with heatDrying gas arrangementsSuperconducting CoilsAutomatic control

A feed-through ultrasonic cleaning system for winding of a large-sized superconducting coil, including a sealed chamber system, a main ultrasonic cleaning system, a deionized water spraying system, a compressed air blow-drying system, an automatic control system. During the winding of an armored superconducting coil, a superconducting conductor which is fed at a constant speed successively passes through a sealed chamber, an ultrasonic cleaning chamber, a first compressed air blow-drying chamber, a deionized water spray chamber, and a second compressed air blow-drying chamber in the ultrasonic cleaning system. By integrating mechanical dynamic sealing, ultrasonic cleaning and automatic control, the present invention meets a special requirement of removing oil and completely cleaning the conductor during the winding of large-sized superconducting coils.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

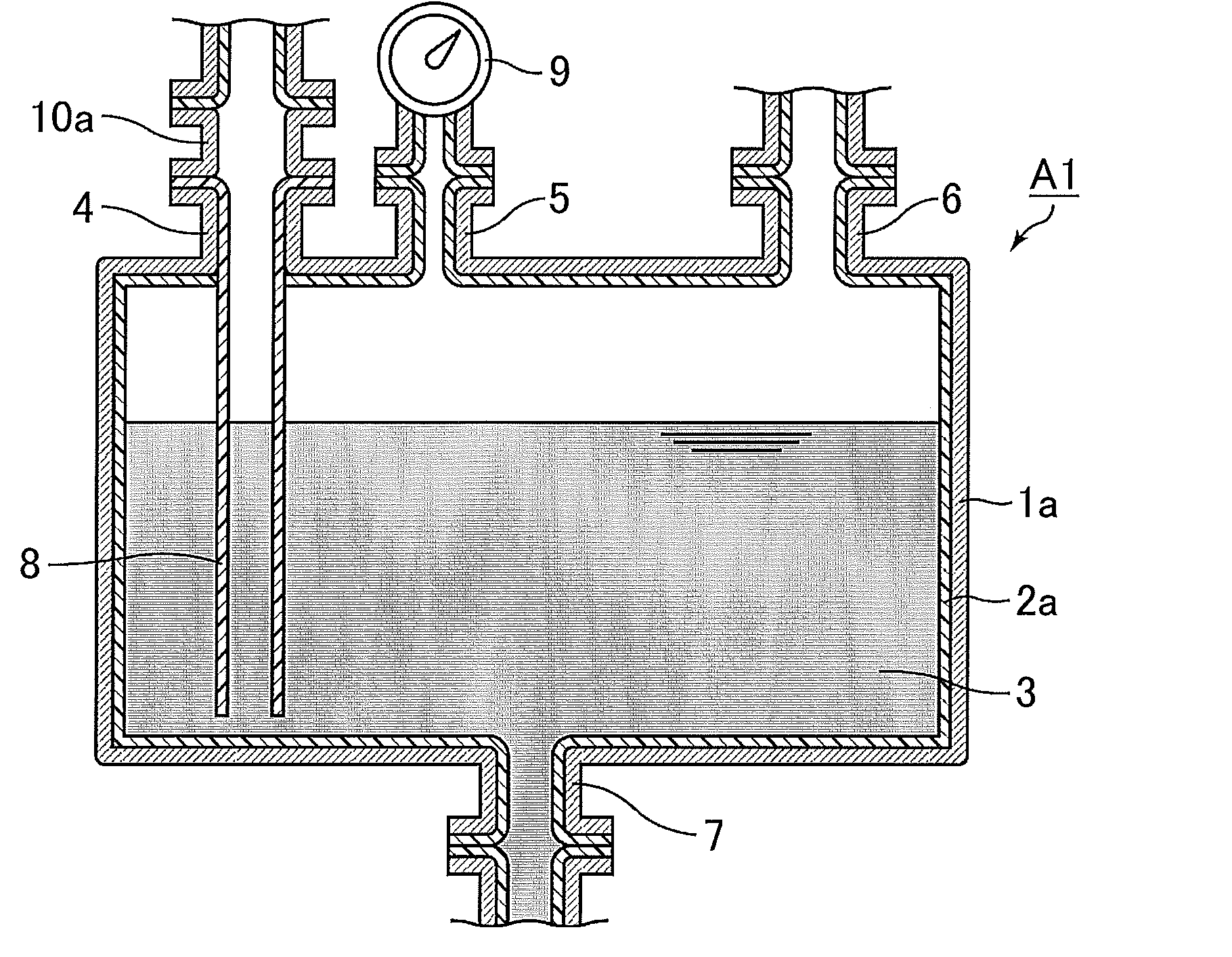

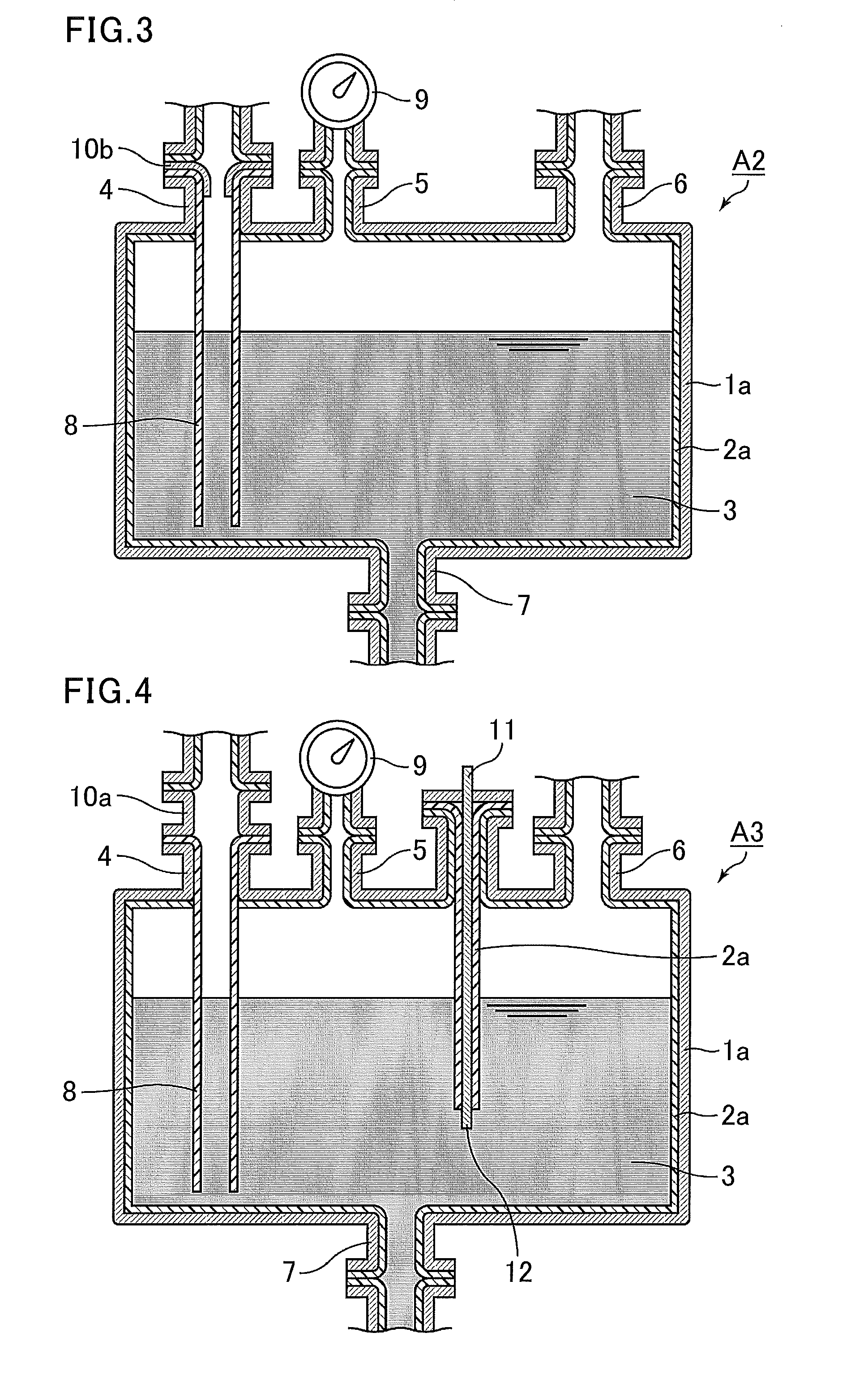

Pressure feed container, storage method using the pressure feed container, and method for transferring liquid using the pressure feed container

InactiveUS20140339321A1Ensure thorough cleaningSuppress electrostatic chargeWatering devicesSemiconductor/solid-state device manufacturingWaferingOrganosolv

The present invention provides a pressure feed container capable of ensuring the cleanliness of a liquid such as a protective film-forming liquid chemical or a protective film-forming liquid chemical kit for preparing the liquid chemical even after long-term storage, and also capable of suppressing electrostatic charge in the liquid. The present invention provides a pressure feed container configured to store a protective film-forming liquid chemical or a protective film-forming liquid chemical kit that is mixed into the protective film-forming liquid chemical, and to transfer a liquid upon application of pressure to the inside of the container, the protective film-forming liquid chemical being for forming a water-repellent protective film on at least surfaces of recessed portions of an uneven pattern formed on a surface of a wafer containing a silicon element at least at a part of the uneven pattern. The protective film-forming liquid chemical contains a nonaqueous organic solvent, a silylation agent, and an acid or a base; the protective film-forming liquid chemical kit includes a treatment liquid A containing a nonaqueous organic solvent and a silylation agent, and a treatment liquid B containing a nonaqueous organic solvent and an acid or a base; the pressure feed container includes a container body configured to contain a liquid selected from the protective film-forming liquid chemical, the treatment liquid A, and the treatment liquid B, and a liquid flowing nozzle configured such that the liquid flows therethrough to be introduced into the container body and / or to be extracted from the container body; the container body includes a metal can body in which a portion configured to contact the liquid is formed from a resin material; the liquid flowing nozzle is provided with a neutralization mechanism configured to reduce electrostatic potential in the liquid; and a liquid contact portion of the liquid flowing nozzle excluding the neutralization mechanism is formed from a resin material.

Owner:CENT GLASS CO LTD

Medical mini-environment device

InactiveUS20100003912A1Eliminating germs in the airQuality assuranceGas treatmentMechanical apparatusBiomedical engineeringMedical treatment

Owner:IND TECH RES INST

Oil pipe inner wall cleaning device and method

PendingCN108212959ASolve cleaning problemsEasy to replaceHollow article cleaningLocking mechanismAir compressor

The invention relates to an oil pipe inner wall cleaning device and method. The oil pipe inner wall cleaning device comprises an air compressor, an air supply hose, a switch valve, a quick inserting connector and a recovery device; an air compressor is connected with one end of the quick inserting connector through the air supply hose; the other end of the quick inserting connector is connected with an oil pipe connector; the recovery device is arranged at the end of a to-be-cleaned oil pipe; the air supply hose is provided with the switch valve; the quick inserting connector comprises a connector body, a locking mechanism and a flow guide structure; the flow guide structure is fixed into the connector body; the locking mechanism is fixed to the outer wall of the connector body; the frontsection of the connector body is provided with a fixing groove; and a sealing gasket is arranged in the fixing groove and located between the oil pipe connector and the connector body. The oil pipe inner wall cleaning device has the advantages that the oil pipe inner wall cleaning problem is solved, the construction period is short, the efficiency is high, the construction cost is reduced, and theeffect that cleaning work is completed within one minute is ensured.

Owner:LIAONING RUIFENG SPECIAL VEHICLE MFG

Housing for fluid lubrication bearing apparatuses

InactiveUS20100061669A1Avoid modificationAvoid deteriorationShaftsRotary machine partsFiberCarbon fibers

A housing for fluid lubrication bearing apparatuses having improved adhesiveness with other components is provided at low costs.A housing 7 constituting a fluid lubrication bearing apparatus 1 was formed of a resin composition comprising polyphenylene sulfide (PPS) as a base resin, and the ratio of the base resin added to the resin composition was set to not lower than 40 vol % but not higher than 70 vol %. Moreover, a composition prepared by adding an epoxy compound having two or more epoxy groups per molecule of the compound and epoxy value of 0.5 meq / g or more to the resin composition so that the amount of epoxy groups in the resin composition is 8 meq / 100 g or more was used. A carbon fiber was added to the resin composition comprising the base resin in an amount of not less than 10 vol % but not more than 35 vol %. An inorganic compound was further added to the resin composition comprising the base resin and carbon fiber so that the inorganic compound makes up the remainder of the base resin and carbon fiber in the resin composition.

Owner:NTN CORP

Cosmetic tool having antibacterial property and method for producing the same

InactiveUS20050244440A1Improve washabilityKeep widthAntibacterial agentsCosmetic preparationsFiberYarn

An antibacterial cosmetic tool is produced by soaking a base material selected from fiber, yarn, pile fabric, animal hair, wig material, polyurethane sponge and NBR sponge into an aqueous solution containing (A) benzyl ammonium chloride compound and (B) naphthoquinone compound, after which the solution is heated to cause 0.1 to 5.0 percent by weight of (A) benzyl ammonium chloride compound and 0.1 to 5.0 percent by weight of (B) naphthoquinone compound to be adsorbed / contained to / by the material.

Owner:NAKAMURA KENJI +1

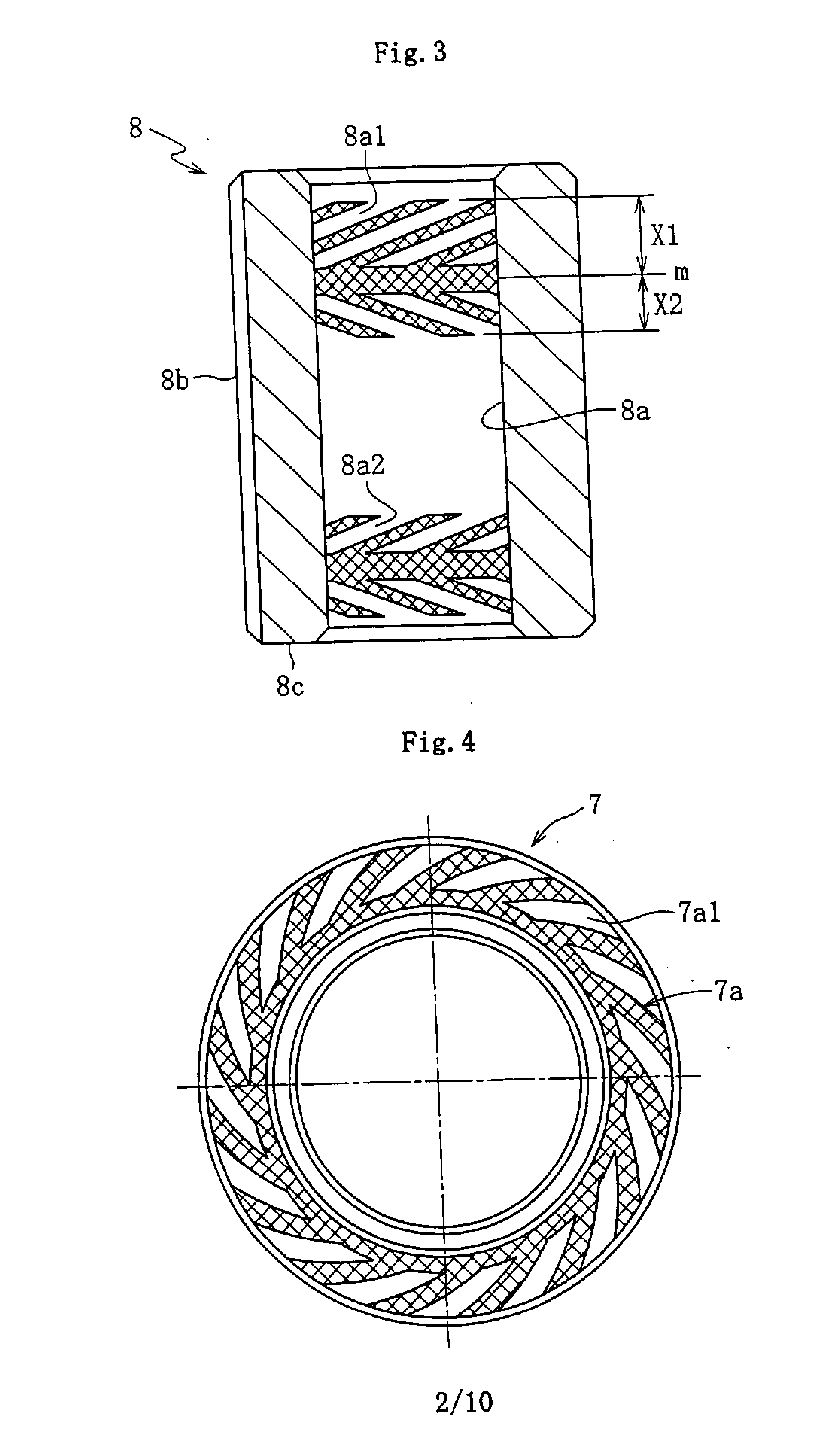

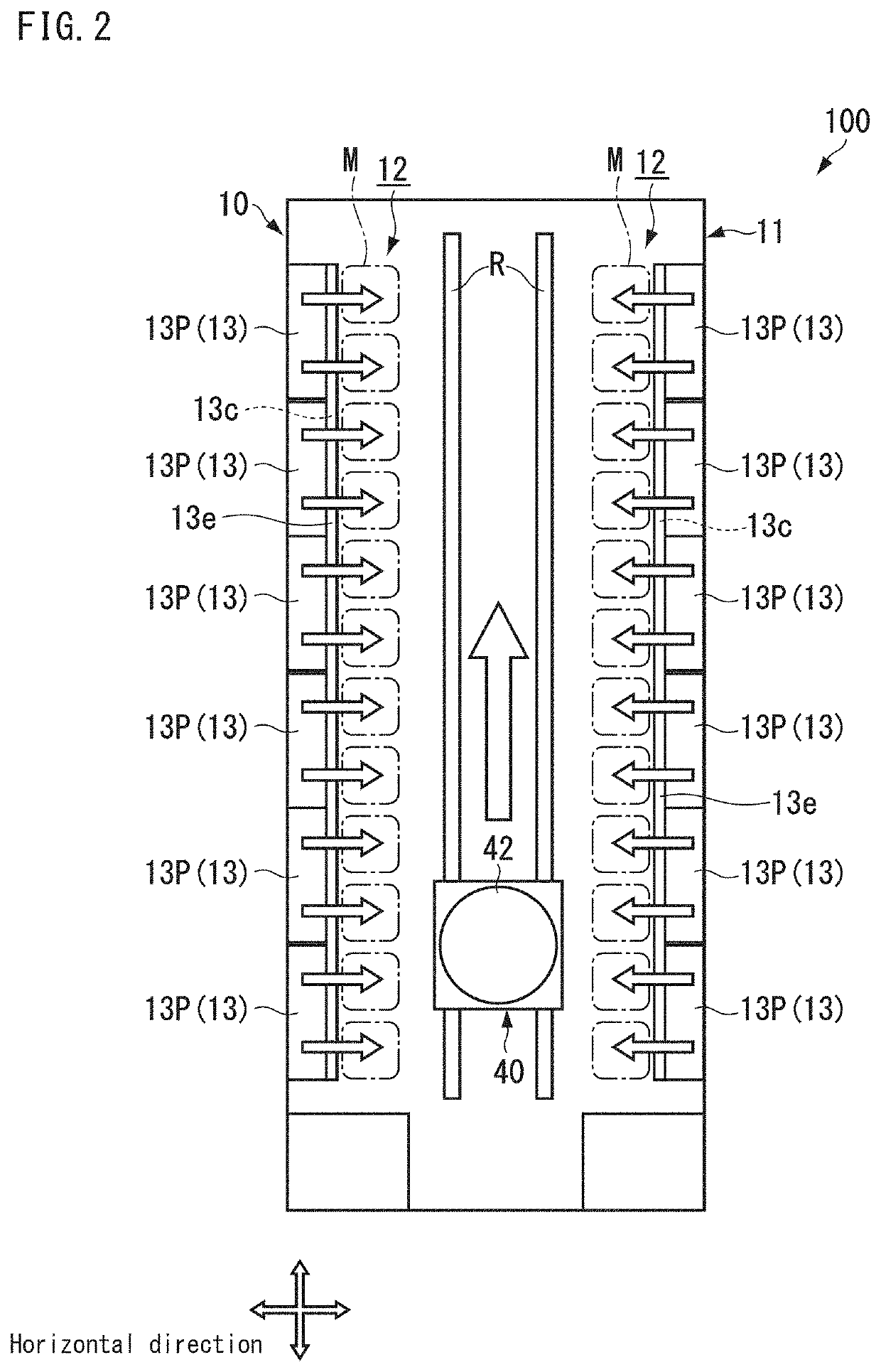

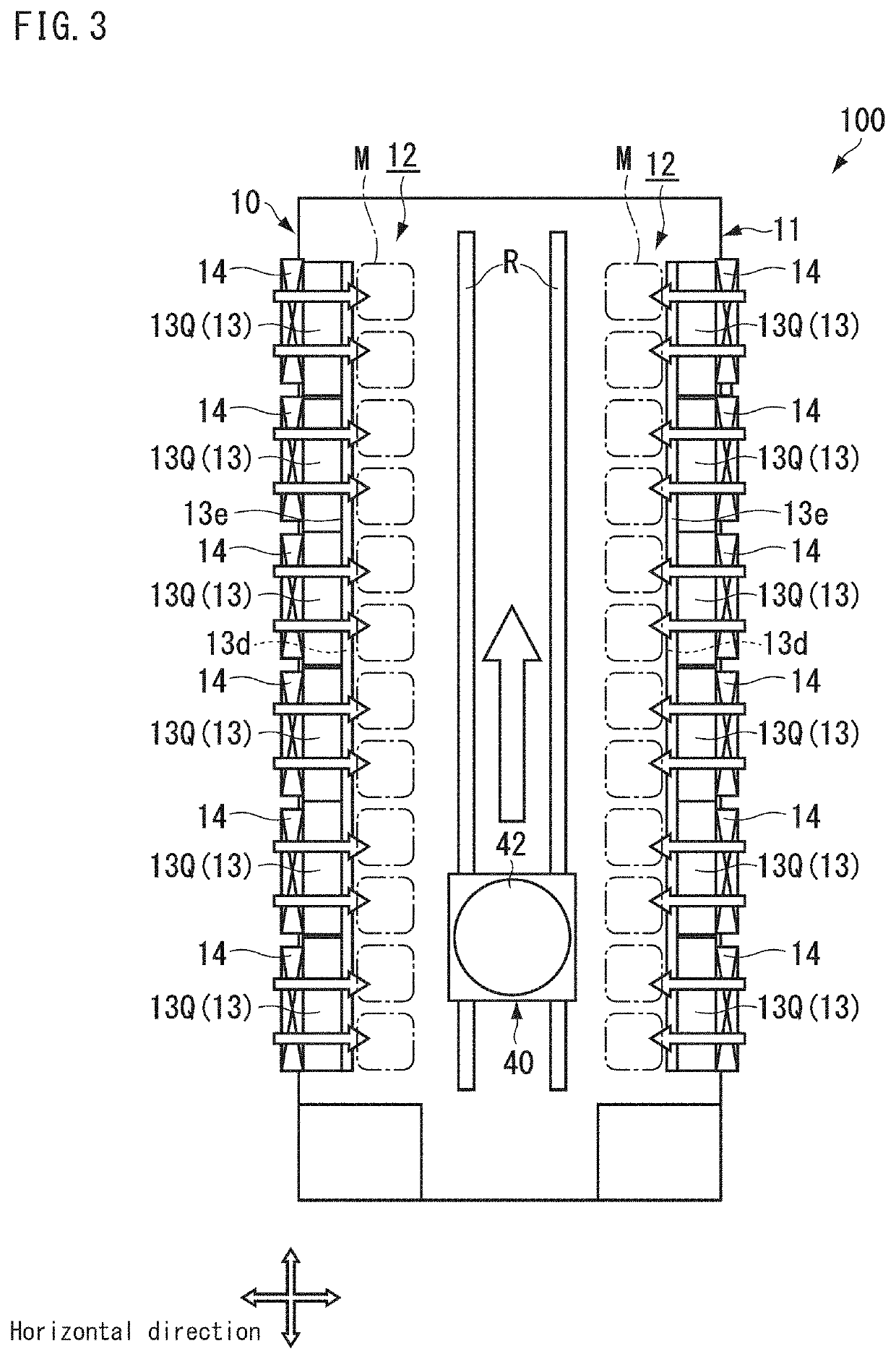

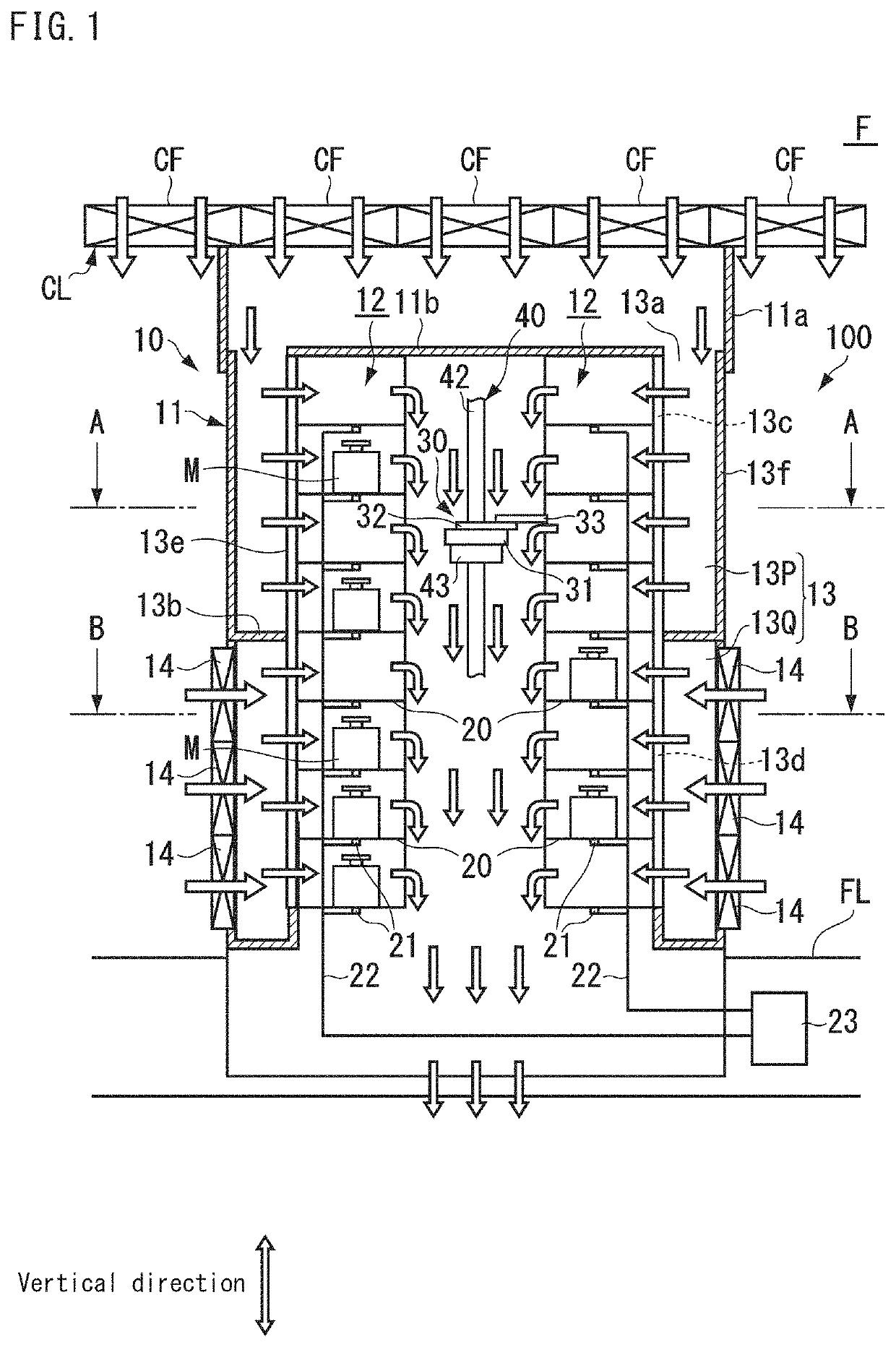

Stocker

ActiveUS20190375587A1Efficiently form in storageEasy maintenanceMechanical apparatusSemiconductor/solid-state device manufacturingEngineeringBlow out

A stocker includes a wall that separates inside and outside of the stocker, a storage area on an inner side of the wall to store articles, a duct on a wall side of the storage area and extending in a vertical direction, an inlet at an upper end of the duct to introduce air flowing downward into the duct, a flow regulator to regulate an airflow between an upper side and a lower side of the duct, blowout openings on a storage area side of the duct to blow out air to the storage area, and a fan on a lower side of the flow regulator of the duct to draw in outside air and introduce the outside air into the duct.

Owner:MURATA MASCH LTD

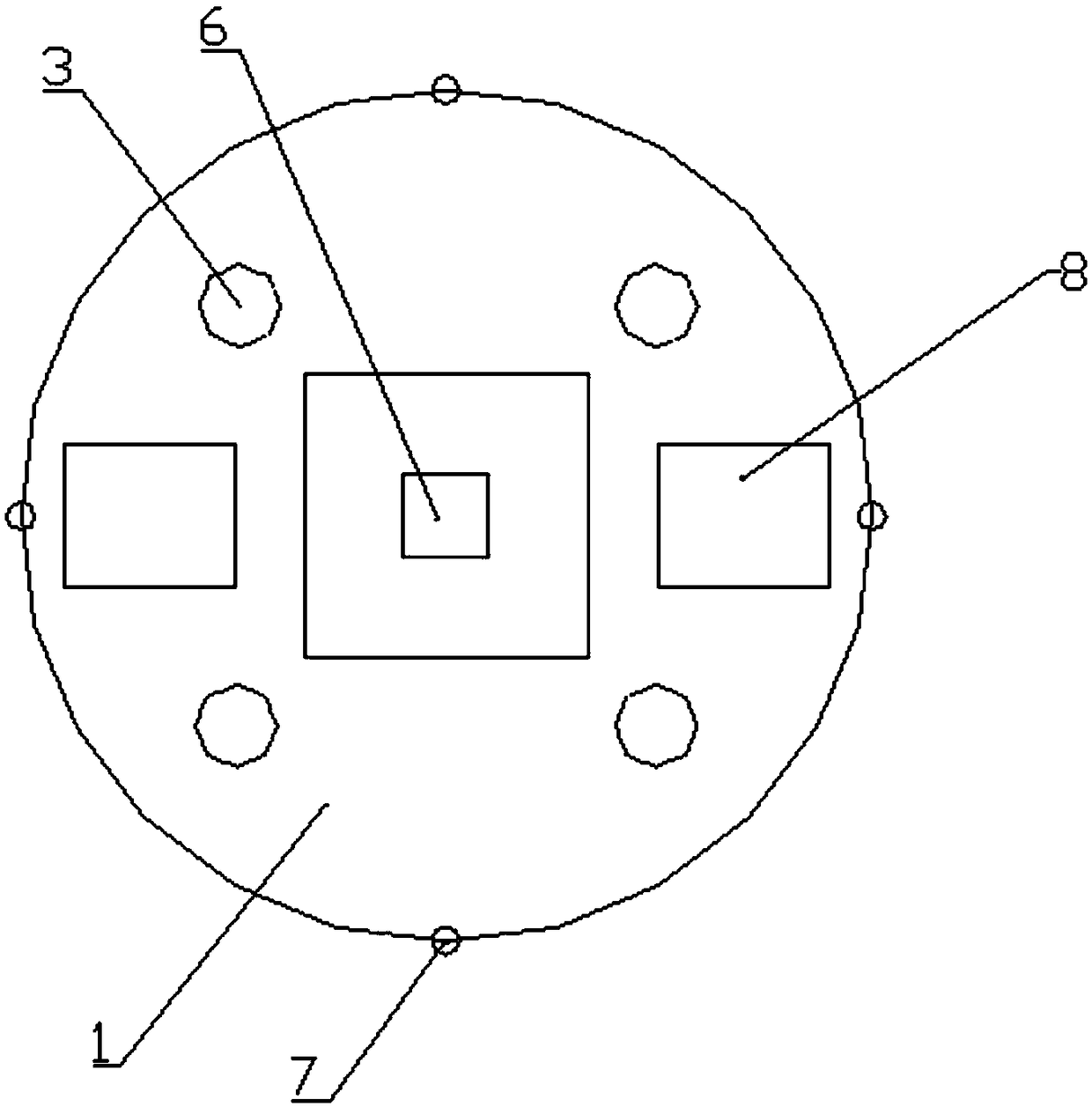

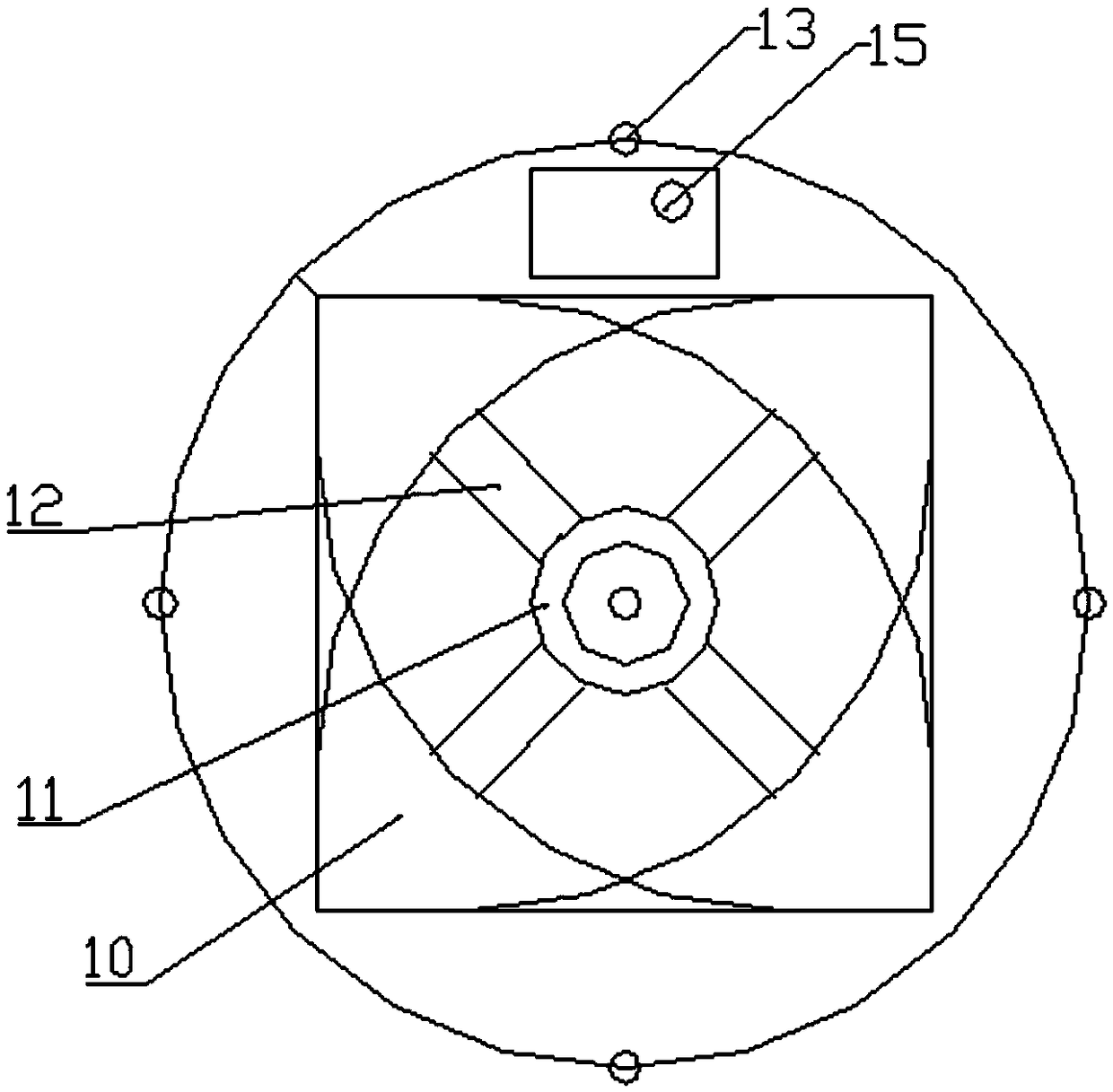

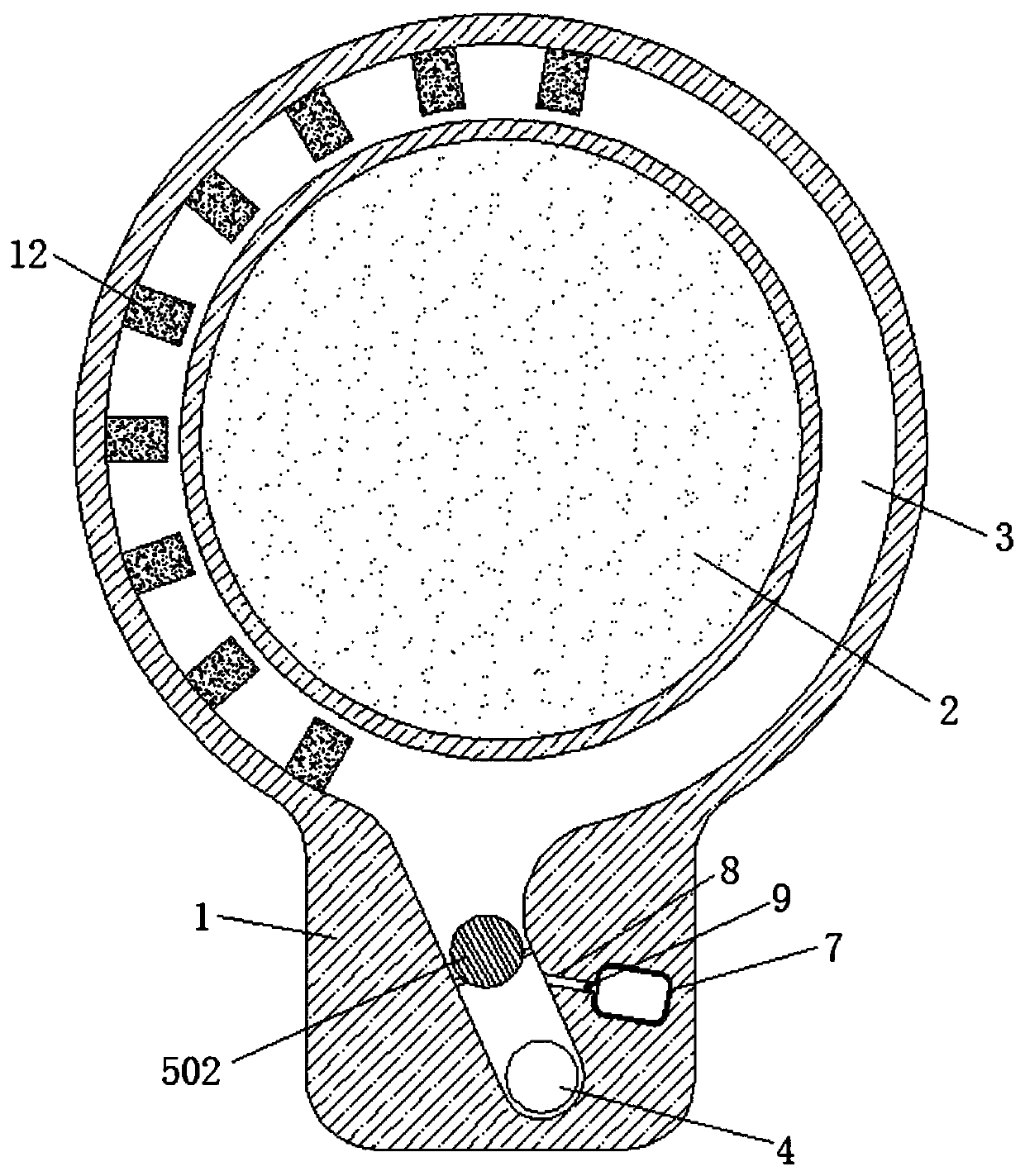

Window-wiping robot conducting blind-area-free cleaning on glass with border

ActiveCN109497883ATo achieve the purpose of cleaningSimple structureWindow cleanersMagnetic effectControl system

The invention provides a window-wiping robot conducting blind-area-free cleaning on glass with a border. The robot comprises a round active face embedded with permanent magnets, a round passive face controllable in form, having the initial form identical to the active face in size and embedded with permanent magnets, and a control system. The permanent magnets are uniformly distributed on two faces, so that the two faces are attracted to two sides of glass through a magnetic effect. The active face is a double-wheeled round body. The passive face comprises a round cleaning face, four irregularcleaning faces and a push-pull device. The round cleaning face is a bottom surface in contact with one side of the glass. Every two of the four irregular cleaning faces are symmetrically distributedwith the circle center of the round cleaning face, the two irregular cleaning faces with symmetrical diagonally are distributed in the same horizontal plane, and the two adjacent irregular cleaning faces are not located on the same horizontal plane. The robot can conduct blind-area-free cleaning on glass with the border, and the problem can be solved that the border and four corners cannot be wiped.

Owner:HEBEI UNIV OF TECH

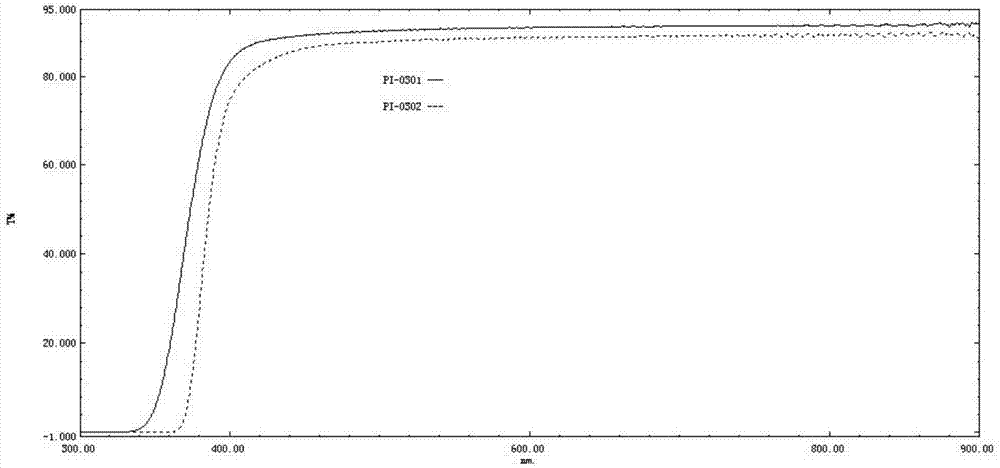

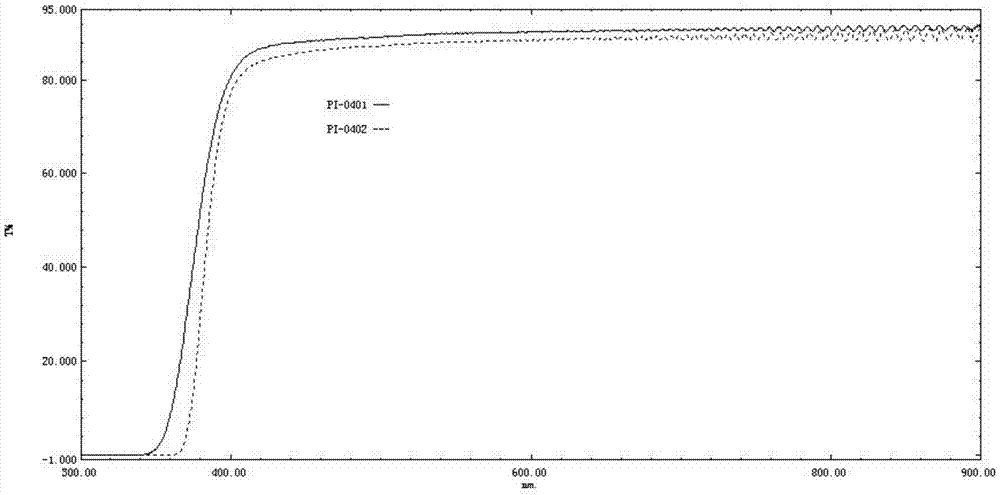

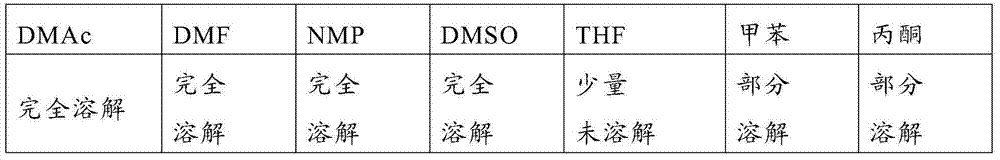

Preparation method of soluble polyimide resin

The invention provides a preparation method of soluble polyimide resin. The preparation method comprises the following steps: performing vacuum defoamation treatment on a polyimide solution; continuously extruding the polyimide solution after the vacuum defoamation treatment in a polar solvent, so as to obtain tow-shaped resin with a diameter of 0.01-0.05 mm; washing the tow-shaped resin with water and drying, so as to obtain a finished product of the soluble polyimide resin. According to the preparation method disclosed by the invention, the polyimide solution is not required to be diluted but directly extruded and molded to form the tow-shaped resin, so that the usage of an organic solvent can be reduced, the follow-up water washing and drying can be convenient, and the residues of an organic reagent and an inorganic salt can be less; secondly, the preparation method can be used for implementing continuous production, and the resin is high in yield and good in safety and industrial application; furthermore, as for the soluble polyimide resin for preparing a colorless transparent polyimide material, the preparation method ensures that the resin is thoroughly cleaned and the solvent is removed cleanly, so that the thin film prepared by the resin is higher in light transmittance.

Owner:长春聚明光电材料有限公司 +2

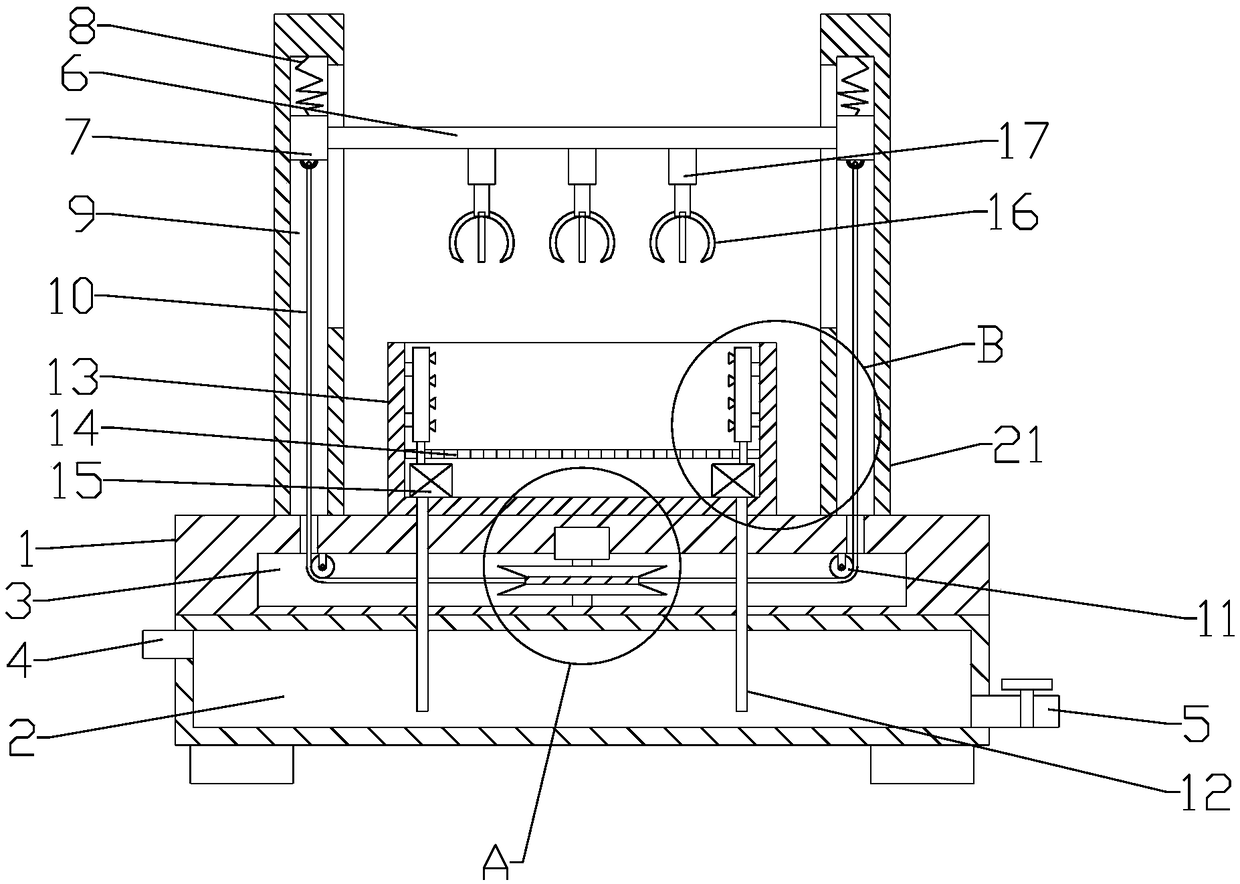

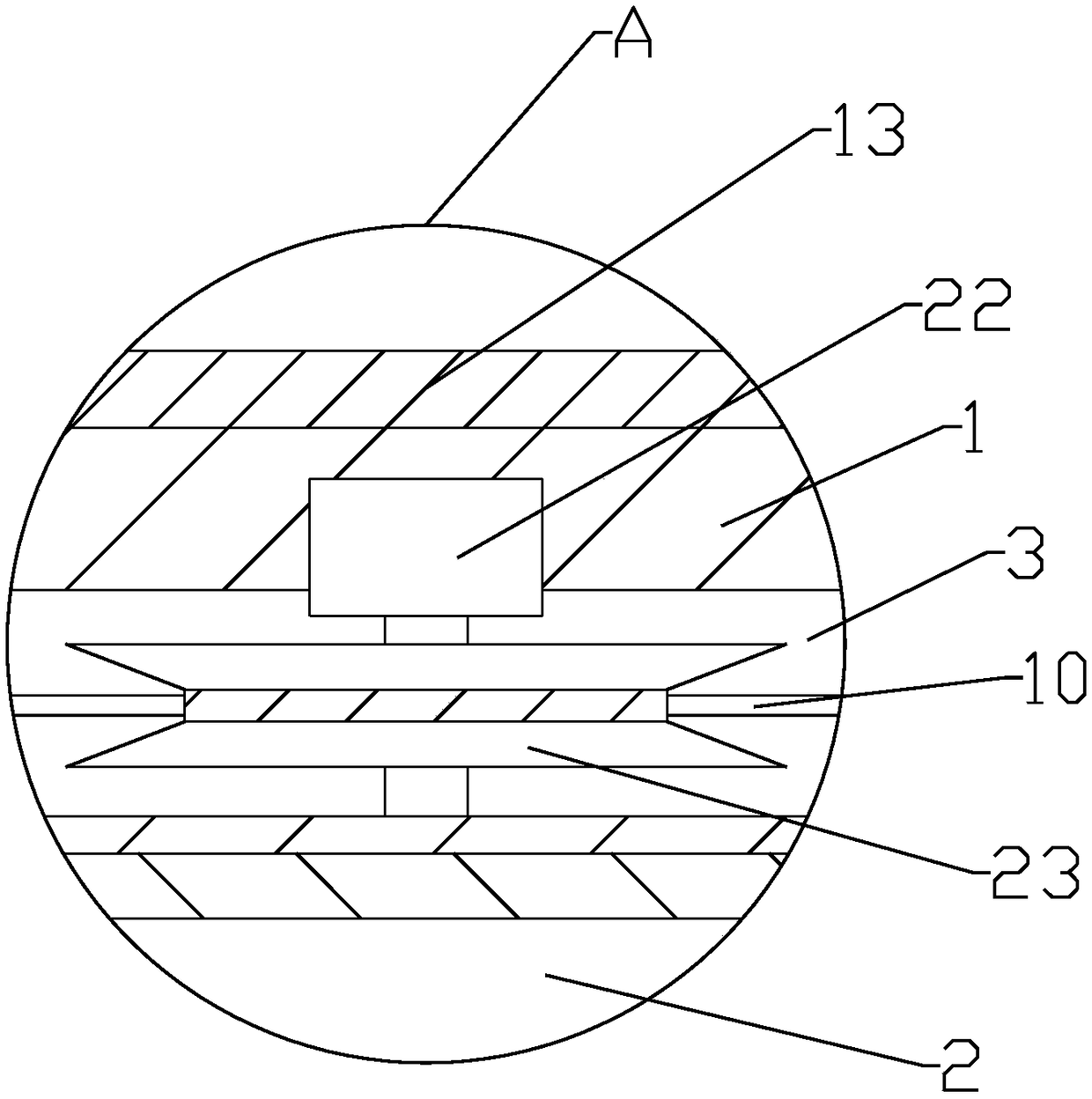

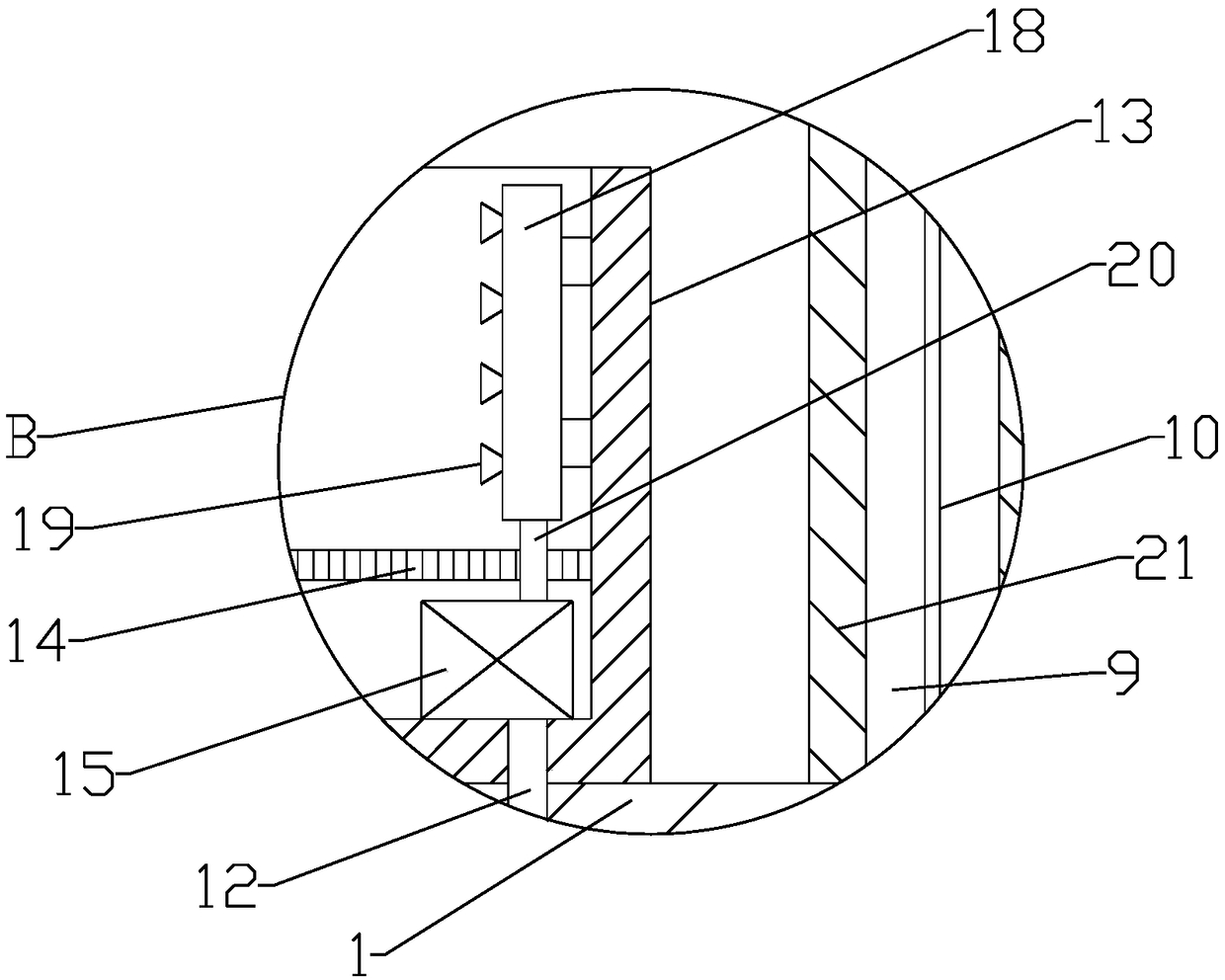

Cleaning device for electronic technological product accessory

InactiveCN108856082AEasy to useWill not cause a collisionCleaning using liquidsSpray nozzleIndustrial engineering

The invention discloses a cleaning device for an electronic technological product accessory. The cleaning device for the electronic technological product accessory comprises a base, a cleaning liquidcavity, a power cavity, a lifting cross beam, rectangular sliding blocks, springs, a rigid stay cord, a cleaning box, mechanical grippers, spray nozzles, support stand columns and a winding wheel. According to the cleaning device for the electronic technological product accessory, through cooperative use of the lifting cross bean, the rectangular sliding blocks, the springs, the rigid stay cords,the cleaning box, the mechanical grippers, the spray nozzles, the support stand columns and the winding wheel, the mechanical grippers can isolate and fix the electronic product accessories and protects the electronic product accessories against collision, it is avoided that the electronic product accessories collide during cleaning and are damaged, and normal use of the electronic products is guaranteed; and due to use of a water pump and the spray nozzles, the electronic product accessories can be comprehensively cleaned, it is guaranteed that the electronic product accessories are thoroughly cleaned, and the problem that the cleaning effect of a cleaning device is poor is solved.

Owner:苏州和必尔斯电子科技有限公司

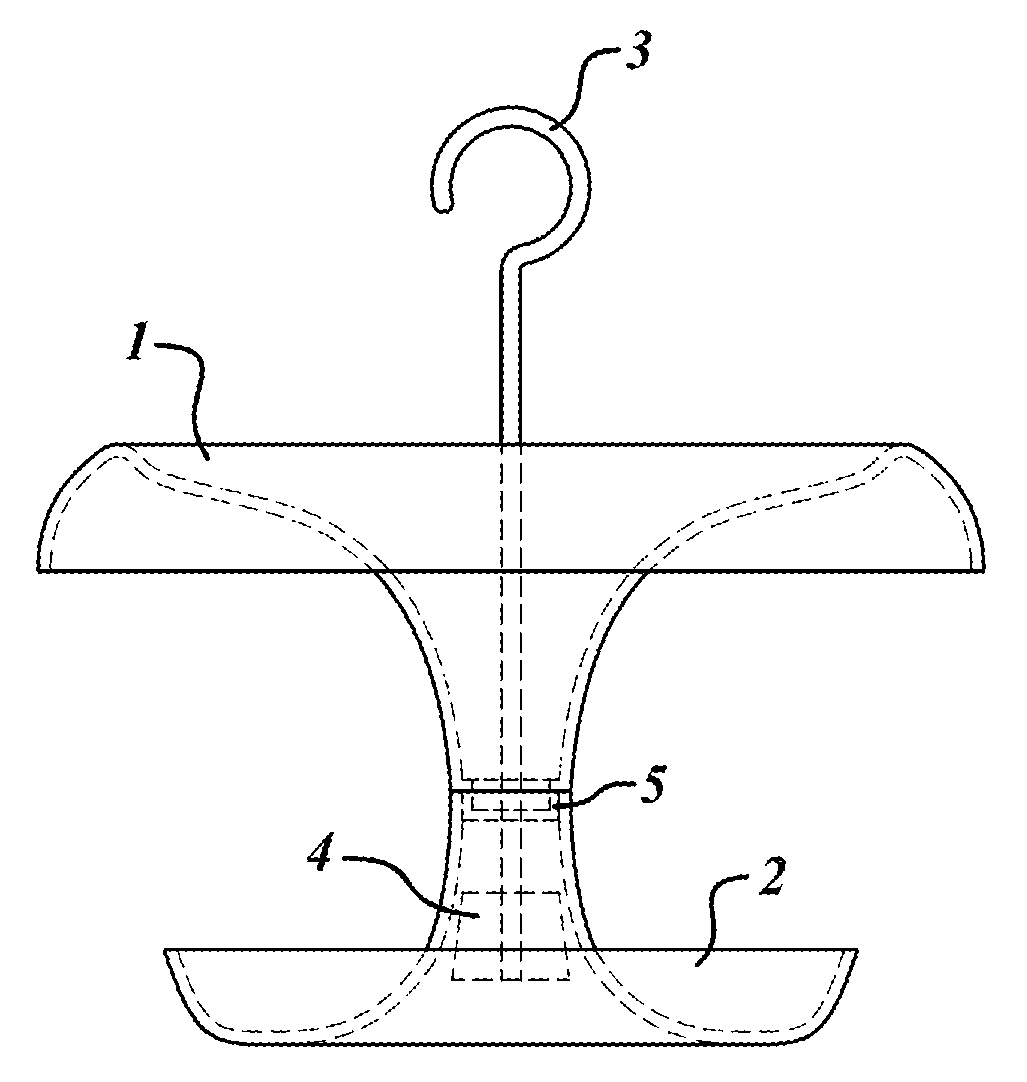

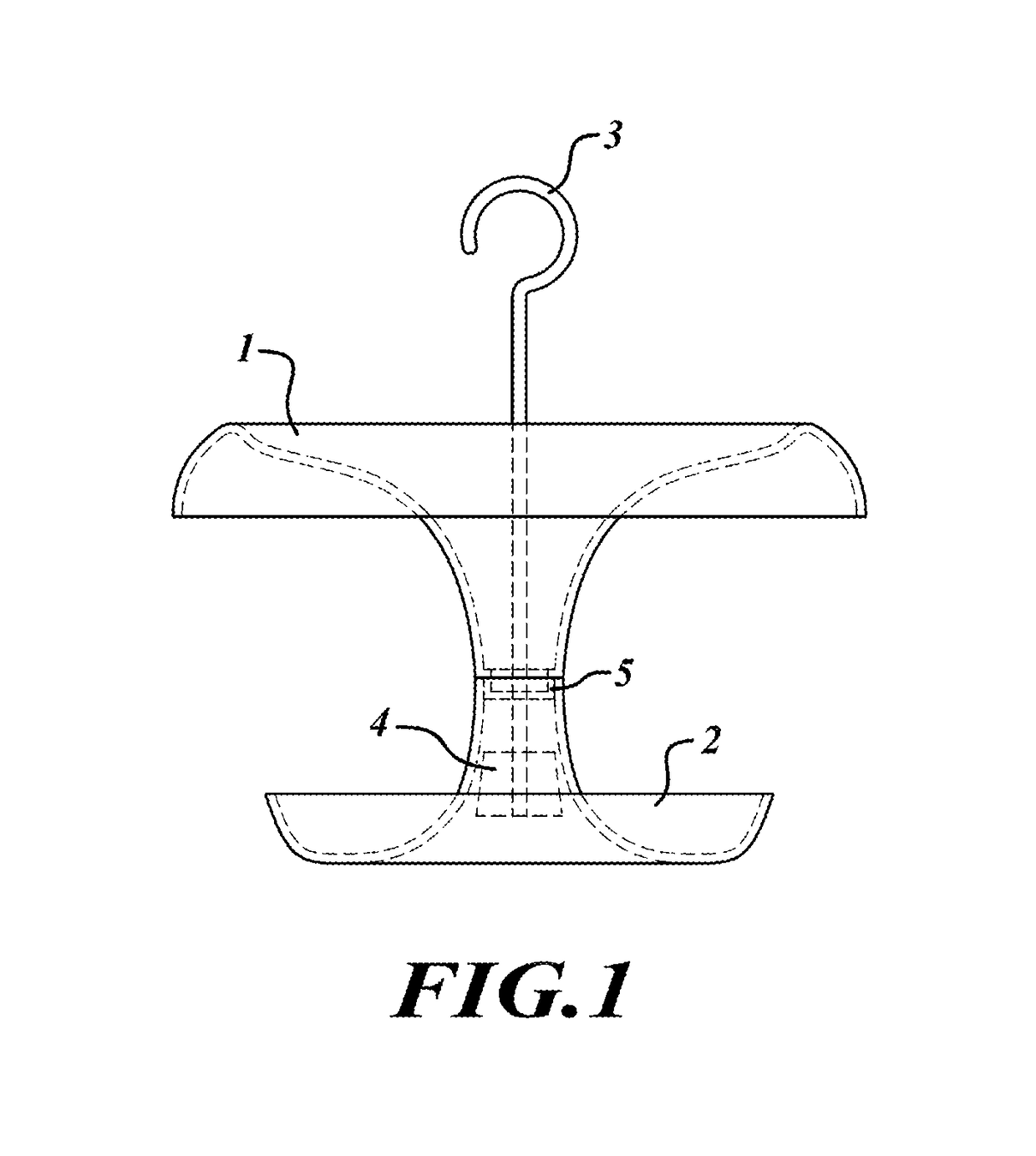

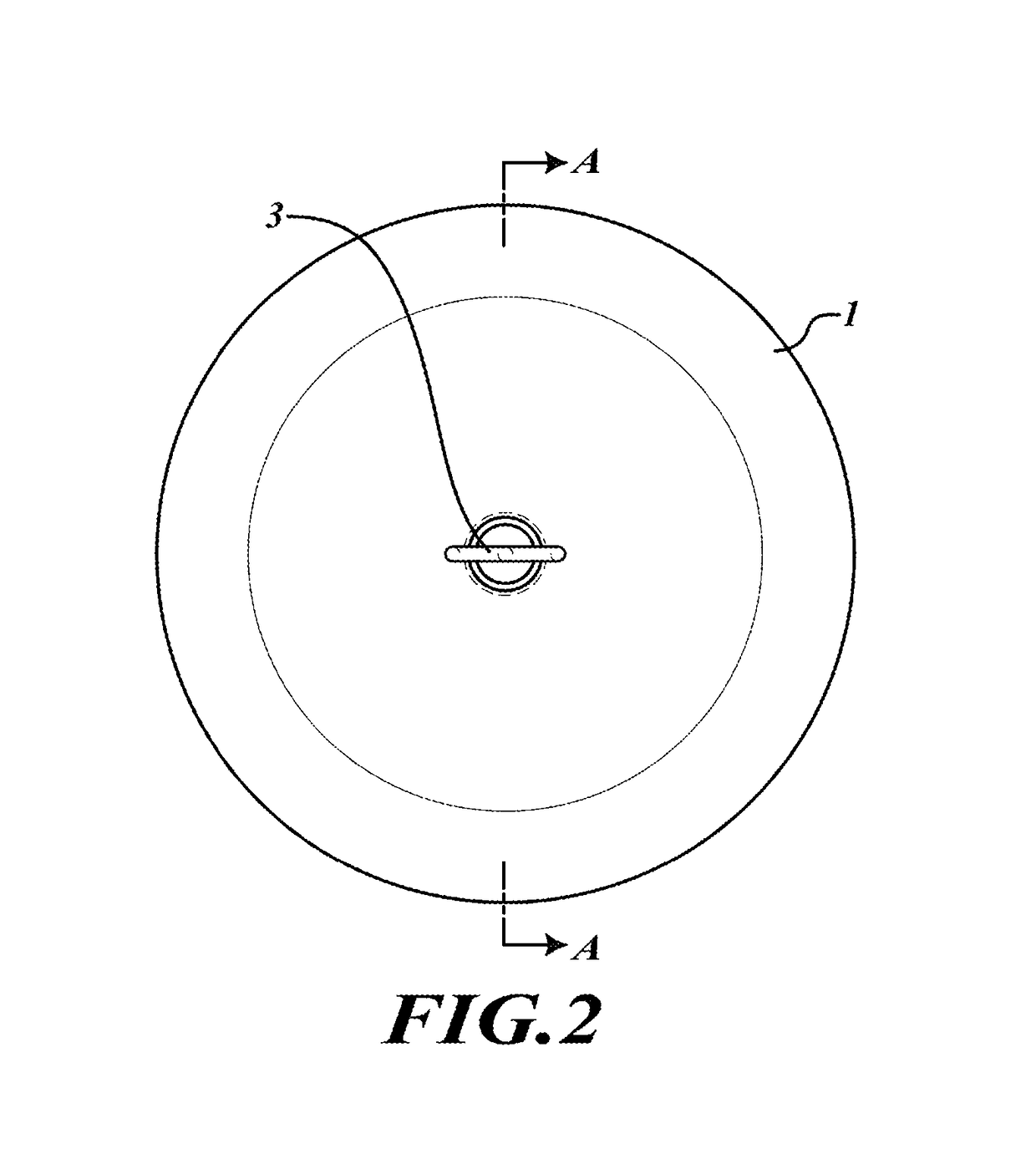

Water storage type bird feeding device

A water storage type bird feeding device includes: a water storage part, which is in a cylindrical shape for water storage, a food storage part, which is arranged below the water storage part and comprises a cylindrical portion and a disk-like portion, the cylindrical portion and the disk-like portion are in communication to form a communicating cylinder portion, the disk-like portion is used to save food, a column stopper, which is able to move up and down in the communicating cylinder portion; a hook, which is connected to the column stopper for hanging the bird feeding device, wherein the communicating cylinder portion comprises a smallest diameter portion at a central portion thereof in a vertical direction, and the diameter of the column stopper is larger than an inner diameter of the smallest diameter portion.

Owner:LF CENTENNIAL

Fire-fighting unmanned aerial vehicle lens cleaning device capable of preventing smoking based on magnetic force change

ActiveCN110976351AAvoid the problem of being blurred by smokeProcess stabilityAircraft componentsTelevision system detailsHeat conductingUncrewed vehicle

The invention provides a fire-fighting unmanned aerial vehicle lens cleaning device capable of preventing smoking based on magnetic force change. The fire-fighting unmanned aerial vehicle lens cleaning device comprises a lens barrel body, wherein a sliding groove is formed in the inner part of the lens barrel body and is positioned on the outer side of a protective lens; a sliding seat is movablyconnected to the inner part of the sliding groove and is positioned above a storage seat; cleaning cotton is arranged between the sliding seat and the storage seat; a heat conducting rod extending into an air cavity is fixedly inserted into the front surface of the lens barrel body; uniformly distributed conducting strips are fixedly arranged on the left side of the sliding groove; and electromagnets corresponding to the conducting strips are fixedly arranged at the bottom of the sliding groove. The closer an unmanned aerial vehicle is to a fire area, the higher the air temperature is, heat istransmitted into the air cavity through the heat conducting rod, the inner pressure of the air cavity is increased to a certain degree and then ejects a valve, the air flow pushes the sliding seat torotate along the sliding groove, power is provided through the conducting strips and the electromagnets, the sliding seat pulls the cleaning cotton to wipe and clean the protective lens, and the problem that the protective lens of a camera on the unmanned aerial vehicle is smoked and blurred is avoided.

Owner:浙江翔龙航空科技有限公司

Dynamic bearing device

Disclosed is a dynamic bearing device which allows production of a smaller housing at low cost and which suppresses ion elution from the resin portion to thereby maintain cleanliness in the dynamic bearing device and exert a desired bearing performance. A dynamic bearing device 1 is equipped with a bearing sleeve 8 fixed to the inner periphery of the housing 7, and a rotary member rotatable relative to the bearing sleeve 8 and the housing 7, in which the rotary member is supported in the radial direction and the thrust direction in a non-contact manner by a dynamic pressure action of a lubricant fluid generated in a bearing clearance. The housing 7 is formed by injection molding of a resin composition containing polyphenylene sulfide (PPS) as the base resin and PAN type carbon fibers as a filler.

Owner:NTN CORP

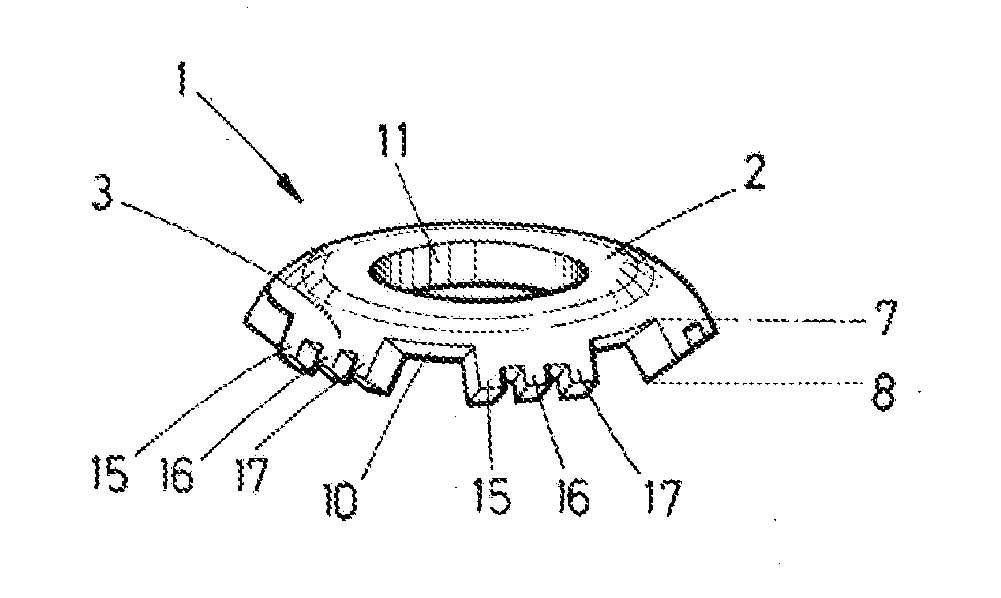

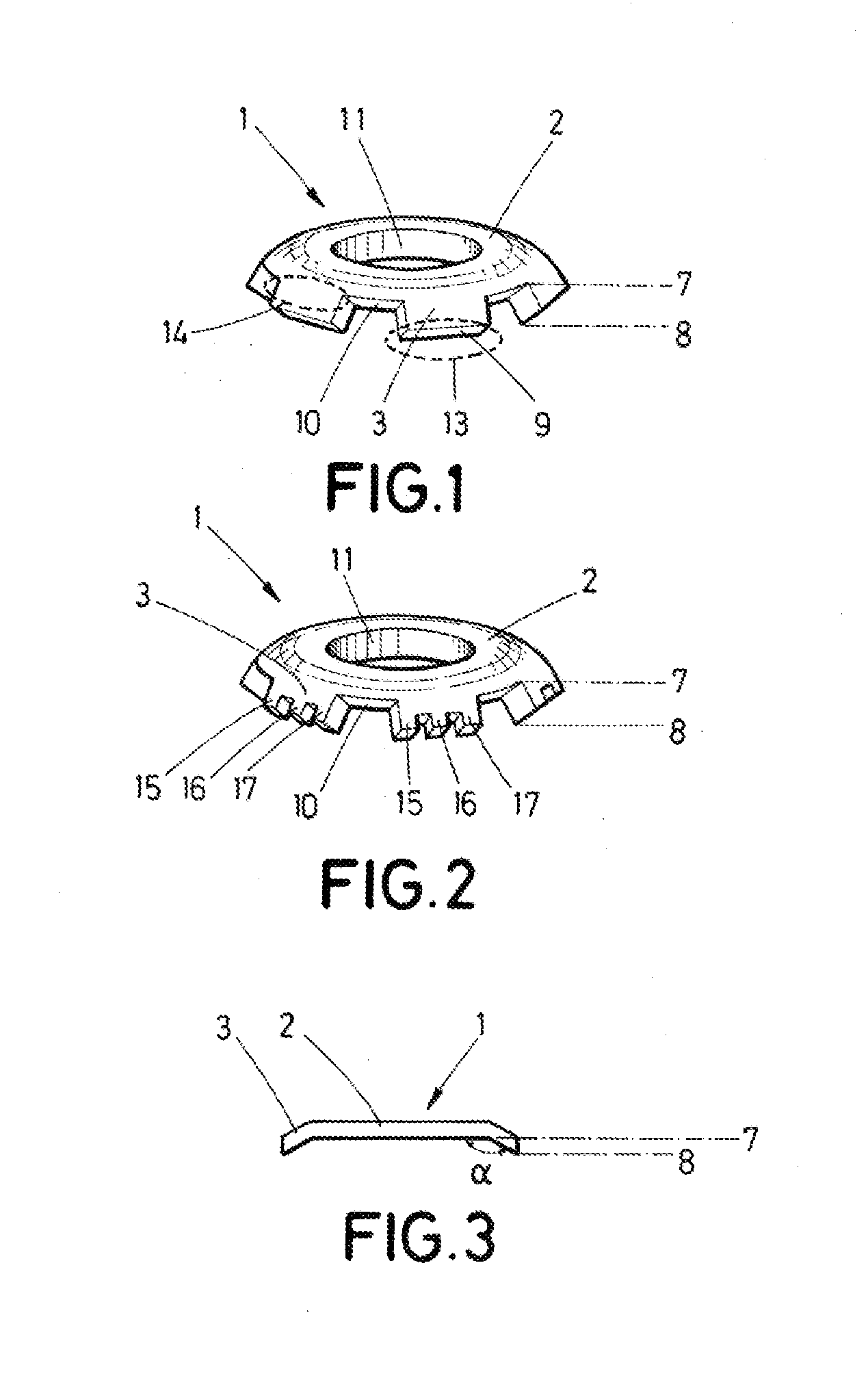

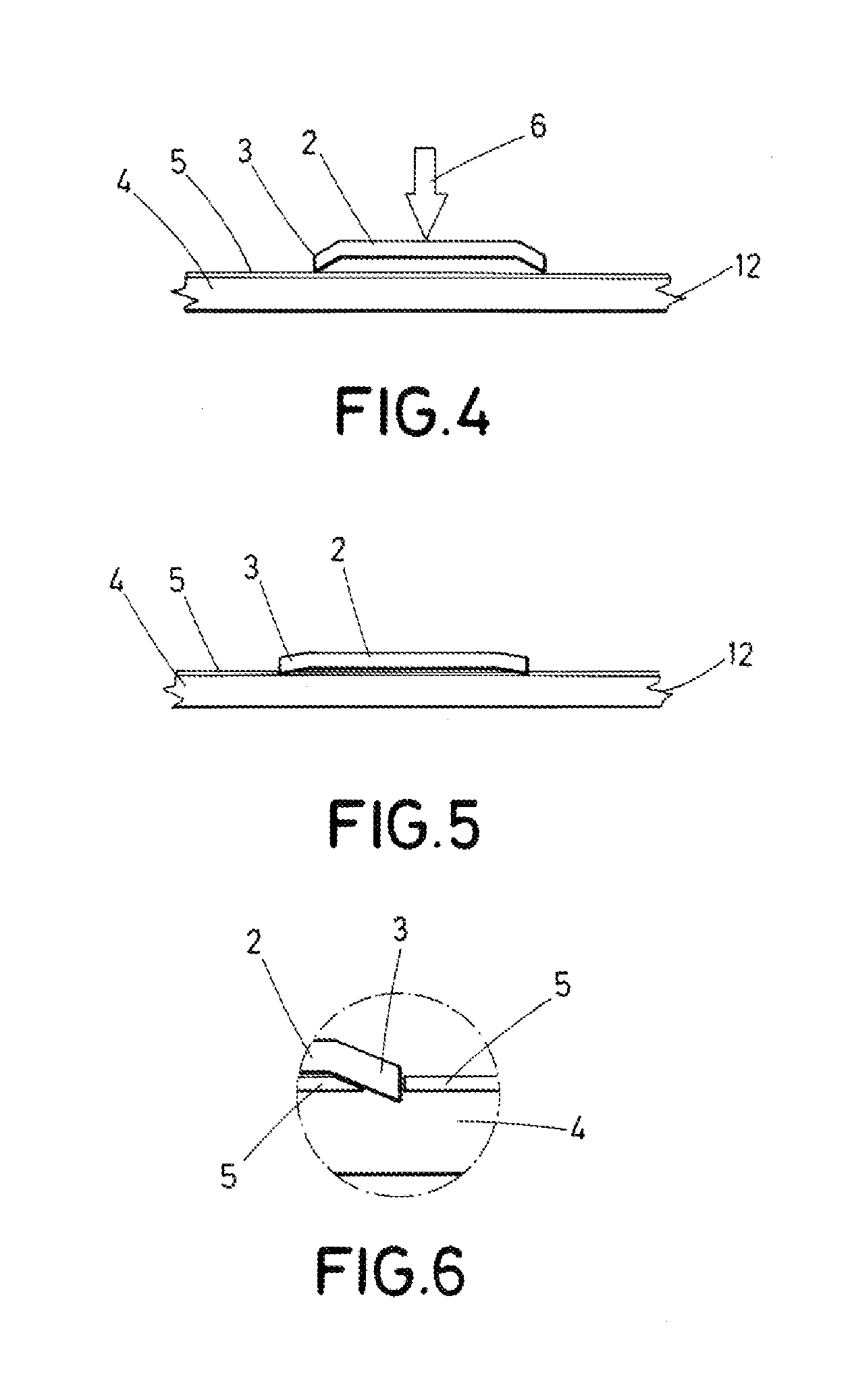

Washer for Establishing Electrical Continuity

InactiveUS20160336661A1Efficient removalAchieve electrical continuityVehicle connectorsElectric connection structural associationsElectrical connectionEngineering

A washer is designed to establish a reliable electrical connection between the washer and a core structure of the main conductor aircraft structure. The washer includes a conductive central main body arranged substantially in a first plane and including an opening adapted to receive a fastener and an outer edge and at least three serrated conductive projections. Each serrated projection includes a first end and a second end. The first end is attached to the conductive central main body and the second end is a free end including at least one conductive tooth. The second end is located in a second plan other than the first plane and is of the type that can deform under pressure. The attachment between the conductive central main body and each serrated conductive projection is of the type that can deform under pressure.

Owner:AIRBUS DEFENCE & SPACE

Stocker

ActiveUS10889438B2Efficiently formedEnsure thorough cleaningMechanical apparatusLighting and heating apparatusEngineeringMechanics

A stocker includes a wall that separates inside and outside of the stocker, a storage area on an inner side of the wall to store articles, a duct on a wall side of the storage area and extending in a vertical direction, an inlet at an upper end of the duct to introduce air flowing downward into the duct, a flow regulator to regulate an airflow between an upper side and a lower side of the duct, blowout openings on a storage area side of the duct to blow out air to the storage area, and a fan on a lower side of the flow regulator of the duct to draw in outside air and introduce the outside air into the duct.

Owner:MURATA MASCH LTD

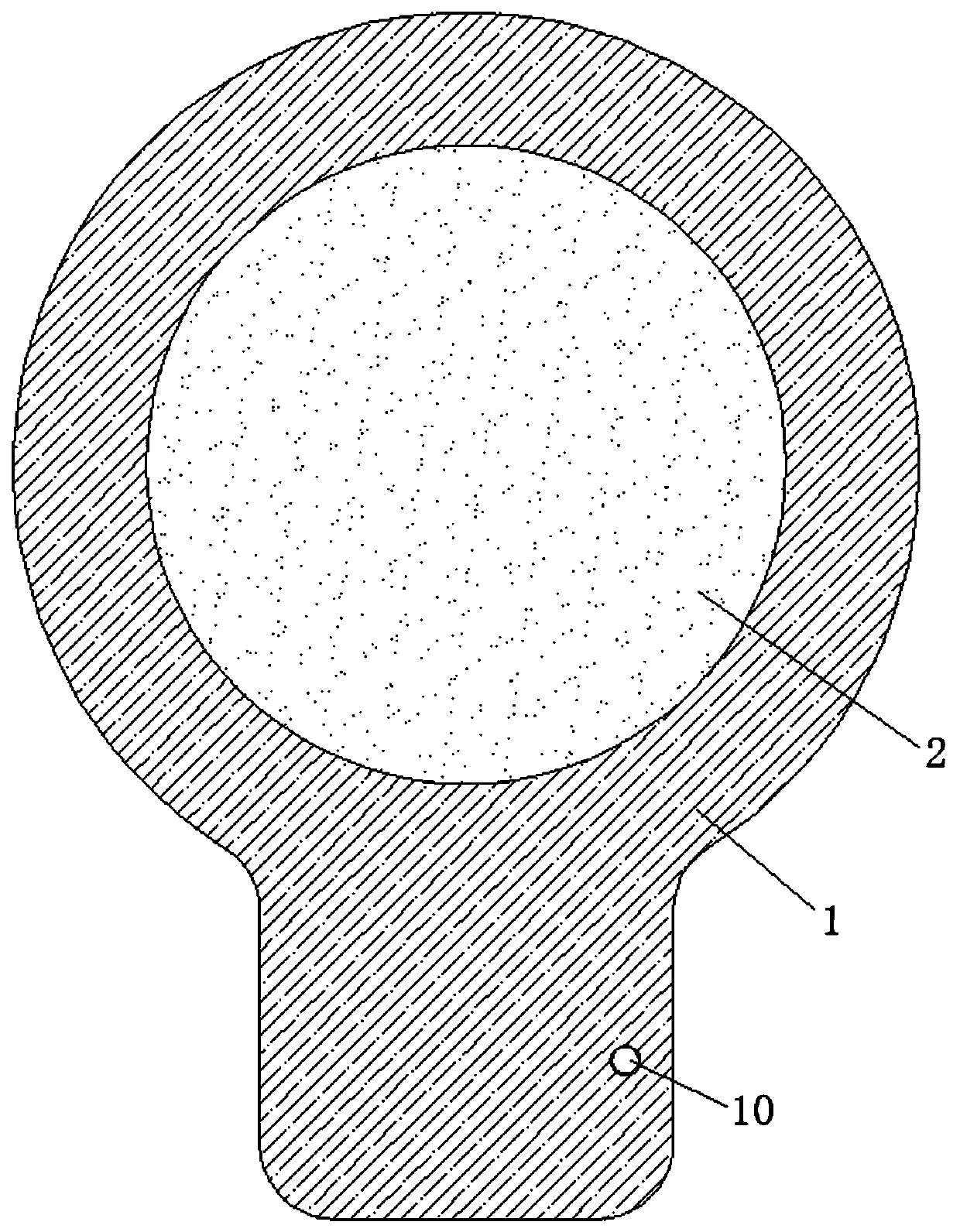

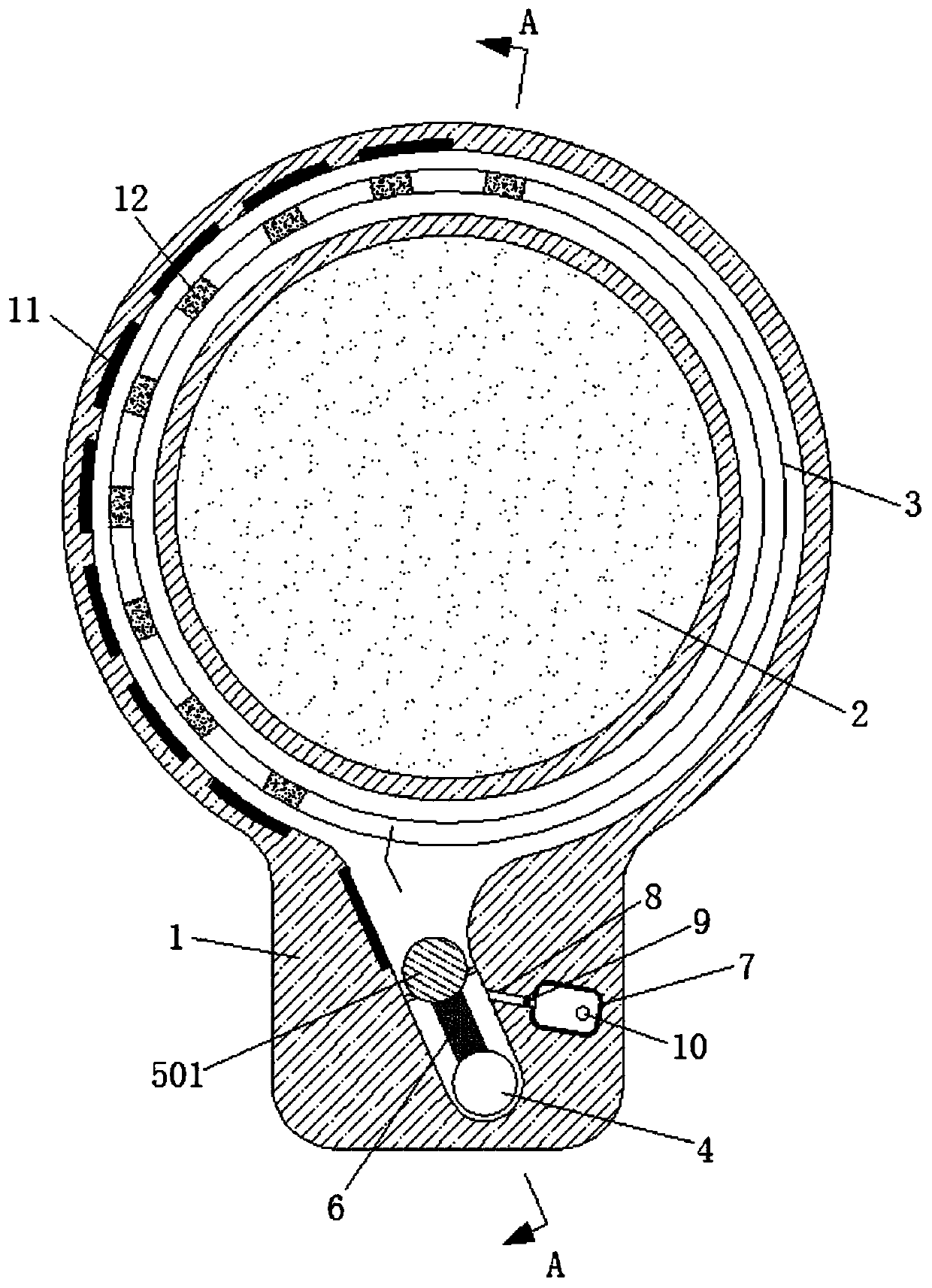

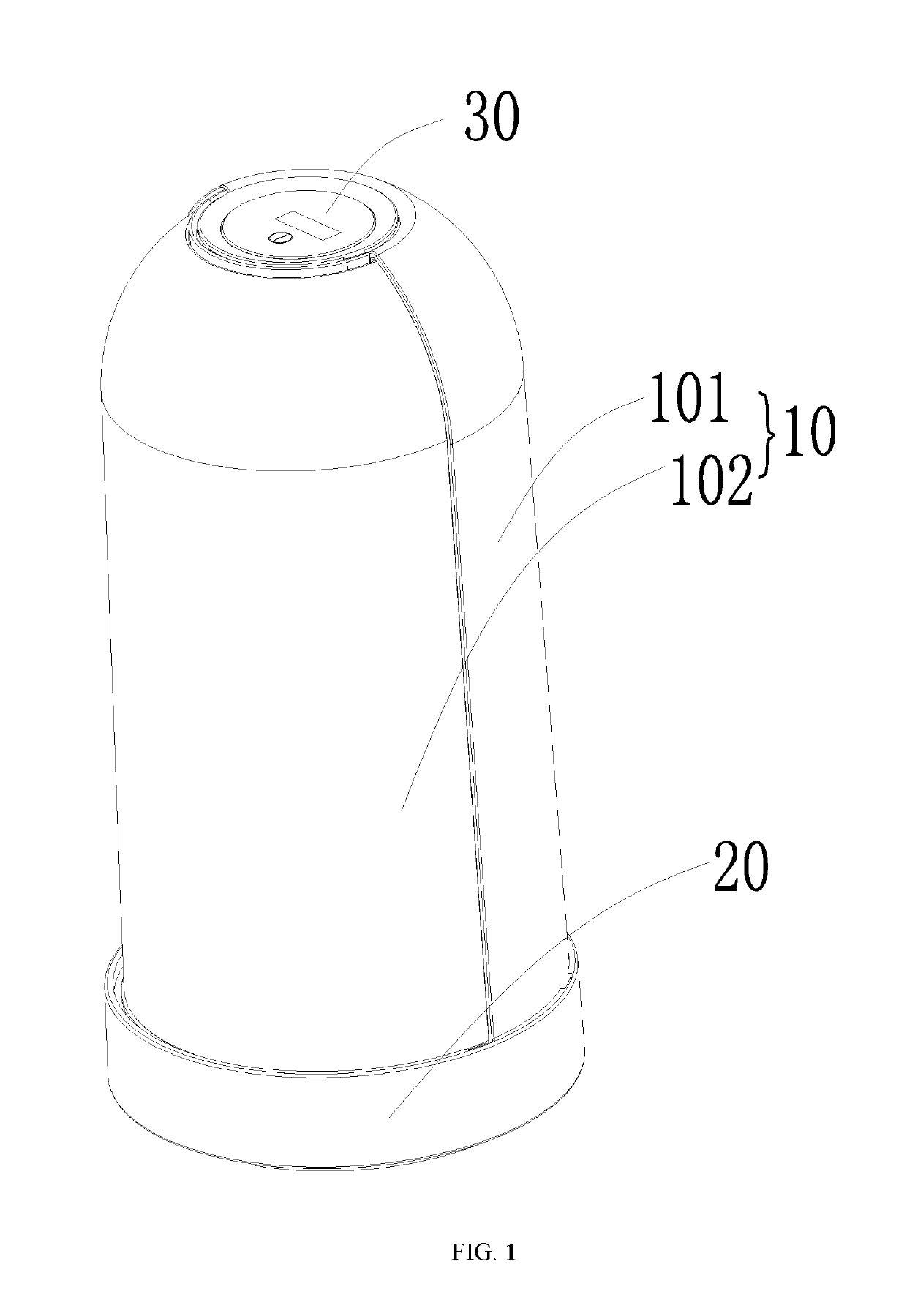

Sterilization box

InactiveUS10279063B2Ensure thorough cleaningBrushesDrying gas arrangementsAir cycleBiomedical engineering

The present application belongs to the technical field of household commodity and provides a sterilization box applicable to sterilize cosmetic tools, which comprises a base assembly, a housing assembly connected to the base assembly and cooperating with the base assembly to form a first cavity, and a supporting assembly connected in the first cavity and being able to connect with a plurality of cosmetic tools. The base assembly is provided therein with a second cavity. The sterilization box further comprises a circulation assembly configured to drive air circulations in the first cavity and in the second cavity and a sterilization assembly configured to sterilize the cosmetic tools. The circulation assembly includes a first ventilation assembly cooperating with the second cavity and a second ventilation assembly cooperating with the first cavity. A heating assembly cooperating with the first ventilation assembly is connected in the second cavity.

Owner:IPM KOREA CO LTD

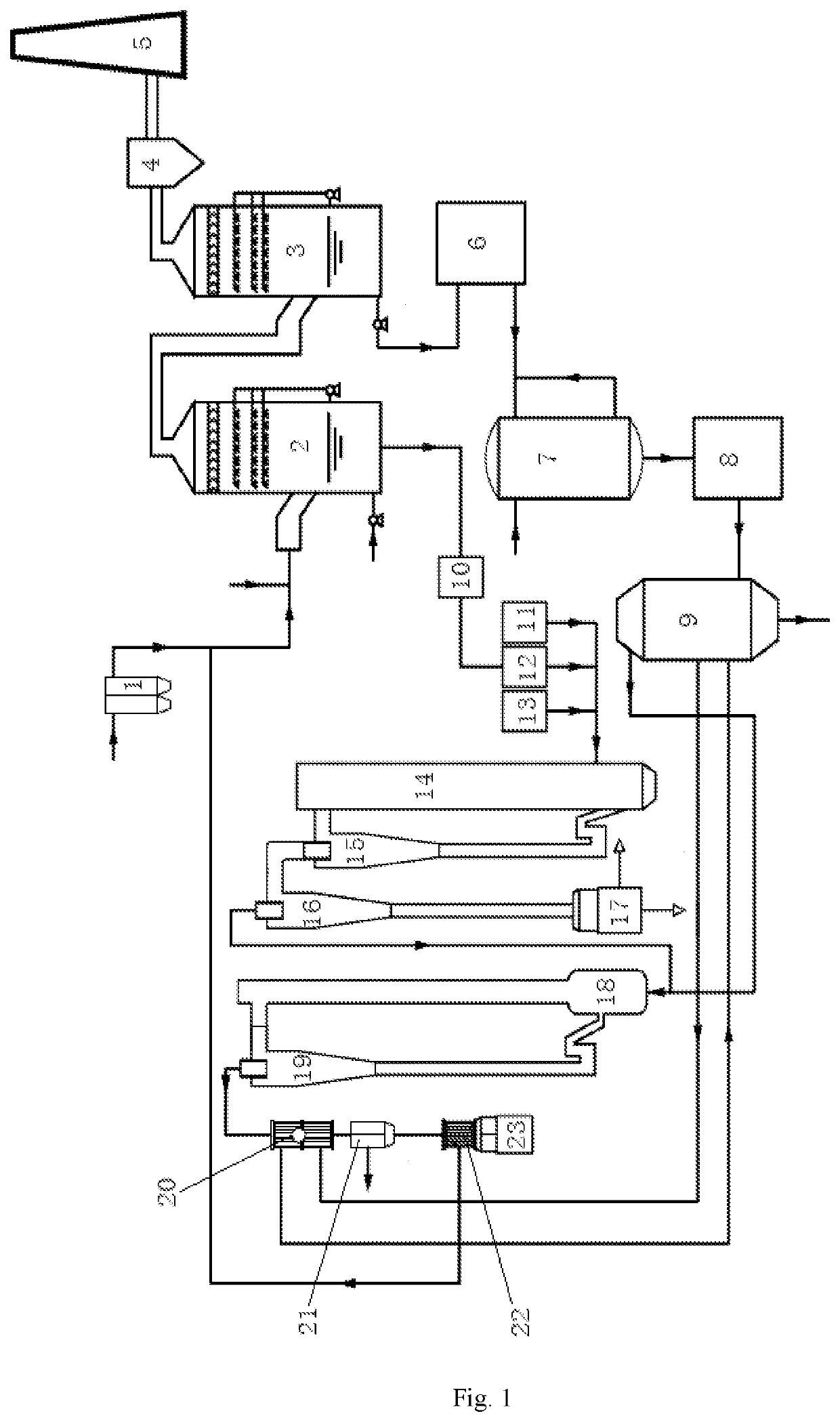

Process for preparing sulfur from reduction of sulfate/ nitrate by iron-carbon and recovering desulfurization/ denitration agents

ActiveUS20210331922A1Alleviate shortagesReduce exploitationNitrous oxide captureGas treatmentFlue gasNitrate salts

The present invention discloses a process for preparing sulfur from reduction of sulfate / nitrate by iron-carbon and recovering desulfurization / denitration agents. High-concentration SO2 flue gas produced by calcination of a sulfate and NOx produced by heating decomposition of a nitrate can be directly reduced to elemental sulfur vapor and N2 through reaction with an iron-carbon material at a high temperature. Then, after dust removal, cooling and fine dust removal, sulfur is recovered by a sulfur recovery device, and metal oxides can replace alkaline mineral resources such as limestone as raw materials of desulfurization (denitration) agents. This process can recycle the desulfurization and denitration agents.

Owner:SHANDONG UNIV

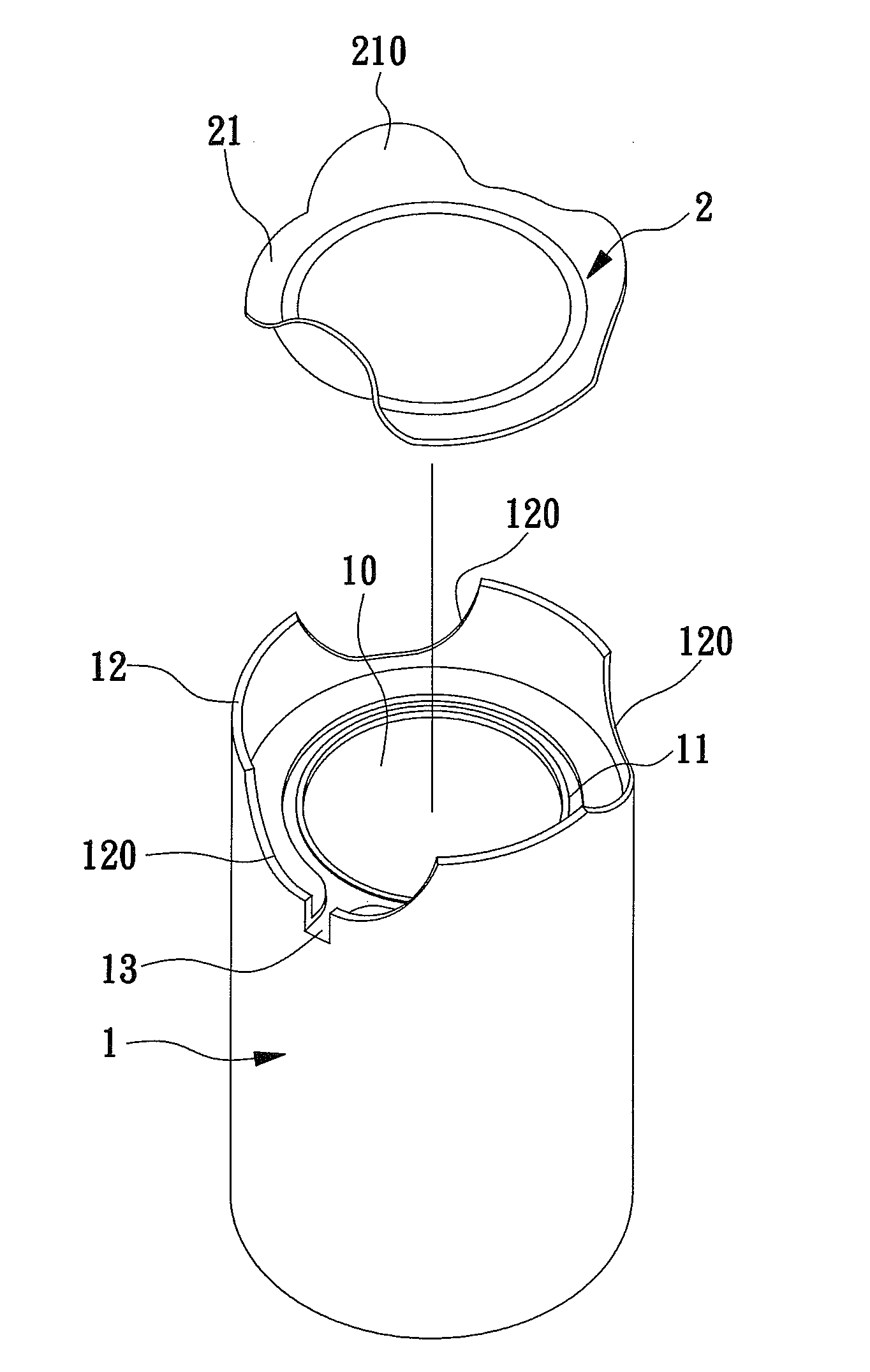

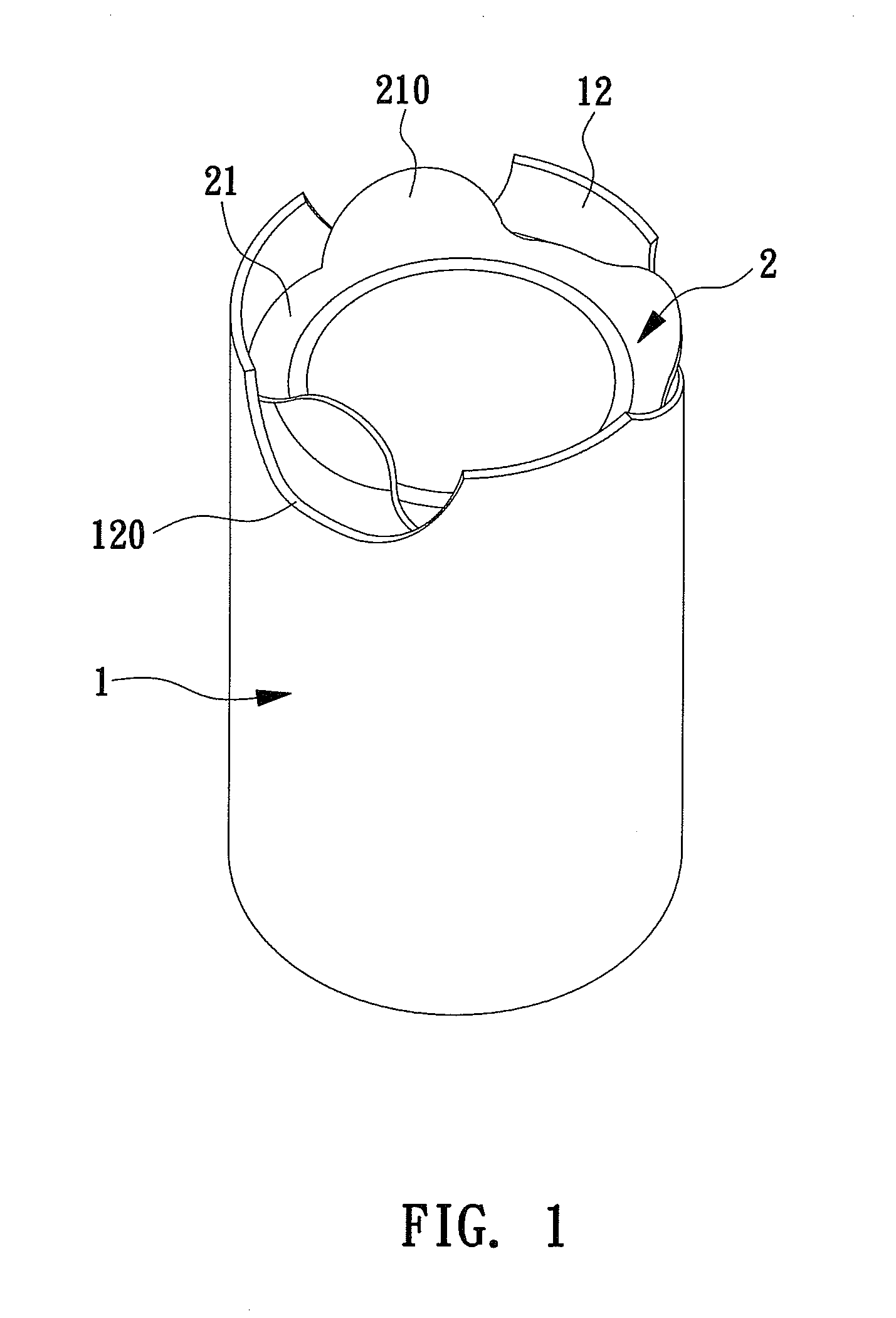

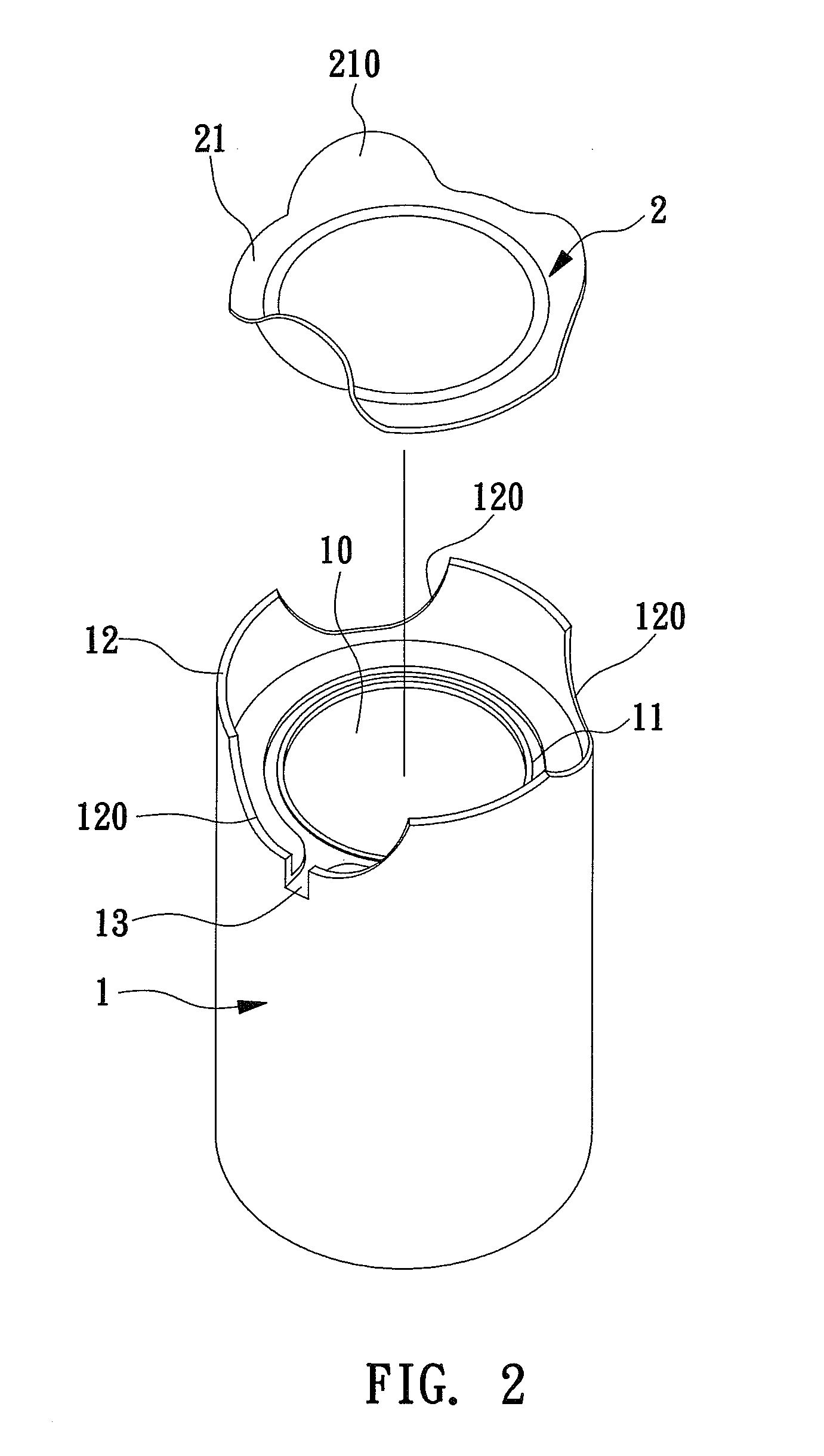

Container with Easily-Detached Lid

ActiveUS20130134162A1Easy to separateEnsure thorough cleaningCapsClosure using stoppersBiomedical engineering

Owner:NAT TAIPEI UNIV OF TECH

Crystal-growing furnace with convectional cooling structure

InactiveUS8062423B2Rapid coolingShorten the timeAfter-treatment apparatusPolycrystalline material growthStream flowIngot

A crystal-growing furnace with a convectional cooling structure includes a furnace body, a heating room, and at least one heater. The heating room is accommodated in the furnace body, and includes an upper partition, a plurality of side partitions, and a lower partition. The upper partition is provided with an upper opening, and the lower partition with a central opening. Further, the heating room is provided with an upper door, a lower door, an upper driver, and a lower driver. When silicon slurry is to be cooled and solidified, cooling gaseous stream flows into a lower portion of the heating room through the central opening. Then the upper opening is opened by the upper door which is driven by the upper driver, so that heated gaseous stream is discharged from the upper opening and flows downward along furnace inside wall, and flows back to the heating room from the central opening. Therefore, an automatic convectional circulating cooling flow field can be formed, such that the silicon slurry can be cooled quickly with time saved and production efficiency improved. Further, in the process of cooling and crystal growing from the silicon slurry, solidification and crystallization start from bottom to upward of the silicon slurry, such that inner stress and corner fracture may not be occurred to the silicon crystal ingots, and that a desirable quality of the silicon crystal ingots can be obtained.

Owner:GREEN ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com