Preparation method of soluble polyimide resin

A soluble polyimide and polyimide technology, applied in the field of polyimide materials, can solve the problems of difficult drying and collection of flocculent resin, unfavorable industrial continuous production, incomplete cleaning, etc., and achieve good safety and industrial applicability, easy washing and drying, and less residue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The embodiment of the present invention discloses a preparation method of a soluble polyimide resin, comprising the following steps:

[0026] (A) polyimide solution is subjected to vacuum defoaming treatment;

[0027] (B) continuously extruding the polyimide solution after the vacuum defoaming treatment in a polar solvent to obtain a tow-shaped resin with a diameter of 0.01 to 0.05 mm;

[0028] (C) washing the tow-shaped resin with water and drying to obtain a finished product of soluble polyimide resin.

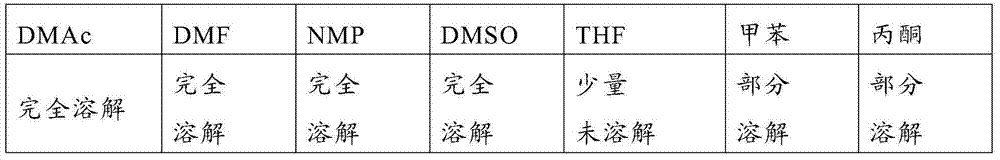

[0029] In the present invention, it mainly relates to a method for obtaining a polyimide resin through processing a polyimide solution. According to the present invention, the source of the polyimide solution is not particularly limited, any polyimide solution that is obtained through polymerization well known to those skilled in the art and used to prepare soluble polyimide resins can be prepared by itself , You can also buy commercially available products.

[003...

Embodiment 1

[0039] A polyimide solution prepared by a high-temperature solution polymerization method is provided, and the polyimide solution is 3,3'-dimethyl-4,4'-diaminodiphenylmethane ( DMMDA) and 3,3',4,4'-benzophenonetetraacid dianhydride (BTDA) are polymerized in phenol by heating at 180°C, and the apparent viscosity of the polyimide solution is 12000cp.

[0040] The polyimide solution was vacuum defoamed for 12 hours, the temperature of the solution was 25°C, and after filtration, it was poured into the resin former through a metering pump. The polyimide solution passes through the small holes and continuously separates out the tow-shaped resin in the precipitation tank. The precipitation tank is a mixed solvent of ethanol and DMAc, with a flow rate of 10m / min; the filamentous resin is washed at 80°C for 5 minutes at a speed of 2m / min, and washed with water at 25°C for 5min; the filamentous resin is washed at a speed of 2m / min After drying at 140° C. for 5 minutes and at 160° C. f...

Embodiment 2

[0056] Provides a polyimide solution prepared by chemical imidization, the polyimide solution is made of 1,4-bis(4-aminophenoxy)benzene (APB) in a molar ratio of 0.3:0.7:1 , 3,3'-diamino-4,4'-diaminodiphenylmethane (DMMDA) and 3,3',4,4'-diphenyl ether dianhydride (ODPA) in N,N-dimethylmethane Polymerization in amide (DMF) obtains, and the imide catalyst and the dehydrating agent adopted in the polymerization process are acetic anhydride and triethylamine respectively, and wherein the mol ratio of ODPA and acetic anhydride, triethylamine is 1:2:1; The described The apparent viscosity of the polyimide solution was 155000 cp.

[0057] The polyimide solution was vacuum defoamed for 12 hours, and the solution temperature was 25°C. After filtering, it was injected into the resin former through a metering pump. The polyimide solution passes through the small holes and continuously separates out the tow-shaped resin in the precipitation tank. The precipitation tank is a mixed solven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com