Device for self-expanding of expanded base

A self-expansion and expansion force technology, applied in the field of bottom-expanding self-expansion devices, can solve the problems of easy-to-collapse holes, low pile-forming efficiency, and easy direct erosion of concrete by harmful substances, so as to reduce disturbance and construction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

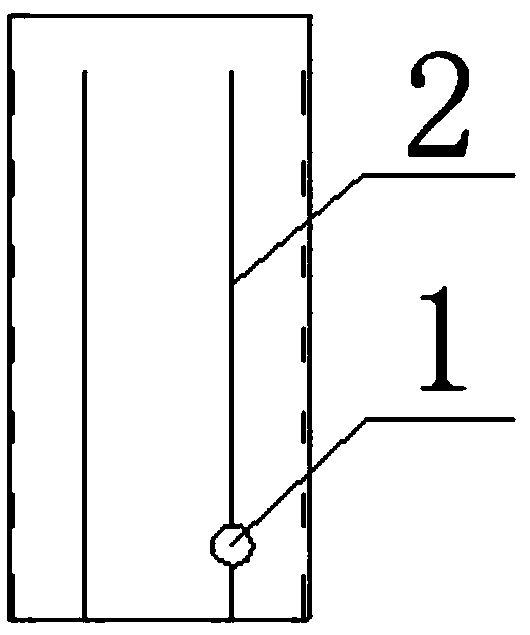

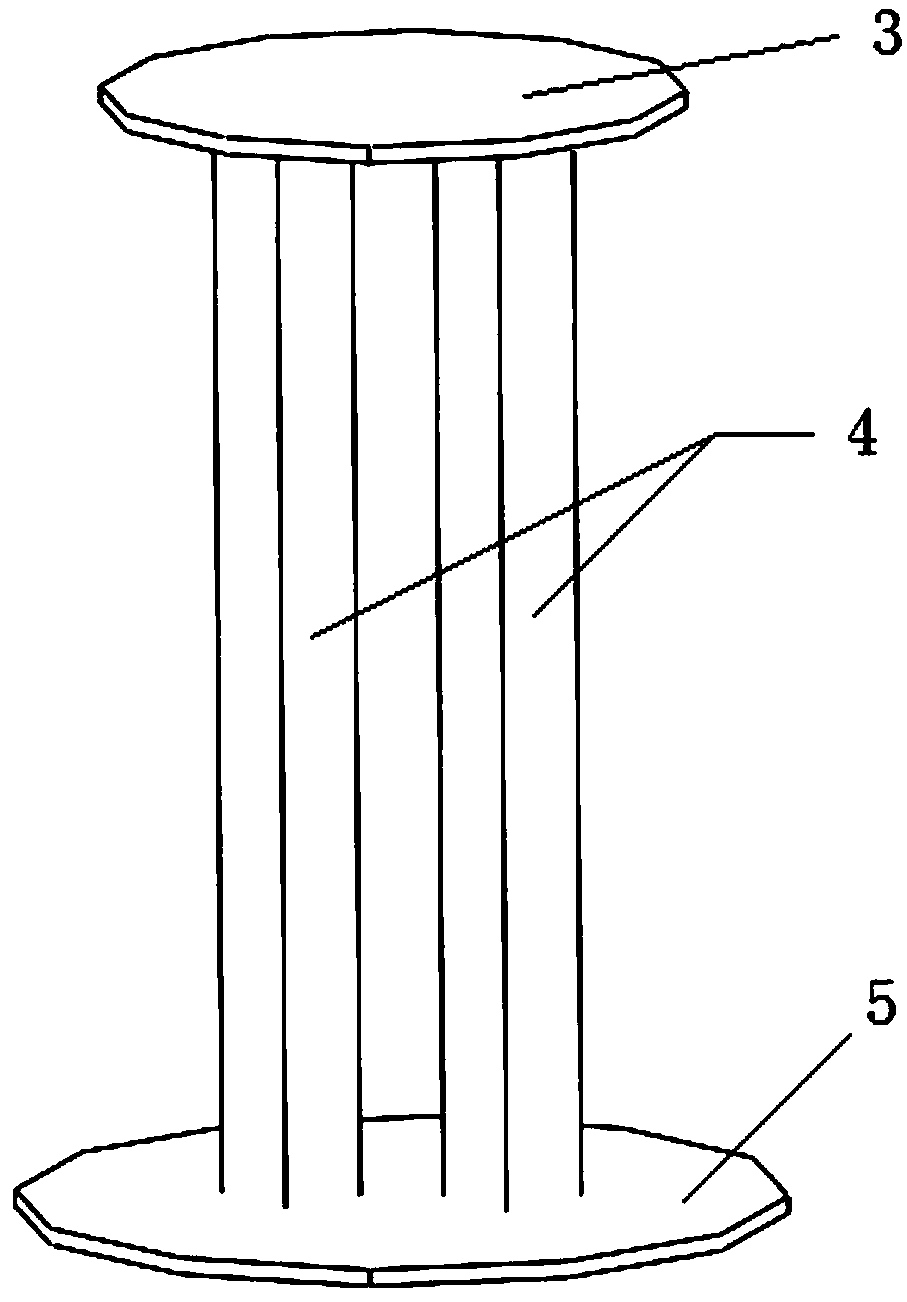

[0028] Such as figure 1 As shown, a self-expanding device for expanding the bottom includes the outer wall of the self-expanding box and the I-shaped structure; the self-expanding box is filled with expansion materials, and the self-expanding box and the I-shaped structure limit the The upward and downward expansion force of an intumescent material so that it can only expand horizontally. The outer wall of the self-expanding tank is provided with an equally divided cutting seam 2, wherein the bottom is completely cut, and the upper part remains uncut. A grouting hole 1 is provided on the self-expansion tank, and the main function is to pour expansion material into the expansion tank through the grouting hole.

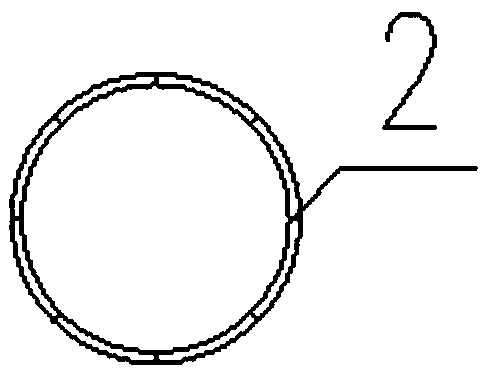

[0029] Such as figure 2 As shown, the cutting standard for equally dividing the cutting seam 2 outside the self-expansion tank is to determine an x-axis direction in a plane parallel to the upper and lower circular steel plates, and take the x-axis direction as a ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com