Ink printing transferred rubber pedal pad vulcanization forming mould and manufacturing method

A technology of ink printing and vulcanization molding, which is applied in the field of rubber product manufacturing, can solve the problems of high cost, high reject rate, and easy deformation of surface printing, and achieve the effects of preventing deformation and aliasing, improving pass rate, and ensuring transfer quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

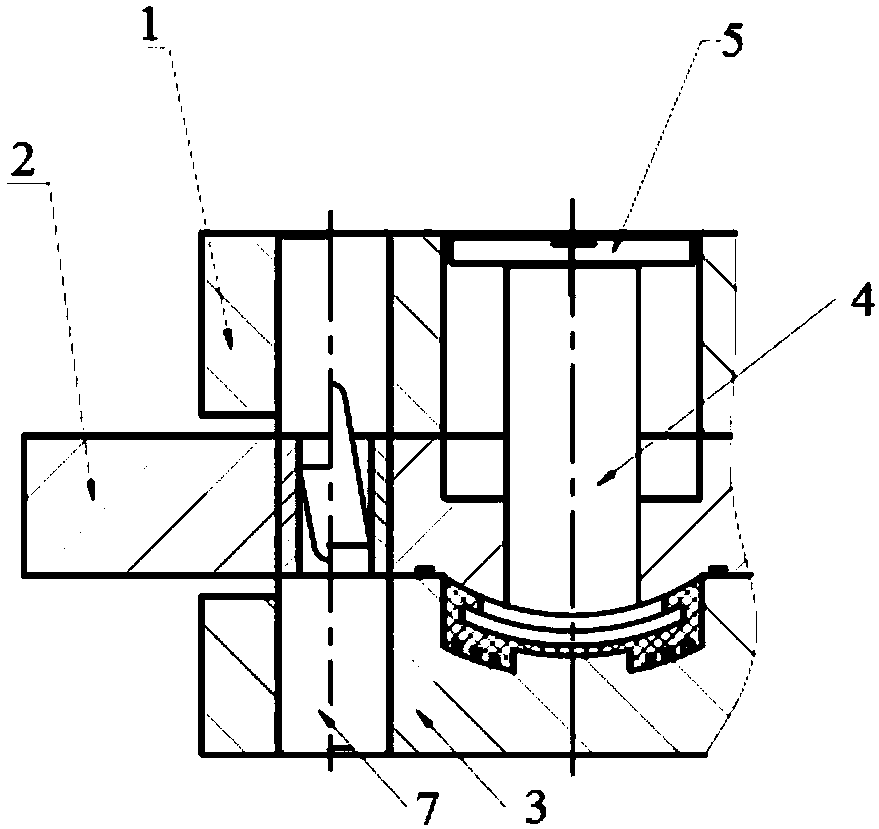

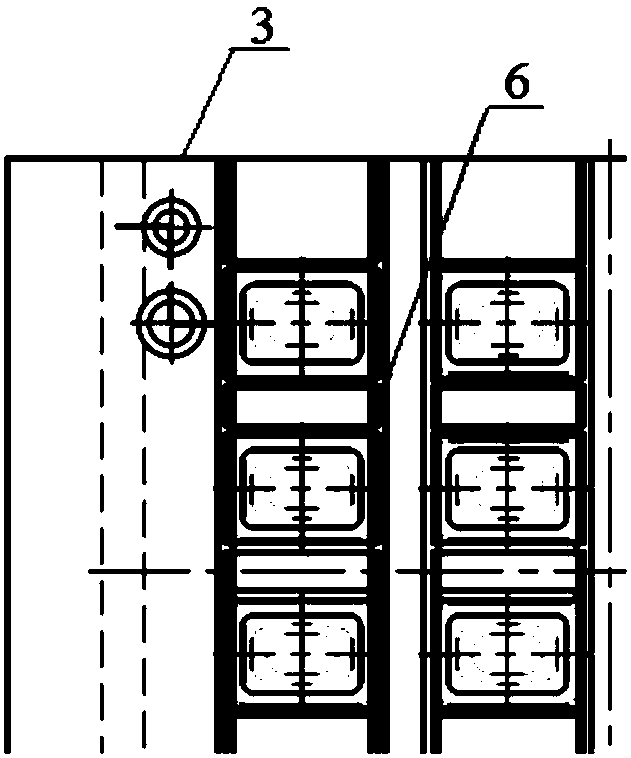

[0041] combine figure 1 , figure 2 , the vulcanization molding die of a kind of ink printing transfer printing rubber pedal mat of the present embodiment, comprises upper mold 1, middle mold 2, lower mold 3 and floating mandrel 4, wherein the lower surface of middle mold 2 and the upper surface of lower mold 3 The surfaces are respectively provided with mold cavities, and after the mold is closed, the above mold cavities together form the rubber cavity for the printing ink printing transfer rubber pedal pad to be formed, and the middle mold 2 and the upper mold 1 are respectively processed with upper and lower floating core molds 4 The opening of the movement, the top of the opening of the upper mold 1 is located above the floating mandrel 4 and is provided with a limiting disc 5 . Such as figure 2 As shown, the top surface of the lower mold 3 is provided with well-shaped glue running grooves 6 distributed around the cavity of the lower mold 3 , and the glue running groove...

Embodiment 2

[0044] The vulcanization molding die for ink printing transfer rubber pedal pads of this embodiment is basically the same in structure as embodiment 1, the main difference is that the mold of this embodiment can be provided with at least one row of ink printing transfer rubber pedal pads as required Rubber cavities are used for forming, and the rubber running grooves 6 corresponding to the cavities of each row of lower dies 3 are connected to each other. In this embodiment, two rows of rubber cavities are provided, combined with figure 2 , the rubber running grooves around the cavity of each row of lower dies are connected to each other to form a well-shaped rubber running groove. In the present embodiment, the width and height of the rubber running groove 6 are 2.5 mm, and the floating core 4 and the middle mold 2 are clearance fit, and the gap is 0.08 mm, and the floating height of the floating core 4 is 30 mm.

[0045] Adopt above-mentioned vulcanization molding die, the m...

Embodiment 3

[0056] The vulcanization molding die of a kind of ink printing transfer printing rubber pedal pad of this embodiment, its structure is basically the same as embodiment 2, and its difference mainly lies in: the width and the height of rubber running groove 6 in this embodiment are 3mm, floating core Between 4 and the middle mold 2 is clearance fit, and its clearance is 0.12mm, and the floating height of the floating mold core 4 is 40mm.

[0057] A kind of manufacturing method of ink printing transfer printing rubber pedal mat of this embodiment, its basic preparation steps are the same as embodiment 2, the difference is that: material blank is made up of following components according to weight parts: styrene-butadiene rubber: 50 parts, Natural rubber: 50 parts, high wear-resistant carbon black: 65 parts, semi-reinforcing carbon black: 20 parts, zinc oxide: 4.5 parts, stearic acid: 1.2 parts, calcined clay: 16 parts, solid Malone: 0.9 parts, Paraffin wax: 0.5 parts, anti-agin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com