Hydraulic tensioner

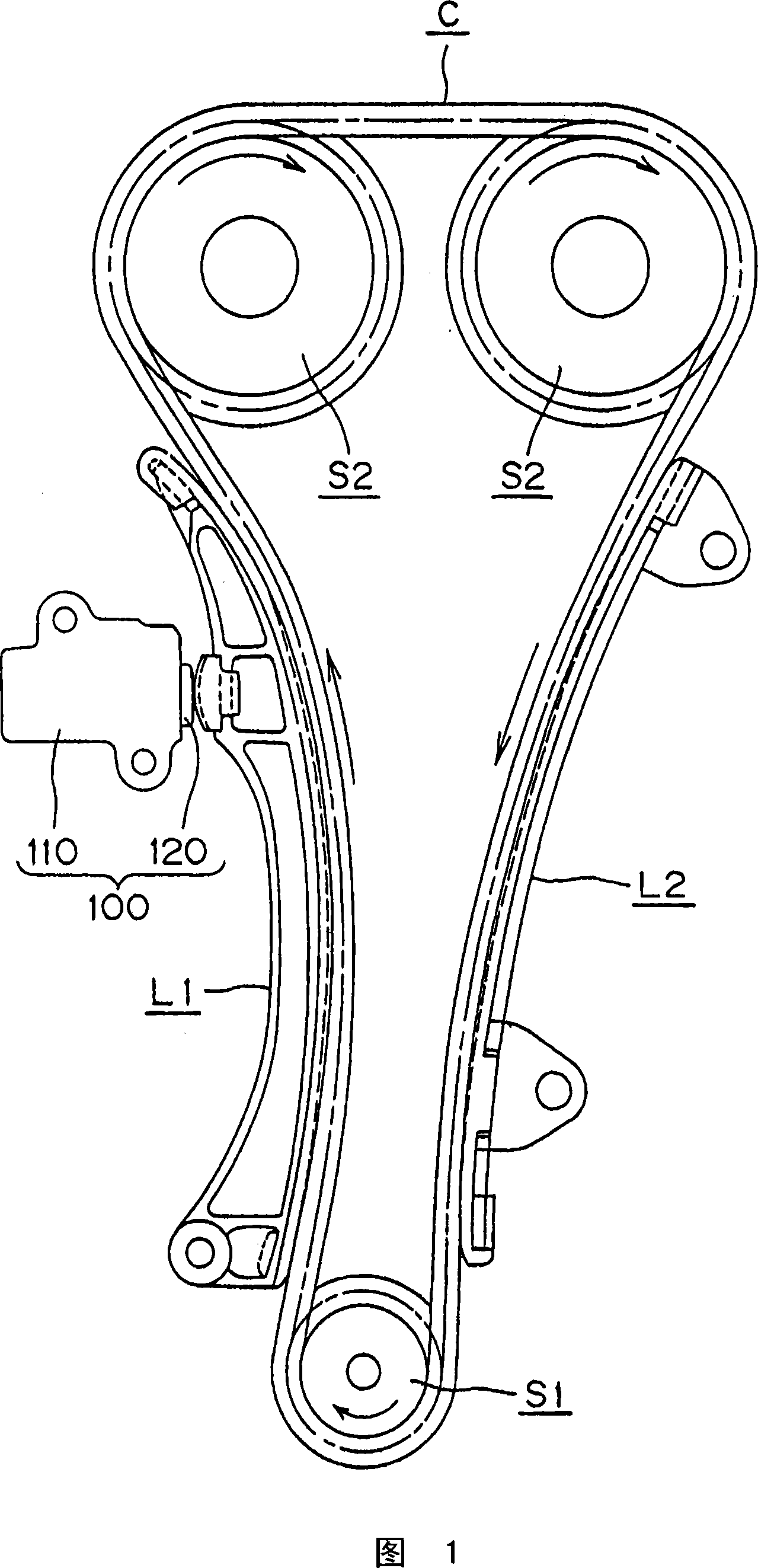

A tensioner, hydraulic technology, applied to belts/chains/gears, mechanical equipment, transmissions, etc., to achieve high hardness, restrain elastic deformation, and low linear expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

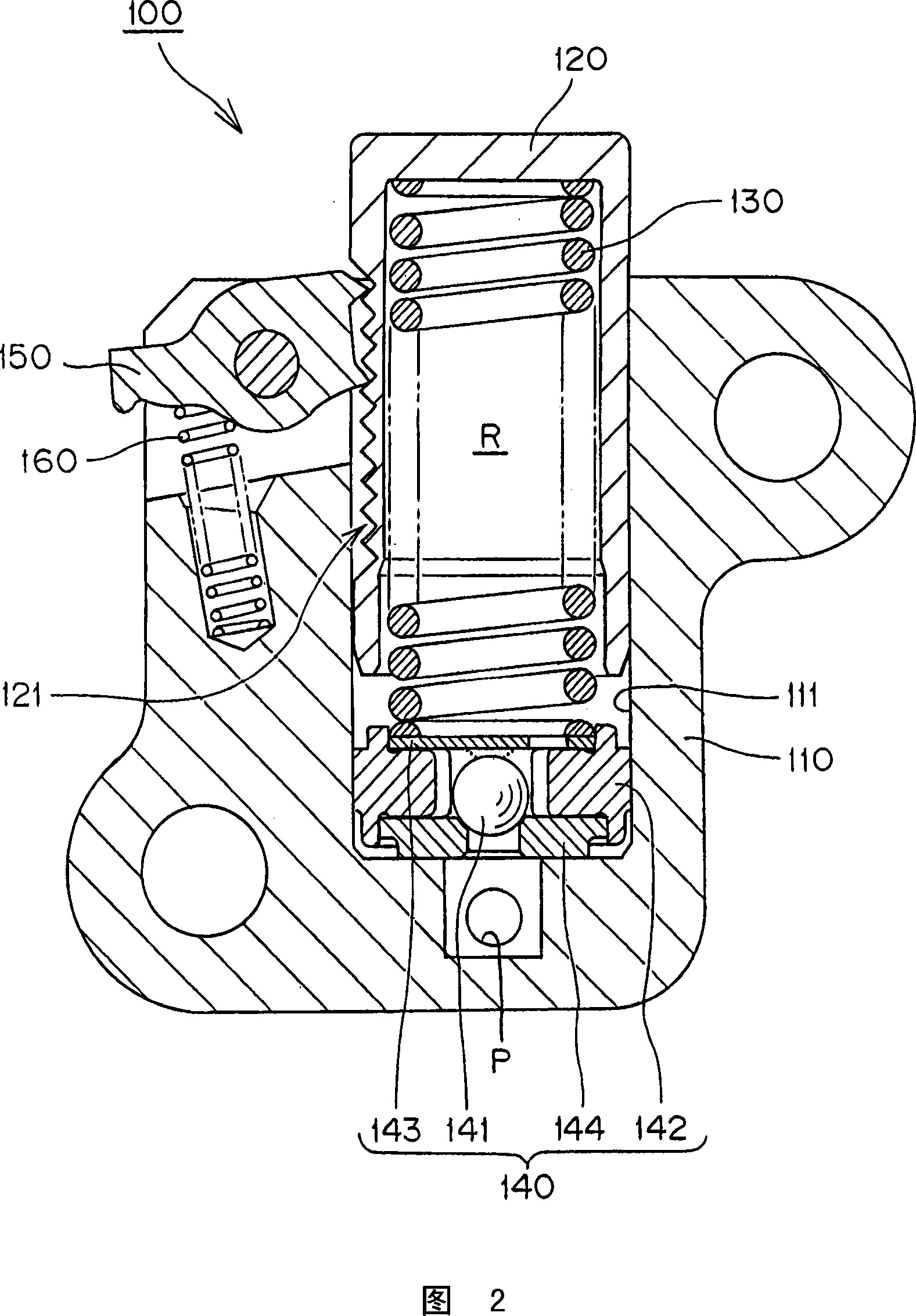

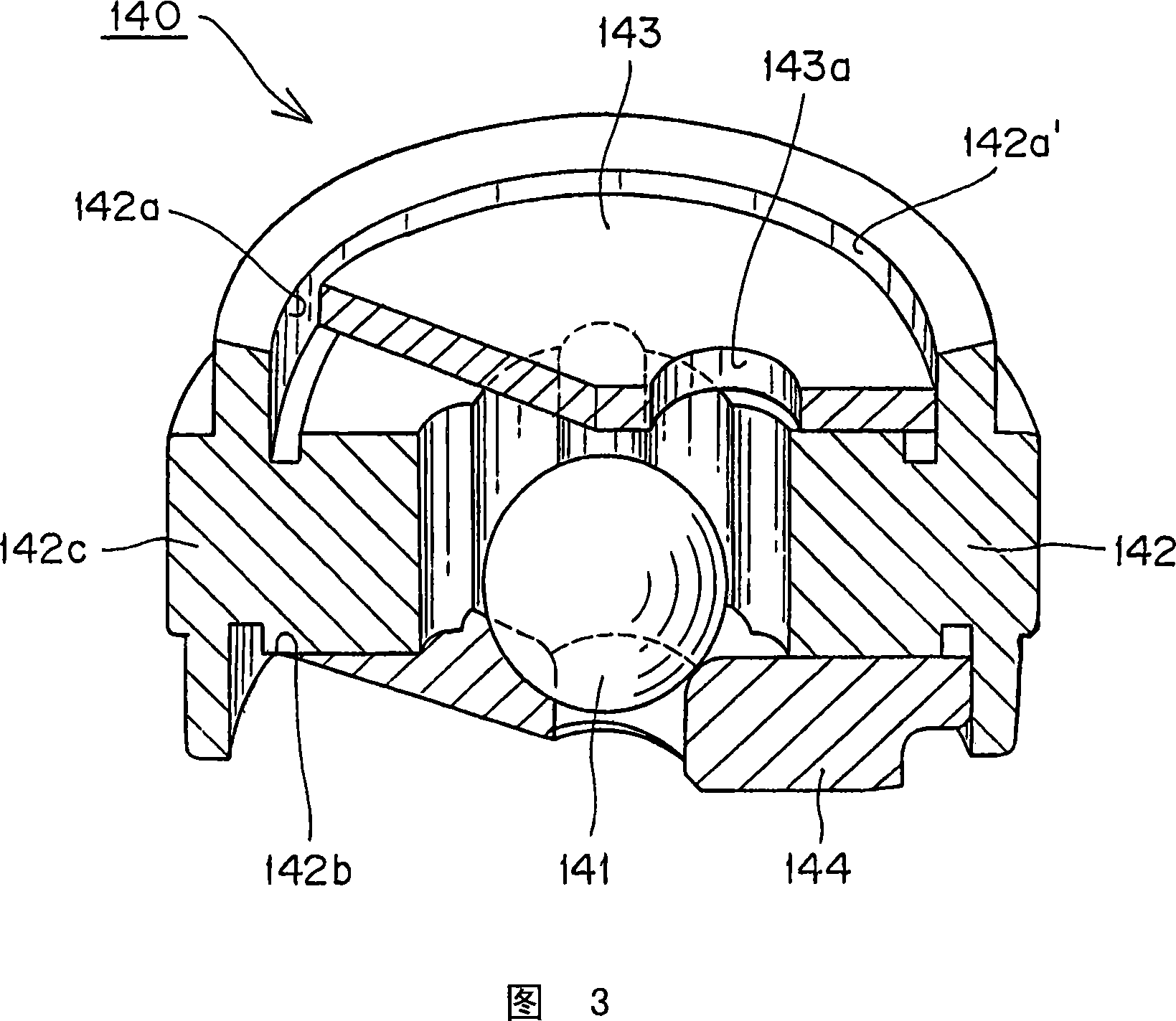

[0057] The hydraulic tensioner of the present invention has a plunger protruding slidably from the plunger receiving hole of the casing body toward the traveling chain, and is accommodated in a high-pressure oil chamber formed between the plunger receiving hole and the plunger. The spring for urging the plunger in the protruding direction of the plunger, and the check valve unit assembled at the bottom of the plunger receiving hole to prevent the pressure oil in the high-pressure oil chamber from flowing backward, wherein the check valve The unit includes: a one-way ball valve that restricts the flow of pressure oil; a steel ball guide that has an inner peripheral wall that moves the one-way ball valve in an enclosed state; a steel retainer that mounts the high-pressure oil on the ball guide chamber side, and has a pressure oil communication hole for the pressure oil to flow to the high pressure oil chamber side under the condition that the one-way ball valve is sealed in the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com