Method for establishing metal-organic framework composite coating on surface of magnesium metal

An organic framework and composite coating technology, applied in the direction of metal material coating process, etc., can solve the problems of poor adhesion of polymer coating film base, accelerated corrosion of magnesium metal, implant failure, etc., to achieve stable coating, The effect of promoting growth and differentiation, and controlling the rate of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

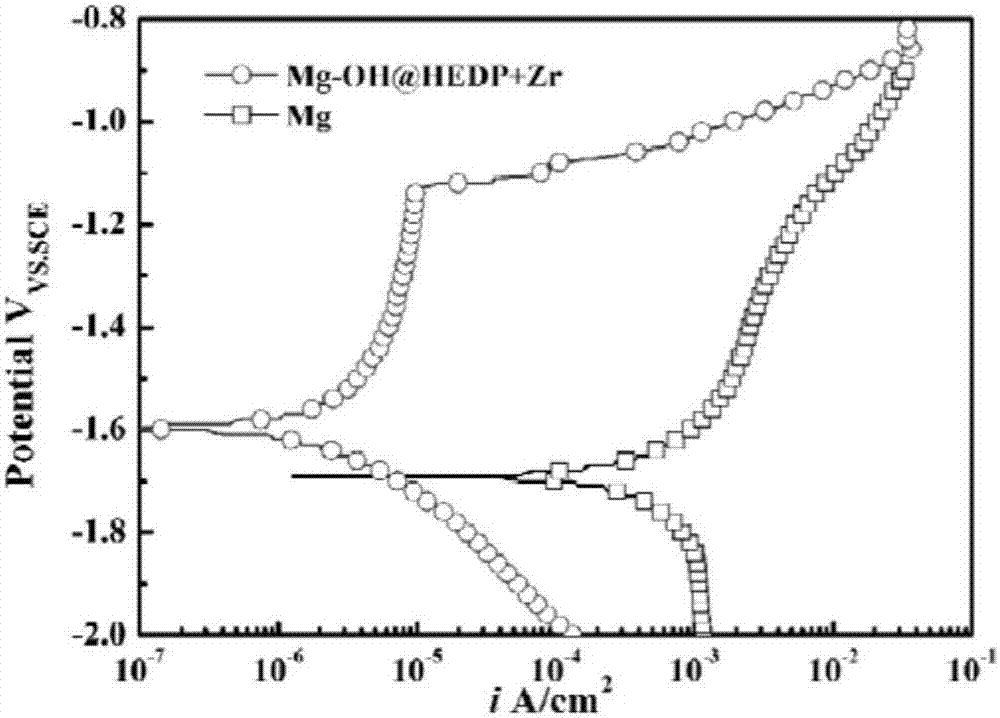

[0031] A method for constructing a metal-organic framework composite coating on a magnesium metal surface, the steps of which are:

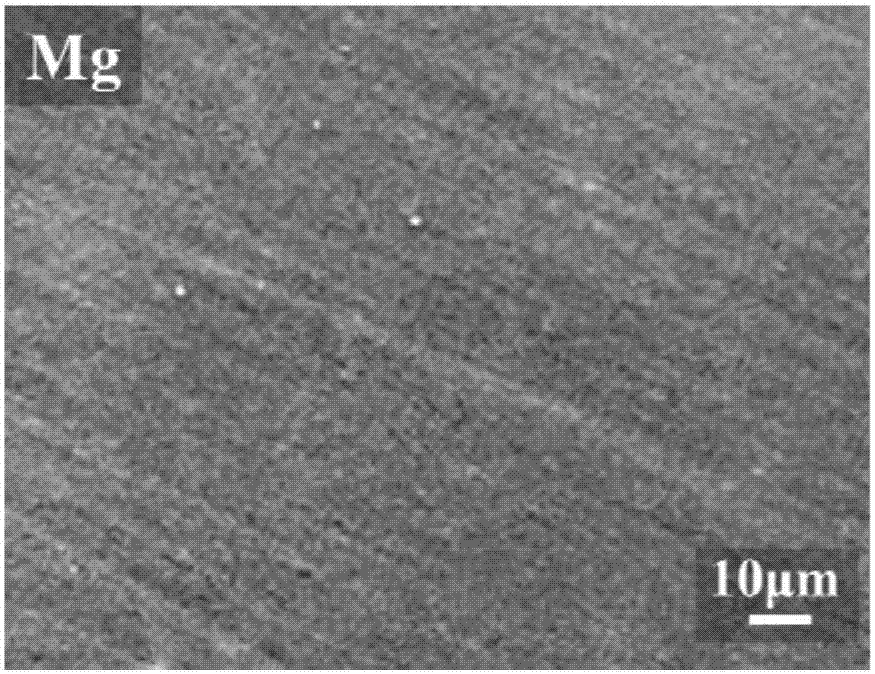

[0032] A. The magnesium metal sheet is polished and polished with silicon carbide sandpaper, then ultrasonically cleaned with deionized water, absolute ethanol, acetone, and pickling solution, and then vacuum-dried;

[0033] B. Soak the magnesium metal sheet obtained in step A in 2mol / L, 65°C NaOH solution for 14 hours to obtain the magnesium metal sheet activated by alkali;

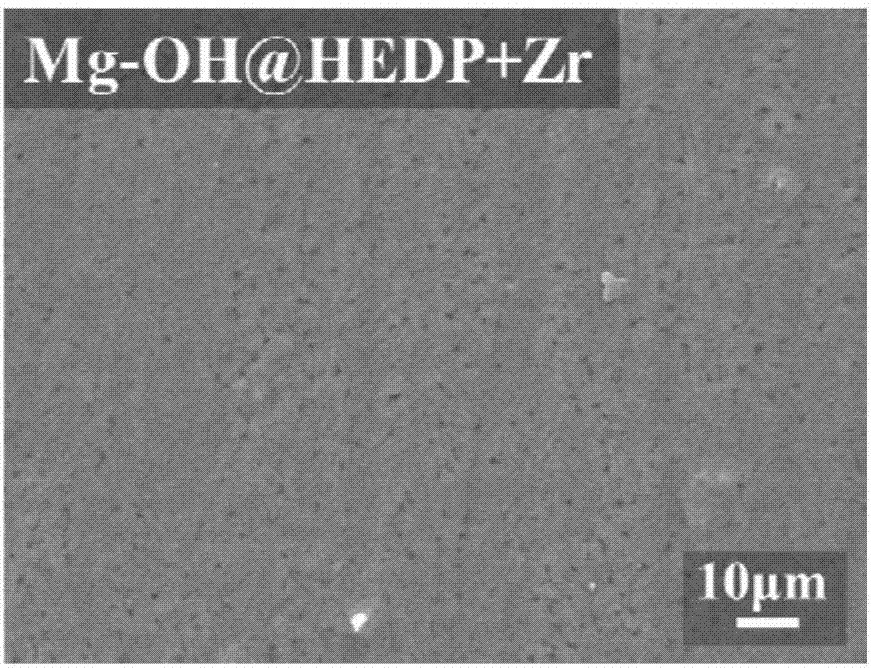

[0034] C, configuration concentration is the hydroxy ethylidene diphosphoric acid (HEDP) solution of 0.4g / L, then adjusts its pH to 8 with NaOH;

[0035] D, deionized water and absolute ethanol are formulated into a mixed solvent at a volume ratio of 1.0:1, and then ZrOCl 2 ·8H 2 O is dissolved in a mixed solvent to obtain a zirconium ion solution with a concentration of 0.8mmol / L;

[0036] E. Put the alkali-activated magnesium metal sheet obtained in step B into the hyd...

Embodiment 2

[0041] A method for constructing a metal-organic framework composite coating on a magnesium metal surface, the steps of which are:

[0042] A. The magnesium metal sheet is polished and polished with silicon carbide sandpaper, then ultrasonically cleaned with deionized water, absolute ethanol, acetone, and pickling solution, and then vacuum-dried;

[0043] B. Put the magnesium metal sheet obtained in step A into 4mol / L, 55°C NaOH solution and soak for 10h to obtain the magnesium metal sheet after alkali activation;

[0044] C, configuration concentration is the hydroxy ethylidene diphosphoric acid (HEDP) solution of 0.6g / L, then adjusts its pH to 7 with NaOH;

[0045]D, deionized water and absolute ethanol are formulated into a mixed solvent at a volume ratio of 1.2:1, and then ZrOCl 2 ·8H 2 O is dissolved in a mixed solvent to obtain a zirconium ion solution with a concentration of 1.2mmol / L;

[0046] E. Put the alkali-activated magnesium metal sheet obtained in step B into...

Embodiment 3

[0051] A method for constructing a metal-organic framework composite coating on a magnesium metal surface, the steps of which are:

[0052] A. The magnesium metal sheet is polished and polished with silicon carbide sandpaper, then ultrasonically cleaned with deionized water, absolute ethanol, acetone, and pickling solution, and then vacuum-dried;

[0053] B. Soak the magnesium metal sheet obtained in step A for 12 hours in a 3mol / L, 60°C NaOH solution to obtain an alkali-activated magnesium metal sheet;

[0054] C, configuration concentration is the hydroxyethylidene diphosphoric acid (HEDP) solution of 0.5g / L, then adjusts its pH to 7.5 with NaOH;

[0055] D, deionized water and absolute ethanol are formulated into a mixed solvent at a volume ratio of 0.8:1, and then ZrOCl 2 ·8H 2 O is dissolved in a mixed solvent to obtain a zirconium ion solution with a concentration of 1.0mmol / L;

[0056] E. Put the alkali-activated magnesium metal sheet obtained in step B into the hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com