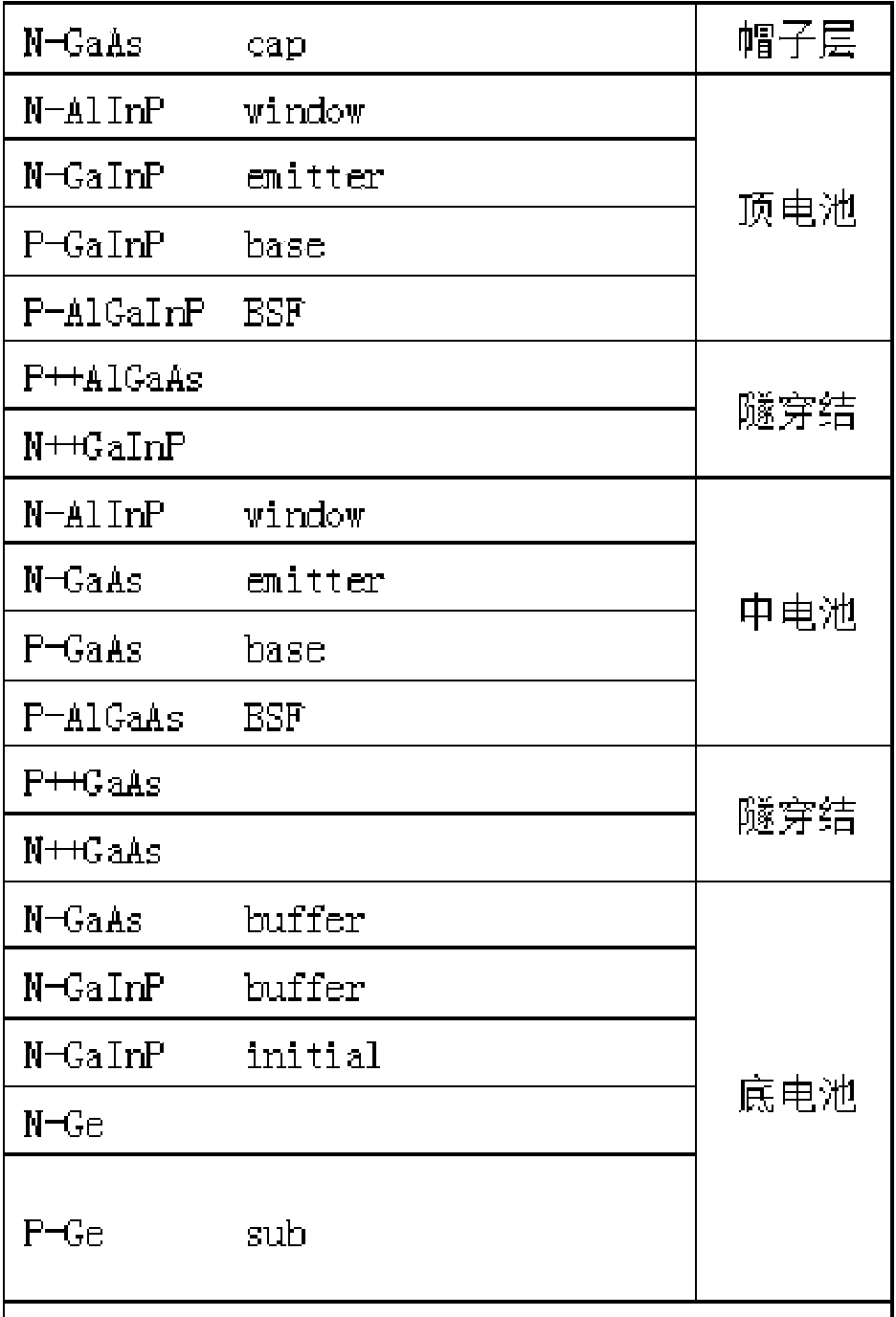

Etching solution for selectively etching gallium arsenide solar cell cap layer and preparation method thereof

A technology of solar cells and gallium arsenide, which is applied in the direction of chemical instruments and methods, circuits, electrical components, etc., can solve problems such as difficult control, increase in battery chip resistance, and grid line shedding, so as to reduce preparation costs and enhance uniformity , Good repeatable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1. An etchant for selectively etching the cap layer of a gallium arsenide solar cell, 800 g of solid citric acid with a purity greater than 99.8%, 500 g of hydrogen peroxide with a mass concentration of 30%, and 35 g of a mixture of methylamine and ethylamine g, 25 g of a mixture of glycine and halosine, and 1000 g of deionized water are mixed and dissolved. After fully dissolving, adjust the pH to 8-10 with sodium hydroxide or potassium hydroxide solution to prepare a corrosion solution.

[0031] The specific operation steps are:

[0032] 1. First pour 800g of solid citric acid with a purity greater than 99.8% into the quartz cylinder;

[0033] 2. Add 1000 g deionized water to the quartz cylinder;

[0034] 3. Add 35 g of a mixture of methylamine and ethylamine and 25 g of a mixture of glycine and halosine into the quartz jar at the same time, stir with a glass rod and heat the quartz jar at the same time;

[0035] 4. After fully dissolving, add 500 g of hy...

Embodiment 2

[0037] Embodiment 2. An etching solution for selectively etching the cap layer of a gallium arsenide solar cell, using 1500 g of solid citric acid with a purity greater than 99.8%, 800 g of hydrogen peroxide with a mass concentration of 30%, and 180 g of a mixture of methylamine and ethylamine. g, 180 g of a mixture of glycine and halosine, and 1000 g of deionized water are mixed and dissolved. After fully dissolving, adjust the pH to 8-10 with sodium hydroxide or potassium hydroxide solution to prepare a corrosion solution.

[0038] The specific operation steps are:

[0039] 1. First pour 1500g of solid citric acid with a purity greater than 99.8% into the quartz cylinder;

[0040] 2. Add 1000 g deionized water to the quartz cylinder;

[0041] 3. Add 180 g of a mixture of methylamine and ethylamine and 180 g of a mixture of glycine and halosine into the quartz cylinder at the same time, stir with a glass rod and heat the quartz cylinder at the same time;

[0042] 4. After f...

Embodiment 3

[0044] Embodiment 3. An etching solution for selectively etching the cap layer of a gallium arsenide solar cell, 100 g of solid citric acid with a purity greater than 99.8%, 150 g of hydrogen peroxide with a mass concentration of 30%, and 15 g of a mixture of methylamine and ethylamine g, 15 g of a mixture of glycine and halosine, and 1000 g of deionized water are mixed and dissolved. After fully dissolving, adjust the pH to 8-10 with sodium hydroxide or potassium hydroxide solution to prepare a corrosion solution.

[0045] The specific operation steps are:

[0046] 1. First pour 100g of solid citric acid with a purity greater than 99.8% into the quartz cylinder;

[0047] 2. Add 1000 g deionized water to the quartz cylinder;

[0048] 3. Add 15 g of a mixture of methylamine and ethylamine and 15 g of a mixture of glycine and halosine into the quartz jar at the same time, stir with a glass rod and heat the quartz jar at the same time;

[0049] 4. After fully dissolving, add 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com