Composite corrosion inhibitor for seawater circulation cooling system carbon steel material anticorrosion

A technology of circulating cooling system and composite corrosion inhibitor, applied in the field of seawater corrosion inhibitor, can solve the problems of harmful microbial corrosion, biofouling, inability to establish passivation, etc., and achieve the effect of reducing use cost and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The composite corrosion inhibitor used for the anticorrosion of carbon steel materials in the seawater circulating cooling system provided by this embodiment is composed of sodium molybdate, polyaspartic acid PASP, benzalkonium bromide, sodium citrate and sodium silicate, wherein molybdate The mass ratio of sodium, polyaspartic acid PASP, benzalkonium bromide, sodium citrate and sodium silicate is 1:2:4:4:8.

[0038] Wherein the benzalkonium bromide is a benzalkonium bromide solution with a mass percentage of 5%; the polyaspartic acid is a polyaspartic acid aqueous solution with a mass percentage of 40%.

[0039] The preparation method of the composite corrosion inhibitor is to take each component of the above mass distribution ratio and mix them evenly.

[0040] The corrosion inhibition effect of the composite corrosion inhibitor in the present invention is illustrated below by specific test data:

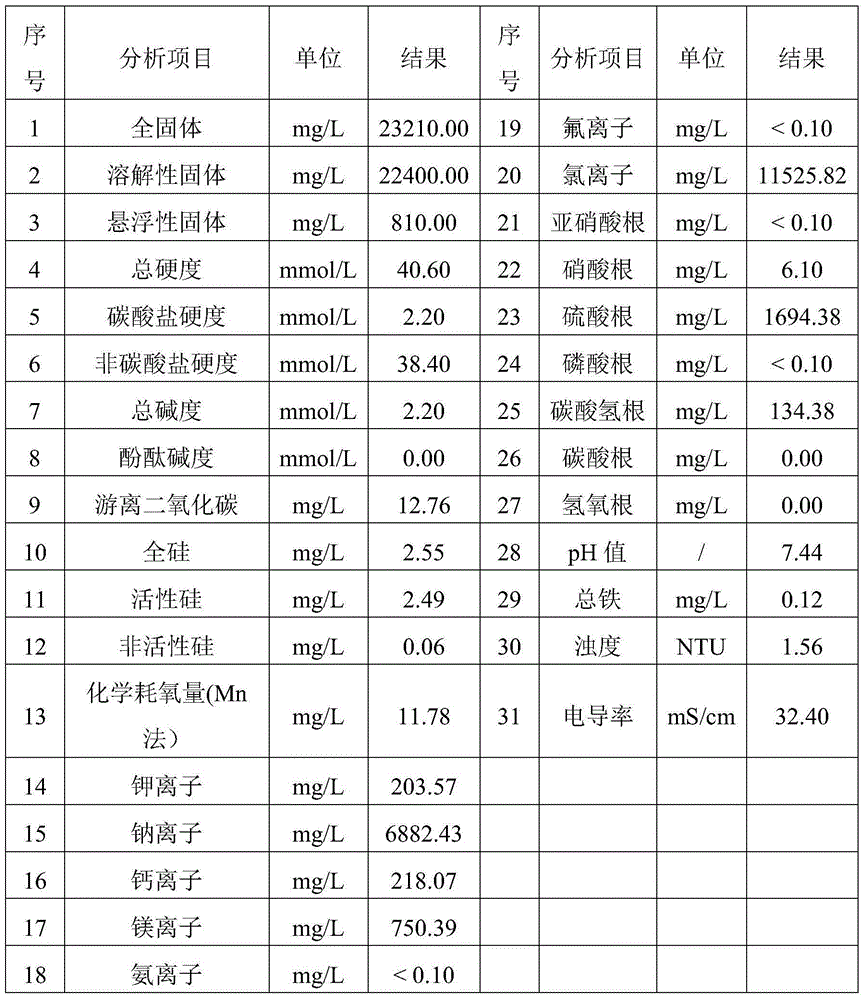

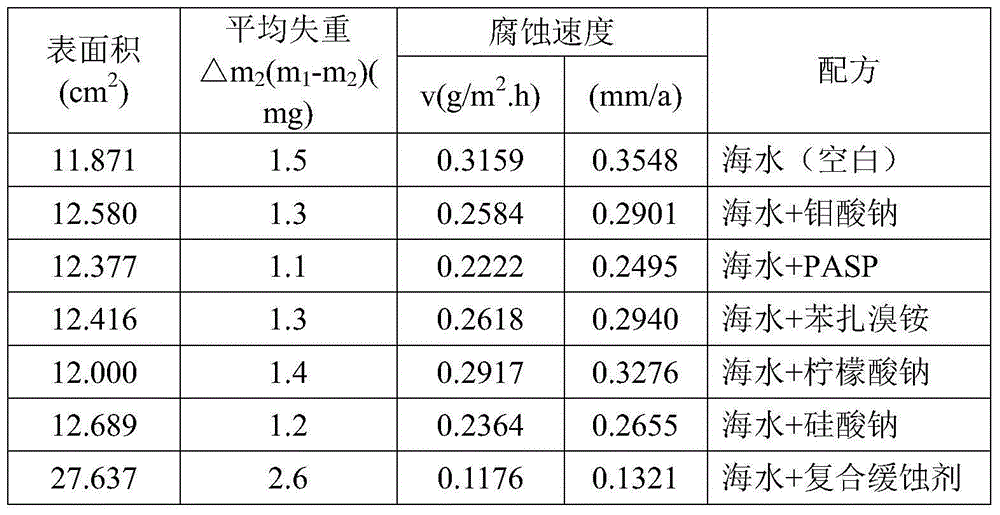

[0041] 1. Corrosion rate of Q235 carbon steel in an actual seawater w...

Embodiment 2

[0064] The composite corrosion inhibitor used for the anticorrosion of carbon steel materials in the seawater circulation cooling system provided by this embodiment is composed of sodium molybdate, polyaspartic acid PASP, benzalkonium bromide, sodium citrate and sodium silicate, wherein molybdate The mass ratio of sodium, polyaspartic acid PASP, benzalkonium bromide, sodium citrate and sodium silicate is 0.8:2.5:3.5:4.5:7.5.

[0065] Wherein the benzalkonium bromide is a benzalkonium bromide solution with a mass percentage of 5%; the polyaspartic acid PASP is a polyaspartic acid PASP aqueous solution with a mass percentage of 40%.

[0066] The preparation method of the composite corrosion inhibitor is to take each component of the above mass distribution ratio and mix them evenly.

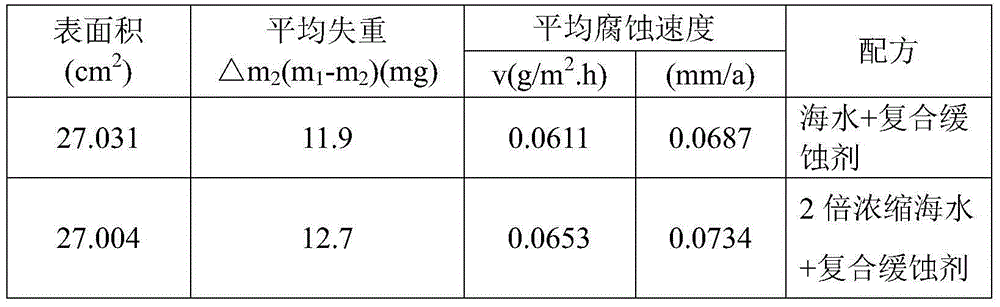

[0067] The corrosion inhibition effect of the composite corrosion inhibitor used in the anticorrosion of carbon steel materials in the seawater circulating cooling system provided in this embodimen...

Embodiment 3

[0069] The composite corrosion inhibitor used for the anticorrosion of carbon steel materials in the seawater circulation cooling system provided by this embodiment is composed of sodium molybdate, polyaspartic acid PASP, benzalkonium bromide, sodium citrate and sodium silicate, wherein molybdate The mass ratio of sodium, polyaspartic acid PASP, benzalkonium bromide, sodium citrate and sodium silicate is 1.2:1.5:4.5:3.5:8.5.

[0070] Wherein the benzalkonium bromide is a benzalkonium bromide solution with a mass percentage of 5%; the polyaspartic acid PASP is a polyaspartic acid PASP aqueous solution with a mass percentage of 40%.

[0071] The preparation method of the composite corrosion inhibitor is to take each component of the above mass distribution ratio and mix them evenly.

[0072] The corrosion inhibition effect of the composite corrosion inhibitor used in the anticorrosion of carbon steel materials in the seawater circulating cooling system provided in this embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com