MEMS sandwich accelerometer sensitive chip wet etching processing method

A wet corrosion and accelerometer technology, which is used in the measurement of acceleration, velocity/acceleration/impact measurement, acceleration measurement using inertial force, etc., to achieve the effect of simple process, high reliability, and improved corrosion processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

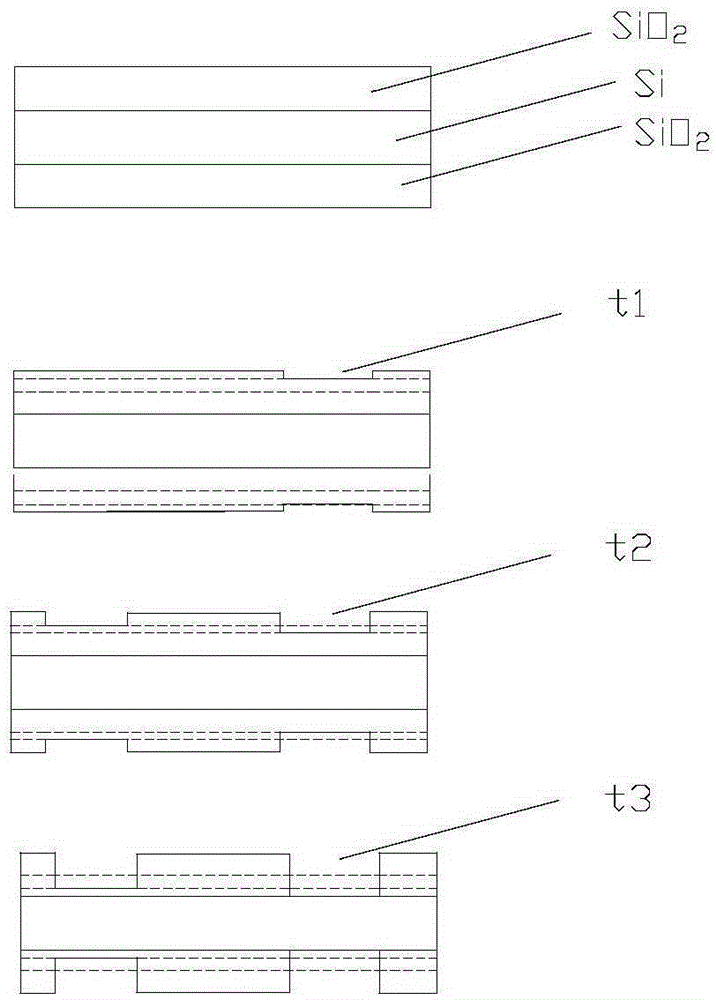

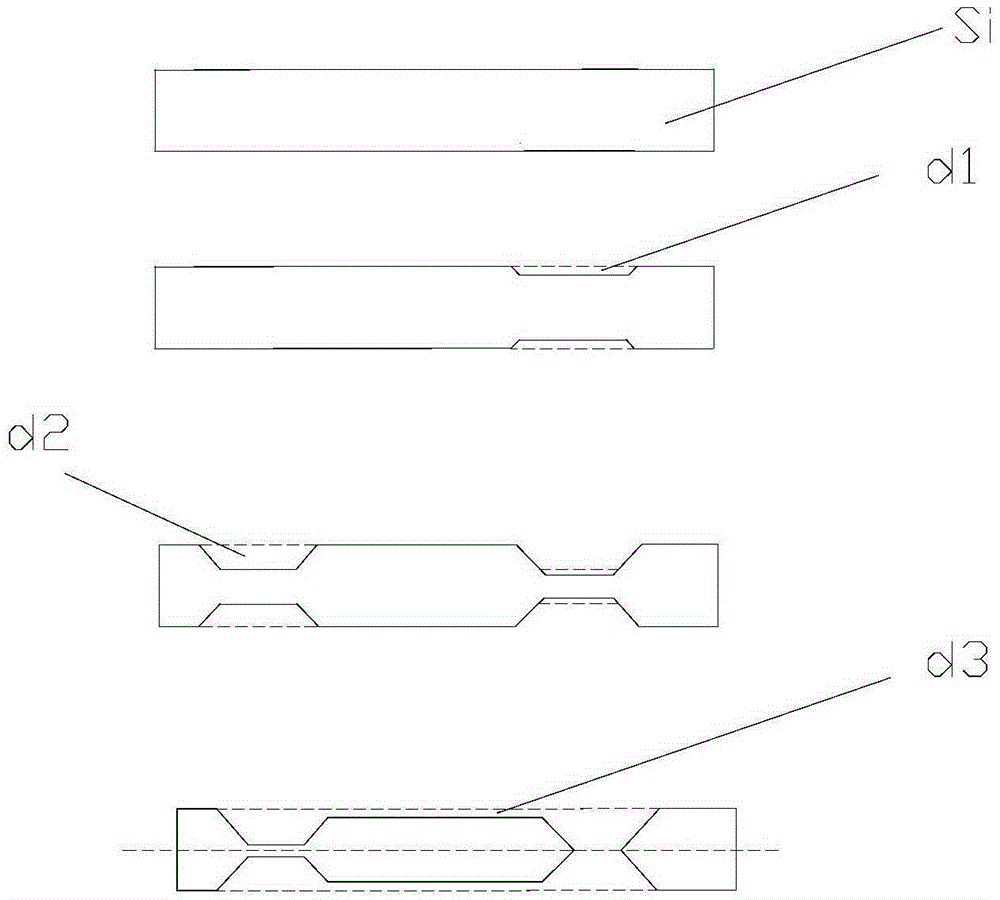

[0028] The detailed process of the present invention is introduced in detail below:

[0029] 1) To generate silicon wafer oxide film, perform wet oxygen oxidation on silicon wafer at 1000-1100°C, oxygen flow rate is 0.6-1.0l / min, oxidation time is more than 20 hours, and film thickness is 3μm-3.2μm at t;

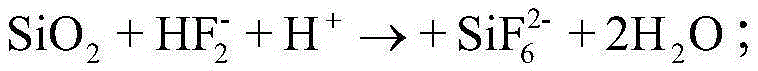

[0030] The chemical reaction formula for the formation of wet oxide layer is:

[0031] Si+2H 2 O = SiO 2 +2H 2

[0032] 2) Three times of layered processing on the oxide film, three times of conventional double-sided photolithography etching on the oxide film, the structure is formed by transferring three different positive resist patterns, and the pattern part of each exposure includes For the graphic part of the last exposure, the processing and etching size is below 3 microns. During photolithography, the surface of the oxide film of the silicon wafer can be treated as a relatively flat plane, and it is etched under the protection of glue every time. The etching solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com