Accelerated corrosion method and device for FRP reinforced damaged RC component in simulated marine environment

A marine environment, accelerated corrosion technology, used in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of slow FRP-concrete interface performance, long time required for steel corrosion, and a lot of manpower and material resources. To achieve the effect of controllable steel corrosion degree, reduce test limit and save time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

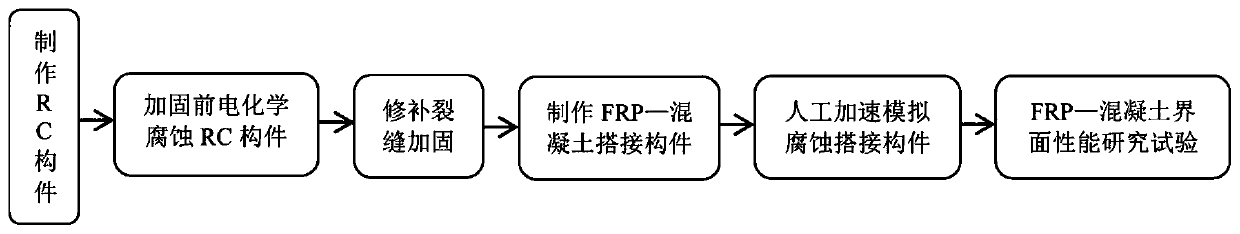

[0047] This embodiment is an embodiment of an accelerated corrosion method for simulating FRP reinforced damaged RC components in a marine environment, and includes the following steps, such as figure 1 Shown:

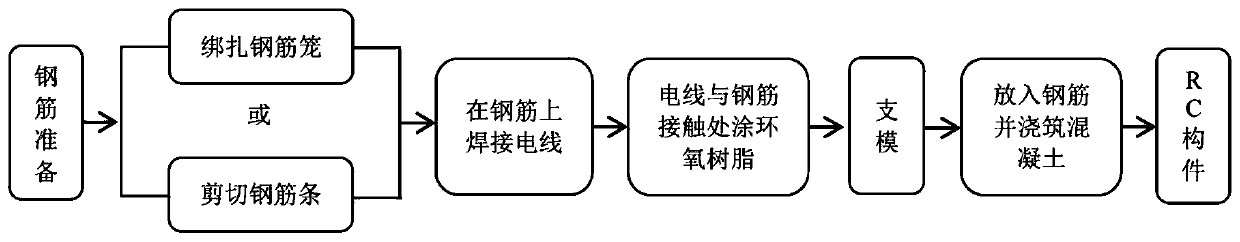

[0048] S10. Making RC components, the steel bars of the RC components are connected with wires;

[0049] S20. The RC component in step S10 is at least partially immersed in the electrolyte solution, the wire is connected to the positive electrode of the power supply, and the negative electrode of the power supply is connected to the cathode in the electrolyte solution, and the electrochemical corrosion of the steel bar is artificially accelerated to obtain a damaged RC component with cracks. In the embodiment, the power supply uses a DC stabilized power supply with a maximum output voltage of 450V and a maximum output current of 2A, and the outer wall of the power supply of this embodiment is provided with a voltage regulation switch and a current regulation switch to facil...

Embodiment 2

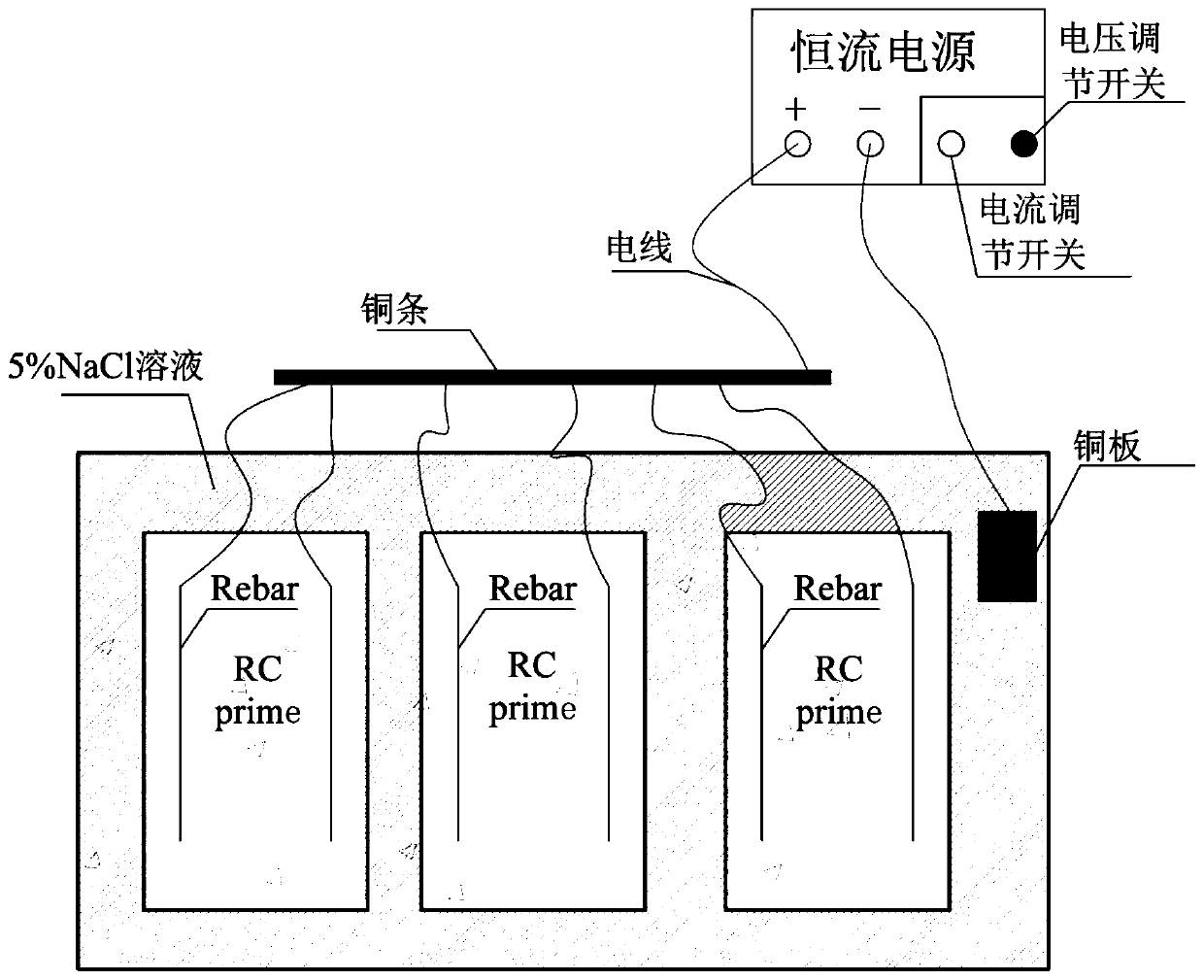

[0077] This embodiment is an embodiment of an accelerated corrosion device for FRP reinforcement of damaged RC components in a marine environment. It includes a corrosion tank containing an electrolyte solution, an RC component at least partially placed in the electrolyte solution, a cathode placed in the electrolyte solution, and a power source RC components are obtained by pouring steel bars and concrete. The steel bars are electrically connected to the positive pole of the power source, and the cathode is electrically connected to the negative pole of the power source.

[0078] Such as image 3 As shown, the RC components placed in the electrolyte solution are in multiple groups, and the multiple groups of steel bars are electrically connected to the conductive bars, and the conductive bars are electrically connected to the positive pole of the power supply. Multiple groups of RC components are corroded at the same time, which can improve the corrosion efficiency; and the arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com