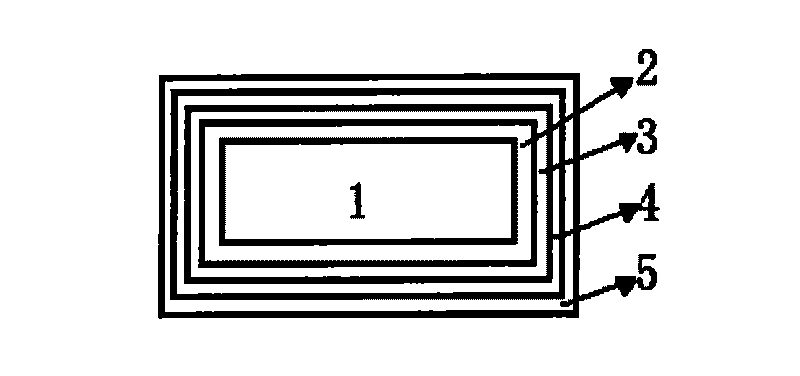

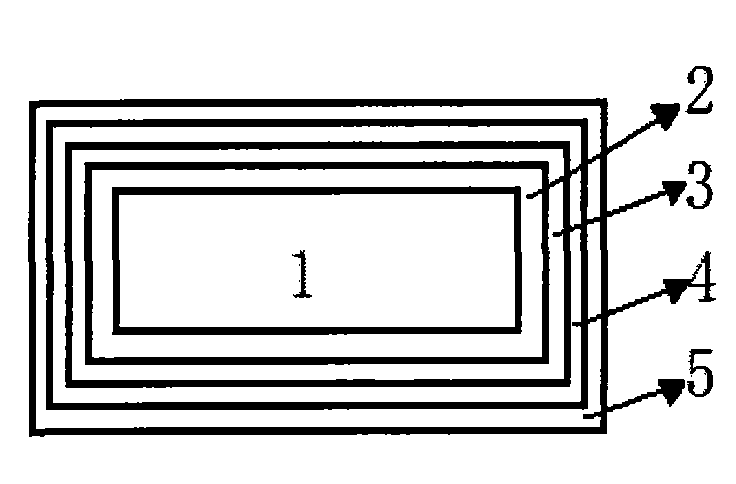

Absorbable magnesium alloy bracket of inorganic and organic antiseptic biocompatible composite coating and preparation method thereof

A magnesium alloy stent, biocompatibility technology, applied in coating, anodic oxidation, medical science, etc., can solve the problems of no drug-loaded coating and fast degradation speed, so as to improve the surface biocompatibility and solve the problem of degradation If the speed is too fast, the effect of improving the anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Magnesium alloy WE42 (mass fraction: Y3.7-4.3%, RE (Nd: 2.0-2.5%, HeavyE: balance): 2.4-4.4%, Zr>0.4%, Shanxi Magnesium Industry Group) is laser engraved into a stent, Then it is placed in the mixture containing mass concentration 7% HCl, mass concentration 8% FeCl 2 Ultrasonic treatment in the pickling solution for 30 minutes, then put it in a vacuum furnace for annealing treatment, raise the temperature to 1100°C at a rate of 3°C / min, keep it for 30 minutes, and then lower it to 20°C at a rate of 4°C / min ℃, and then ultrasonically cleaned with a power of 500W in deionized water for 15 minutes and then dried. The magnesium alloy organic-inorganic composite coating on the surface of the cell experiment has good biocompatibility, and the degradation products are non-toxic.

[0027] An inorganic anti-corrosion coating was prepared on the dried magnesium alloy stent. The micro-arc oxidation method is adopted, and the electrolyte composition is NaOH1-100g / L, NaOH 2 SiO 3...

Embodiment 2

[0033] The experimental conditions and operation process are the same as in Example 1. In the process of preparing the micro-arc oxidation inorganic coating, the oxidation time is changed to 20-120min, and the oxidation current is changed to 0.01A, 0.05A, 0.1A, 0.2A, 0.4A , 0.6A, 0.8A, 1.0A, 1.2A, 1.4A, 1.6A, 2.0A, magnesium alloy organic-inorganic composite coating on the surface of cell experiments has good biocompatibility, and the degradation products are non-toxic.

[0034] The prepared stent was tested in artificial simulated body fluid at 37°C, and the results showed that the corrosion resistance of the inorganic-organic composite coated magnesium alloy stent prepared by PLLA sealing was much higher than that of the unsealed inorganic coated magnesium alloy stent The corrosion resistance of magnesium alloy can be changed by changing the current parameters. The corrosion resistance of the micro-arc oxidation current density of 0.5A is 30 times that of the magnesium alloy ...

Embodiment 3

[0036] Experimental condition and operating process are identical with embodiment 1, just change micro-arc oxidation time to be 20-120min, oxidation current density is 0.01-2.0A\cm 2 , similar to Examples 1 and 2, only changed: in the process of preparing the organic PLLA sealing coating, the molecular weight of PLLA was changed, the magnesium alloy organic-inorganic composite coating on the surface of the cell experiment had good biocompatibility, and the degradation products were non-toxic.

[0037] The prepared stents were tested in artificial simulated body fluid at 37°C. The results showed that the degradation cycles of PLLA-sealed magnesium alloys with different molecular weights were different. The polymer coatings were degraded within 150-360 days, and the metal stents were degraded within 240-420 days. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com