Making of novel monocrystalline silicon chip suede making additive and simple suede making method

A monocrystalline silicon wafer and additive technology, which is applied in the direction of single crystal growth, single crystal growth, and final product manufacturing, can solve problems such as low conversion efficiency of solar cells, inability to remove monocrystalline silicon wafers, and serious environmental pollution, and achieve shortening Texturing time, reducing water surface tension, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

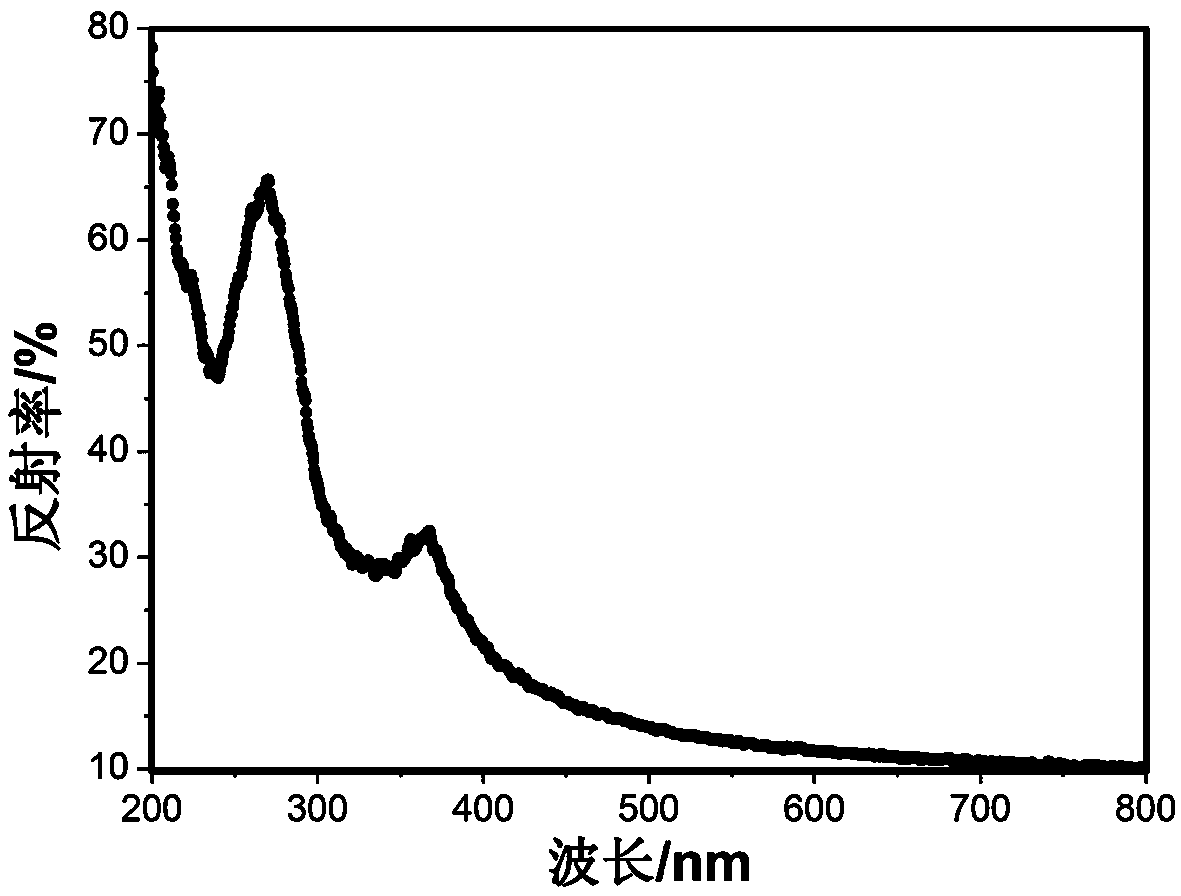

Embodiment 1

[0032] (1) Preparation of velvet additives: 2 g rhamnose, 0.5 g didecyl dimethyl ammonium bromide, 3 g glutathione, 2 g catechol, 0.1 g ethylene glycol, 1 g Barium chloride was added to the remaining amount of water (95 ml), and mixed evenly to prepare 100 g of texturing additives.

[0033] (2) Prepare velvet solution: dissolve 200 g of sodium hydroxide in deionized water to obtain 40 kg of alkali solution; add 100 g of velvet additive prepared in step (1) to the alkali solution and mix evenly to obtain velvet liquid.

[0034] (3) Submerge the monocrystalline silicon wafer in the texturing solution described in (2) to perform texturing on the surface of the silicon wafer, the texturing temperature is 75°C, and the texturing time is 900 s.

Embodiment 2

[0036] A kind of texturing method of monocrystalline silicon chip, concrete steps are as follows:

[0037] (1) Preparation of additives for velvet: 3 g rhamnose, 1.5 g didecyl dimethyl ammonium bromide, 5 g glutathione, 2.2 g catechol, 0.5 g ethylene glycol, 2 g Barium chloride was added to the rest of the water (95 ml), and mixed evenly to prepare 100 g of texturing additive.

[0038] (2) Prepare velvet solution: dissolve 80 g of sodium hydroxide in deionized water to obtain 10 kg of alkali solution; add 100 g of velvet additive prepared in step (1) to the alkali solution and mix evenly to obtain velvet solution .

[0039] (3) Submerge the monocrystalline silicon wafer in the texturing solution described in (2) for texturing the surface of the silicon wafer, the texturing temperature is 80°C, and the texturing time is 600 s.

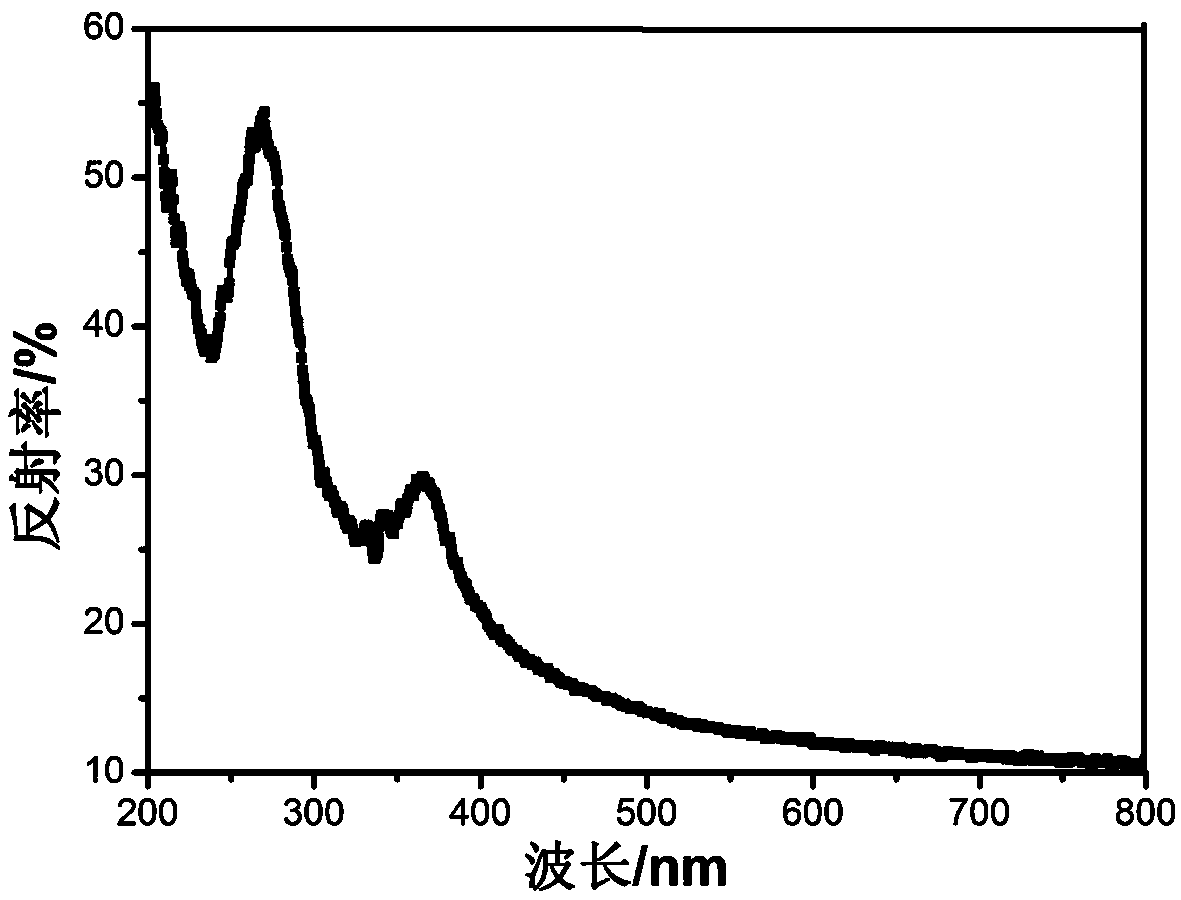

Embodiment 3

[0041] A kind of texturing method of monocrystalline silicon chip, concrete steps are as follows:

[0042] (1) Preparation of additives for velvet: 5 g rhamnose, 1 g didecyl dimethyl ammonium bromide, 4 g glutathione, 5 g catechol, 0.3 g ethylene glycol, 0.5 g Barium chloride was added to the rest of the water (95 ml), and mixed evenly to prepare 100 g of texturing additive.

[0043] (2) Prepare velvet solution: dissolve 100 g of sodium hydroxide in deionized water to obtain 5 kg of alkali solution; add 100 g of velvet additive prepared in step (1) to the alkali solution and mix evenly to obtain velvet solution .

[0044] (3) Submerge the monocrystalline silicon wafer in the texturing solution described in (2) to perform texturing on the surface of the silicon wafer, the texturing temperature is 82°C, and the texturing time is 800 s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com