A low-weight monocrystalline silicon texturing additive and its application

An additive and silicon texturing technology, which is applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of weight reduction, short service life, and low production capacity of texturing silicon wafers, and reduce the weight loss of silicon wafers , reduce reflectivity and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

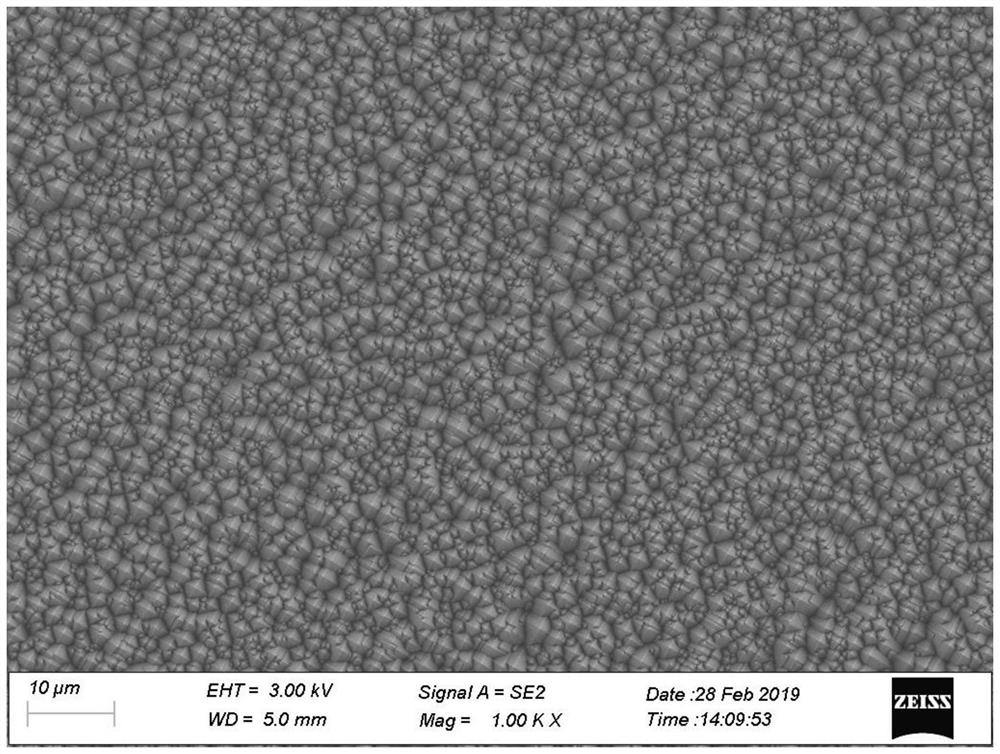

Image

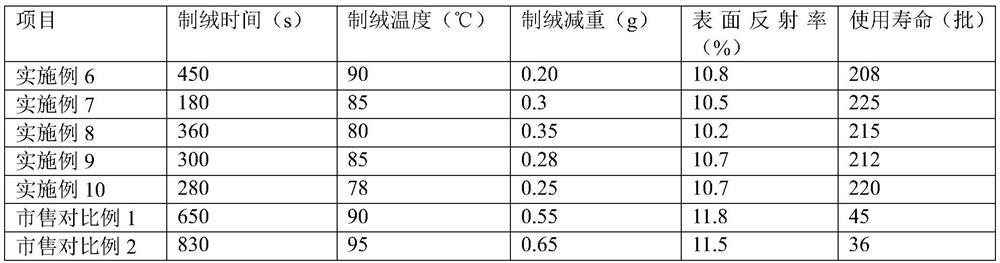

Examples

Embodiment 1

[0038] A low-weight monocrystalline silicon texturing additive, the monocrystalline silicon texturing additive comprises the following components in terms of weight percentage: 0.01% sodium cellulose sulfonate, 0.1% sodium carboxymethyl cellulose, tannin 0.01% acid, 0.05% water-soluble polymer protective agent, 1% potassium hydroxide, and the balance is water.

[0039] Wherein: the preparation method of described sodium cellulose sulfonate is as follows:

[0040] (1) Enzymolysis: add the cellulose to the solution containing polysaccharide hydrolase at a concentration of 10u / g after crushing, hydrolyze at 30°C for 2 hours, raise the temperature of the system until the polysaccharide hydrolase denatures, and let it cool down to room temperature centrifuged, and the supernatant was freeze-dried to obtain a cellulose hydrolyzate with a certain degree of polymerization;

[0041] (2) Sulfonation: Mix the obtained cellulose hydrolyzate with dichloromethane according to the mass rati...

Embodiment 2

[0048] A low-weight monocrystalline silicon texturing additive, the monocrystalline silicon texturing additive includes the following components in terms of weight percentage: sodium starch sulfonate 1%, sodium carboxymethyl starch 3%, baicalein 1 %, water-soluble polymer protective agent 0.5%, sodium hydroxide 2%, and the balance is water.

[0049] Wherein: the preparation method of described sodium starch sulfonate is as follows:

[0050] (1) Enzymatic hydrolysis: Add the starch to a solution containing polysaccharide hydrolase at a concentration of 25u / g after crushing, hydrolyze at 55°C for 5 hours, raise the temperature of the system until the polysaccharide hydrolase denatures, let it cool down to room temperature, and then centrifuge Separating, taking the supernatant and freeze-drying to obtain a starch hydrolyzate with a certain degree of polymerization;

[0051] (2) Sulfonation: mix the obtained starch hydrolyzate with ethyl acetate according to the mass ratio of 1:...

Embodiment 3

[0058] A low-weight monocrystalline silicon texturing additive, the monocrystalline silicon texturing additive comprises the following components in terms of weight percentage: 0.5% sodium fructan sulfonate, carboxymethyl chitosan or sodium alginate 2%, 0.5% of liquiritigenin, 0.25% of water-soluble polymer protective agent, 0.15% of cesium hydroxide, and the balance is water.

[0059] Wherein: the preparation method of described sodium fructan sulfonate is as follows:

[0060] (1) Enzymolysis: Grind fructan and add it to a solution containing polysaccharide hydrolase at a concentration of 20u / g. After hydrolysis at 50°C for 3 hours, raise the temperature of the system until the polysaccharide hydrolase denatures, and let stand to cool down to room temperature. After centrifugation, the supernatant was freeze-dried to obtain a fructan hydrolyzate with a certain degree of polymerization;

[0061] (2) Sulfonation: Mix the obtained fructan enzymolyzate with n-hexane according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com