Additive for alkali environment-protecting type no-alcoholic felting liquid of mono-crystal silicone chip and using method thereof

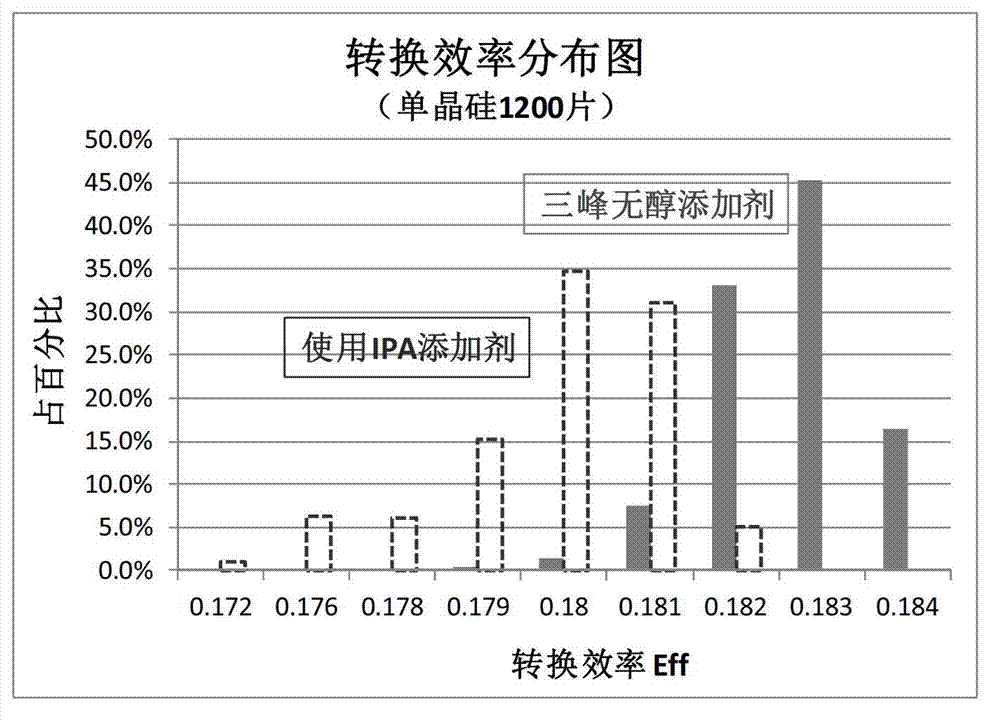

An additive, single-crystal silicon technology, applied in chemical instruments and methods, crystal growth, post-processing details, etc., can solve the problems of poor surface uniformity of silicon wafers, poor texturing stability, and large amount of silicon wafer corrosion. , to achieve the effect of improving photoelectric conversion efficiency, shortening texturing time, and uniform color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Prepare additives, take 0.05 grams of edible protein powder with more than 85% protein, take 0.01 grams of anionic surfactant (a kind of detergent), take 0.001 grams of vitamins, donkey-hide gelatin, and tea polyphenols, and 99.939 grams of deionized water. Dissolve protein powder, detergent, vitamins, donkey-hide gelatin, and tea polyphenols in deionized water to make a 100-gram solution.

[0037] Prepare the texturing solution, dissolve 5 grams of NaOH in 995 grams of deionized water to obtain 1000 grams of alkaline alcohol-free texturing solution; add 20 grams of additives to the 1000 grams of alkaline alcohol-free texturing solution.

[0038] The monocrystalline silicon wafers for solar cells are immersed in the texturing solution added with additives for surface texturing, the texturing temperature is 70°C, and the texturing time is 720s, and the texturing is completed.

Embodiment 2

[0040] Prepare additives, take 0.05 grams of edible protein powder with more than 85% protein, take 0.01 grams of anionic surfactant (a kind of detergent), take 0.001 grams of vitamins, donkey-hide gelatin, and tea polyphenols, and 99.939 grams of deionized water. Dissolve protein powder, detergent, vitamins, donkey-hide gelatin, and tea polyphenols in deionized water to make a 100-gram solution.

[0041] Prepare the texturing solution, dissolve 11 grams of NaOH in 989 grams of deionized water to obtain 1000 grams of alkaline alcohol-free texturing solution; add 25 grams of additives to the 1000 grams of alkaline alcohol-free texturing solution.

[0042] The monocrystalline silicon wafer for solar cells is immersed in the texturing solution added with additives for surface texturing, the texturing temperature is 75°C, and the texturing time is 900s, and the texturing is completed.

Embodiment 3

[0044] Prepare additives, take 1 gram of food foaming agent, 1 gram of household neutral surfactant (a kind of detergent), 0.003 grams of vitamins, donkey-hide gelatin, and tea polyphenols, and 97.997 grams of deionized water. Powder, detergent, vitamins, donkey-hide gelatin, and tea polyphenols were dissolved in deionized water to make a 100-gram solution.

[0045] Prepare the texturing solution, dissolve 100 grams of NaOH in 900 grams of deionized water to obtain 1000 grams of alkaline alcohol-free texturing solution; add 50 grams of additives to the 1000 grams of alkaline alcohol-free texturing solution.

[0046] The monocrystalline silicon wafer for solar cells is immersed in the texturing solution added with additives for surface texturing, the texturing temperature is 90° C., and the texturing time is 1200 s, and the texturing is completed.

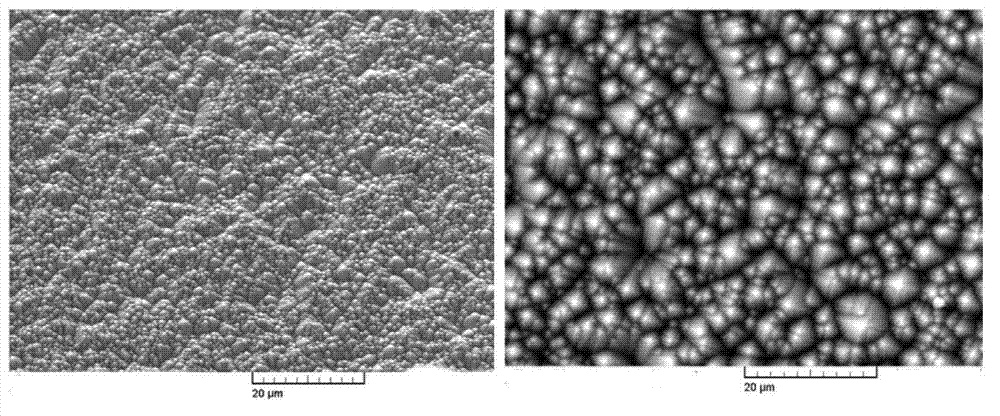

[0047] see figure 1 as shown, figure 1 It is a comparison diagram of the scanning electron microscope plan view of the textured ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com