Cerium-zirconium-palladium nanopowder catalyst and preparation and application thereof

A nano-powder and catalyst technology, applied in the field of nano-powder morphology cerium-zirconium-palladium catalyst and its preparation, can solve problems such as process complexity, achieve uniform system structure, no loss of noble metal active component distribution, and high chemical stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

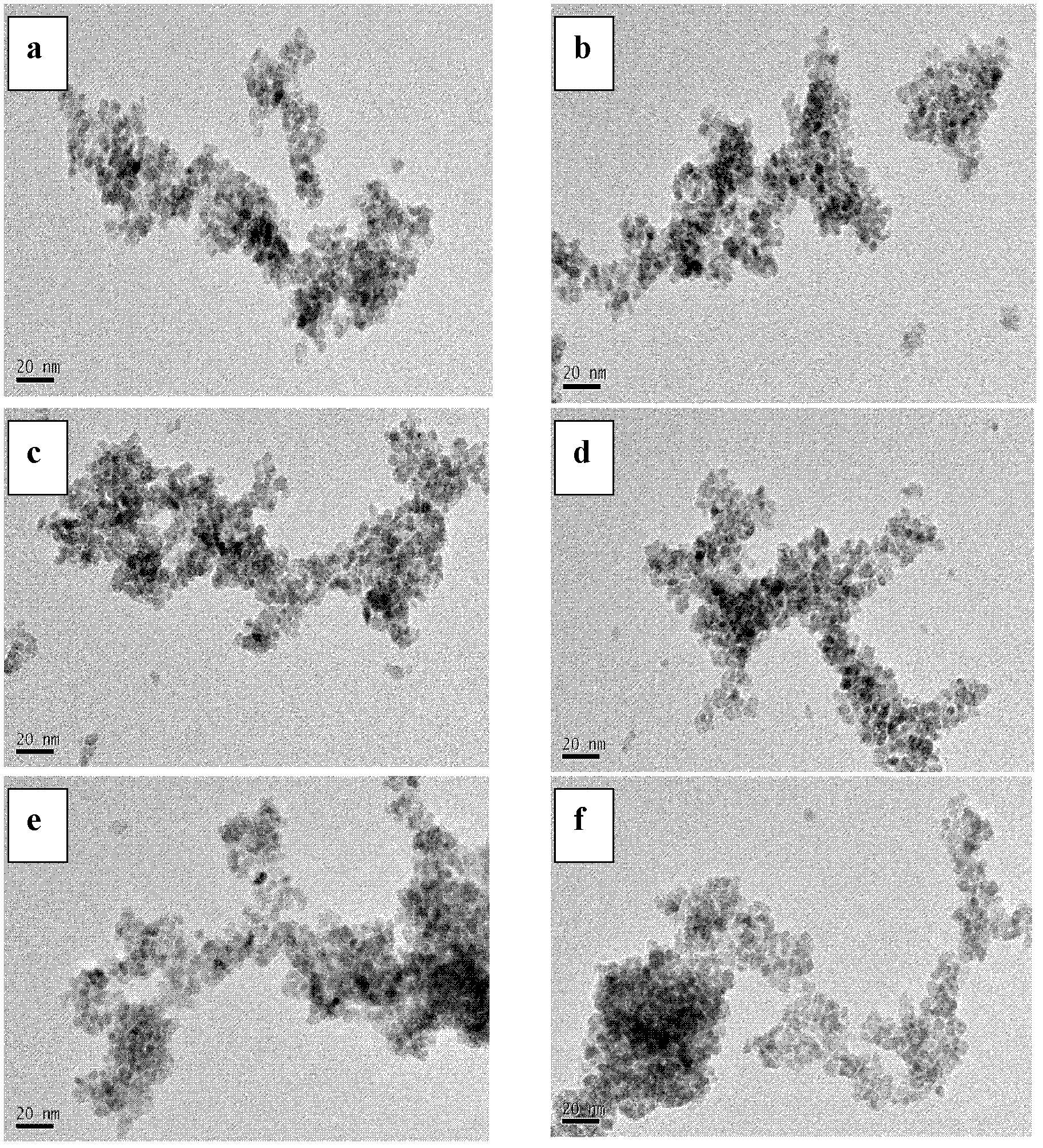

[0034] Weigh Ce(NO 3 )·6H 2 O 3.4740g, ZrOCl 2 ·8H 2 O 0.6445g was dissolved in 20ml of absolute ethanol, and 1g of P123 template was added at the same time, placed in a 35°C water bath, and stirred vigorously for 2 hours to obtain a uniform transparent yellowish sol. Then add 0.0041g Pd(NO 3 )·2H 2 O (according to 0.1wt% Pd loading), continue to stir vigorously for 8 hours, transfer it to a constant temperature and humidity drying box with a petri dish, control the temperature at 35°C, and the relative humidity at 40°C, and evaporate the solvent in this environment and induce P123 The self-assembly of the self-assembly, the evaporation induction time lasted for 48 hours to form a gel, and then dried at 100°C for 24 hours, and finally baked at 400°C for 4 hours, with a heating rate of 1°C per minute. Obtain the cerium zirconium palladium solid solution of nanopowder morphology, Figure 1a-f The TEM photos of the catalyst are provided, and the catalysts have formed nanopo...

Embodiment 2

[0036] Preparation condition and preparation procedure are the same as example 1, just Pd(NO 3 )·2H 2 The amount of O added was changed to 0.0081, 0.0203, 0.0406, 0.0813, and 0.2032g, respectively, so that the loading amount of Pd was 0.2wt%, 0.5wt%, 1.0wt%, 2.0wt%, and 5.0wt%.

Embodiment 3

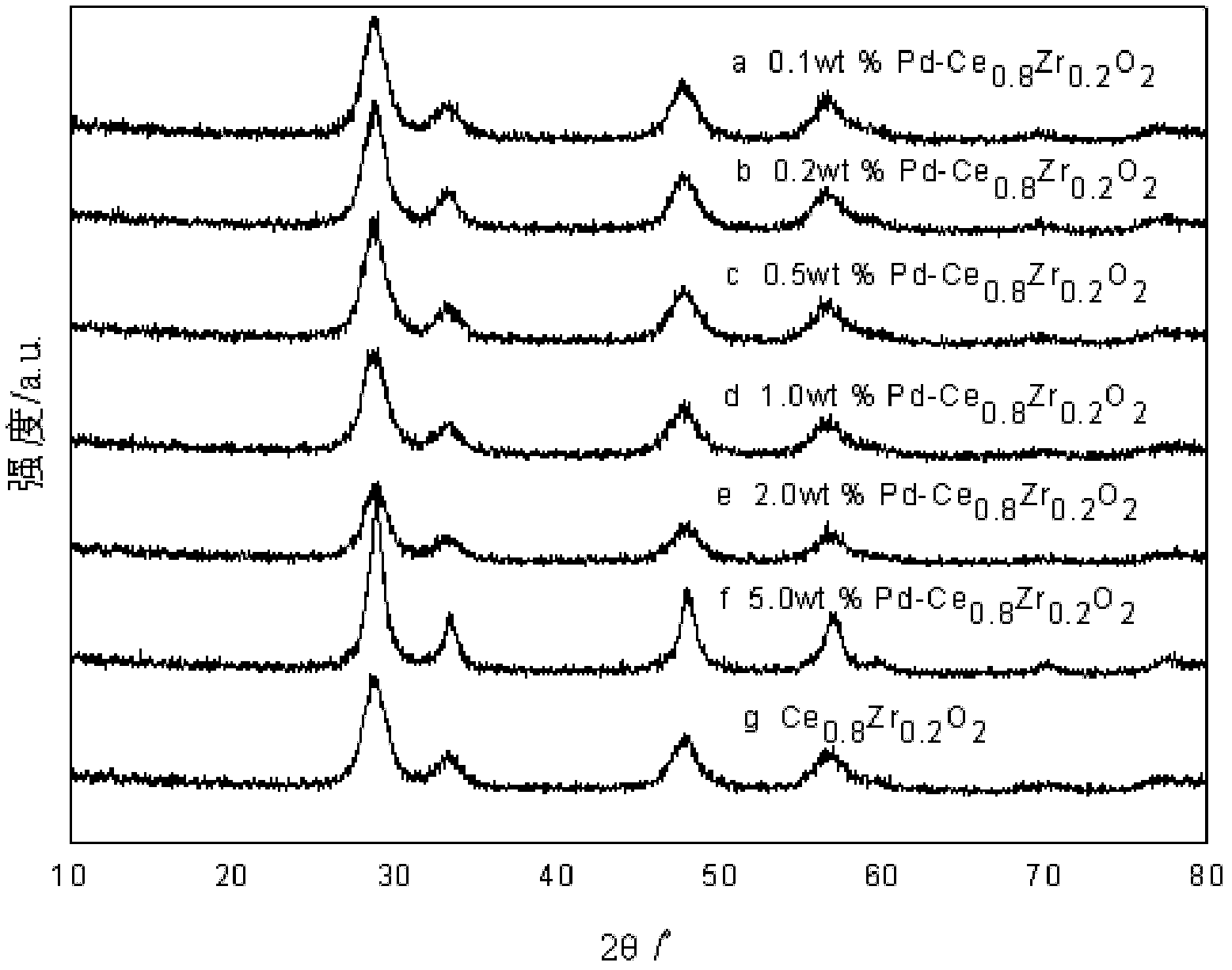

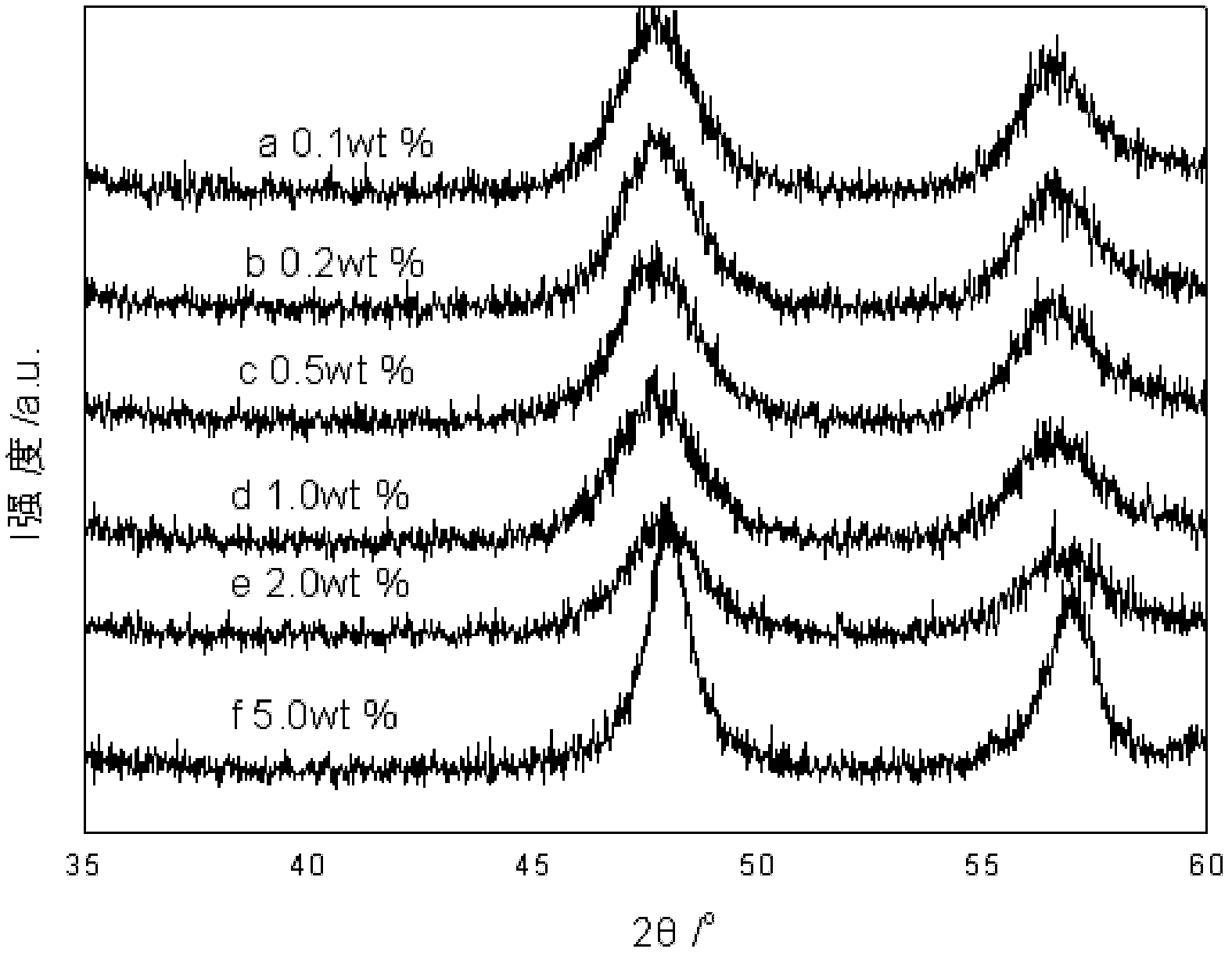

[0038] Observation of prepared catalyst (a) 0.1wt%Pd / Ce by transmission electron microscope (TEM) 0.8 Zr 0.2 o 2 , (b) 0.2wt% Pd / Ce 0.8 Zr 0.2 o 2 , (c) 0.5wt% Pd / Ce 0.8 Zr 0.2 o 2 , (d) 1.0wt% Pd / Ce 0.8 Zr 0.2 o 2 (e) 2.0wt% Pd / Ce 0.8 Zr 0.2 o 2 , (f) 5.0wt% Pd / Ce 0.8 Zr 0.2 o 2 shape. The crystal phase structure of the catalyst was analyzed by X-ray diffraction (XRD), and the crystallite size and unit cell parameters of the catalyst were calculated by Scherrer's formula.

[0039] Figure 1a-f Through the TEM results of the samples, it can be seen that the particle size of the prepared catalyst particles is 5-10nm, the particle size is uniform, and it has a nano-powder shape. There are large gaps between the particles, which can provide a large space for the catalytic reaction. interface.

[0040] Take the half width β of the diffraction peak corresponding to the crystal plane of the sample (111), and use the Scherrer formula: D=0.89λ / (βcosθ) to calculate x...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com