Method for preparing monodisperse silver-palladium composite microsphere

A composite microsphere and monodisperse technology, which is applied in the field of synthesis of monodisperse silver-palladium composite microspheres, can solve the problem of high cost and achieve the effects of low cost, easy cleaning and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

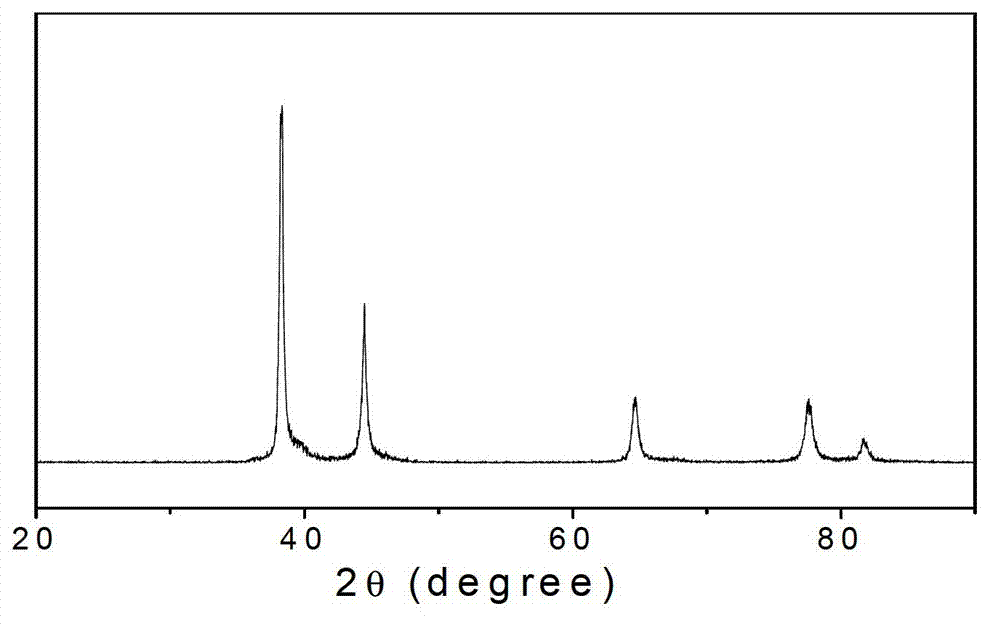

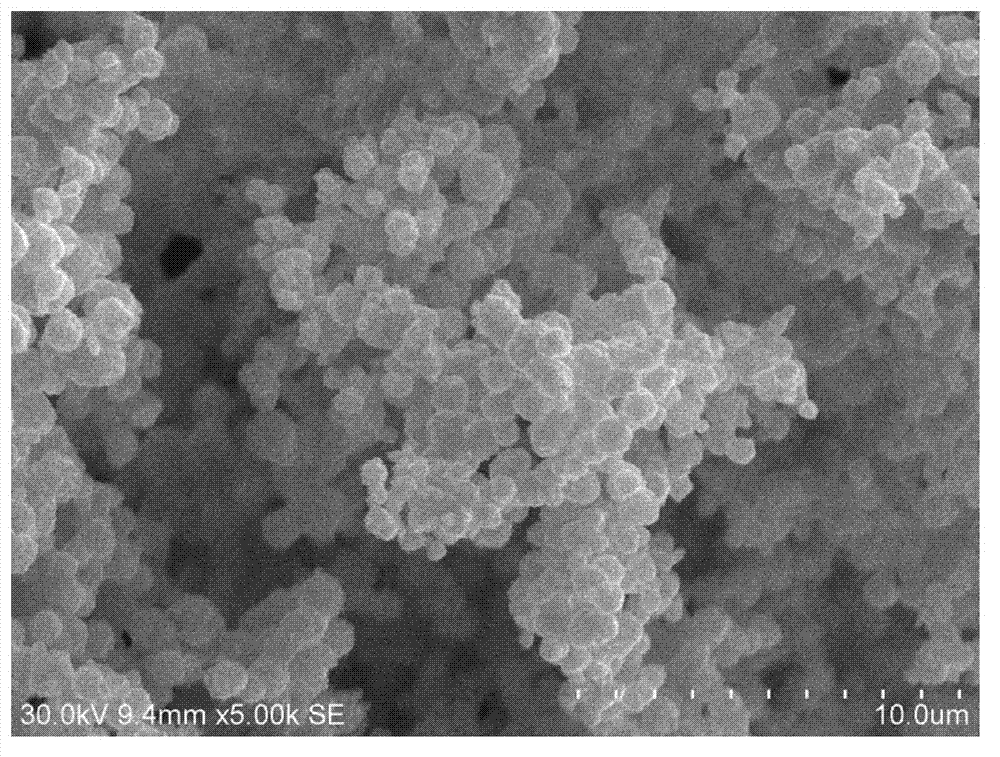

[0021] Add silver nitrate containing 4.5g silver, palladium nitrate containing 0.5g palladium, 2mg gelatin and 25mL deionized water into a 150mL beaker in turn. into a separatory funnel; hydrazine hydrate with 10 times the molar number of silver palladium was added to 75 mL of deionized water and stirred evenly as a reducing solution; at 15° C., the raw material solution was added dropwise to the reducing solution, and reacted at this temperature for 5 minutes. The XRD diffraction peaks of the sample are as figure 1 As shown in , the peak shape is similar to the standard peak of cubic phase elemental silver (JCPDS No. 04-0783), but the peak position is slightly shifted to high angle, and the peak of elemental palladium basically does not appear, indicating that the product under this condition is The composite structure of the alloy; the morphology is as figure 2 shown. It can be seen that the product is a well-dispersed spherical powder with a size of about 750nm and unifo...

Embodiment 2

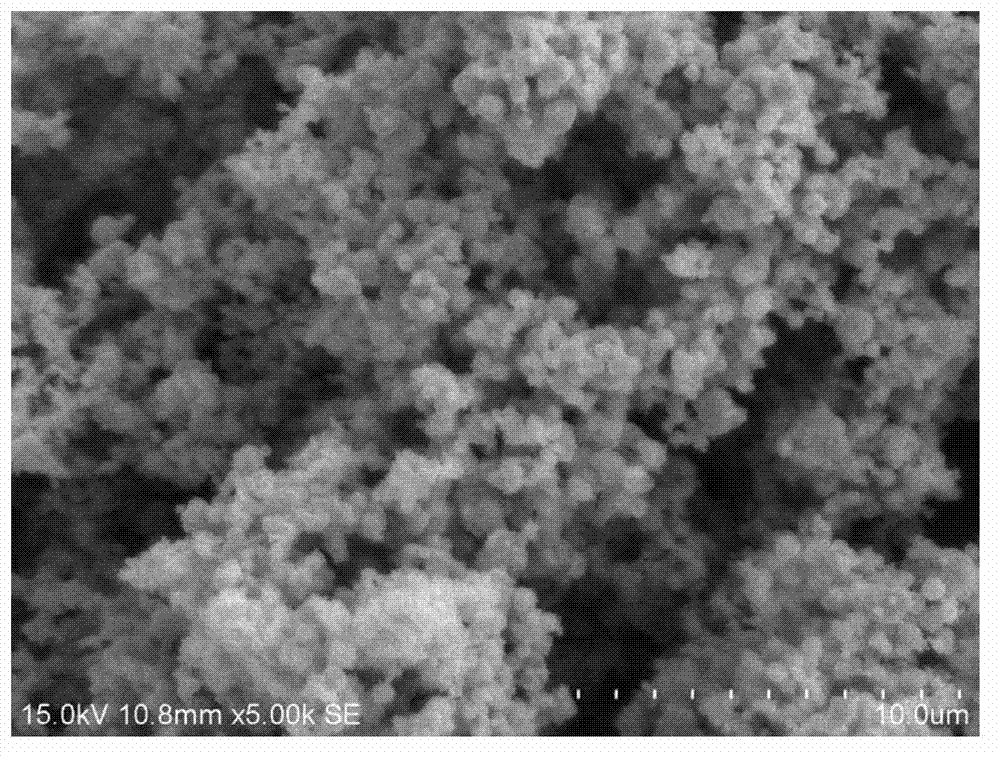

[0023] Add silver nitrate containing 4.5g of silver, palladium nitrate containing 0.5g of palladium, 8mg of gelatin and 25mL of deionized water into a 150mL beaker in sequence. into a separatory funnel; hydrazine hydrate with 2 times the molar number of silver palladium was added to 75mL deionized water and stirred evenly as a reducing solution; at 45°C, the raw material solution was added dropwise to the reducing solution, and reacted at this temperature for 30min. looks like image 3 shown. It can be seen that the product is a well-dispersed spherical powder with a size of about 350 nm and uniform distribution.

Embodiment 3

[0025] Add silver nitrate containing 4.5g of silver, palladium nitrate containing 0.5g of palladium, 0.5mg of gelatin and 25mL of deionized water into a 150mL beaker in sequence, after completely dissolving, add alkali solution under stirring, adjust the pH of the solution to 9, and transfer into a separatory funnel; hydrazine hydrate with 5 times the molar number of silver palladium was added to 75mL deionized water and stirred evenly as a reducing solution; at 30°C, the raw material solution was added dropwise to the reducing solution, and reacted at this temperature for 15min. The product looks like Figure 4 shown. It can be seen that the product is a well-dispersed spherical powder with a size of about 550 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com