Compounding method for palladium/graphene structural carbon material combined electrode catalyst

A composite electrode, graphene technology, applied in structural parts, battery electrodes, circuits, etc., can solve the problems of affecting the electrochemical activity and stability of catalysts, poor electrochemical stability of catalysts, palladium nanoparticles falling off, etc. Strong anti-poisoning ability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

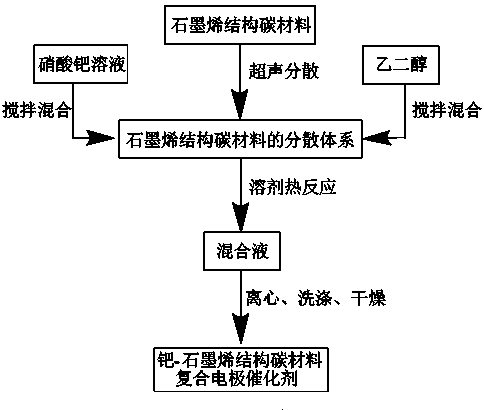

[0023] Implementation example 1: Palladium-graphene composite electrode catalyst (mass ratio palladium:graphene=1:1)

[0024] In the first step, 0.10 g of natural graphite is added to 1000 mL of 1-methyl-2-pyrrolidone, ultrasonicated at 20 ° C for 2 hours and then left to stand to obtain a graphene dispersion solution;

[0025] Second step, measure the dispersion solution of 120mL graphene, add the 0.94mol / L palladium nitrate solution of 40mL ethylene glycol and 0.012mL respectively thereinto, stir;

[0026] In the third step, the reaction system in the second step is transferred to a hydrothermal kettle for reaction at 120° C. for 12 hours;

[0027] In the fourth step, the reaction system in the third step is centrifuged to separate the solid product, washed with deionized water, and dried to obtain a palladium-graphene composite electrode catalyst.

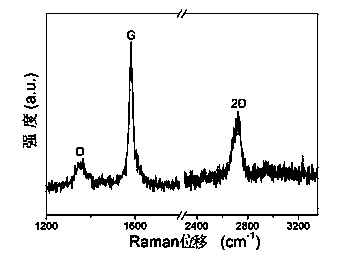

[0028] figure 2 For adopting the Raman spectrogram of the palladium-graphene catalyst that embodiment example 1 prepares....

Embodiment 2

[0030] Implementation example 2: Palladium-carbon nanotube composite electrode catalyst (mass ratio palladium: carbon nanotube=10:1)

[0031] In the first step, add 0.01g of carbon nanotubes to 1000mL of 1-methyl-2-pyrrolidone, ultrasonicate for 1 hour at 25°C and let stand;

[0032] In the second step, measure 120 mL of the dispersion solution of multi-walled carbon nanotubes, add 600 mL of ethylene glycol and 0.122 mL of 0.94 mol / L palladium nitrate solution, and stir evenly;

[0033] In the third step, the reaction system in the second step is transferred to a hydrothermal kettle for reaction at 200° C. for 2 hours;

[0034] In the fourth step, the reaction system in the third step is centrifuged to separate the solid product, washed with deionized water, and dried to obtain a palladium-carbon nanotube composite electrode catalyst.

Embodiment 3

[0035] Implementation example 3: Palladium-fullerene composite electrode catalyst (mass ratio palladium:fullerene=1:10)

[0036] In the first step, 1.00g of fullerene was added to 1000mL of 1-methyl-2-pyrrolidone, ultrasonicated at 30°C for 3 hours and left to stand;

[0037] In the second step, measure 120 mL of fullerene dispersion solution, add 24 mL of ethylene glycol and 0.122 mL of 0.94 mol / L palladium nitrate solution, and stir evenly;

[0038] In the third step, the reaction system in the second step is transferred to a hydrothermal kettle for reaction at 20° C. for 36 hours;

[0039] In the fourth step, the reaction system in the third step is centrifuged to separate the solid product, washed with deionized water, and dried to obtain a palladium-fullerene composite electrode catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com