Preparation method for dendritic copper-palladium nanocrystalline alloy and product of preparation method

A palladium nano- and dendritic technology is applied in the field of preparation of copper-palladium nanocrystalline alloys, which can solve the problems of unfriendly environment, difficulty in large-scale production and high reaction temperature, and achieve the effects of cheap reagents, easy dispersion and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) 15mg palladium acetylacetonate (Pd(acac) 2 ), 13mg copper acetylacetonate (Cu(acac) 2 ), 100mg tungsten carbonyl and 50mg polyvinylpyrrolidone (PVP: molecular weight 29000) were dissolved in 10ml benzyl alcohol and stirred at room temperature for 1h.

[0025] (2) Transfer the reaction solution obtained in (1) to a 20ml round bottom flask, and react at 120°C for 2h.

[0026] (3) Centrifuge the product obtained in (2) at a speed of 8000-12000 rpm / min for 10 min, and remove the supernatant.

[0027] (4) ultrasonically disperse the precipitate obtained in (3) in ethanol, and store at room temperature.

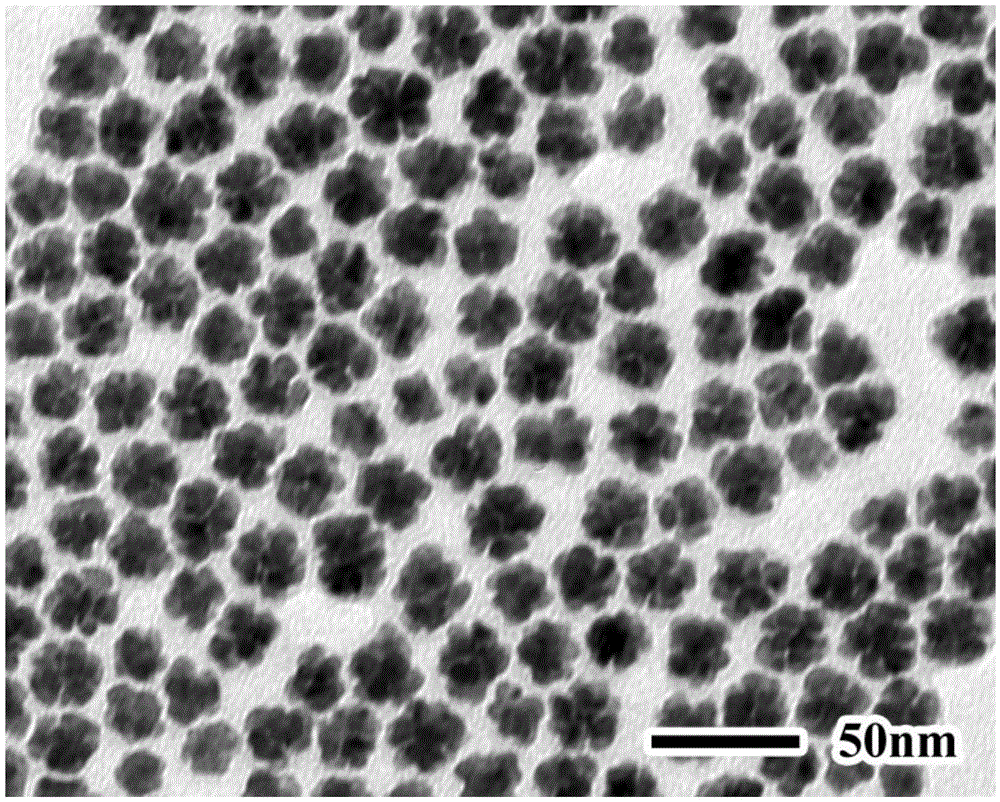

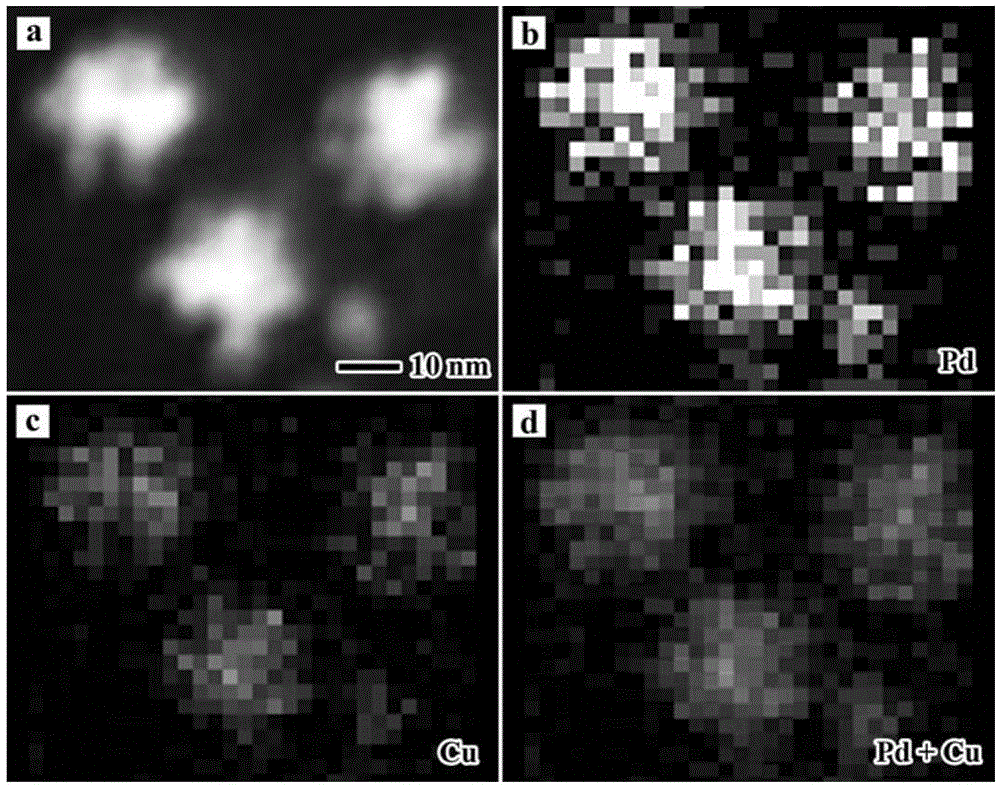

[0028] figure 1 with figure 2 The transmission electron micrographs and transmission energy spectra of the dendritic copper-palladium nanocrystalline alloy synthesized in this embodiment are respectively. from figure 1 It can be seen that the dendritic nanocrystals with uniform size are obtained in this example. figure 2 is the transmission energy spectrum, fi...

Embodiment 2

[0030] (1) 7.5mg palladium acetylacetonate (Pd(acac) 2 ), 19.5mg copper acetylacetonate (Cu(acac) 2 ), 100mg tungsten carbonyl and 50mg polyvinylpyrrolidone (PVP: molecular weight 29000) were dissolved in 10ml benzyl alcohol and stirred at room temperature for 1h.

[0031] (2) Transfer the reaction solution obtained in (1) to a 20ml round bottom flask, and react at 120°C for 2h.

[0032] (3) Centrifuge the product obtained in (2) at a speed of 8000-12000 rpm / min for 10 min, and remove the supernatant.

[0033] (4) ultrasonically disperse the precipitate obtained in (3) in ethanol, and store at room temperature.

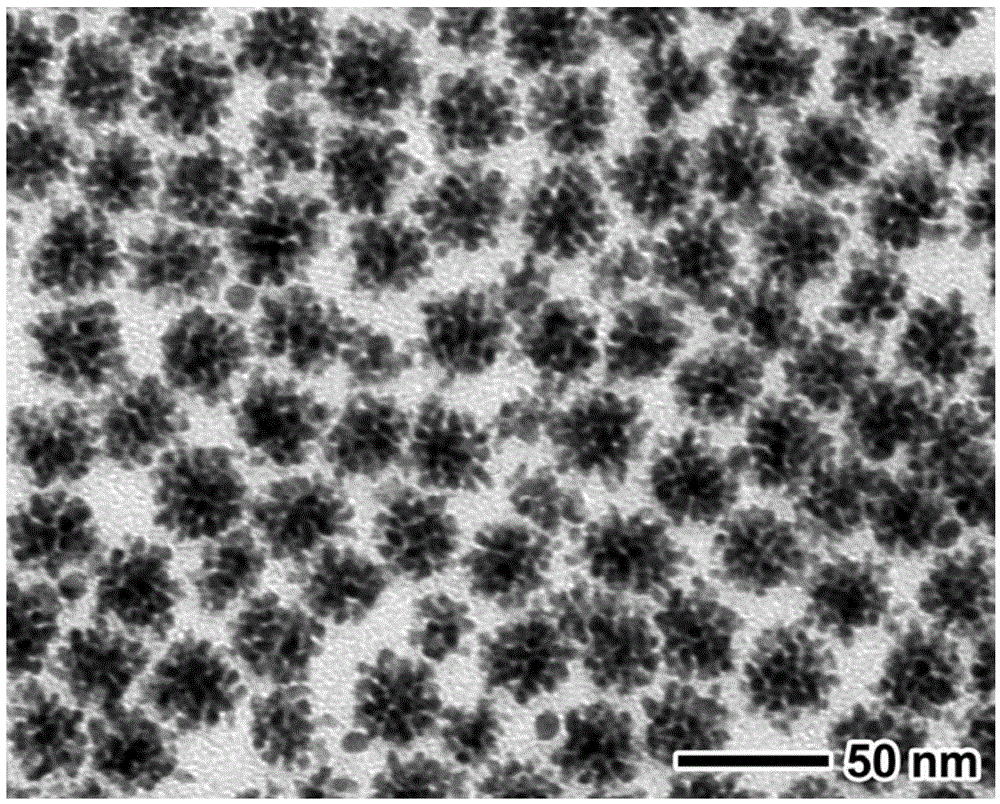

[0034] image 3 It is a transmission electron micrograph of the dendritic copper-palladium nanocrystalline alloy synthesized in this embodiment. When the copper content in the copper-palladium alloy increases, the dendritic structure of the alloy becomes more significant.

Embodiment 3

[0036] (1) 15mg palladium acetylacetonate (Pd(acac) 2 ), 13mg copper acetylacetonate (Cu(acac) 2 ), 100 mg of ascorbic acid and 50 mg of polyvinylpyrrolidone (PVP: molecular weight of 50000) were dissolved in 10 ml of benzyl alcohol and stirred at room temperature for 1 h.

[0037] (2) The reaction solution obtained in (1) was transferred to a 20ml round bottom flask, and reacted at 140°C for 2h.

[0038] (3) Centrifuge the product obtained in (2) at a speed of 8000-12000 rpm / min for 10 min, and remove the supernatant.

[0039] (4) ultrasonically disperse the precipitate obtained in (3) in ethanol, and store at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com