Palladium-transition metal oxide-graphene ternary composite catalyst and preparation method thereof

A composite catalyst and transition metal technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, preparation of organic compounds, etc., to achieve high catalytic activity, good stability, good application prospects and economical benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

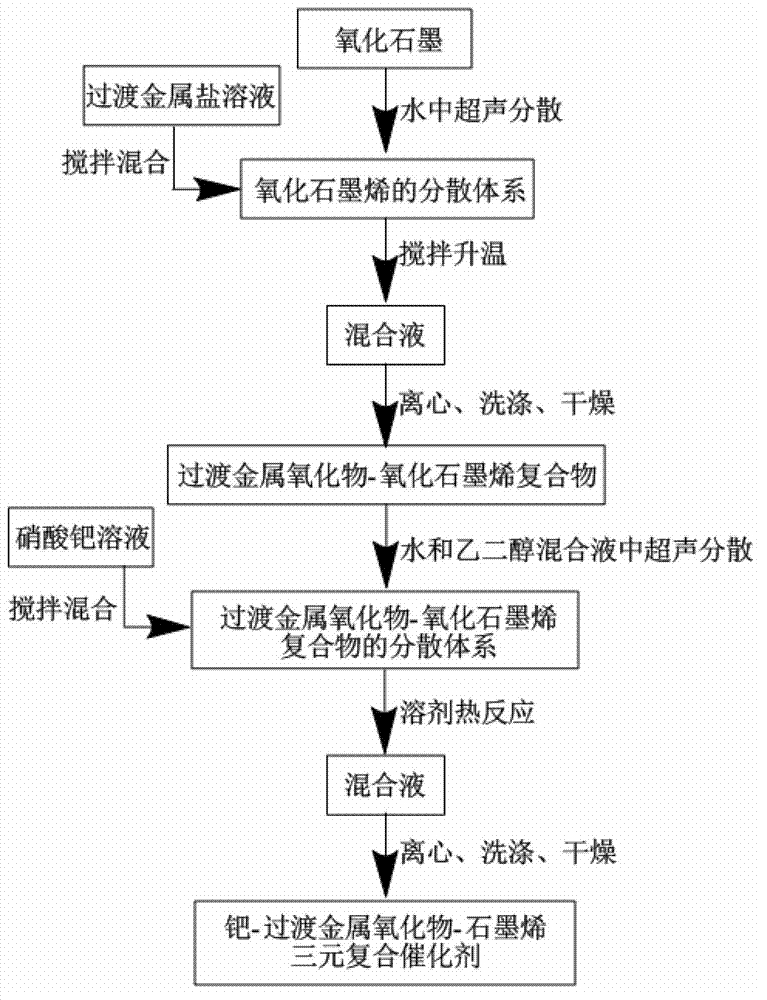

Method used

Image

Examples

Embodiment 1

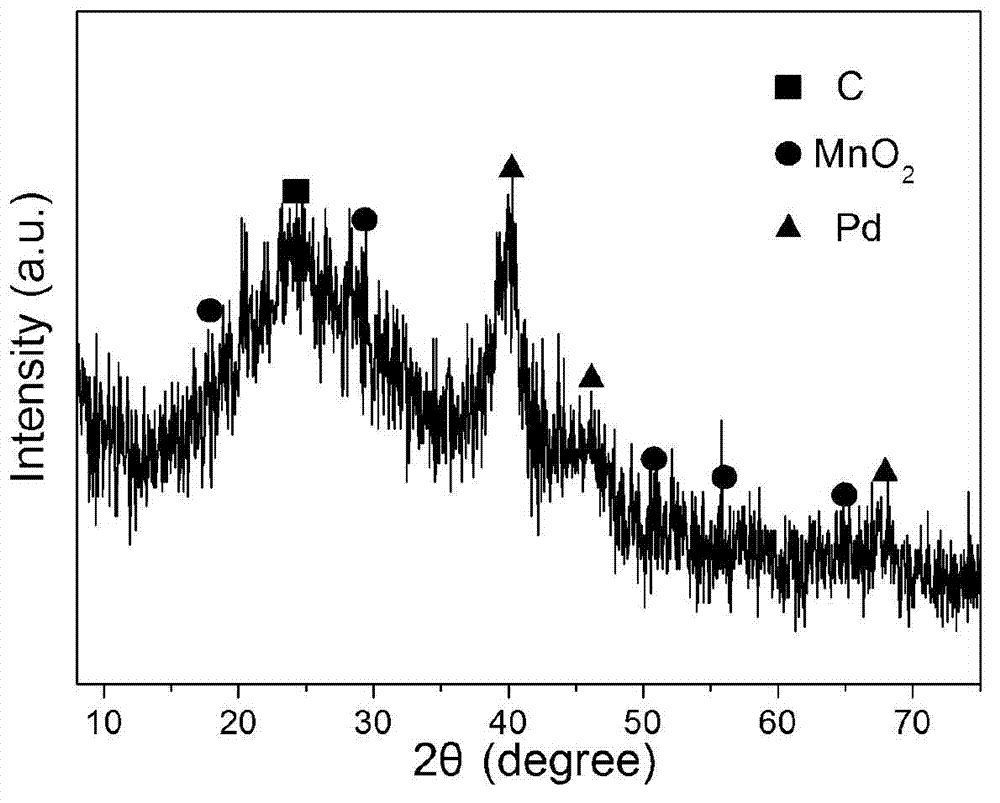

[0028] Embodiment 1: palladium-manganese dioxide-graphene ternary composite catalyst (manganese dioxide: the mass ratio of graphene oxide is 1:4.6; Palladium: the mass ratio of manganese dioxide-graphene oxide binary composite is 1 :10)

[0029] (1) Add 400mg of graphite oxide into 600mL of deionized water, and ultrasonicate at 30°C for 2 hours to obtain a dispersed solution of graphene oxide;

[0030] (2) Add 20mL of 0.50mol / L potassium permanganate solution to the system in the first step, and stir and react at 20°C for 12 hours;

[0031] (3) Centrifuge the system in the second step to separate the solid product, wash it with deionized water, and dry it at 60°C to obtain a manganese dioxide-graphene oxide composite;

[0032] (4) Weigh 20 mg of the manganese dioxide-graphene oxide composite obtained in the third step, place it in a mixture of 30 mL deionized water and 50 mL ethylene glycol, and ultrasonicate at 30°C for 2 hours to obtain manganese dioxide- Dispersion soluti...

Embodiment 2

[0037] Example 2: Palladium-titania-graphene ternary composite catalyst (mass ratio of titanium dioxide: graphene oxide is 1:10; palladium: titanium dioxide-graphene oxide binary composite mass ratio is 40:1)

[0038] (1) Add 400mg of graphite oxide to 4000mL of deionized water, and sonicate at 20°C for 1 hour to obtain a dispersed solution of graphene oxide;

[0039] (2) Add 0.18mL of butyl titanate to the system in the first step, and stir and react at 120°C for 1 hour;

[0040] (3) Centrifuge the system in the second step to separate the solid product, wash it with deionized water, and dry it at 40°C to obtain a titanium dioxide-graphene oxide composite;

[0041] (4) Weigh 8 mg of the titanium dioxide-graphene oxide composite obtained in the third step, place it in a mixture of 10 mL deionized water and 70 mL ethylene glycol, and ultrasonicate at 20°C for 1 hour to obtain a titanium dioxide-graphene oxide composite The dispersion solution of the substance;

[0042] (5) Add ...

Embodiment 3

[0044] Example 3: Palladium-cobalt tetroxide-graphene ternary composite catalyst (mass ratio of cobalt tetroxide:graphene oxide is 10:1; palladium:cobalt tetroxide-graphene oxide binary composite mass ratio is 1:40)

[0045] (1) Add 400mg of graphite oxide to 40mL of deionized water, and ultrasonicate at 40°C for 3 hours to obtain a dispersed solution of graphene oxide;

[0046] (2) Add 49.83mL of 1.0mol / L cobalt nitrate solution to the system in the first step, and stir and react at 200°C for 72 hours;

[0047] (3) Centrifuge the system in the second step to separate the solid product, wash it with deionized water, and dry it at 80°C to obtain the tricobalt tetroxide-graphene oxide composite;

[0048] (4) Weigh 800 mg of the tricobalt tetroxide-graphene oxide composite obtained in the third step, place it in a mixture of 70 mL deionized water and 10 mL ethylene glycol, and ultrasonicate at 40°C for 3 hours to obtain the tricobalt tetroxide-graphene oxide composite The disper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com