Palladium/nitrogen-doped graphene composite electrode catalyst and preparation method thereof

A nitrogen-doped graphene and composite electrode technology, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems that are not suitable for large-scale industrial production and preparation High cost, complex process and other issues, to achieve excellent electrochemical performance, long cycle life and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

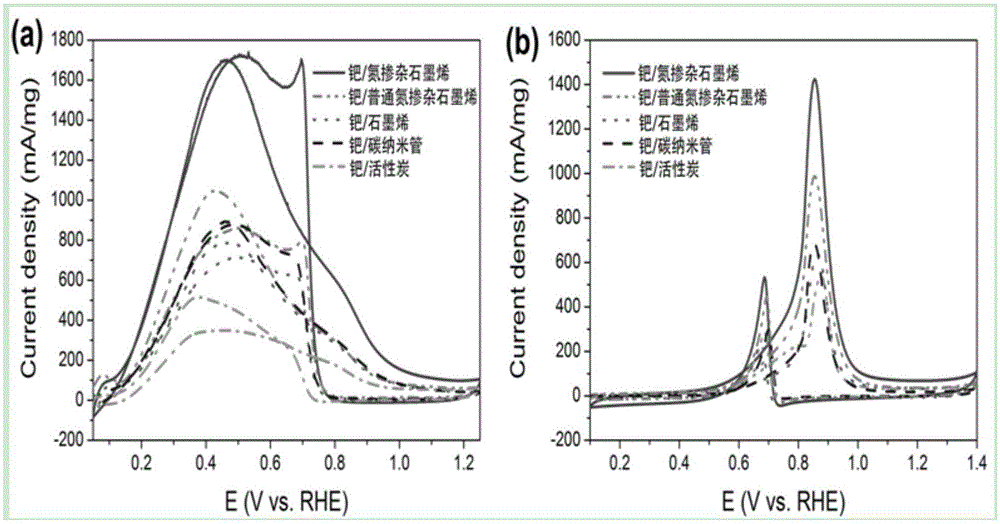

Embodiment 1

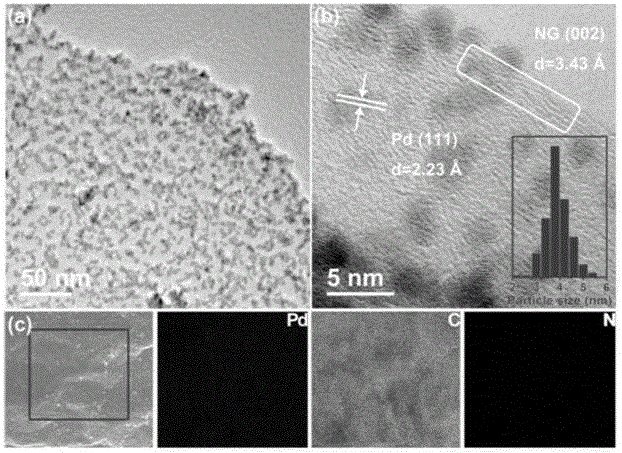

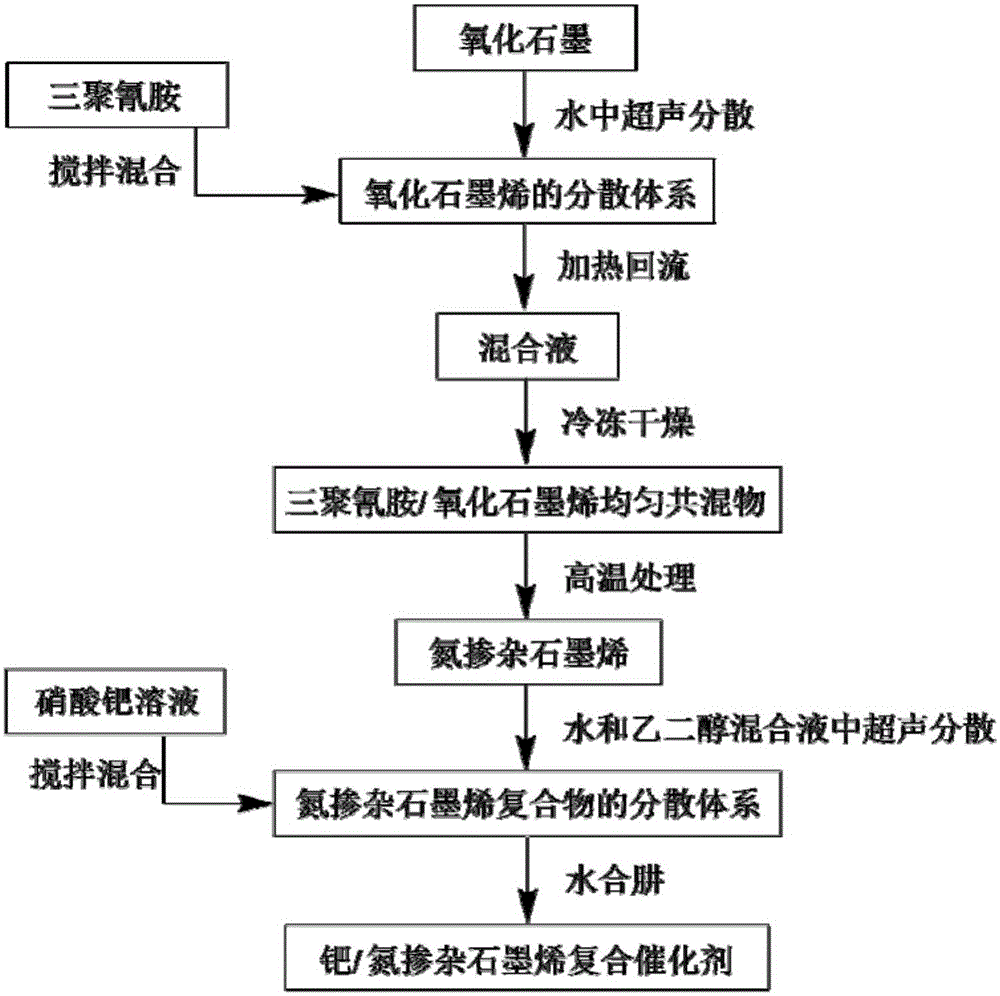

[0037] Step 1: Disperse 200 mg of graphite oxide ultrasonically in 50 mL of deionized water for 2 hours to obtain a graphene oxide solution;

[0038] In the second step, 200mg of melamine was added to the system of the first step, and heated to reflux at 80°C for 2 hours, and stirred to reduce to room temperature;

[0039] The third step is to freeze-dry the reaction system of the second step;

[0040] In the fourth step, the powder obtained after the third step freeze-drying is heat-treated at 500°C for 1 hour under a nitrogen atmosphere, and then the temperature is raised to 700°C for 2 hours to obtain nitrogen-doped graphene;

[0041] In the fifth step, 10 mg of the nitrogen-doped graphene obtained in the fourth step is ultrasonically dispersed in 80 mL of ethylene glycol solution for 2 hours to obtain a dispersion solution of the nitrogen-doped graphene;

[0042] In the sixth step, add 0.025mL of 0.73mol / L palladium nitrate solution to the system of the fifth step and mix and stir f...

Embodiment 2

[0046] The first step: ultrasonically disperse 100 mg of graphite oxide in 100 mL of deionized water for 2 hours to obtain a graphene oxide solution;

[0047] In the second step, 300mg of melamine was added to the system of the first step, and heated to reflux at 80°C for 2 hours, and stirred to reduce to room temperature;

[0048] The third step is to freeze-dry the reaction system of the second step;

[0049] In the fourth step, the powder obtained after the third step freeze-drying is heat-treated at 700°C for 4 hours in a nitrogen atmosphere to obtain nitrogen-doped graphene;

[0050] In the fifth step, 10 mg of the nitrogen-doped graphene obtained in the fourth step is ultrasonically dispersed in 50 mL of ethylene glycol solution for 2 hours to obtain a dispersion solution of the nitrogen-doped graphene;

[0051] In the sixth step, 0.012 mL of 0.73 mol / L palladium nitrate solution was added to the system in the fifth step and mixed and stirred for 20 minutes;

[0052] In the seventh...

Embodiment 3

[0055] Step 1: Disperse 200 mg of graphite oxide ultrasonically in 100 mL of deionized water for 2 hours to obtain a graphene oxide solution;

[0056] In the second step, 400mg of melamine was added to the system of the first step, and heated to reflux at 80°C for 2 hours, and stirred to reduce to room temperature;

[0057] The third step is to freeze-dry the reaction system of the second step;

[0058] In the fourth step, the powder obtained after the third step freeze-drying is heat-treated at 550°C for 2 hours under a nitrogen atmosphere, and then the temperature is increased to 800°C for 2 hours to obtain nitrogen-doped graphene;

[0059] In the fifth step, 10 mg of the nitrogen-doped graphene obtained in the fourth step was ultrasonically dispersed in a 100 mL ethylene glycol solution for 2 hours to obtain a dispersion solution of the nitrogen-doped graphene;

[0060] In the sixth step, add 0.025mL of 0.73mol / L palladium nitrate solution to the system of the fifth step and mix and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com