Bio-reduction preparation method of palladium catalyst

A palladium catalyst, biological technology, applied in the field of palladium catalyst bioreduction preparation, can solve the problems such as the application of Pd nanoparticles has not been reported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

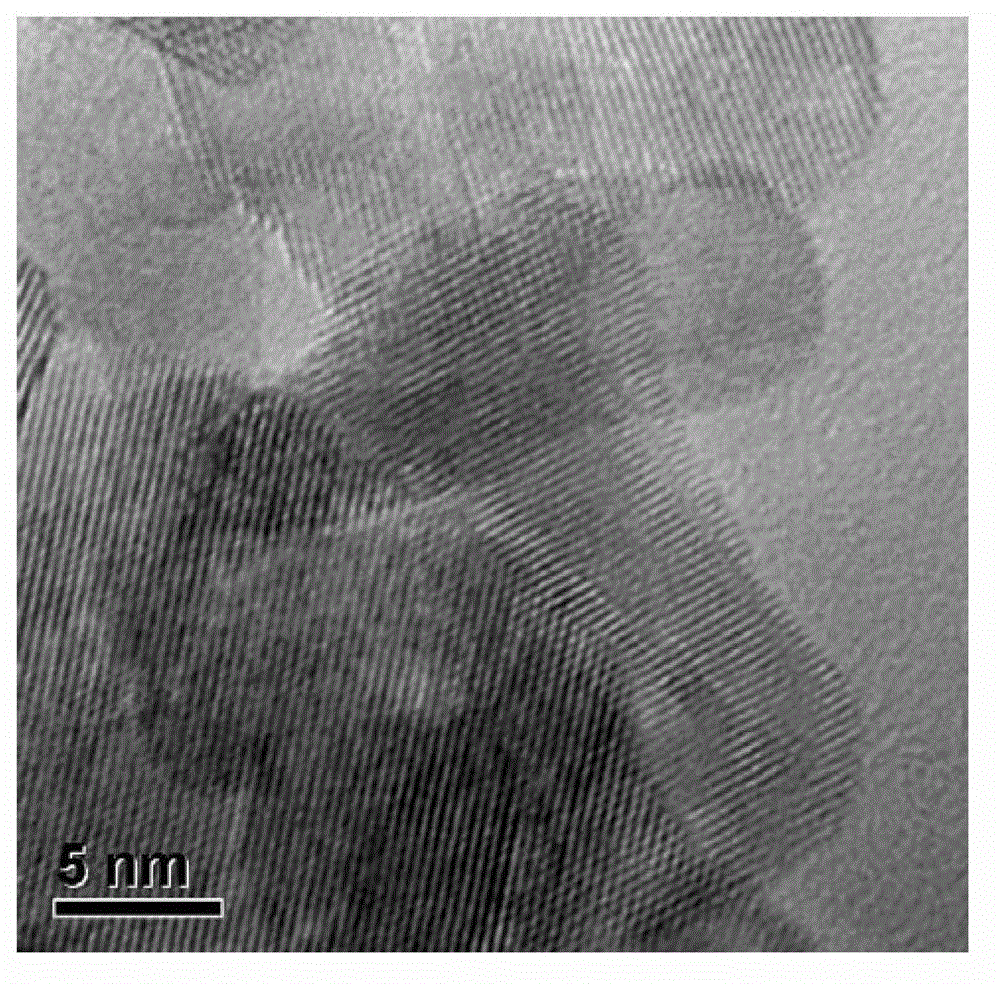

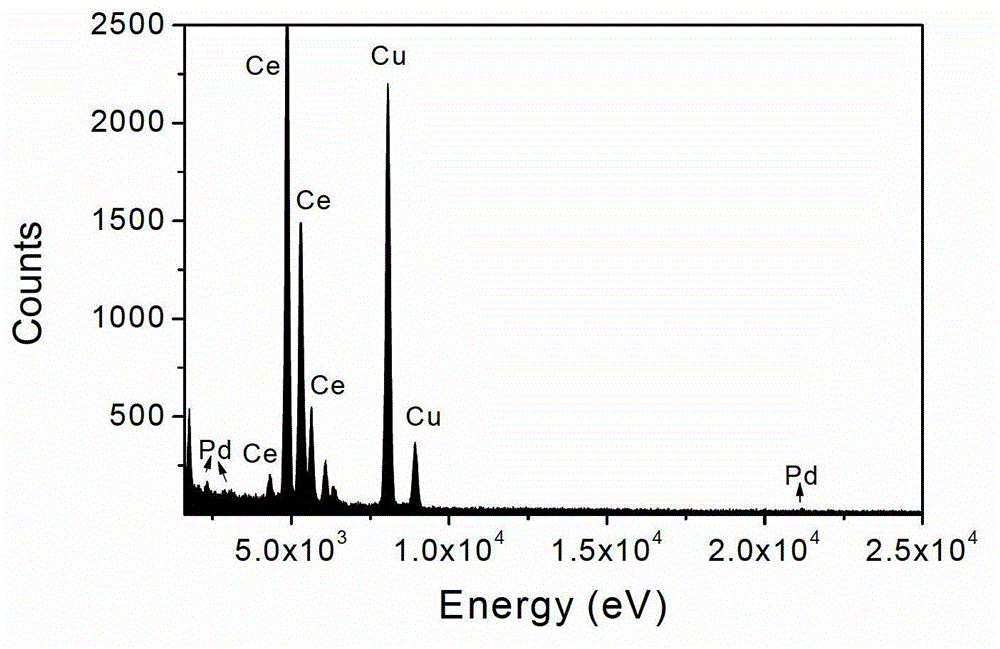

Method used

Image

Examples

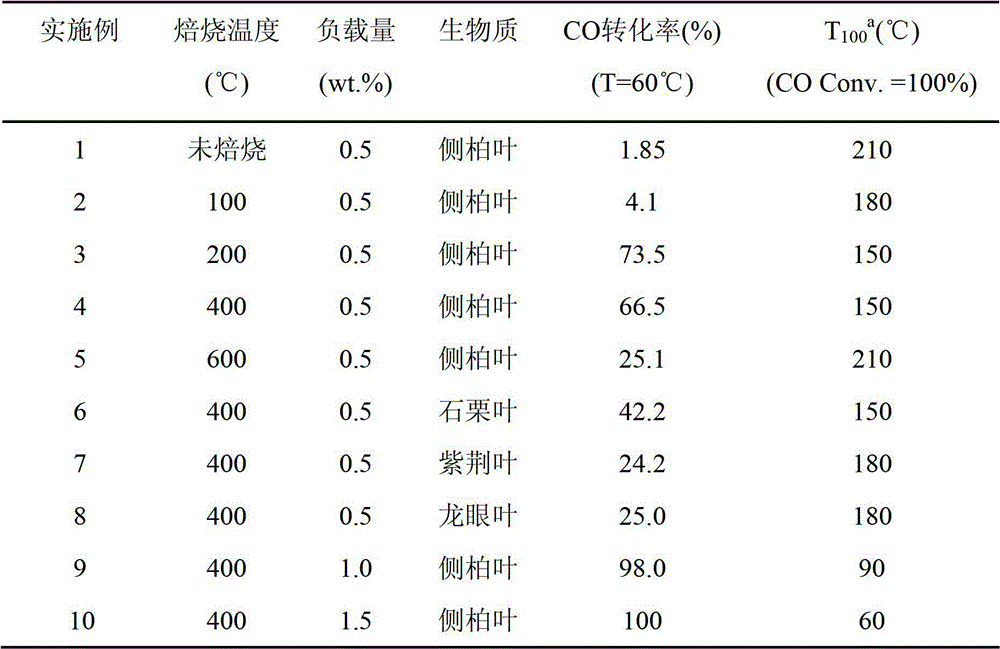

Embodiment 1

[0020] Preparation of orientalis leaf extract: take 3g of orientalis leaf dry powder, add 300mL of deionized water, put it in a constant temperature water bath shaker at 30°C, shake at 150r / min for 2h, filter, and obtain 10g / L orientalis extract. Catalyst preparation: Take 380 μL of Pd(NO 3 ) 2 The solution was added to 27 mL of deionized water and mixed well. Add 0.6g CeO 2 carrier, stirred for 0.5h to promote the adsorption of the carrier to the precursor. Then, add 30 mL of the above-mentioned orientalis leaf extract, and continue to stir for 1 h. After vacuum drying for 20 h, catalyst A was obtained.

Embodiment 2

[0022] The preparation of orientalis leaf extract is as in Example 1. Catalyst preparation: Take 380 μL of Pd(NO 3 ) 2 The solution was added to 27 mL of deionized water and mixed well. Add 0.6g CeO 2 Carrier, continue to stir for 0.5h to promote the full adsorption of the precursor to the carrier. Add 30 mL of the above-mentioned orientalis leaf extract, and continue stirring for 1 h. Vacuum dried for 20h. Calcined at 100°C for 2h in an air atmosphere to obtain catalyst B.

Embodiment 3

[0024] The preparation of orientalis leaf extract is as in Example 1. Catalyst preparation: Take 380 μL of Pd(NO 3 ) 2 The solution was added to 27 mL of deionized water and mixed well. Add 0.6g CeO 2 Carrier, continue to stir for 0.5h to promote the full adsorption of the precursor to the carrier. Add 30 mL of the above-mentioned orientalis leaf extract, and continue stirring for 1 h. Vacuum drying for 20 hours, followed by calcination at 300°C for 2 hours in an air atmosphere to obtain catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com