Graphite-phase carbon nitride-modified carbon black-loaded platinum-palladium alloy nano electrocatalyst and preparation method

A graphite-phase carbon nitride and platinum-palladium alloy technology is applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science. Electrocatalyst activity and other issues, to achieve the effect of good electrochemical catalytic oxidation performance, strong electrochemical corrosion resistance, and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

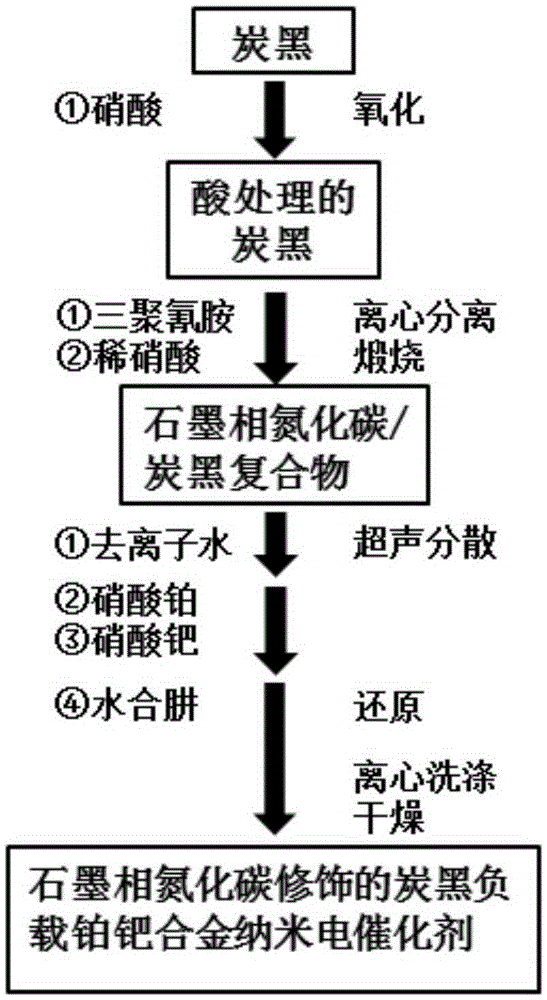

[0028] Implementation example 1: the preparation method of the carbon black loaded platinum-palladium alloy nano electrocatalyst of graphite phase carbon nitride (30%) modification of the present invention, comprises the following steps:

[0029] The first step, the 1gVulcan XC-72R was placed in 100g of concentrated nitric acid, stirred evenly, transferred into a 200mL hydrothermal kettle, and reacted at 120°C for 12h. The product is centrifuged and dried to obtain acid-treated carbon black;

[0030] In the second step, 300 mg of melamine and 700 mg of acid-treated carbon black were dispersed into 100 mL of deionized water;

[0031] In the third step, 40 mL of dilute nitric acid (0.1 mol / L) was dropped into the dispersion obtained in the second step and stirred for 1 h, centrifuged, washed with ethanol for 3 times, and dried;

[0032] In the fourth step, the melamine / carbon black mixture obtained in the third step is calcined in a nitrogen atmosphere at 400° C. for 2 hours ...

Embodiment 2

[0034] Implementation example 2: the preparation method of the carbon black supported platinum-palladium alloy nano electrocatalyst of graphite phase carbon nitride (50%) modification of the present invention, comprises the following steps:

[0035] The first step, with the first step in implementation example 1, drying obtains acid-treated carbon black;

[0036] In the second step, 500 mg of melamine and 500 mg of acid-treated carbon black were dispersed in 22 mL of ethylene glycol;

[0037] In the third step, 66 mL of dilute nitric acid (0.12 mol / L) was dropped into the dispersion liquid obtained in the second step and stirred for 1 h, centrifuged, washed with ethanol for 3 times, and dried;

[0038] The fourth step is to calcinate the melamine / carbon black mixture obtained in the third step in a nitrogen atmosphere at 350° C. for 1 hour to obtain a graphite phase carbon nitride / carbon black composite;

[0039]The fifth step is to disperse 20 mg of the graphite phase carbon...

Embodiment 3

[0041] Implementation example 3: the preparation method of the carbon black supported platinum-palladium alloy nano electrocatalyst of graphite phase carbon nitride (70%) modification of the present invention, comprises the following steps:

[0042] The first step, with the first step in implementation example 1, drying obtains acid-treated carbon black;

[0043] In the second step, 700 mg of melamine and 300 mg of acid-treated carbon black were dispersed in 62.5 mL of ethylene glycol;

[0044] In the third step, 100 mL of dilute nitric acid (0.15 mol / L) was dropped into the dispersion obtained in the second step and stirred for 1 h, centrifuged, washed with ethanol for 3 times, and dried;

[0045] In the fourth step, the melamine / carbon black mixture obtained in the third step is calcined in a nitrogen atmosphere at 350° C. for 3 hours to obtain a graphite phase carbon nitride / carbon black composite;

[0046] The fifth step is to disperse 20 mg of the graphite phase carbon n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com