Method for preparing all-trans tretinoin

A technology of all-trans retinoic acid and retinoic acid, applied in the field of preparation of all-trans retinoic acid, can solve the problems of low yield of all-trans retinoic acid, high cost, difficult operation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

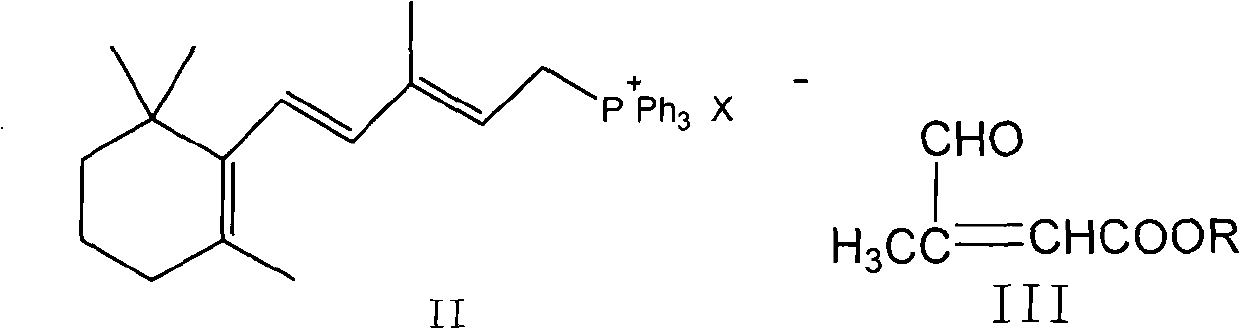

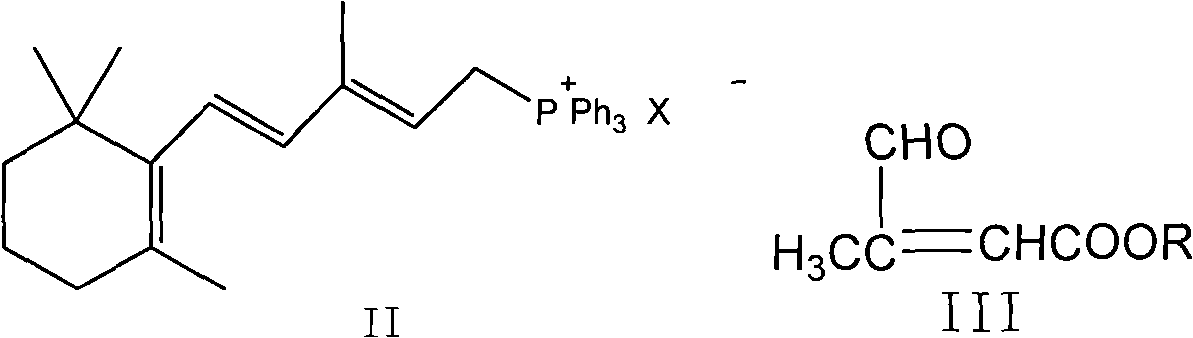

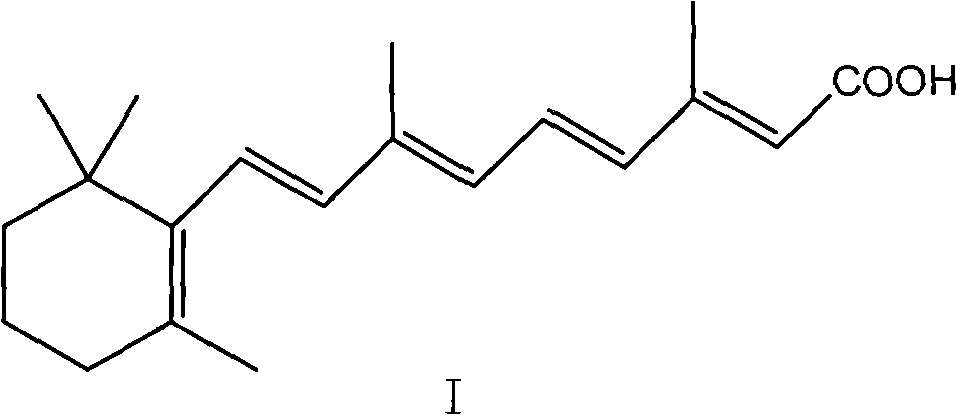

[0038] The preparation of the mixture of embodiment 1 all-trans retinoic acid (I) and 11-cis-retinoic acid (VI)

[0039] Under nitrogen conditions, 500.4g of [3-methyl-5-(2,6,6-trimethyl-1-cyclohexen-1-yl)-2,4-pentadiene]-triphenyl Phosphine chloride salt (WITTIG salt) and 187g of β-formyl butyl crotonate were dissolved in 1947ml of isopropanol, cooled to -10°C, 1250ml of 2N potassium hydroxide isopropanol solution was added dropwise, and When the temperature was kept between -10 and 0°C, the addition was completed and reacted for 1 hour. The reaction solution was added to water, extracted with 2×1000ml of petroleum ether, the organic layers were combined, washed with 2×300ml of water, and evaporated under reduced pressure. The solvent was removed to obtain 325 g (yield 99.0%) of a brown oily liquid, which contained 61% all-trans butyl retinoate and 36.1% 11-cis-butyl retinoate as detected by HPLC.

[0040] Under the condition of blowing nitrogen, 325 g of the mixture of all-...

Embodiment 211

[0041] Example 211 - Transformation of cis-retinoic acid into all-trans retinoic acid (1)

[0042] Under the condition of nitrogen flow, the mixed acid solution prepared in Example 1 was heated to 50° C., then a mixture of 330 mg palladium nitrate, 2160 mg triphenylphosphine, 1600 mg triethylamine and 250 ml acetonitrile was added, and the mixture was reacted for 1 hour and detected by HPLC The result was 95.3% all-trans retinoic acid and 1.1% 11-cis-retinoic acid, 600-700g of solvent was evaporated under reduced pressure, cooled to 0°C, kept for 2 hours, filtered to obtain 226.2g of all-trans retinoic acid, detected by HPLC The content is 99.6%.

Embodiment 311

[0043] Example 311-Transformation of cis-retinoic acid to all-trans retinoic acid (2)

[0044] Under the condition of nitrogen flow, the mixed acid solution prepared in Example 1 was heated to 50° C., then a mixture of 116 mg of palladium nitrate, 796 mg of triphenylphosphine, 528 mg of triethylamine and 132 ml of acetonitrile was added, reacted for 2 hours, and detected by HPLC The result was 93.3% all-trans retinoic acid and 3.1% 11-cis-retinoic acid, 600-700g of solvent was evaporated under reduced pressure, cooled to 0°C, kept for 2 hours, filtered to obtain 214.2g of all-trans retinoic acid, detected by HPLC The content is 99.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com