Preparation method of Pd-Fe/SiO2 hydrogenation catalyst

A technology of hydrogenation catalysts and additives, which is applied in the field of preparation of highly active and stable Pd-Fe/SiO2 hydrogenation catalysts, can solve the problems of poor selectivity, waste of noble metal Pd, and easy corrosion, and achieve enhanced shape-selective catalysis, inhibition of Effects of grain growth and high catalytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

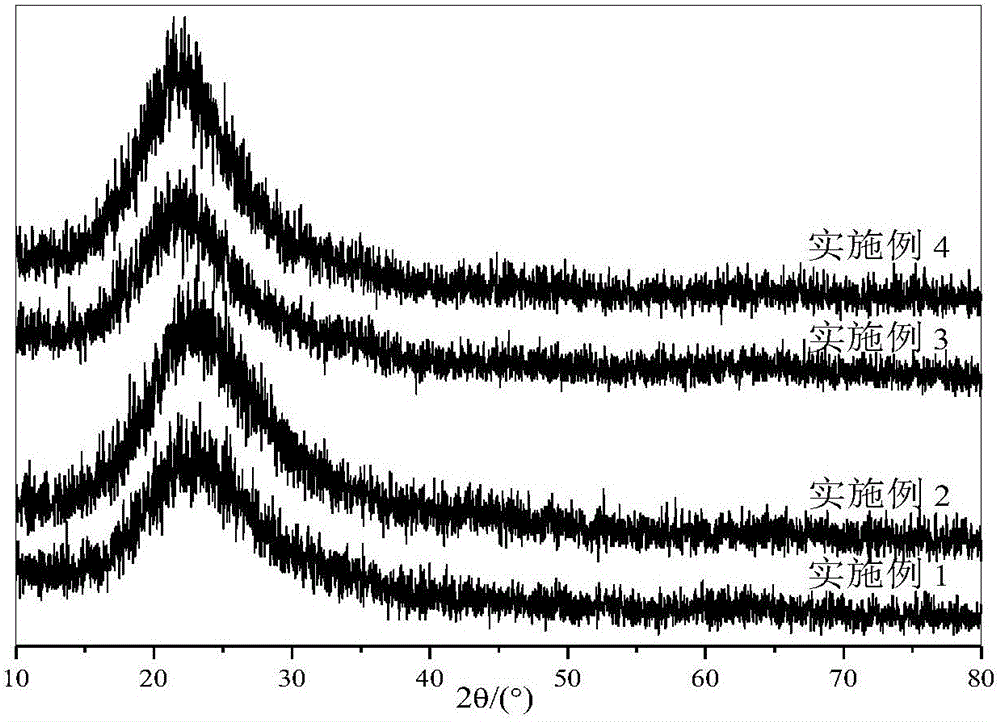

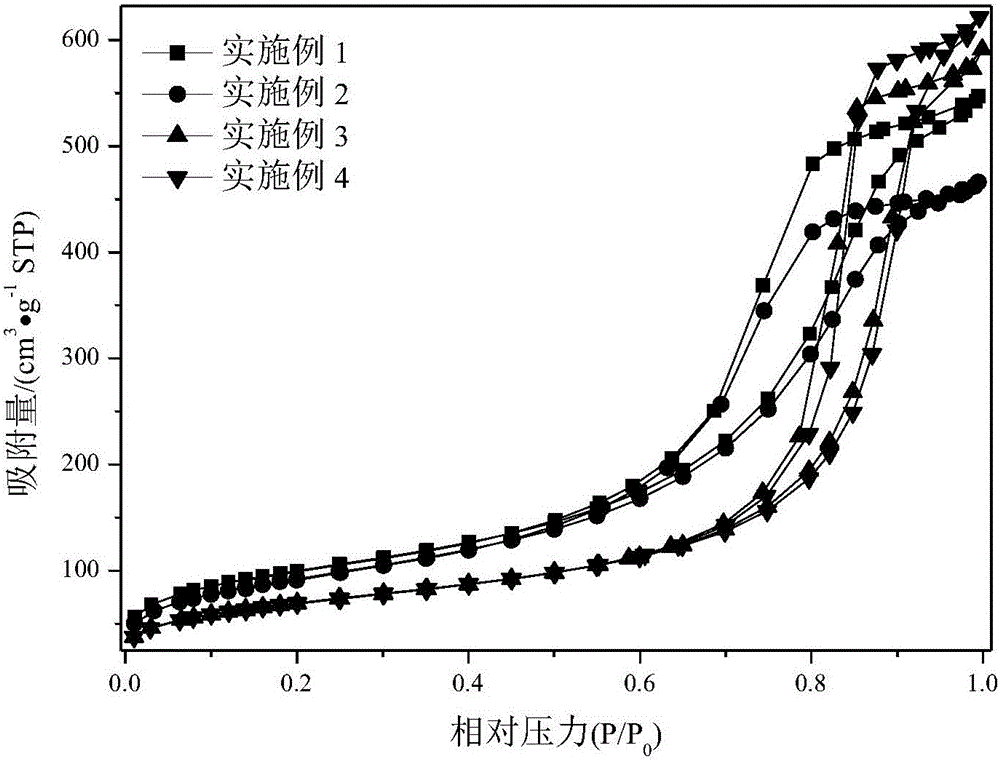

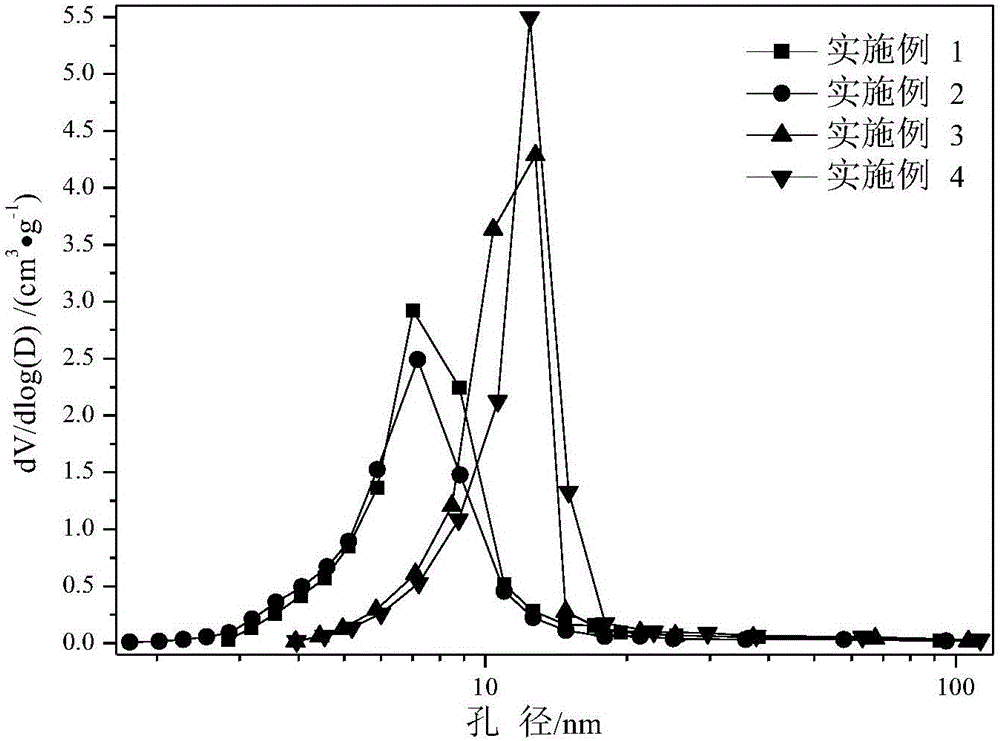

[0030] First, 2.3mLTEOS, 1gP123 and 0.1853g (Fe(NO 3 ) 3 ﹒ 9H 2 O) Mix and dissolve in 70 mL of HNO at pH=1 at room temperature with magnetic stirring 3 solution (0.1mol / L), and then transfer this solution to a 100ml hydrothermal kettle for hydrothermal reaction at 110°C for 24h. The resulting precipitate was transferred to a beaker and washed with HNO 3 Adjust the pH of the solution to 3.0-3.5, and after aging for 4 hours at room temperature, the aged precipitate was centrifuged and washed to neutrality at a speed of 6000r / min, then dried overnight at 110°C, and roasted at 500°C for 4h (starting from room temperature, heating Fe-modified SiO was obtained after a rate of 4°C / min) 2 carrier.

[0031] Take the above 1g carrier and use 0.005g PdCl at 60°C 2 (0.3wt%) dissolved in HNO corresponding to saturated water absorption3 Solution (pH=3.5, 3.16×10 -4 mol / L) solution obtained by impregnating with equal volume for 2 h, then impregnating with 4 mL, 0.1 mol / L NaOH soluti...

Embodiment 2

[0034] First, 2.3 mL of LTEOS and 1 g of P123 were mixed and dissolved in 70 mL of HNO at pH=1 at room temperature with magnetic stirring 3 solution (0.1mol / L), and then transfer this solution to a 100ml hydrothermal kettle for hydrothermal reaction at 110°C for 24h. The resulting precipitate was transferred to a beaker and washed with HNO 3 Adjust the pH of the solution to 3.0-3.5, and after aging for 4 hours at room temperature, the aged precipitate was centrifuged and washed to neutrality at a speed of 6000r / min, then dried overnight at 110°C, and roasted at 500°C for 4h (starting from room temperature, heating The carrier was obtained after a rate of 4 °C / min).

[0035] Take the above 1g carrier and use 0.005g PdCl at 60°C 2 (0.3wt%) dissolved in HNO corresponding to saturated water absorption 3 Solution (pH=3.5, 3.16×10 -4 mol / L) of the obtained solution was impregnated in equal volume for 2 h, and then was impregnated with 4 mL of 0.1 mol / L NaOH solution at 60° C. fo...

Embodiment 3

[0038] First, 2.3mLTEOS, 3.3mLTPAOH and 0.1853g (Fe(NO 3 ) 3 ﹒ 9H 2 O) Mix and dissolve in 70 mL of HNO at pH=1 at room temperature with magnetic stirring 3 solution (0.1mol / L), and then transfer the solution to a 100ml hydrothermal kettle for hydrothermal reaction at 170°C for 24h. The resulting precipitate was transferred to a beaker and washed with HNO 3 Adjust the pH of the solution to 3.0-3.5, and after aging for 4 hours at room temperature, the aged precipitate was centrifuged and washed to neutrality at a speed of 6000r / min, then dried overnight at 110°C, and roasted at 500°C for 4h (starting from room temperature, heating The carrier was obtained after a rate of 4 °C / min).

[0039] Take the above 1g carrier and use 0.005g PdCl at 60°C 2 (0.3wt%) dissolved in HNO corresponding to saturated water absorption 3 Solution (pH=3.5, 3.16×10 -4 mol / L) of the obtained solution was impregnated in equal volume for 2 h, and then was impregnated with 4 mL of 0.1 mol / L NaOH s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com