A kind of preparation method of bacterial cellulose supported nanometer palladium catalyst

A technology of bacterial cellulose and nano-palladium, which is applied in chemical instruments and methods, preparation of organic compounds, catalysts for physical/chemical processes, etc., can solve the problems of high cost, complicated preparation process, etc. Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

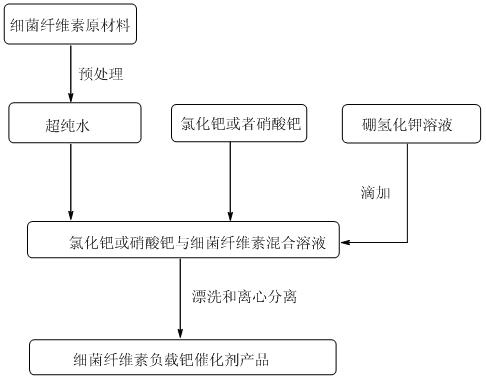

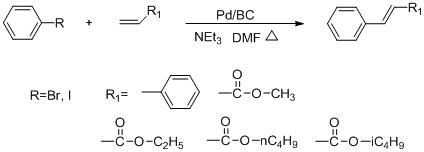

Method used

Image

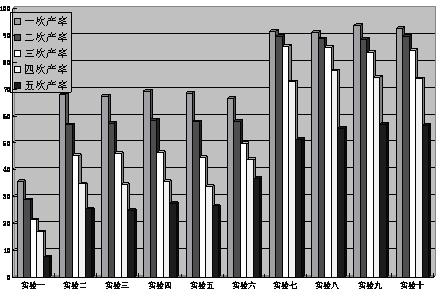

Examples

Embodiment 1

[0034] Implementation example 1: the preparation method of bacterial cellulose supported palladium catalyst of the present invention may further comprise the steps:

[0035] In the first step, 0.5% NaOH solution was added to 3 g of wet bacterial cellulose, boiled for 2 hours, then treated with 1.0% acetic acid solution for 50 minutes, and then washed with deionized water until neutral;

[0036] In the second step, the product obtained in the first step is added into 50 mL of ultrapure water, and fully stirred;

[0037] The 3rd step, the 2nd step product is added 0.17g palladium chloride, fully stirs;

[0038] In the fourth step, the system of the third step is ventilated with nitrogen to remove oxygen;

[0039] In the fifth step, the temperature is raised to 135°C, and the reaction is carried out under reflux and nitrogen atmosphere for 6 hours;

[0040] In the sixth step, slowly add 50 mL of 0.035 g / mL potassium borohydride solution to the product in the fifth step;

[004...

Embodiment 2

[0043] Implementation example 2: the preparation method of bacterial cellulose supported nano palladium catalyst of the present invention may further comprise the steps:

[0044] In the first step, add 1.0% NaOH solution to 3 g of wet bacterial cellulose, boil for 1 hour, then treat with 1.5% acetic acid solution for 30 minutes, and finally wash with deionized water until neutral;

[0045] In the second step, the product obtained in the first step is added into 50 mL of ultrapure water, and fully stirred;

[0046] The 3rd step, the 2nd step product is added 0.26g palladium chloride, fully stirs;

[0047] In the fourth step, the system of the third step is ventilated with nitrogen to remove oxygen;

[0048] In the fifth step, the temperature is raised to 140° C., and the reaction is carried out under reflux and nitrogen atmosphere for 5 hours;

[0049] In the sixth step, slowly add 30 mL of 0.040 g / mL potassium borohydride solution to the product in the fifth step;

[0050] ...

Embodiment 3

[0052] Implementation example 3: the preparation method of bacterial cellulose supported palladium catalyst of the present invention may further comprise the steps:

[0053] In the first step, add 2.0% NaOH solution to 3 g of wet bacterial cellulose, boil for 0.5 hours, then treat with 2.0% acetic acid solution for 20 minutes, and then wash with deionized water until neutral;

[0054] In the second step, the product obtained in the first step is added into 50 mL of ultrapure water, and fully stirred;

[0055] The 3rd step, the 2nd step product is added 0.51g palladium chloride, carry out thorough stirring;

[0056] In the fourth step, the system of the third step is ventilated with nitrogen to remove oxygen;

[0057] In the fifth step, the temperature is raised to 145°C, and the reaction is carried out under reflux and nitrogen atmosphere for 5 hours;

[0058] In the sixth step, slowly add 50 mL of 0.045 g / mL potassium borohydride solution to the product in the fifth step; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com