A kind of preparation method of hydroisomerization/cracking catalyst and catalyst

A cracking catalyst, hydroisomerization technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc. The effect of increasing diesel content and lube base oil content, excellent isomerization performance, and good cracking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

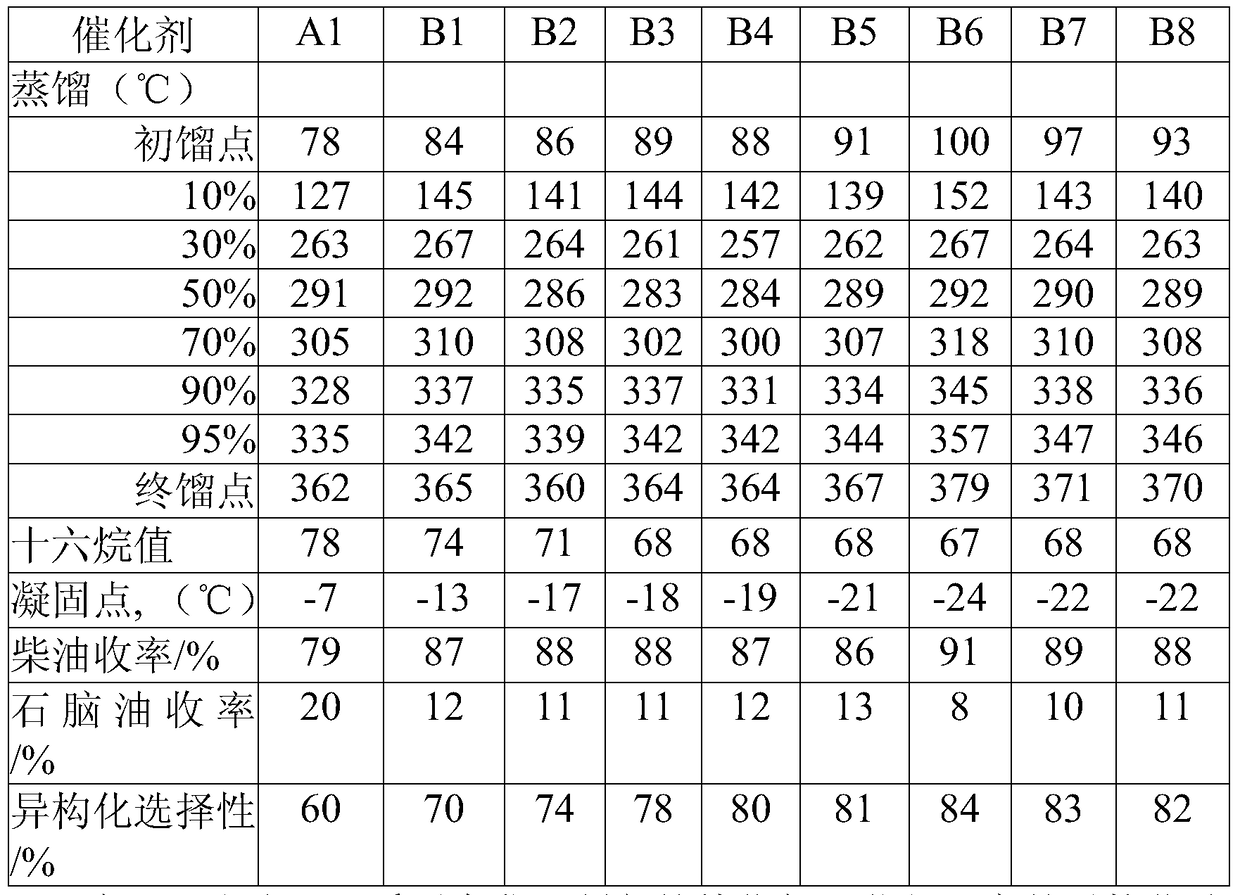

Embodiment 1

[0029] Take 100 g of sodium-type ZSM-23 molecular sieve containing isopropylamine template agent, put it in 3 L of NaOH solution with a concentration of 0.2 mol / L, at 80 ° C, treat for 180 min, filter, wash until the eluent is neutral, dry and The template agent was removed by roasting; the resulting product was placed in 2 L of 0.5 mol / L NH 4 NO 3 In the solution, at 60°C, exchange for 180min, filter, wash with deionized water until the eluent becomes neutral, continuously exchange (repeat the above operation) twice, after drying at 120°C, calcinate at 550°C for 24h to obtain Hydrogen ZSM-23 molecular sieve (H-ZSM-23). Take 30g of alumina (γ-Al 2 O 3 ) mixed evenly with it, add 80g 5wt.% HNO 3 The solution was kneaded at room temperature for 2 hours, extruded at room temperature by an automatic extruder, dried naturally, dried at 120 °C for 4 hours, and calcined at 550 °C for 8 hours to obtain the molecular sieve carrier H-ZSM-23 carrier). Use 10 mL of platinum (Pt) 0.05...

Embodiment 2

[0031] Take 100 g of sodium-type ZSM-23 molecular sieve containing isopropylamine template agent, put it in 3 L of NaOH solution with a concentration of 0.4 mol / L, at 80 ° C, treat for 180 min, filter, wash until the eluent is neutral, dry and The template agent was removed by roasting; the resulting product was placed in 2 L of 0.5 mol / L NH 4 NO 3In the solution, at 60°C, exchange for 180min, filter, wash with deionized water until the eluent becomes neutral, continuously exchange (repeat the above operation) twice, after drying at 120°C, calcinate at 550°C for 24h to obtain Hydrogen ZSM-23 molecular sieve (H-ZSM-23). Take 30g of alumina (γ-Al 2 O 3 ) mixed evenly with it, add 80g 5wt.% HNO 3 The solution was kneaded at room temperature for 2 hours, extruded at room temperature by an automatic extruder, dried naturally, dried at 120 °C for 4 hours, and calcined at 550 °C for 8 hours to obtain the molecular sieve carrier H-ZSM-23 carrier). Use 10 mL of platinum (Pt) 0.05 ...

Embodiment 3

[0033] Take 100 g of sodium-type ZSM-23 molecular sieve containing isopropylamine template agent, put it in 3 L of NaOH solution with a concentration of 0.6 mol / L, at 80 ° C, treat for 180 min, filter, wash until the eluent is neutral, dry and The template agent was removed by roasting; the resulting product was placed in 2 L of 0.5 mol / L NH 4 NO 3 In the solution, at 60°C, exchange for 180min, filter, wash with deionized water until the eluent becomes neutral, continuously exchange (repeat the above operation) twice, after drying at 120°C, calcinate at 550°C for 24h to obtain Hydrogen ZSM-23 molecular sieve (H-ZSM-23). Take 30g of alumina (γ-Al 2 O 3 ) mixed evenly with it, add 80g 5wt.% HNO 3 The solution was kneaded at room temperature for 2 hours, extruded at room temperature by an automatic extruder, dried naturally, dried at 120 °C for 4 hours, and calcined at 550 °C for 8 hours to obtain the molecular sieve carrier H-ZSM-23 carrier). Use 10 mL of platinum (Pt) 0.05...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com