Preparation method of butanediol secondary hydrogenation catalyst by butynediol two-step hydrogenation

A technology for butynediol and butanediol production, which is applied in the direction of hydrogenation preparation, etc. It can solve the problems of poor catalyst stability, influence on normal operation, and reactor pressure fluctuations, etc., and achieve long catalyst service life, high catalytic activity and selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

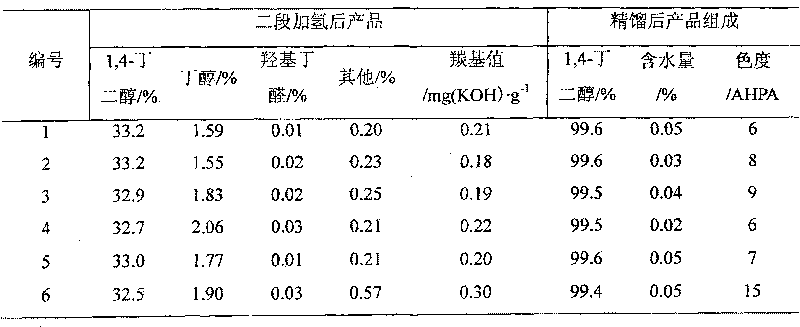

Examples

Embodiment I

[0022] Take an alumina carrier, impregnate it with a conventional soluble magnesium salt, dry it, and roast it to obtain a carrier containing 4% by weight of magnesium; take 100 g of this carrier and treat it at 150 ° C for 10 min at 0.1 mm Hg pressure, or directly place it in a blast oven at 150 ° C Heat for 3 hours, then lower to room temperature for later use; weigh 59.4g nickel nitrate hexahydrate, 50.8g nickel acetate tetrahydrate and 1g polyethylene glycol 4000 to prepare 200mL mixed nickel salt solution; take 200mL prepared mixed nickel salt solution for immersion Put it into 100g of the treated carrier, let it stand at room temperature for 2h; filter off the excess solution, dry at 120°C for 8h, heat up to 450°C for 8h to decompose the salt, and then put it in H 2 Reduction treatment was carried out at 350° C. for 30 h in a stream, and after cooling down to room temperature, it was deactivated by oxygen to obtain Catalyst No. 1.

Embodiment 2

[0024] An alumina carrier was taken, impregnated with a conventional soluble copper salt, dried, and calcined to obtain a carrier containing 3% by weight of copper; the rest of the steps were the same as in Example 1 to obtain Catalyst No. 2.

Embodiment 3

[0026] An alumina carrier was taken, impregnated with a conventional soluble molybdenum salt, dried, and calcined to obtain a carrier containing 4% by weight of molybdenum; the rest of the steps were the same as in Example 1 to obtain catalyst No. 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com