Method for preparing pseudo-boehmite by using high-alumina fly ash

A high-alumina fly ash, pseudo-boehmite technology, applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, aluminate/alumina/aluminum hydroxide purification, etc. The problems of popularization and application of boehmite, high production cost, and large raw materials are used to achieve the effect of low production cost, comprehensive utilization, and pure crystal phase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

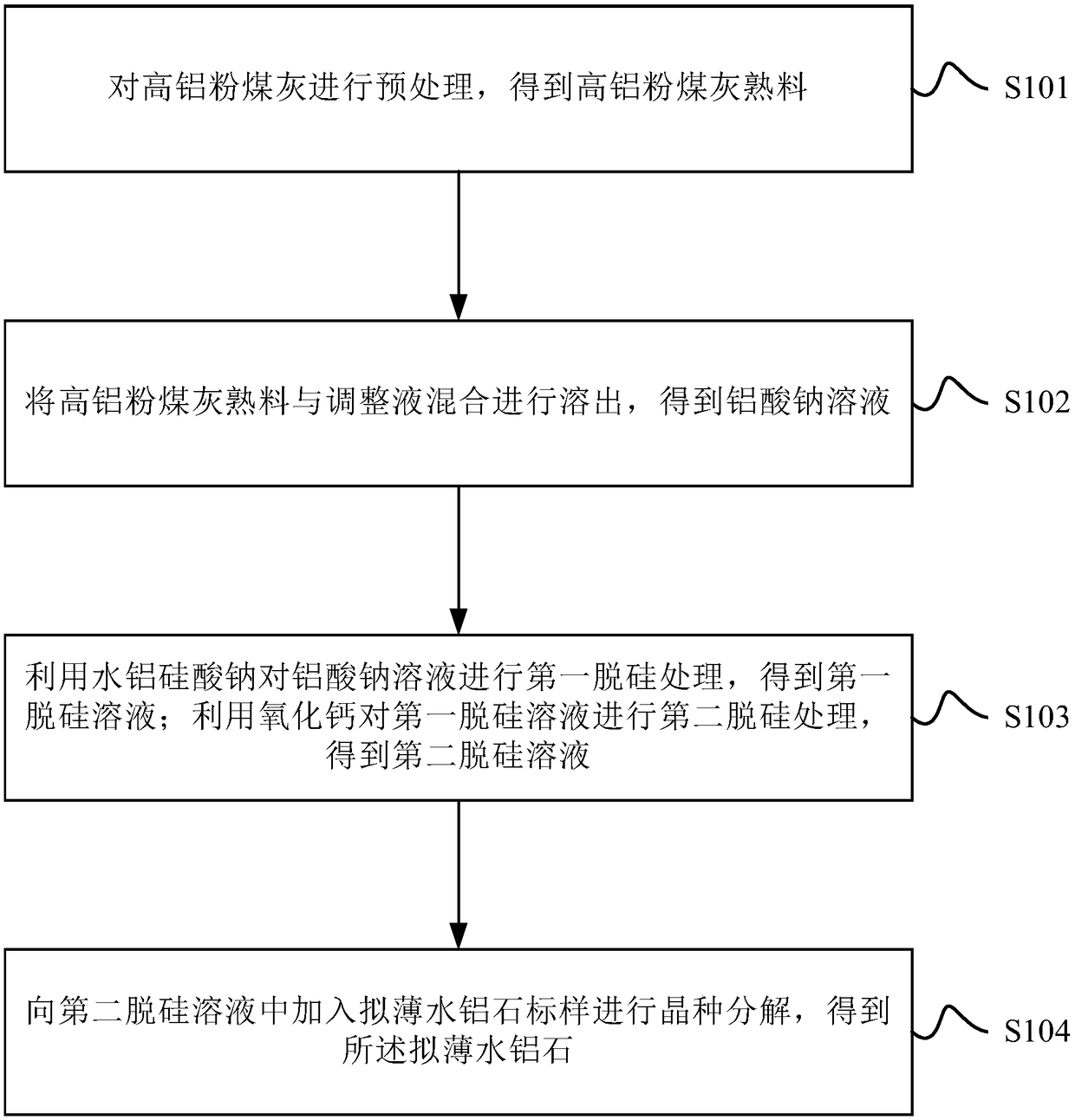

Method used

Image

Examples

Embodiment 1

[0058] In this example, Inner Mongolia Datang high-alumina fly ash is used as a raw material to prepare pseudo-boehmite. The preparation method includes the following steps:

[0059] 1. Pretreatment

[0060] Mix high-alumina fly ash with 20% sodium hydroxide solution (mass ratio of high-alumina fly ash to sodium hydroxide is 1:0.5) in a stirred container at normal pressure for pre-desilication reaction, and control the pre- The reaction temperature of the desiliconization reaction is 85°C, and the reaction time of the pre-desilication reaction is controlled to be 3.0h;

[0061] After the pre-desiliconization reaction is completed, liquid-solid separation is carried out on the reaction system, and the filter cake is washed to obtain fly ash filter cake and desiliconization liquid.

[0062] After mixing the fly ash filter cake with soda lime to obtain a mixed material, the mixed material is placed in a rotary kiln at 1240° C., and sintered for 2.0 hours to prepare high-alumina ...

Embodiment 2

[0076] In this example, Inner Mongolia Datang high-alumina fly ash is used as a raw material to prepare pseudo-boehmite. The preparation method includes the following steps:

[0077] 1. Pretreatment

[0078] Mix high-alumina fly ash with 20% sodium hydroxide solution (mass ratio of high-alumina fly ash to sodium hydroxide is 1:0.5) in a stirred container at normal pressure for pre-desilication reaction, and control the pre- The reaction temperature of the desiliconization reaction is 85°C, and the reaction time of the pre-desilication reaction is controlled to be 3.0h;

[0079] After the pre-desiliconization reaction is completed, liquid-solid separation is carried out on the reaction system, and the filter cake is washed to obtain fly ash filter cake and desiliconization liquid.

[0080] After mixing the fly ash filter cake with soda lime to obtain a mixed material, the mixed material is placed in a rotary kiln at 1240° C., and sintered for 2.0 hours to prepare high-alumina ...

Embodiment 3

[0094] In this example, Inner Mongolia Datang high-alumina fly ash is used as a raw material to prepare pseudo-boehmite. The preparation method includes the following steps:

[0095] 1. Pretreatment

[0096] Mix high-alumina fly ash with 20% sodium hydroxide solution (mass ratio of high-alumina fly ash to sodium hydroxide is 1:0.5) in a stirred container at normal pressure for pre-desilication reaction, and control the pre- The reaction temperature of the desiliconization reaction is 85°C, and the reaction time of the pre-desilication reaction is controlled to be 3.0h;

[0097] After the pre-desiliconization reaction is completed, liquid-solid separation is carried out on the reaction system, and the filter cake is washed to obtain fly ash filter cake and desiliconization liquid.

[0098] After mixing the fly ash filter cake with soda lime to obtain a mixed material, the mixed material is placed in a rotary kiln at 1240° C., and sintered for 2.0 hours to prepare high-alumina ...

PUM

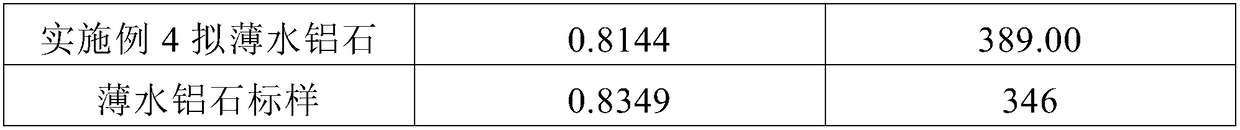

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com