Magnetic graphene oxide/sodium alginate/sodium carboxymethyl cellulose composite material and preparation method thereof

A technology of sodium carboxymethylcellulose and sodium alginate, applied in chemical instruments and methods, alkali metal oxides/hydroxides, alkali metal compounds, etc., can solve the problems of reducing adsorption rate, limiting contact efficiency, etc. Good mechanical strength, large specific surface area, stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

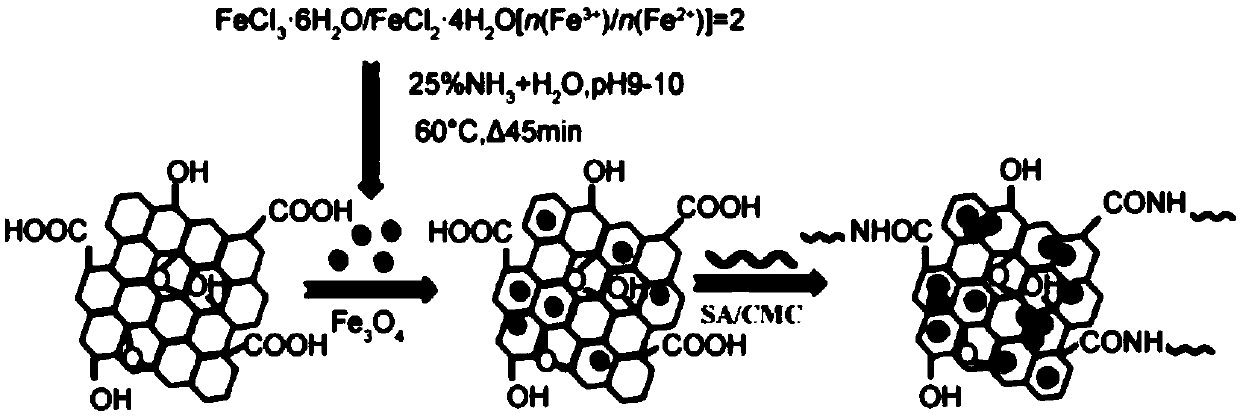

[0053] (1) Preparation of magnetic graphene oxide: 1.0 g of synthesized graphene oxide was ultrasonically dispersed in 100 mL of ultrapure water. Under nitrogen protection, 1.3gFeCl 3 , 0.5g FeCl 2 (2:1 molar ratio) was dissolved in 100mL ultrapure water, and 25% ammonia water was quickly added to pH=10. The mixture was stirred at high temperature for 1 h. Cool to room temperature, wash with ultrapure water and absolute ethanol three times, and dry in vacuum for 12 hours.

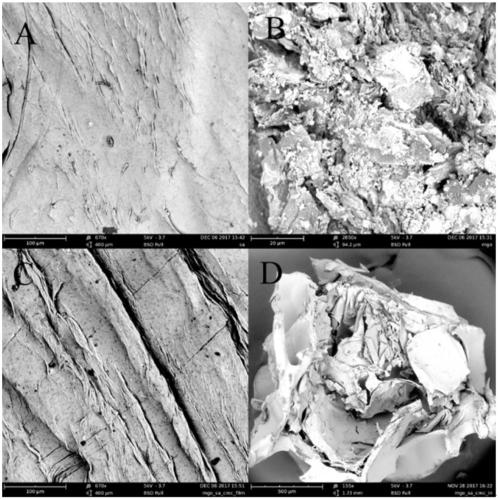

[0054] (2) Preparation of magnetic graphene oxide / sodium alginate / sodium carboxymethyl cellulose: Take 0.3g of magnetic graphene oxide and add it to a beaker containing 100ml of ultrapure water, ultrasonically disperse it for 2 hours, and dissolve 1g of seaweed Add sodium carboxymethyl cellulose and 0.5 g sodium carboxymethyl cellulose to the aqueous solution of magnetic graphene oxide uniformly dispersed by ultrasonic waves, stir at a constant speed for 1 h, drop the mixed solution into 5% calcium chlor...

Embodiment 2

[0057] (1) Preparation of magnetic graphene oxide: 1.0 g of synthesized graphene oxide was ultrasonically dispersed in 100 mL of ultrapure water. Under nitrogen protection, 1.3gFeCl 3 , 0.5g FeCl 2 (2:1 molar ratio) was dissolved in 100mL ultrapure water, and 25% ammonia water was quickly added to pH=10. The mixture was stirred at high temperature for 1 h. Cool to room temperature, wash with ultrapure water and absolute ethanol three times, and dry in vacuum for 12 hours.

[0058] (2) Preparation of magnetic graphene oxide / sodium alginate / sodium carboxymethyl cellulose: Take 0.1 g of magnetic graphene oxide and add it to a beaker containing 100 ml of ultrapure water, ultrasonically disperse it for 2 hours, and dissolve 1 g of seaweed Add sodium carboxymethyl cellulose and 0.5 g sodium carboxymethyl cellulose to the aqueous solution of magnetic graphene oxide uniformly dispersed by ultrasonic waves, stir at a constant speed for 1 h, drop the mixed solution into 5% calcium ch...

Embodiment 3

[0061] (1) Preparation of magnetic graphene oxide: 1.0 g of synthesized graphene oxide was ultrasonically dispersed in 100 mL of ultrapure water. Under nitrogen protection, 1.3gFeCl 3 , 0.5g FeCl 2 (2:1 molar ratio) was dissolved in 100mL ultrapure water, and 25% ammonia water was quickly added to pH=10. The mixture was stirred at high temperature for 1 h. Cool to room temperature, wash with ultrapure water and absolute ethanol three times, and dry in vacuum for 12 hours.

[0062] (2) Preparation of magnetic graphene oxide / sodium alginate / sodium carboxymethyl cellulose: Take 1 g of magnetic graphene oxide and add it to a beaker containing 100 ml of ultrapure water, ultrasonically disperse it for 2 hours, and dissolve 1 g of alginic acid Sodium and 0.5g sodium carboxymethylcellulose were added to the magnetic graphene oxide aqueous solution uniformly dispersed by ultrasonic waves, stirred at a constant speed for 1h, the mixed solution was dropped into 5% calcium chloride sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com