Metal-free nitrogen-doped functionalized mesoporous carbon catalyst and preparation method and applications thereof

A carbon catalyst, nitrogen doping technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of low catalytic activity, improve catalytic activity, improve stability, and reduce dependence. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

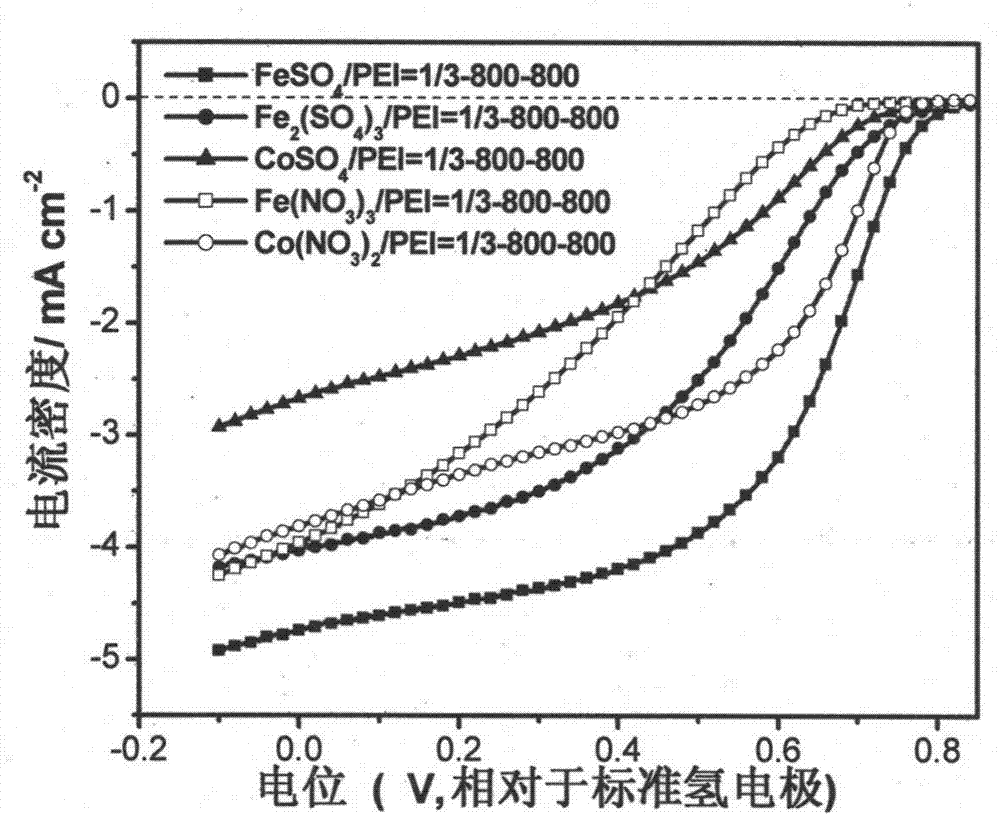

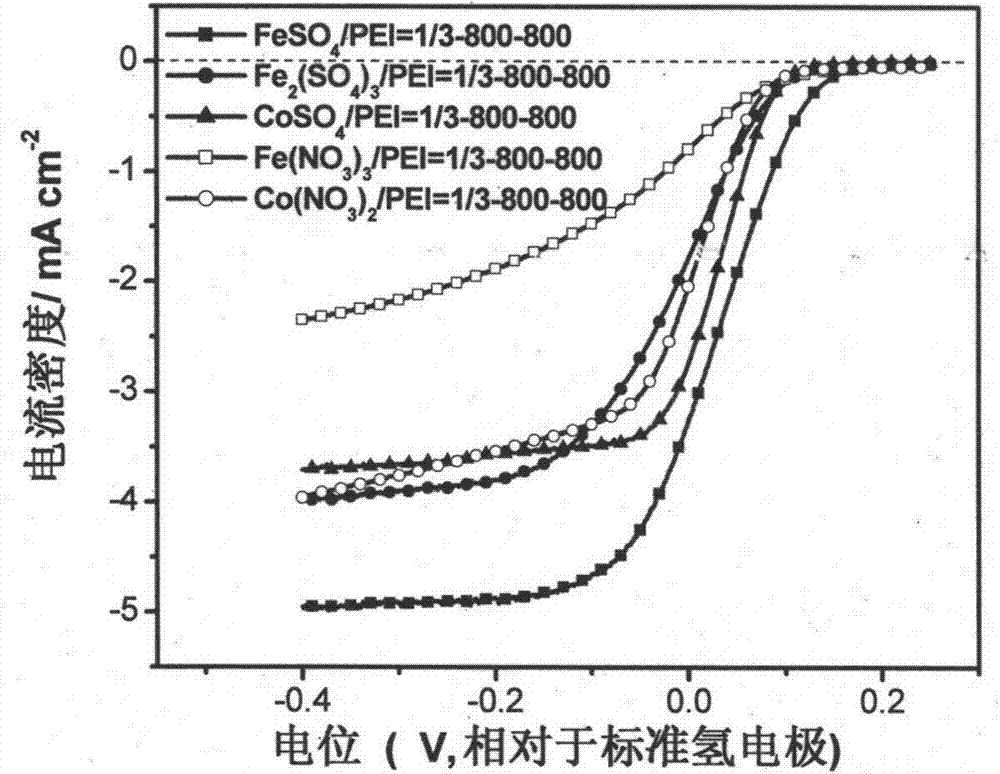

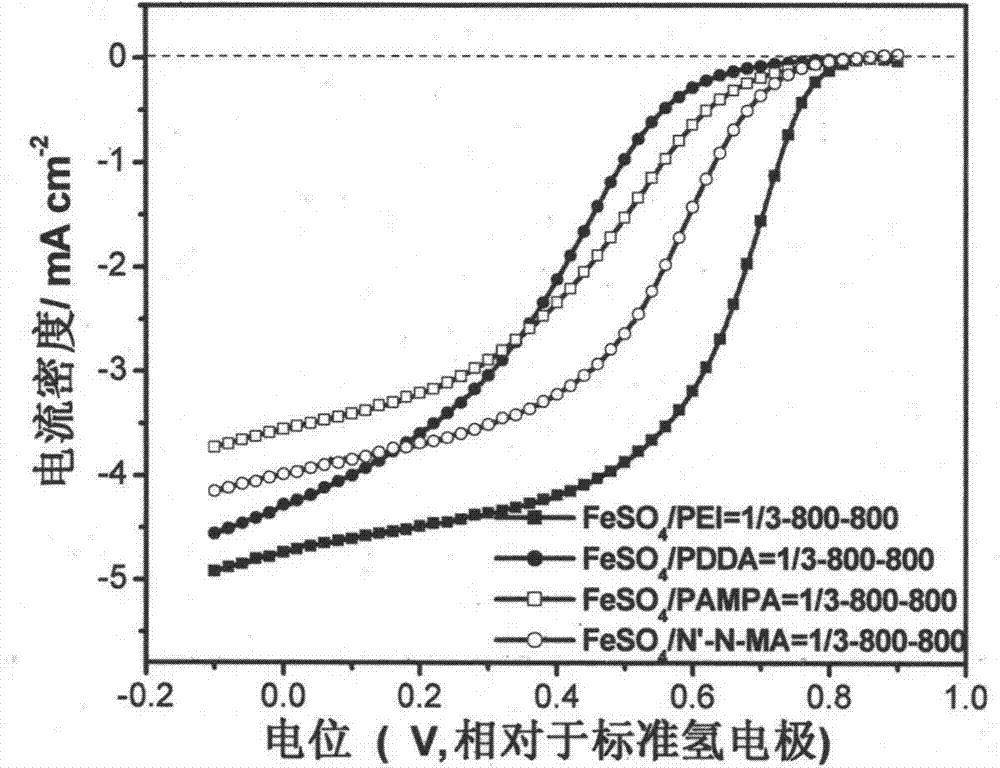

[0038] A metal-free nitrogen-doped functionalized mesoporous carbon catalyst, the precursor of which comprises 46% of the silica with a template diameter of 35nm, and 20% of the nitrogen-containing compound PEI (polyethyleneimine, Sigmaaldrich, 408700-250ML, Mw: 2000) and the transition metal salt heptahydrate ferrous sulfate heptahydrate with a mass content of 34%, the above-mentioned mass content is based on the total mass of the precursor.

[0039] The preparation method of the above-mentioned metal-free nitrogen-doped functionalized mesoporous carbon catalyst is as follows: polyethyleneimine and silicon dioxide are formulated into 50% PEI aqueous solution and 20% SiO 2 Aqueous solution, weigh 0.7448g FeSO 4 ·7H 2 O and 0.9g of 50% PEI aqueous solution, and combine it with 5g of 20% SiO 2 The aqueous solution was mixed uniformly under the condition of stirring, dried in an oven at 85° C. overnight after ultrasonication for 8 hours, and ground into powder to obtain a catal...

Embodiment 2

[0041] A metal-free nitrogen-doped functionalized mesoporous carbon catalyst, the precursor of which comprises 40% template agent with a diameter of 35nm silicon dioxide, 18% nitrogen-containing compound PEI (polyethyleneimine, Sigmaaldrich, 408700-250ML, Mw: 2000) and a transition metal salt iron sulfate with a mass content of 42%, the above mass content is based on the total mass of the precursor.

[0042] The preparation method of the above-mentioned metal-free nitrogen-doped functionalized mesoporous carbon catalyst is as follows: polyethyleneimine and silicon dioxide are formulated into 50% PEI aqueous solution and 20% SiO 2 Aqueous solution, weigh 1.071gFe 2 (SO 4 ) 3 and 0.9g of 50% PEI aqueous solution, and combine it with 5g of 20% SiO 2 The aqueous solution was mixed uniformly under the condition of stirring, dried in an oven at 85° C. overnight after ultrasonication for 8 hours, and ground into powder to obtain a catalyst precursor. Put the above precursor in th...

Embodiment 3

[0044] A kind of metal-doped nitrogen functionalized mesoporous carbon catalyst, its precursor includes the silicon dioxide that the template agent diameter of 45% is 35nm by mass content, the nitrogen-containing compound PEI (polyethyleneimine, Sigmaaldrich) that mass content is 20 , 408700-250ML, Mw: 2000) and transition metal salt cobalt sulfate with a mass content of 35%, the above mass content is based on the total mass of the precursor.

[0045] The preparation method of the above-mentioned metal-free nitrogen-doped functionalized mesoporous carbon catalyst is as follows: polyethyleneimine and silicon dioxide are formulated into 50% PEI aqueous solution and 20% SiO 2 Aqueous solution, weigh 0.7526gCoSO 4 and 0.9g of 50% PEI aqueous solution, and combine it with 5g of 20% SiO 2 The aqueous solution was mixed uniformly under the condition of stirring, dried in an oven at 85° C. overnight after ultrasonication for 8 hours, and ground into powder to obtain a catalyst precur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com