Preparation method of nickel phosphide catalyst carried by composite carrier

A composite carrier and nickel phosphide technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as difficult to be widely used, small specific surface area, poor mechanical strength, etc., to achieve The pore structure is suitable, the specific surface area is large, and the effect of improving the dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

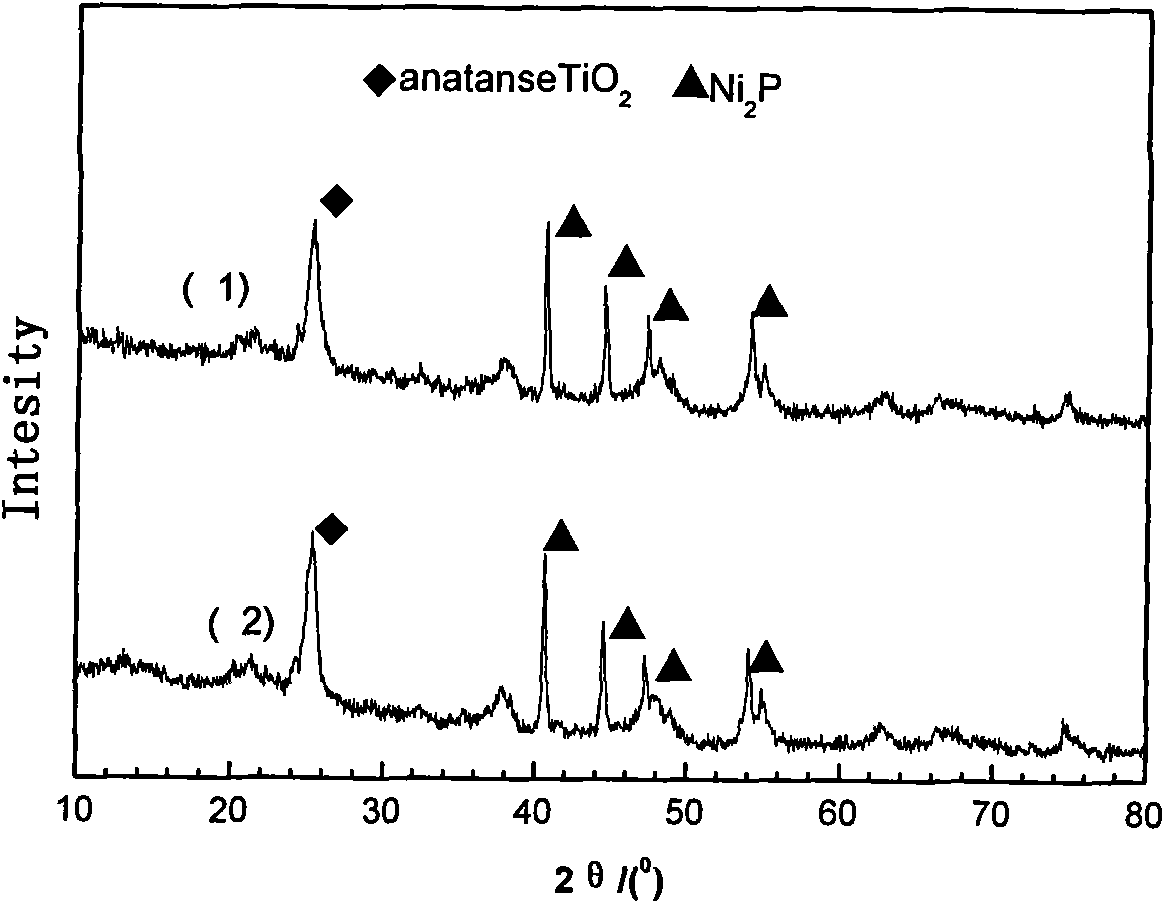

Embodiment 1

[0024] a. Dissolve 13ml of tetrabutyl titanate in 13ml of ethanol and 1.3ml of glacial acetic acid to form a mixed solution of tetrabutyl titanate, and weigh 7.8g of γ-Al 2 o 3 Place in the mixed solution of tetrabutyl titanate, and disperse the above mixed solution under ultrasonic for 30min, with ultrasonic power of 500W. After aging for half a day, the γ-Al 2 o 3 The surface of the carrier is coated with a layer of TiO 2 . After centrifugal filtration, wash three times with absolute ethanol and deionized water respectively, and dry in a drying oven at 120° C. for 12 hours. Place the dried powder in a muffle furnace, calcinate at 300°C for 5 hours, and cool to room temperature to obtain TiO 2 -Al 2 o 3 Composite carrier.

[0025] b. Weigh 8.25 g of the carrier prepared by the above method, and add it into a three-necked flask with a funnel. Weigh 7.5g nickel nitrate Ni (NO 3 ) 2 ·6H 2 O and 6.5g diammonium hydrogen phosphate (NH 4 ) 2 HPO 4Dissolve in 20g deio...

Embodiment 2

[0029] a. Dissolve 13ml of tetrabutyl titanate in 13ml of ethanol and 3.9ml of glacial acetic acid to form a mixed solution of tetrabutyl titanate, and weigh 5.2g of γ-Al 2 o 3 Put it in the mixed solution of tetrabutyl titanate, and disperse the above mixed solution under ultrasonic for 20min, the ultrasonic power is 700W. After aging for half a day, the γ-Al 2 o 3 The surface of the carrier is coated with a layer of TiO 2 . After centrifugal filtration, wash three times with absolute ethanol and deionized water respectively, and dry in a drying oven at 120° C. for 12 hours. Place the dried powder in a muffle furnace, calcinate at 500°C for 3 hours, and cool to room temperature to obtain TiO 2 -Al 2 o 3 Composite carrier.

[0030] b. Weigh 8.5 g of the carrier prepared by the above method, and add it into a three-necked flask with a funnel. Weigh 7.5g nickel nitrate Ni (NO 3 ) 2 ·6H 2 O and 4.5g diammonium hydrogen phosphate (NH 4 ) 2 HPO 4 Dissolve in 22g deio...

Embodiment 3

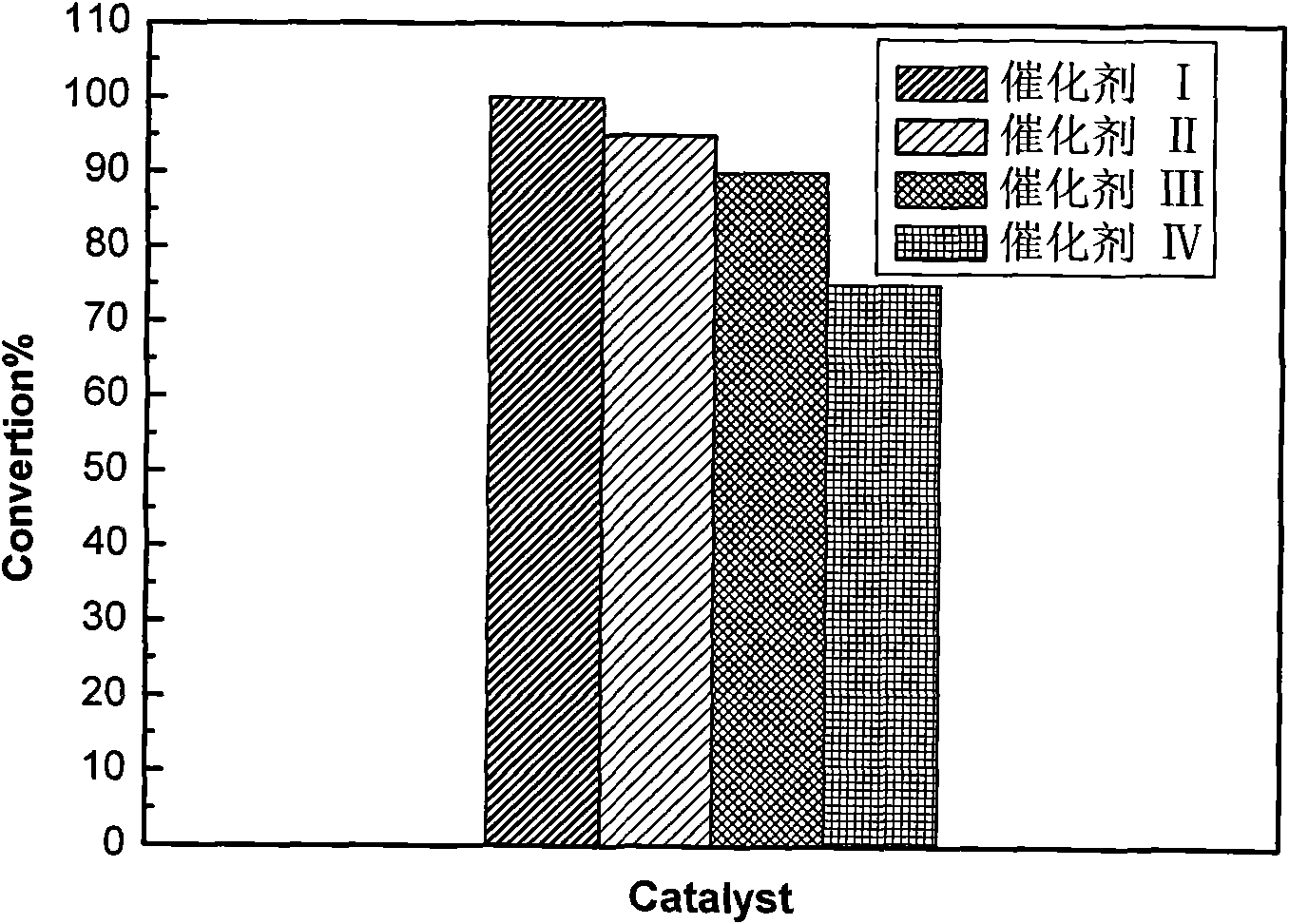

[0033] In this example step a composite carrier TiO 2 -Al 2 o 3 In the preparation process of , the traditional mechanical stirring is used instead of ultrasonic dispersion; in the preparation process of the oxidation state nickel phosphide catalyst precursor in step b, the traditional mechanical stirring is also used instead of ultrasonic impregnation, and drying in a 120 °C drying oven instead of microwave oven Drying under the power of 700W, other operating steps are according to embodiment 1, obtain Ni 2 P / TiO 2 -Al 2 o 3 Catalyst, denoted as Catalyst II. The activity evaluation of the catalyst was carried out according to the method of Example 1. When reacting at 340°C, the desulfurization rate of dibenzothiophene is about 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com