Preparation process of modified heavy calcium carbonate

A kind of heavy calcium carbonate, the technology of preparation process, applied in the direction of calcium carbonate/strontium/barium, cosmetic preparations, cosmetic preparations, etc. performance, high hydrophobicity, uniform dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

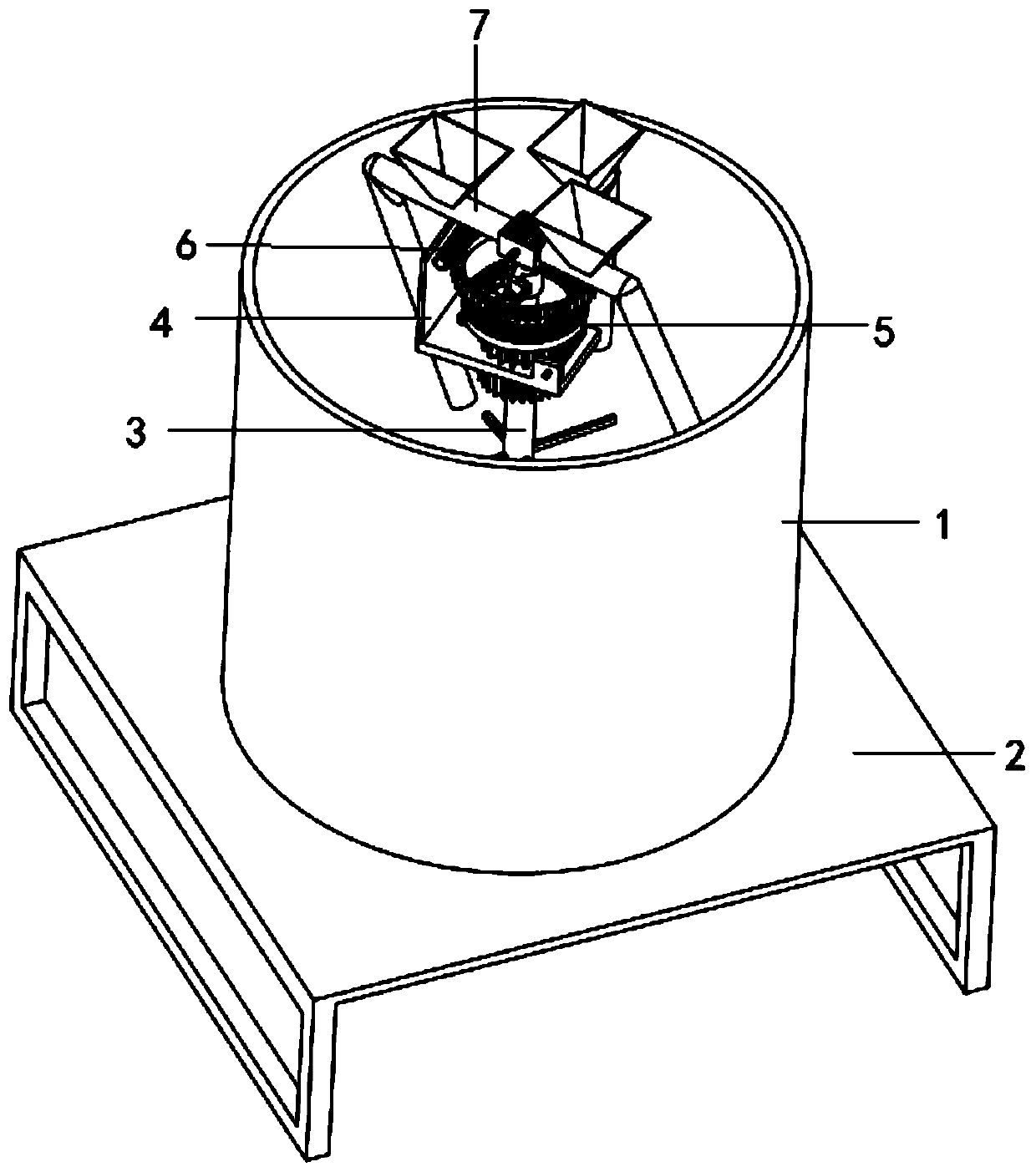

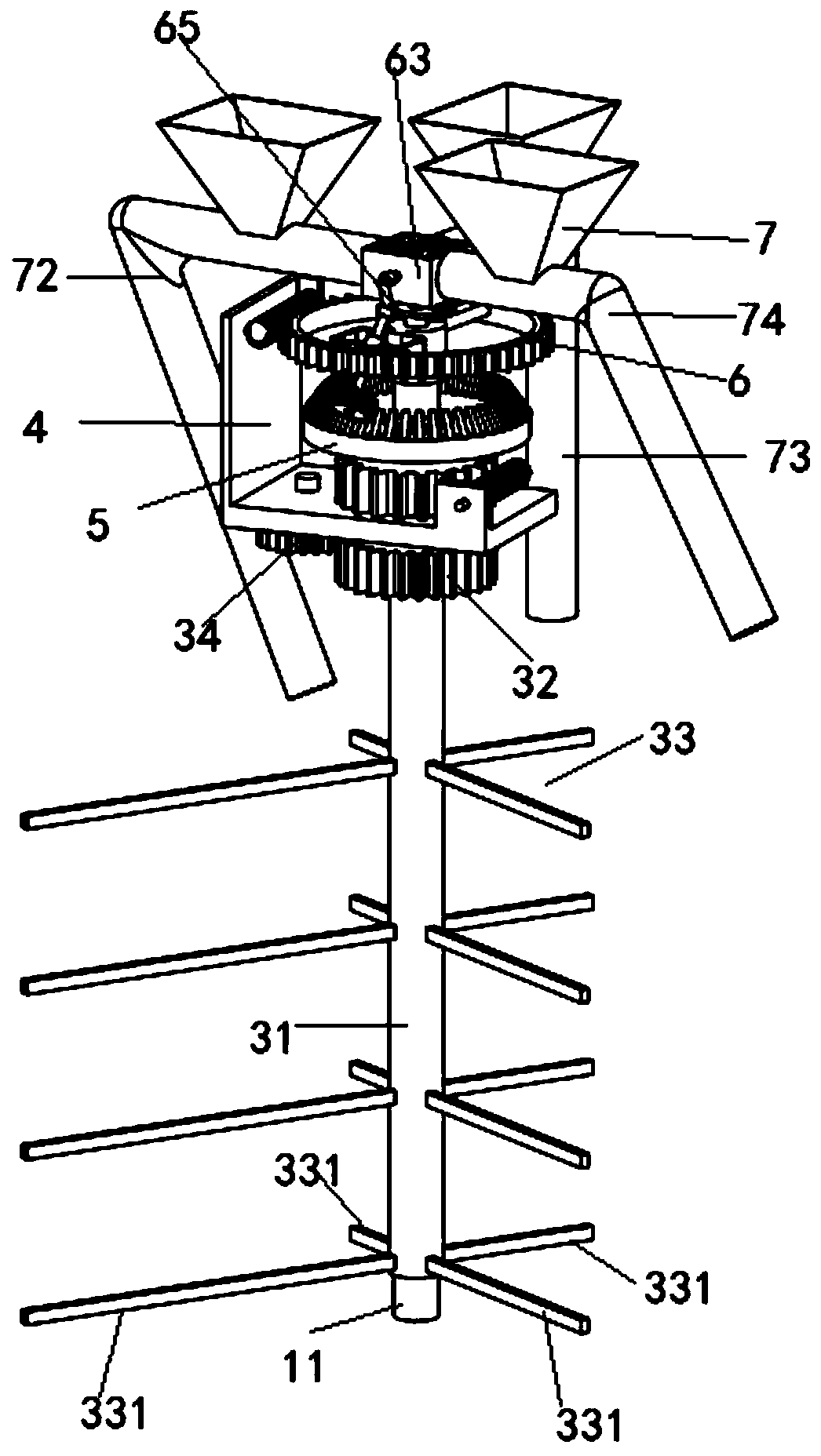

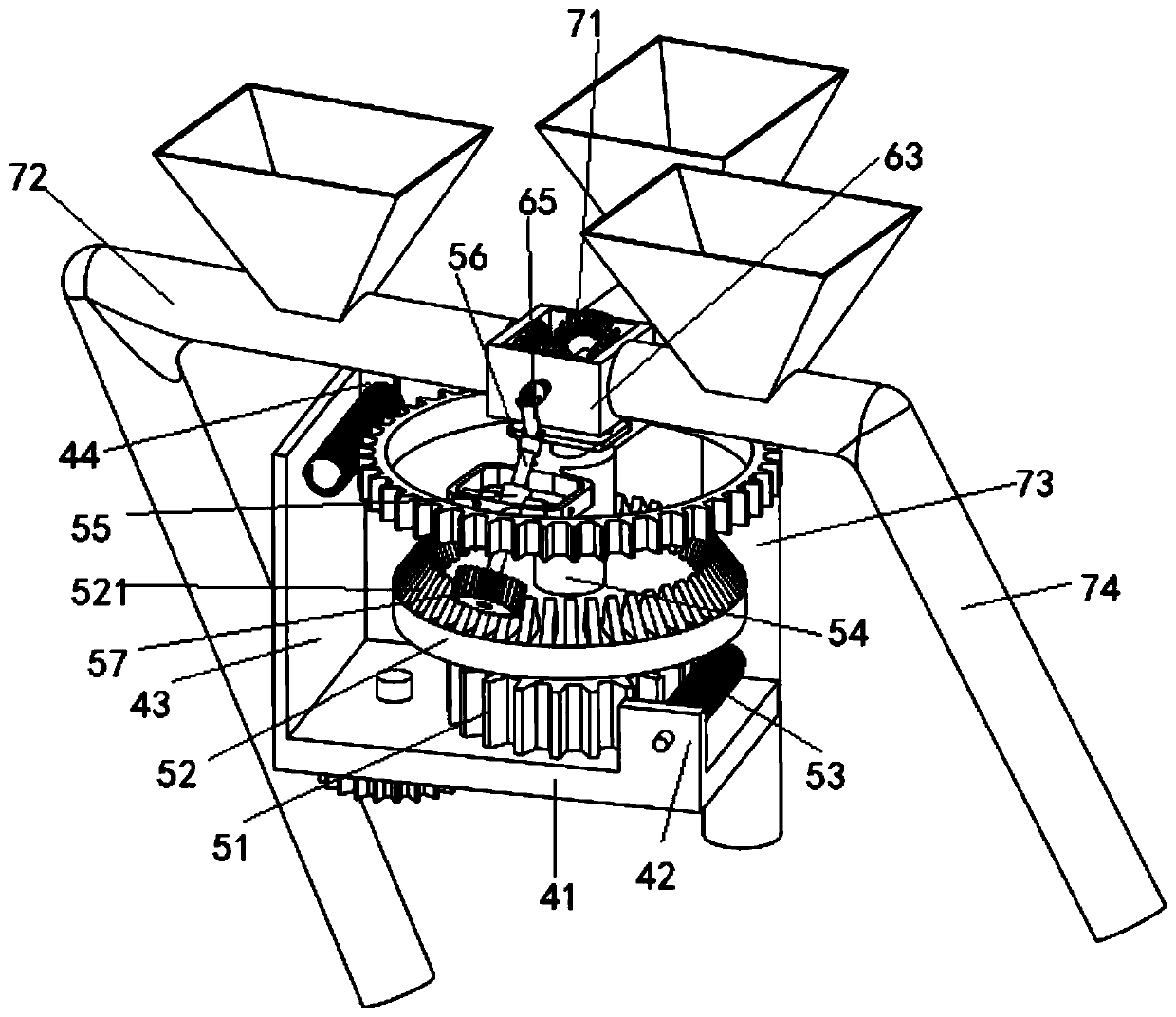

[0029] see Figure 1-6 , describe in detail in conjunction with the following examples:

[0030] In the process of processing and modifying heavy calcium carbonate, usually in order to improve the dispersion performance of calcium carbonate, it is placed to agglomerate when it is used as a filler, which affects the performance of the material. Usually, calcium carbonate is modified by reaction with a modifier. In the process, due to the small particle size of calcium carbonate, directly adding calcium carbonate to the reaction vessel and then stirring and reacting with the modifier will easily cause calcium carbonate to agglomerate, so that it cannot be modified uniformly and completely, which will affect the overall quality of the modified calcium carbonate. Performance, the application prepares a kind of dispersion feeding stirring device that can feed in different directions, while rotating while feeding, and can automatically control the feeding speed. Through this device,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com