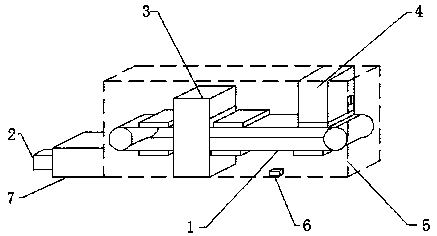

Automatic detection device for appearance of glass tube

An automatic detection and glass tube technology, used in measuring devices, chemical instruments and methods, cleaning flexible objects, etc., can solve the problems that the surface dust cannot be cleaned, the glass tube cannot be cleaned, and the glass tube is fed too much, etc., to achieve production efficiency. High, multi-functional, avoid the effect of overfeeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

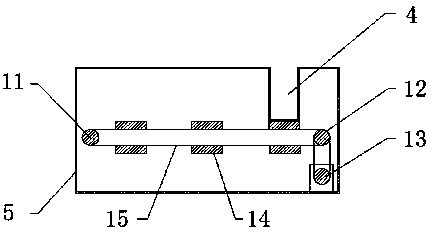

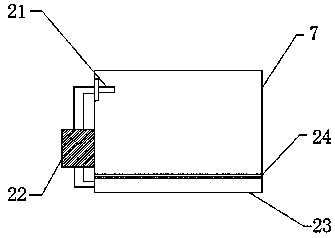

[0025] Specific embodiments: the user connects the present invention with an external power supply, and puts the glass tube to be detected into the feeding chamber 4, the external power supply transmits the electric energy to the storage battery 6 through the wire, and the storage battery 6 stores the electric energy inside, and closes the switch. Connect the internal circuit of the present invention, the storage battery 6 transmits the electric energy to the motor 13 through the electric wire, the electric motor 13 converts the electric energy into mechanical energy, and drives the driving wheel 12 to rotate, the driving wheel 12 utilizes the transmission belt 15 to drive the driven wheel 11 to rotate, and the glass tube moves from the top The material chamber 4 falls on the transmission belt 15 and moves together with the transmission belt 15. When the glass tube moves into the detection chamber 3, the user detects the glass tube. When the lower end surfaces of the feeding ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com