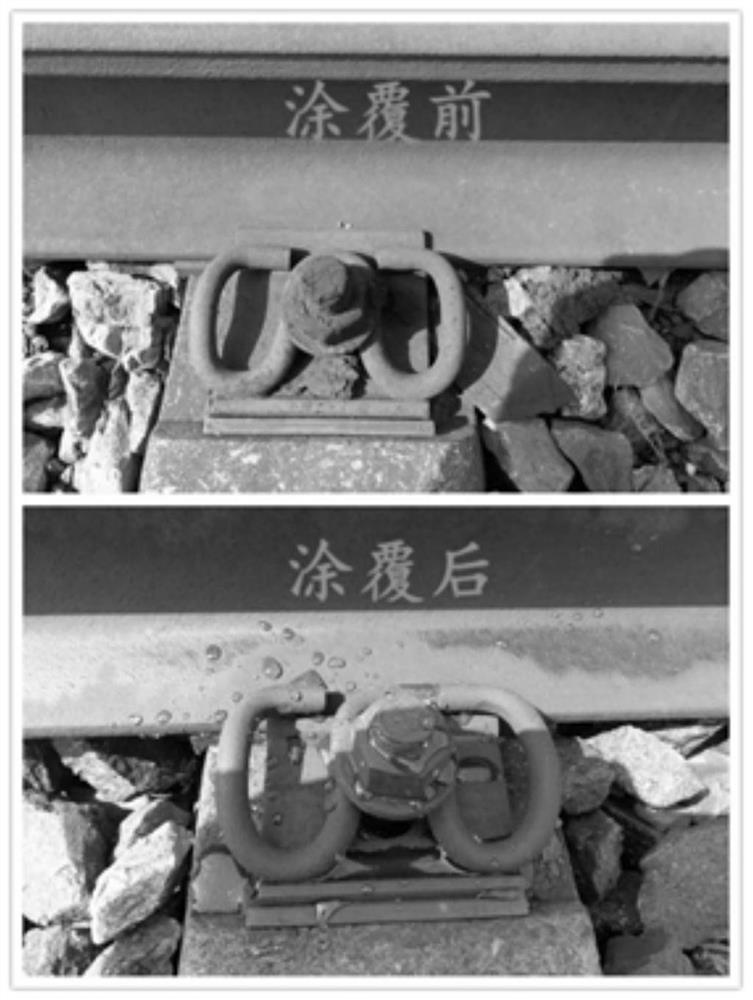

Anti-corrosion composite coating for steel rail fastener elastic strips and bolt spikes and preparation method and coating method thereof

A composite coating and anti-corrosion technology, which is applied in the direction of anti-corrosion coatings, coatings, and devices for coating liquid on the surface, can solve the problems of low bonding force between anti-corrosion grease and rail substrate, low coating efficiency, and short service life. Achieve the effects of reducing the coating workload and labor intensity, good anti-corrosion effect and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

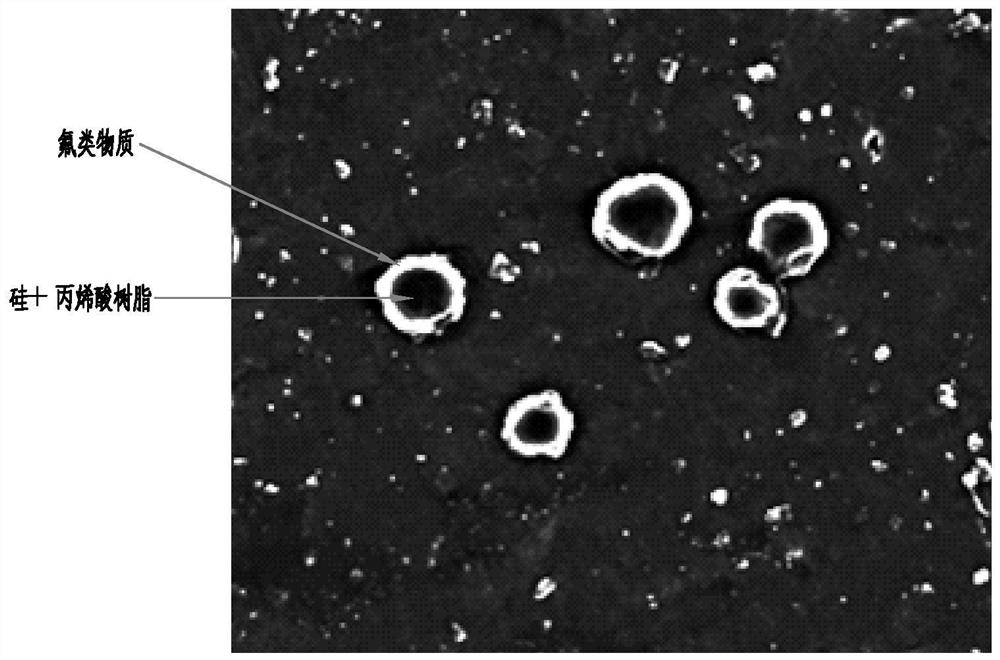

[0053] (1) Configure modified fumed silica:

[0054] Add 300ml of xylene, 14g of fumed white carbon black, 0.56g of water into a 500ml three-necked flask, stir at room temperature for 1 hour, add 2.52g of hexamethyldisilazane, heat and stir, and control the temperature at 110-130 degrees to react After 2 hours, the temperature was lowered, the xylene was evaporated under reduced pressure, the product was poured out, dried and set aside.

[0055] (2) Configure the primer:

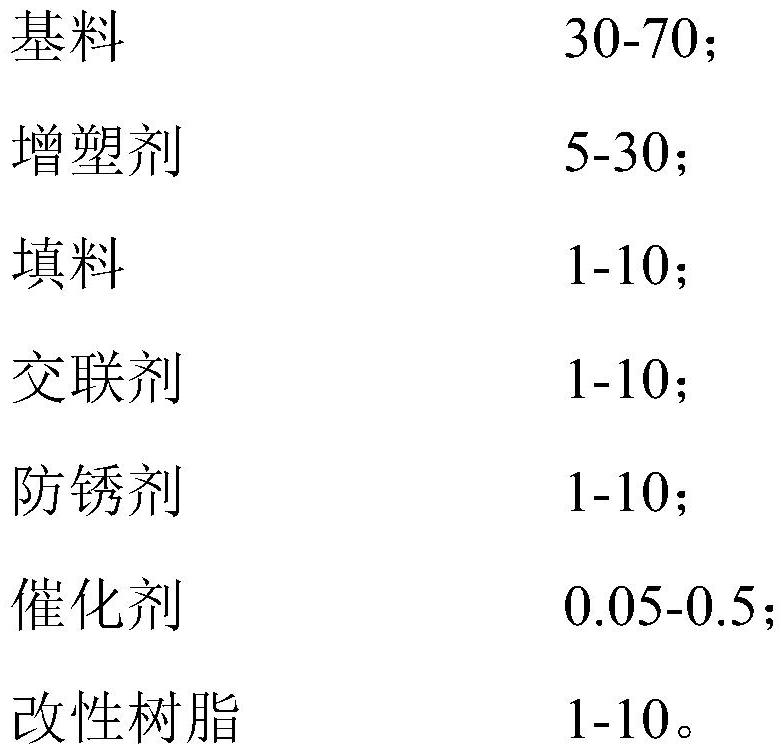

[0056] Heat and mix 30g of α,ω-dihydroxy polydimethylsiloxane with a viscosity (25°C) of 8000cs and a hydroxyl content of 0.004mol / 100g and 5g of silicone oil 201, keep it warm at 160±10°C for 1.5 hours, then add 2g of modified resin EVA, stirred for half an hour, then added 1g of barium petroleum sulfonate, stirred for half an hour, then cooled to 50°C, added 0.5g of vinyl tributylketoximosilane, mixed for 15min, added 0.5g of methyltri Methyl ethyl ketoxime silane, add 0.05g of dibutyltin dilaurate, mix ...

Embodiment 2

[0063] Step (1) is the same as embodiment 1

[0064] (2) Configure the primer:

[0065] Heat and mix 40g of α,ω-dihydroxy polydimethylsiloxane with a viscosity (25°C) of 8000cs and a hydroxyl content of 0.004mol / 100g and 10g of silicone oil 201, keep it warm at 160±10°C for 1.5 hours, then add 5g of modified resin EVA, stirred for half an hour, then added 2g of barium petroleum sulfonate, stirred for half an hour, then cooled to 50°C, added 1g of vinyl tributylketoximosilane, mixed for 15min, added 2g of methyl tributyl ketone Oxime silane, add 0.1g dibutyltin dilaurate, mix evenly, stir for half an hour, reduce pressure for about 5 minutes, remove air bubbles, and obtain the modified silicone rubber of the primer.

[0066] (3) Configure the surface coating:

[0067] Pass N through the reactor for 30min 2 , add 13g acrylic resin, 70g n-butanol, 1g silicone defoamer, turn on the reflux device, stir and heat up to 70±10°C, add dropwise 13g acrylic resin, 1g benzoyl peroxide, ...

Embodiment 3

[0070] Step (1) is the same as embodiment 1

[0071] (2) Configure the primer:

[0072] Heat and mix 50g of α,ω-dihydroxy polydimethylsiloxane with a viscosity (25°C) of 8000cs and a hydroxyl content of 0.004mol / 100g and 15g of silicone oil 201, keep it warm at 160±10°C for 1.5 hours, then add 7g of modified resin EVA, stirred for half an hour, then added 5g of barium petroleum sulfonate, stirred for half an hour, then cooled to 50°C, added 1g of vinyl tributylketoximosilane, mixed for 15min, added 3g of methyl tributyl ketone Oxime-based silane, add 0.2g dibutyltin dilaurate, mix evenly, stir for half an hour, reduce pressure for about 5 minutes, remove air bubbles, and obtain the modified silicone rubber of the primer.

[0073] (3) Configure the surface coating:

[0074] Pass N through the reactor for 30min 2 , add 15g acrylic resin, 80g n-butanol, 1g silicone defoamer, turn on the reflux device, stir and heat up to 70±10°C, add dropwise 15g acrylic resin, 1g benzoyl pero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com