Composite coating for resisting alkalization of wall surface

A composite coating and pan-alkali technology, applied in the field of coatings, can solve the problems of high alkalinity, reduce the alkalinity of walls, and low alkalinity of putty, and achieve the effects of high compactness, reduction of mildew and simple construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

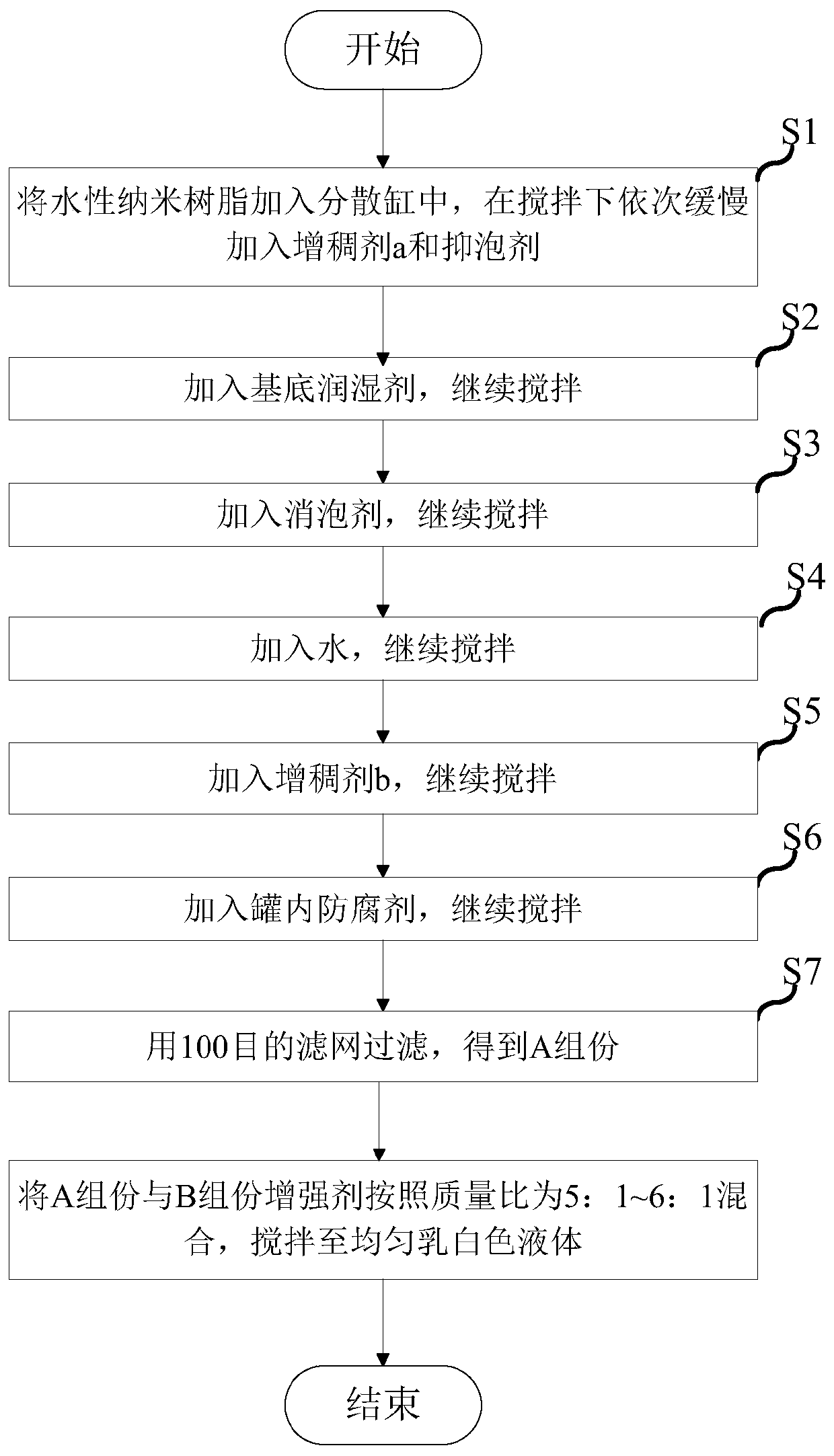

[0019] A kind of wall surface efflorescence-resistant composite paint and its preparation method will be further described in detail below in conjunction with examples, but the scope of protection claimed by the present invention is not limited to the scope indicated by examples.

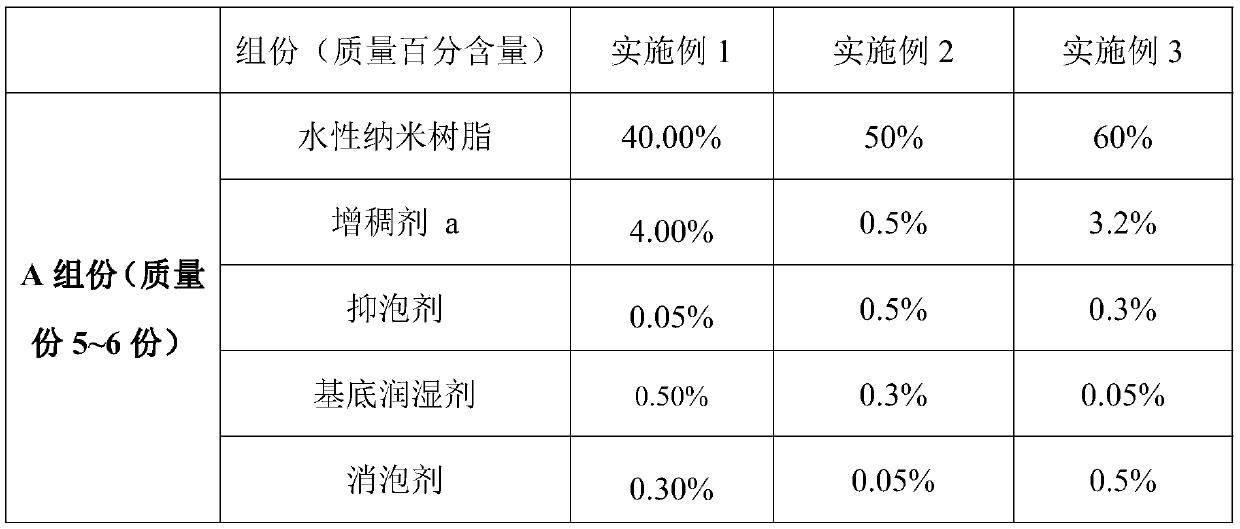

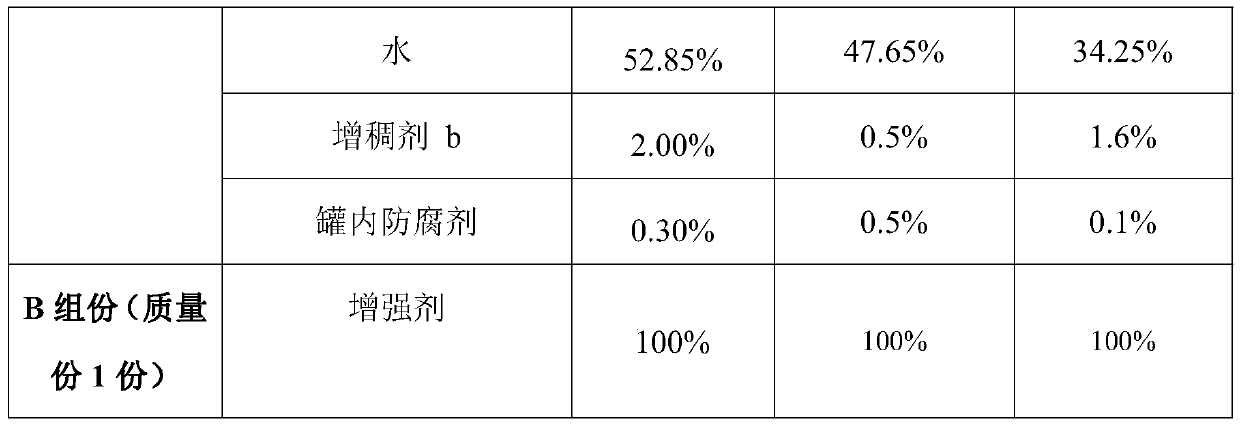

[0020] In some specific embodiments of the present invention, a kind of anti-panthenic base coating on the wall is provided, which comprises A component and B component, and the mass ratio of the A component and the B component is 5: 1-6:1; the component A includes, by mass percentage: 40-60% water-based nano-resin, 0.5-4.0% thickener a, 0.05-0.5% foam suppressor, and 0.05-0.5% base wetting agent 0.5%, defoamer 0.05-0.5%, thickener b 0.5-2.0%, tank preservative 0.1-0.5%, and the balance is water; the B component is a reinforcing agent.

[0021] In some specific embodiments of the present invention, the water-based nano-resin is a polycarbonate nano-scale dispersion with carboxyl and hydroxyl groups ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com