A kind of superhydrophobic material and preparation method thereof

A super-hydrophobic, particle-size technology, applied in the direction of coating, etc., can solve the problems of poor anti-wear ability and super-hydrophobic surface resistance, and achieve the effect of prolonging the freezing time, broad market prospect and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

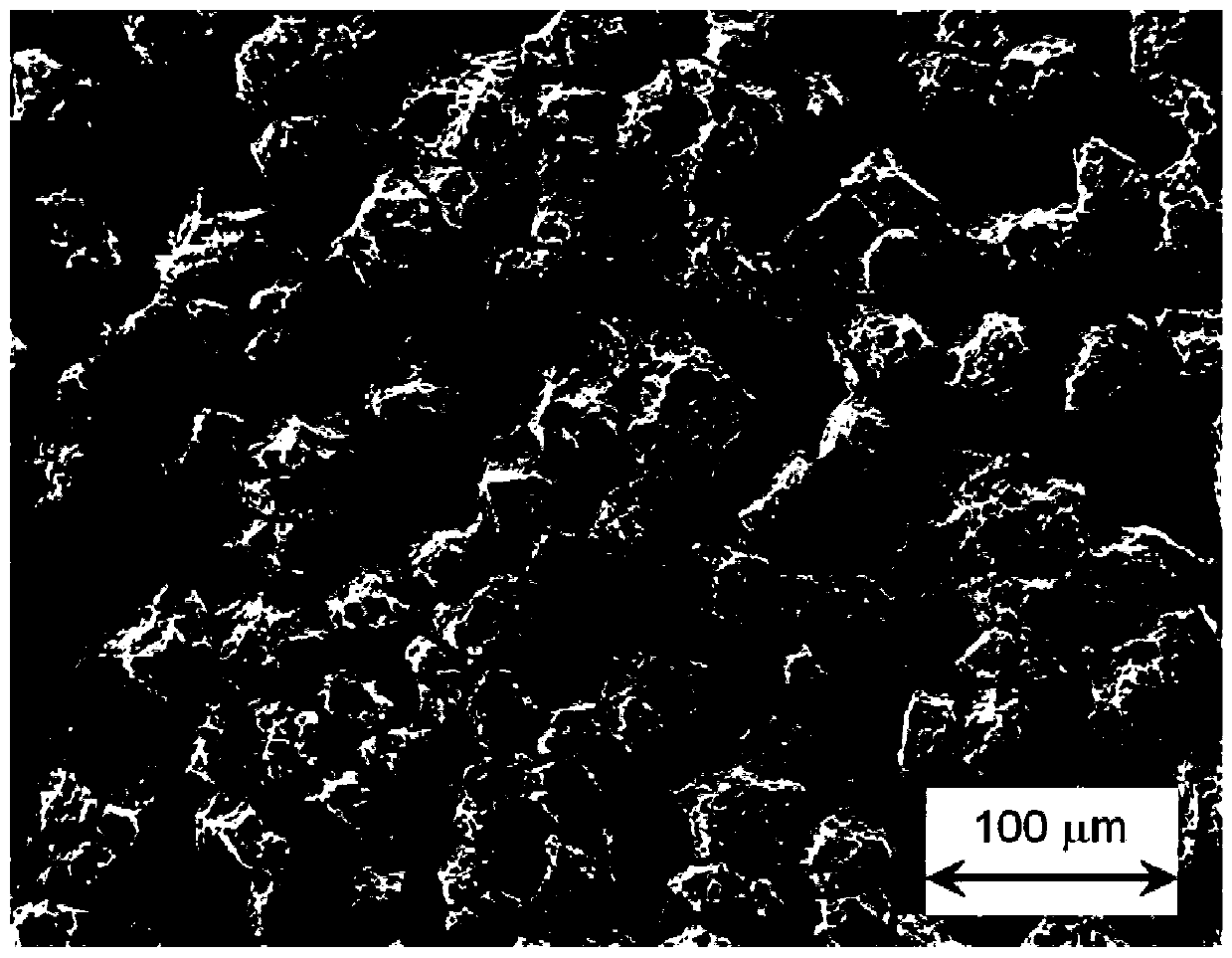

Image

Examples

Embodiment 1

[0047] The metal aluminum alloy is used as the base, and it is polished at least 5 times with 360-grit sandpaper, and then it is cleaned in an ultrasonic water bath. Thereafter, it was washed with isopropanol. After the above operations are completed, it is etched in 2.5 mol / L hydrofluoric acid for 3 minutes. During the process, the aluminum plate rotates evenly in the etching solution at a speed of 16r / min. Repeat the above operation 5 times. Thereafter, the metal aluminum alloy was vertically dipped into the hydrophobic coating containing nanoparticles at a speed of 0.1 mm / s. After the aluminum sheet is completely immersed, rotate the aluminum sheet at a speed of 10r / min, and the immersion time is not less than 7 minutes. Repeat the operation at least 5 times. The coating is formed by mixing organic resin, organic solvent and nano particles, the mass fraction of organic resin is 65%, the mass fraction of organic solvent is 19%, and the mass fraction of nano particles is ...

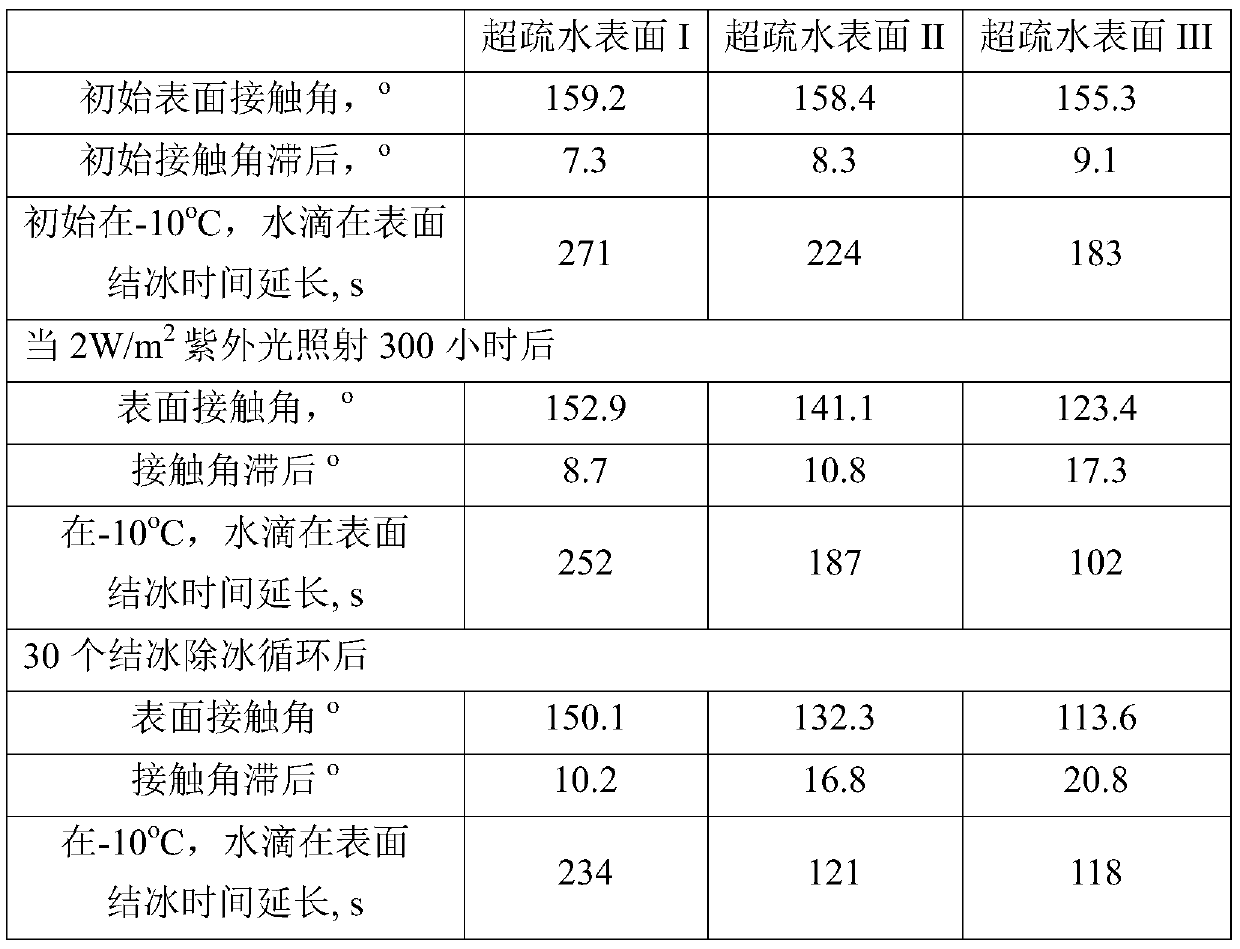

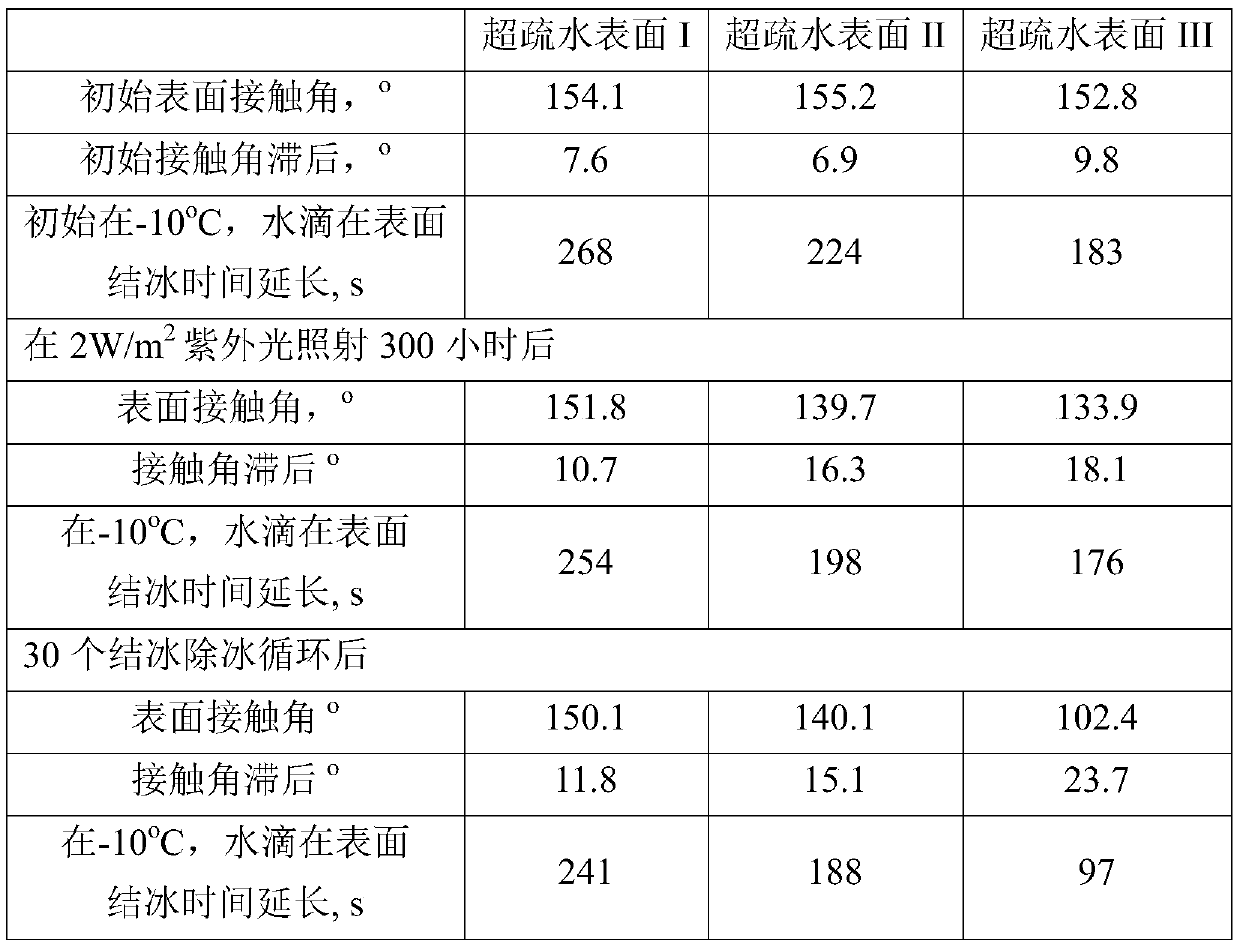

Embodiment 2

[0050] Super-hydrophobic surface I, metal aluminum alloy as the base, polished it at least 5 times with 360-grit sandpaper, and then cleaned it in an ultrasonic water bath. Thereafter, it was washed with toluene. After the above operation is completed, it is etched in 3 mol / L hydrochloric acid for 4 minutes, and the above operation is repeated 5 times. Thereafter, the metal aluminum alloy was dipped into the hydrophobic coating containing nanoparticles at a speed of 0.1 mm / s. After the aluminum sheet is completely immersed, rotate the aluminum sheet at a speed of 10r / min, and the immersion time is not less than 5 minutes. Repeat the above operation 5 times. The coating is formed by mixing organic resin, organic solvent and nano particles, the mass fraction of organic resin is 78%, the mass fraction of organic solvent is 12%, and the mass fraction of nano particles is 10%. Among them, the organic resin is a mixture of perfluoromethyl vinyl ether (CAS No. 1187-93-5) and perfl...

Embodiment 3

[0057] Super-hydrophobic surface I, metal aluminum alloy as the base, polished it at least 5 times with 360-grit sandpaper, and then cleaned it in an ultrasonic water bath. Thereafter, it was washed with isopropanol. After the above operation is completed, it is etched in 3 mol / L hydrochloric acid for 4 minutes, and the above operation is repeated 5 times. Thereafter, the metal aluminum alloy was vertically dipped into the hydrophobic coating containing nanoparticles at a speed of 0.1 mm / s. After the aluminum sheet is completely immersed, rotate the aluminum sheet at a speed of 10r / min, and the immersion time is not less than 5 minutes. Repeat the above operation at least 5 times. The coating is formed by mixing organic resin, organic solvent and nanoparticles, the mass fraction of organic resin is 78%, the mass fraction of organic solvent is 14%, and the mass fraction of nanoparticles is 8%. Among them, the organic resin is a mixture of perfluoroethyl vinyl ether (CAS No. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com