A conductive anti-corrosion coating process for aluminum flow field plate

A conductive anti-corrosion and flow field plate technology, which is applied in the direction of circuits, fuel cells, electrical components, etc., can solve the problems that cannot meet the commercial application of fuel cell aluminum flow field plates, the pollution of the environment by waste liquid containing heavy metal ions, and the physical gas phase. Complicated deposition operation and other issues, to achieve the effect of excellent electrical conductivity and corrosion resistance, excellent electrical conductivity, and cheap process raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

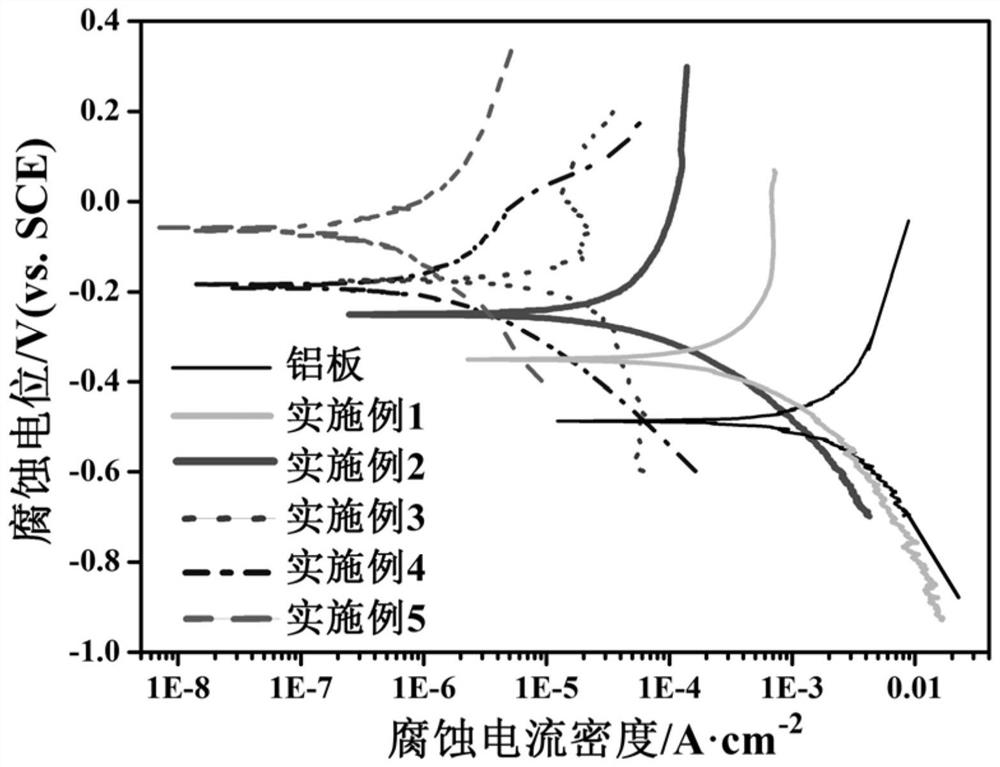

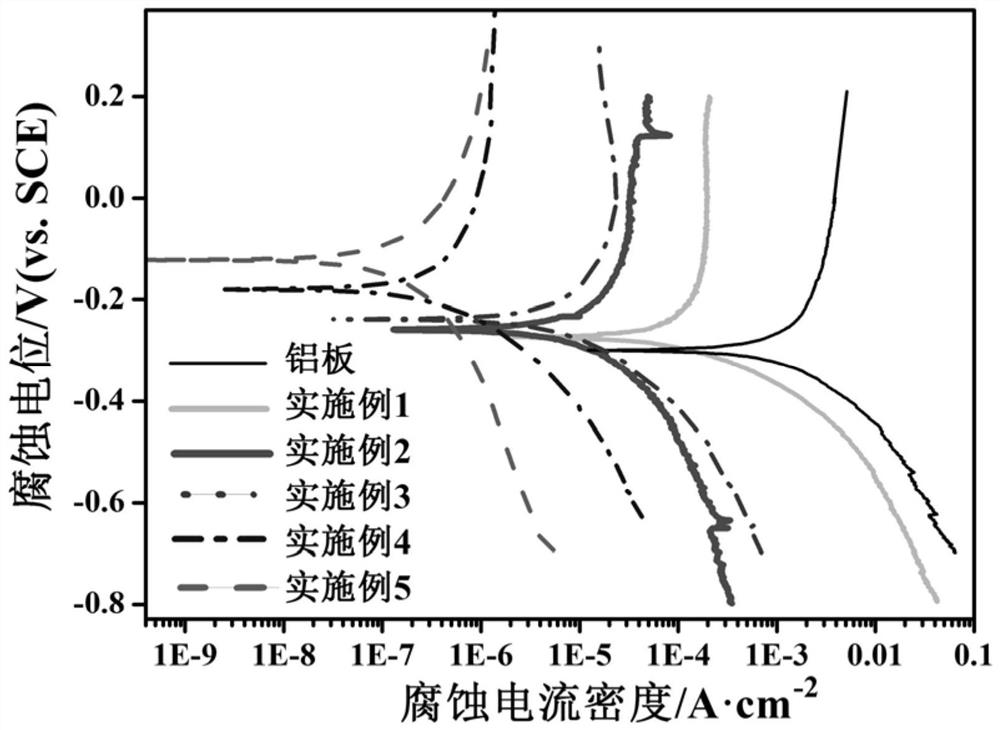

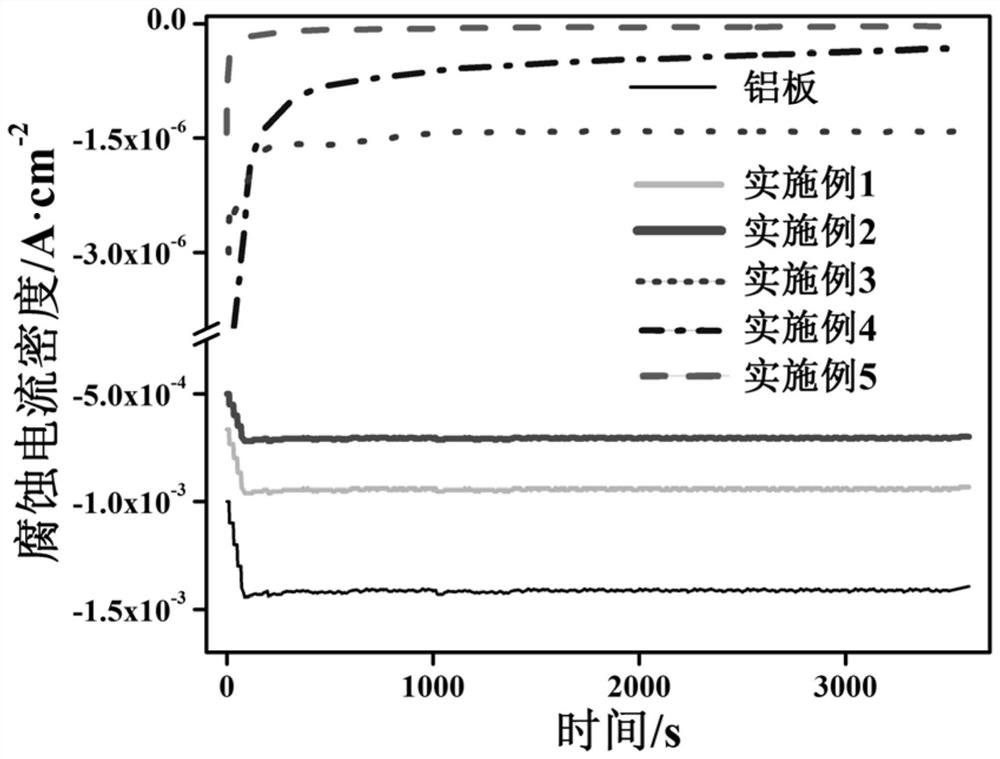

Embodiment 1

[0042] First, use 1200# sandpaper to mechanically polish the aluminum flow field plate, and then use diamond abrasive paste to perform fine polishing on the polished aluminum flow field plate; use acetone solution and ethanol solution to polish the finely polished aluminum flow field Ultrasonic cleaning of the plate; immerse the aluminum flow field plate after ultrasonic cleaning in 1mol / L NaOH solution for 30s; wash the aluminum flow field plate after alkali cleaning with deionized water for 3 times and seal it in deionized water; Immerse the pretreated aluminum flow field plate in a 3 mg / mL graphene oxide aqueous solution containing tetrahydroxyaluminate ions at a concentration of 1 mmol / L for 24 hours at a temperature of 20°C; take out the impregnated aluminum plate The flow field plate is cleaned with deionized water three times and then dried at normal temperature to obtain an aluminum flow field plate coated with a graphene oxide layer; the aluminum flow field plate coate...

Embodiment 2

[0045] First, use 1200# sandpaper to mechanically polish the aluminum flow field plate, and then use diamond abrasive paste to perform fine polishing on the polished aluminum flow field plate; use acetone solution and ethanol solution to polish the finely polished aluminum flow field Ultrasonic cleaning of the plate; immerse the aluminum flow field plate after ultrasonic cleaning in 1mol / L NaOH solution for 30s; wash the aluminum flow field plate after alkali cleaning with deionized water for 3 times and seal it in deionized water; Immerse the pretreated aluminum flow field plate in 2 mg / mL graphene oxide aqueous solution containing tetrahydroxyaluminate ions at a concentration of 80 mmol / L for 2 hours at a temperature of 60°C; take out the impregnated aluminum plate The flow field plate is cleaned with deionized water three times and dried at normal temperature to obtain an aluminum flow field plate coated with a graphene oxide layer; the aluminum flow field plate coated with ...

Embodiment 3

[0048] like Figure 1-Figure 6 As shown, firstly, the aluminum flow field plate is mechanically polished with 1200# sandpaper, and then the polished aluminum flow field plate is finely polished with diamond abrasive paste; Ultrasonic cleaning was performed on the flow field plate; the aluminum flow field plate after ultrasonic cleaning was immersed in 1mol / L NaOH solution for 30s; Ionized water; immerse the pretreated aluminum flow field plate in a 0.1 mg / mL graphene oxide aqueous solution containing tetrahydroxyaluminate ions at a concentration of 3 mmol / L for 3 hours, and the immersion temperature is 90 °C; take out The impregnated aluminum flow field plate was washed three times with deionized water and then dried at room temperature to obtain an aluminum flow field plate coated with a graphene oxide layer; the aluminum flow field plate coated with a graphene oxide layer was impregnated in 160g / L sodium hypophosphite solution for 2 hours at a temperature of 40°C; the treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com