Flame-retardant and heat-insulating nano high-build coating and coating method thereof

A technology of flame-retardant heat preservation and nano-coating, which is applied in the direction of fire-proof coatings, devices for coating liquid on the surface, coatings, etc., which can solve the problems of no flame-retardant effect and unsatisfactory flame-retardant effect, and achieve good heat preservation effect and construction The effect of strong controllability and simple coating method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

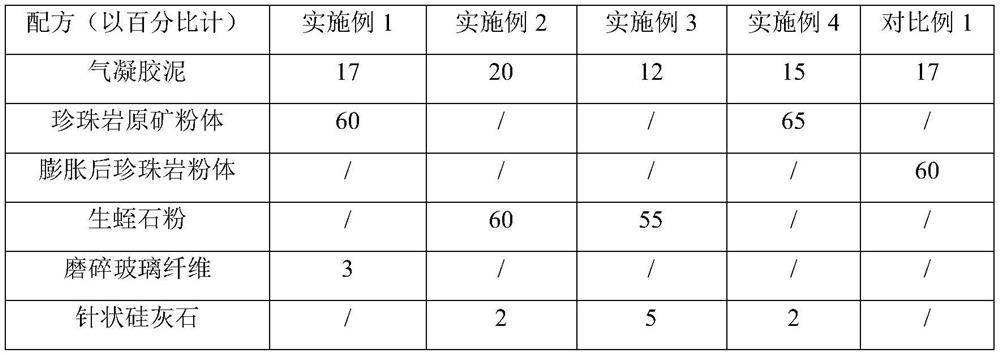

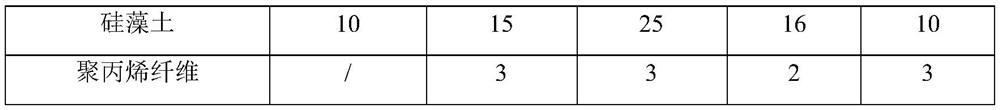

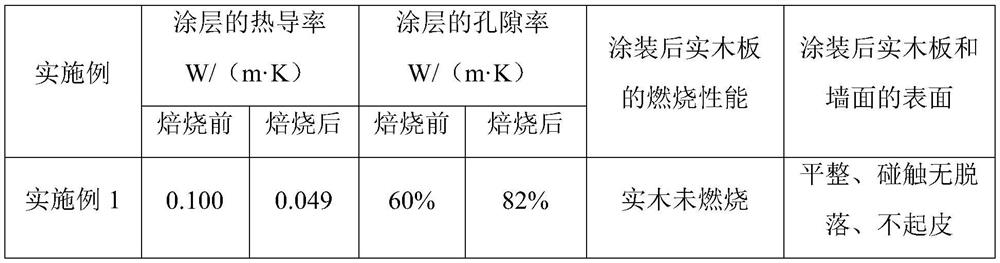

Embodiment 1

[0019] A flame-retardant and heat-preserving nano thick build coating, comprising an inner layer of flame-retardant and heat-preserving nano-coating and a surface layer of flame-retardant and heat-preserving nano-coating; agent, the inner flame retardant and thermal insulation nano-powder includes the following components: 17% airgel mud, 60% expandable inorganic silicate powder material, 10% diatomaceous earth, 3 % inorganic fiber; the surface flame retardant and thermal insulation nano-coating includes surface flame retardant thermal insulation nano powder, adhesive and regulator, and the surface flame retardant thermal insulation nano powder comprises 70% calcium powder, 20% diatom soil and 10% sericite powder. The adhesive is a water-based acrylic adhesive; the input ratio of the adhesive is that the volume ratio of the adhesive to the inner flame-retardant and heat-retaining nano-powder or the surface-layer flame-retardant and heat-preserving nano-powder is 1:5. Wherein,...

Embodiment 2

[0023]A flame-retardant and heat-preserving nano thick build coating, comprising an inner layer of flame-retardant and heat-preserving nano-coating and a surface layer of flame-retardant and heat-preserving nano-coating; agent, the inner flame retardant and thermal insulation nano-powder includes the following components in percentage content: 20% airgel mud, 60% expandable inorganic silicate powder material, 15% diatomaceous earth, 2 % inorganic fibers and 3% organic fibers; the surface flame retardant and thermal insulation nano-coating includes surface flame retardant thermal insulation nano powders, adhesives and regulators, and the surface flame retardant thermal insulation nano powders include 60% calcium powder , 25% diatomaceous earth and 15% sericite powder. The adhesive is a water-based acrylic adhesive; the input ratio of the adhesive is that the volume ratio of the adhesive to the inner flame-retardant and heat-retaining nano-powder or the surface-layer flame-retar...

Embodiment 3

[0027] A flame-retardant and heat-preserving nano thick build coating, comprising an inner layer of flame-retardant and heat-preserving nano-coating and a surface layer of flame-retardant and heat-preserving nano-coating; agent, the inner flame retardant heat preservation nano-powder includes the following components: 12% airgel mud, 55% expandable inorganic silicate powder material, 25% diatomaceous earth, 5% % of inorganic fibers and 3% of organic fibers; the surface flame retardant and thermal insulation nano coatings include surface flame retardant thermal insulation nano powders, adhesives and regulators, and the surface flame retardant thermal insulation nano powders include 85% calcium powder , 10% diatomaceous earth and 5% sericite powder. The adhesive is a water-based acrylic adhesive; the input ratio of the adhesive is that the volume ratio of the adhesive to the inner flame-retardant and heat-retaining nano-powder or the surface-layer flame-retardant and heat-preser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com