A kind of inorganic mineral plate and coating method thereof

A technology of inorganic minerals and coating methods, which is applied to special decorative structures, devices for coating liquid on the surface, and coatings. The effect of simple method and simple production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

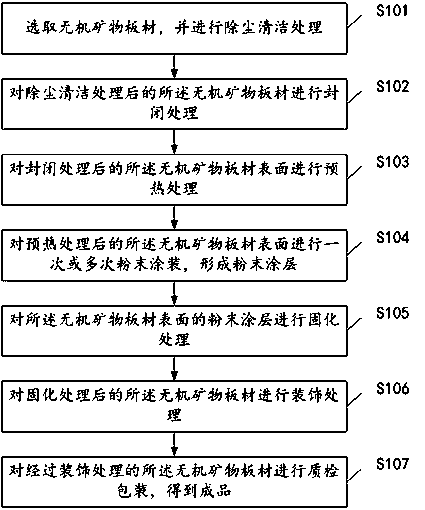

Method used

Image

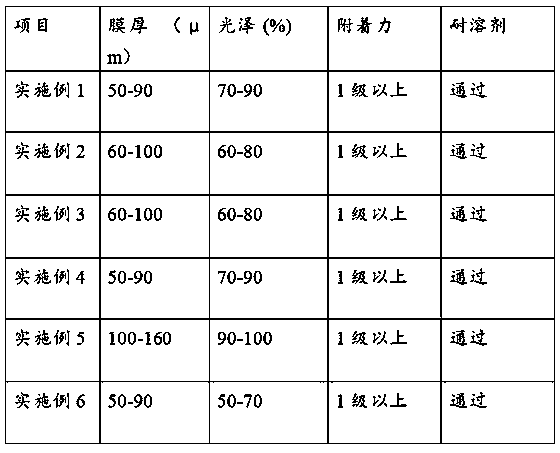

Examples

Embodiment example

[0073] As a preferred embodiment of the present invention, the raw materials of the ultra-low temperature powder coating include: polyester resin, epoxy resin and auxiliary agent, and the auxiliary agent includes one or more of a catalyst, an anti-sticking agent and a defoaming agent .

[0074] Wherein, the main material of the ultra-low temperature powder coating is the main polyester resin containing carboxyl group, the glass transition temperature is 40-60°C, the acid value is 10-75mgKOH / g, and the curing temperature is 90-130°C. Then use low-temperature curing (80-90 ℃) liquid or low-viscosity solid epoxy resin, and use high-efficiency catalyst to carry out low-temperature ring-opening reaction on epoxy resin, add a new type of defoamer for degassing and defoaming, and add a new type of anti-foaming agent. Adhesive to better solve sticking and clumping problems.

[0075] Specifically, the catalyst can be selected from 2-methylimidazole, 2-phenylimidazoline, tertiary amine...

Embodiment 1

[0113] (1) Select calcium silicate fiberboard, and carry out dust removal and cleaning treatment;

[0114] (2) Carry out sticker sealing treatment on the silicon-calcium fiberboard after dust removal and cleaning;

[0115] (3) Carry out preheating treatment on the surface of calcium silicate fiberboard after sealing treatment to improve the surface conductivity of calcium silicate fiberboard, wherein the temperature of preheating treatment is 60°C, and the preheating time is 10 minutes;

[0116] (4) Apply commercially available ultra-low temperature powder paint to the surface of the preheated calcium-silicon fiberboard for one or more times to form a powder coating, wherein the spray particle size of the ultra-low temperature powder paint is 5-25 μm, and the D90 is less than 25μm, the glass transition temperature is 40°C, the gelation time is 50s at 110°C, the curing temperature is 95°C, and the curing time is 4min;

[0117] (5) Curing the powder coating on the surface of ca...

Embodiment 2

[0121] (1) Select gypsum fiberboard and carry out dust removal and cleaning treatment;

[0122] (2) Sealing the gypsum fiberboard coated with ultraviolet radiation curing paint after dust removal and cleaning;

[0123] (3) Perform preheating treatment on the surface of the gypsum fiberboard after sealing treatment to increase the surface conductivity of the gypsum fiberboard, wherein the temperature of the preheating treatment is 70°C, and the preheating time is 3 minutes;

[0124] (4) The preheated gypsum fiberboard surface is coated with commercially available ultra-low temperature powder coating one or more times to form a powder coating, wherein the ultra-low temperature powder coating has a spray particle size of 5-25 μm and a D90 of less than 25 μm , the glass transition temperature is 50°C, the gelling time is 100s at 110°C, the curing temperature is 110°C, and the curing time is 5min;

[0125] (5) Curing the powder coating on the surface of the gypsum fiberboard;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| cure temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com