Patents

Literature

64results about How to "Good wipe resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fire-retarding thermal-shrinked indicated double pipe of radiant cross-linked and its preparation

ActiveCN1896128AGood weather resistanceExcellent wipe resistanceTubular articlesCross-linkCarvacryl acetate

A radiant cross-linking fire-retardant and heat-shrinkage indicating double pipe and its production are disclosed. The process is carried out by taking ethane-vinyl acetate multi-polymer, ethane-ethyl acrylate multi-polymer, ethylene-propylene rubber, fire-retardant decabromodiphenyl ethane, antimonous oxide, surface-activated superfine-magnesium hydrate and auxiliary as raw material, mill granulating, extrude forming, radiant cross-linking, expand sizing, and finish treating. It has better weather-resisting, high and low-temperature-resisting, anti-corrosive and antibacterial performances and long-period storage. It can be used for military industry, aviation and aerospace, civil high-terminal electronic equipment and cable.

Owner:广州凯恒科塑有限公司

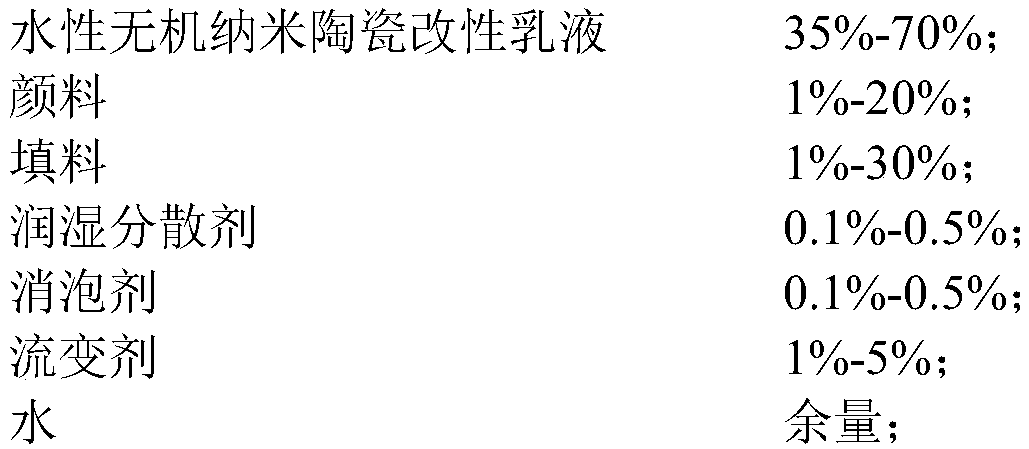

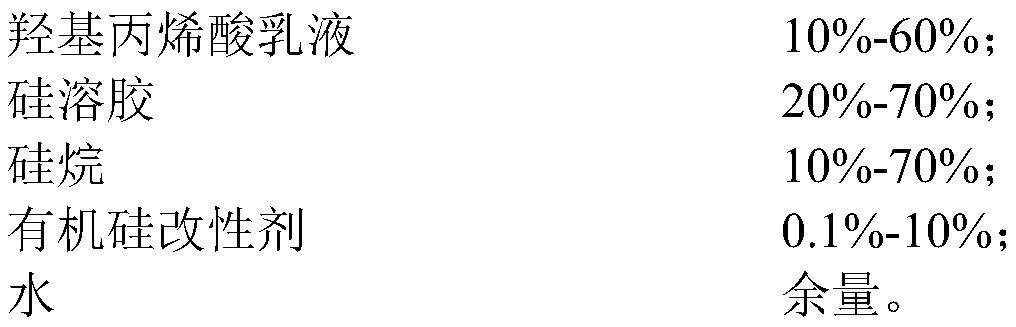

Waterborne anti-doodling and self-cleaning coating and preparation method thereof

ActiveCN109266153AImprove hydrophobicityImprove self-cleaning abilityAntifouling/underwater paintsPaints with biocidesMaterials scienceDefoamer

The invention belongs to the technical field of coating and in particular relates to waterborne anti-doodling and self-cleaning coating and a preparation method thereof. The coating is prepared from the following components: 35 to 70 percent of waterborne inorganic nano-ceramic modified emulsion, 1 to 20 percent of a pigment, 1 to 30 percent of filling, 0.1 to 0.5 percent of a wetting dispersant,0.1 to 0.5 percent of a de-foaming agent, 1 to 5 percent of a rheological agent and the balance of water, wherein the waterborne inorganic nano-ceramic modified emulsion is prepared from 10 to 70 percent of hydroxyl acrylic emulsion, 20 to 70 percent of silica sol, 10 to 70 percent of silane, 0.1 to 10 percent of an organic silicon modifying agent and the balance of water. According to the waterborne anti-doodling and self-cleaning coating, a sol-gel technology is adopted, and inorganic nano modification and organic silicon modification are carried out at the same time, so that the rigidity and wear resistance of the coating can be remarkably improved; a final coating product has good weather resistance and hydrophobic property and is obviously better than that of traditional self-cleaningcoating.

Owner:CHANGSHA HUANGMEI PAINT

Flexible ink for white cover film of LED (Light Emitting Diode) soft light strip plate and preparation method of flexible ink

InactiveCN102532996AMeet the requirements of reflow soldering processImprove bending resistanceInksEngineeringTemperature resistance

The invention relates to the technical field of an LED (Light Emitting Diode) long strip light, in particular to flexible ink for a white cover film of an LED soft light strip plate and a preparation method of the flexible ink. The flexible ink for the white cover film of the LED soft light strip plate is prepared from the following raw materials in percentage by mass: 30-70 percent of thermosetting resin, 2-10 percent of curing agent, 5-30 percent of diluting agent and 10-40 percent of filler. According to the ink and the preparation method thereof, excellent bend resistance performance can be achieved, the wiping resistance performance and the high temperature resistance performance are better, the ink is difficult to crack and yellow under a high temperature condition, and the requirements of a reflow soldering process of the light strip plate are met.

Owner:四川日航电子科技股份有限公司

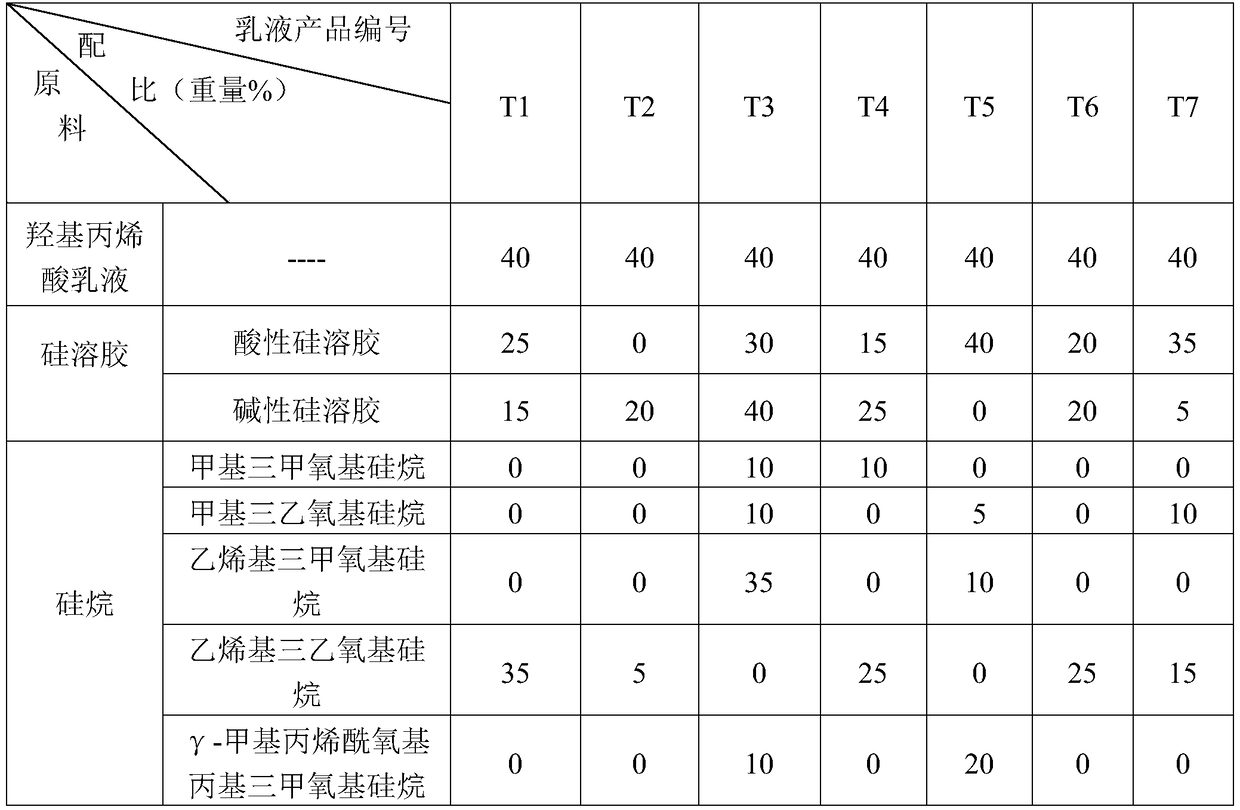

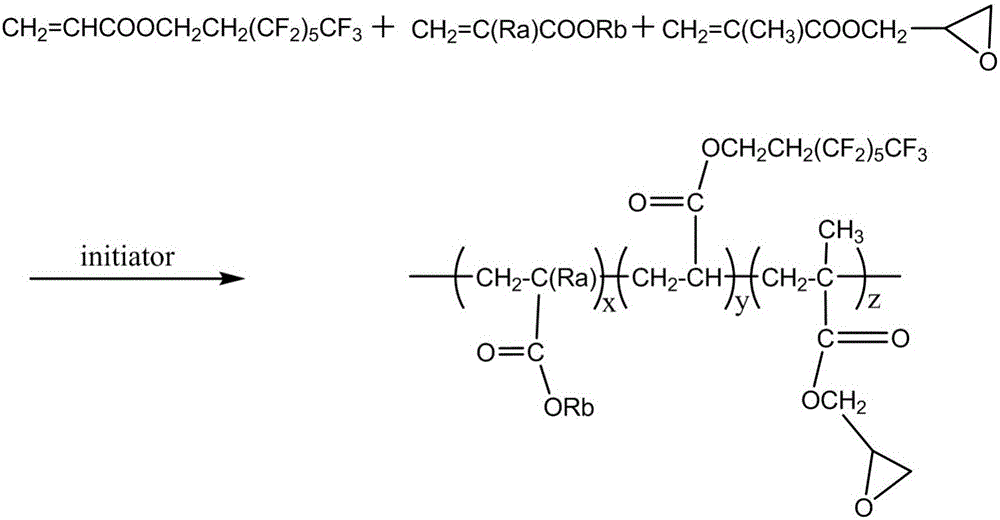

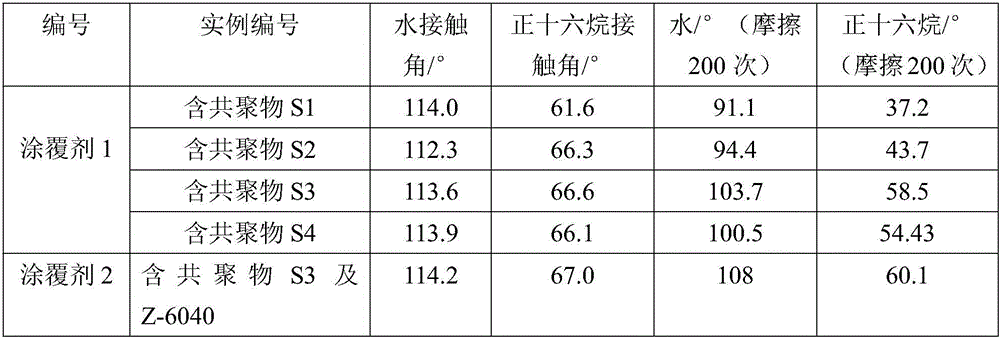

Method for preparing epoxy-fluorinated acrylate polymer coating agent

ActiveCN106280839AExcellent water and oil repellencyGood wipe resistancePretreated surfacesCoatingsEpoxyPolymer science

The invention relates to a method for preparing an epoxy-fluorinated acrylate polymer coating agent. An epoxy-fluorinated acrylate polymer is obtained by a copolymerization reaction of perluorooctyl acrylate, acrylate esters and glycidyl methacrylate. The method comprises the following synthesis steps: (1) preparing perluorooctyl acrylate; (2) preparing the epoxy-fluorinated acrylate polymer. The epoxy-fluorinated acrylate polymer prepared by the invention is subjected to heat curing with steel plates containing amino functional groups. Compared with the current commercially available organosilicon waterproofing agent, the epoxy-fluorinated acrylate polymer coating agent disclosed by the invention has excellent repellency to water and oil and wiping resistance.

Owner:广州市润奥化工材料有限公司

Anti-fog glass for automobile and preparation method

InactiveCN107285629AGood anti-fog performanceImprove water resistanceCoatingsGlycerolTemperature difference

The invention discloses anti-fog glass for an automobile and a preparation method. The glass is prepared from the following components: silicon dioxide, sodium silicate, aluminium oxide, calcium oxide, magnesium oxide, sodium oxide, titanium dioxide, butyl titanate, glycerol, 2M hydrochloric acid and a proper amount of a solvent. The preparation method comprises the following steps: firstly, preparing a glass substrate, and then coating the surface of the glass substrate with a nanometer titania coating film. The glass has a relatively good anti-fog effect, relatively good water-tolerant and wiping-resistant properties; when being applied to automotive mount, the glass is capable of effectively avoiding the fogging phenomenon of the automotive glass caused by large temperature difference between inside and outside of the automobile, and the use safety is greatly improved.

Owner:HEFEI LIYUTAI GLASS PROD CO LTD

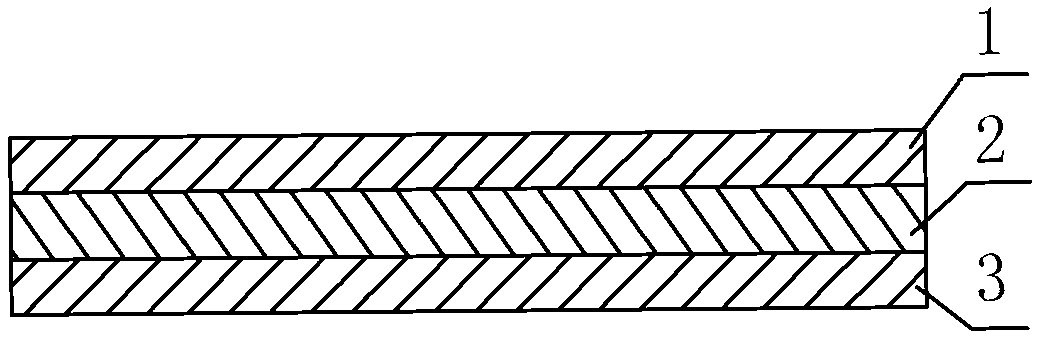

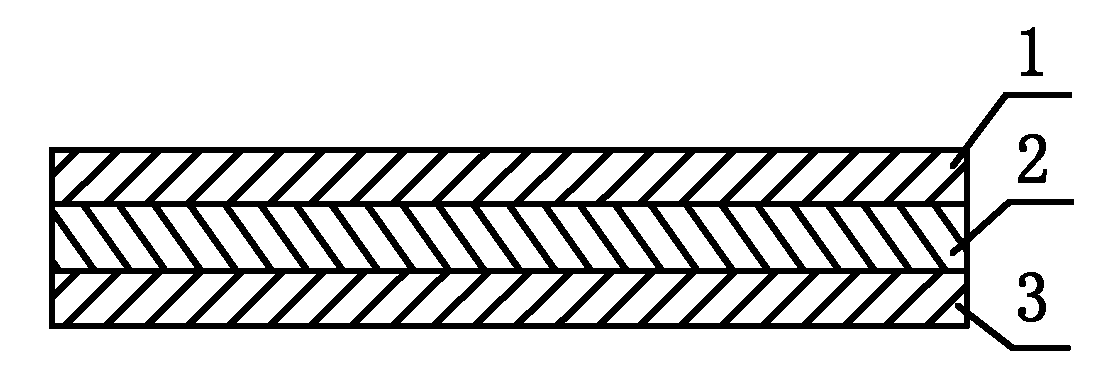

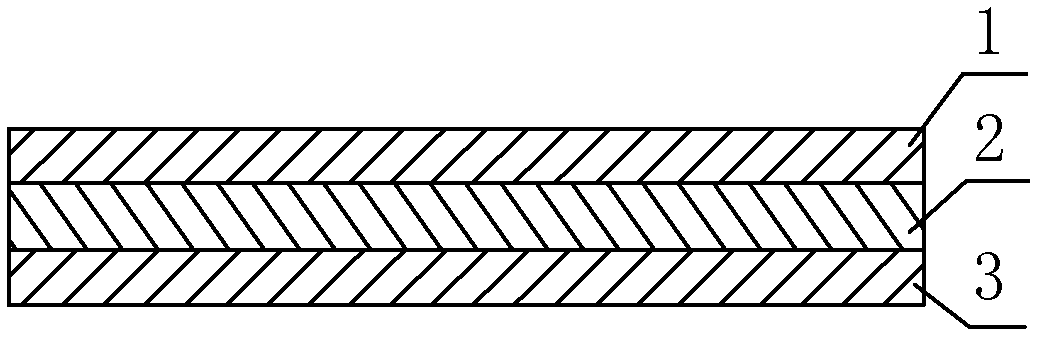

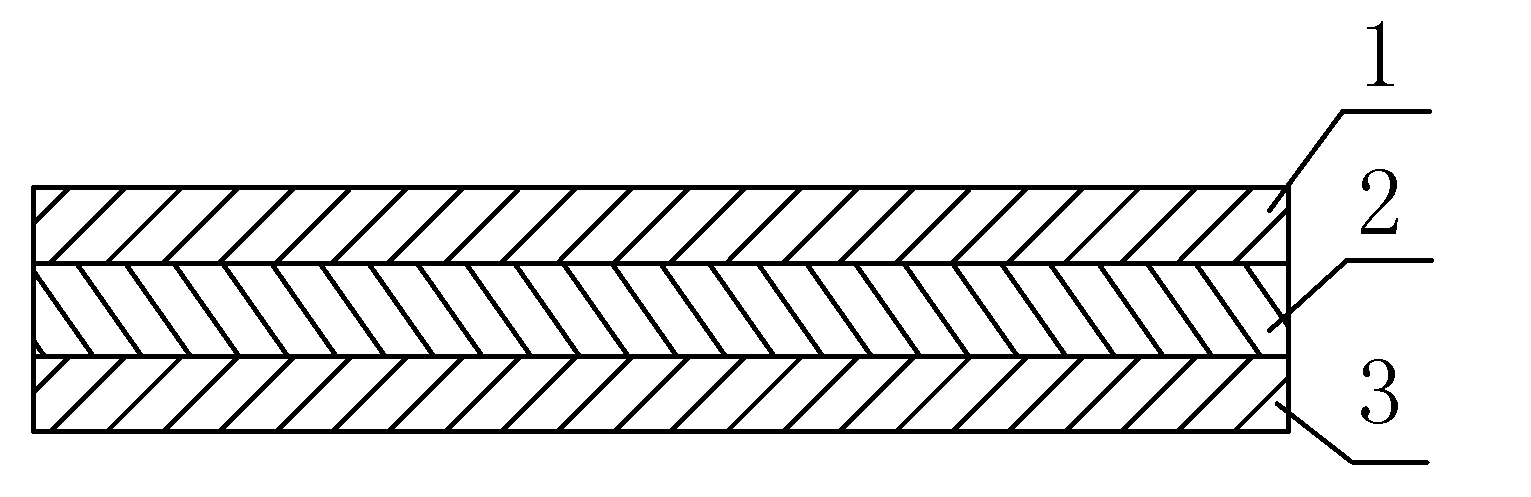

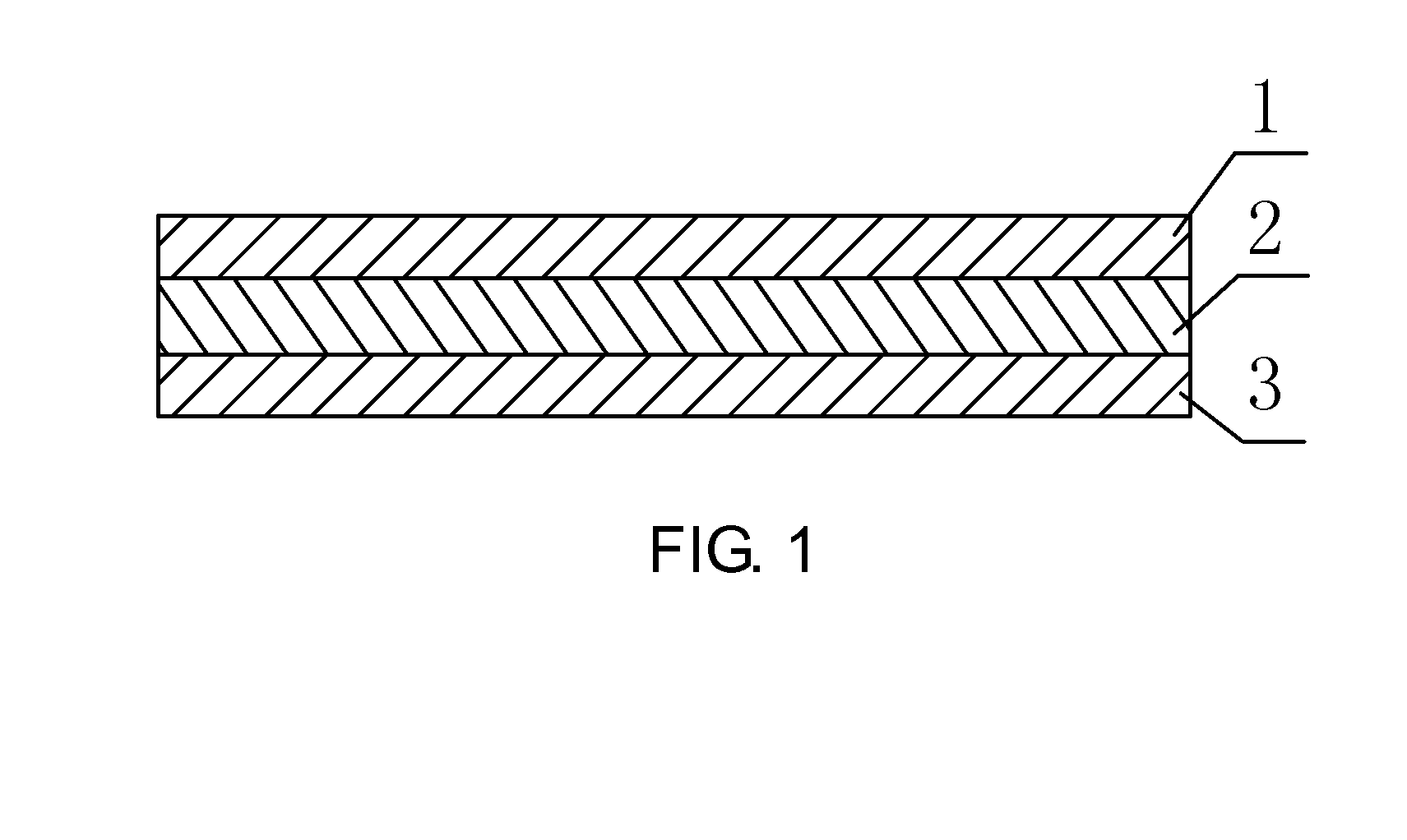

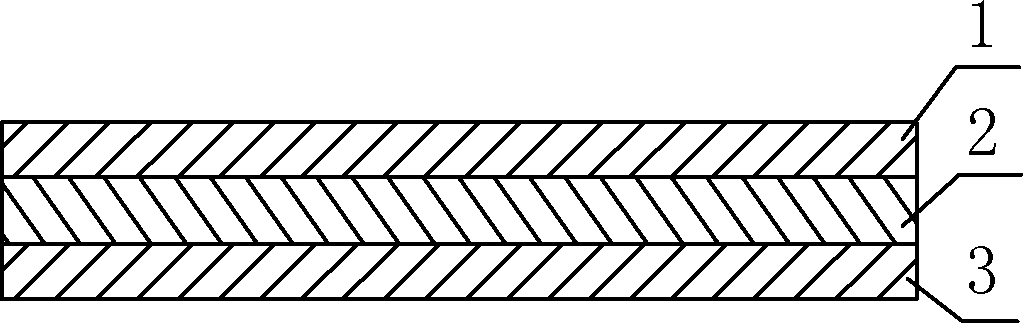

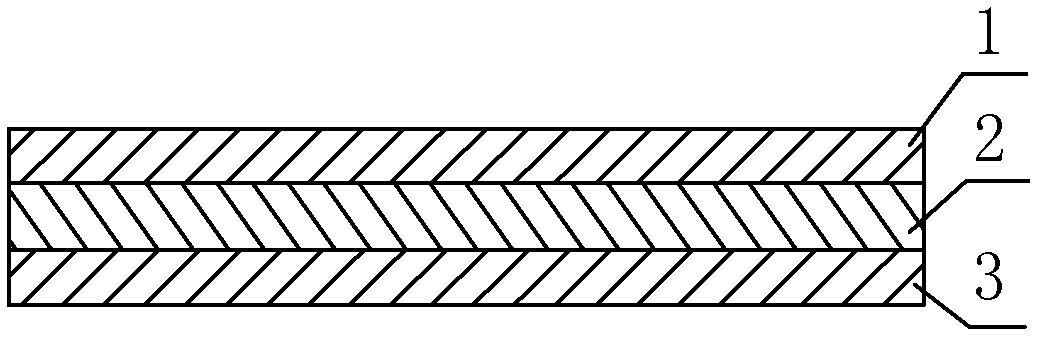

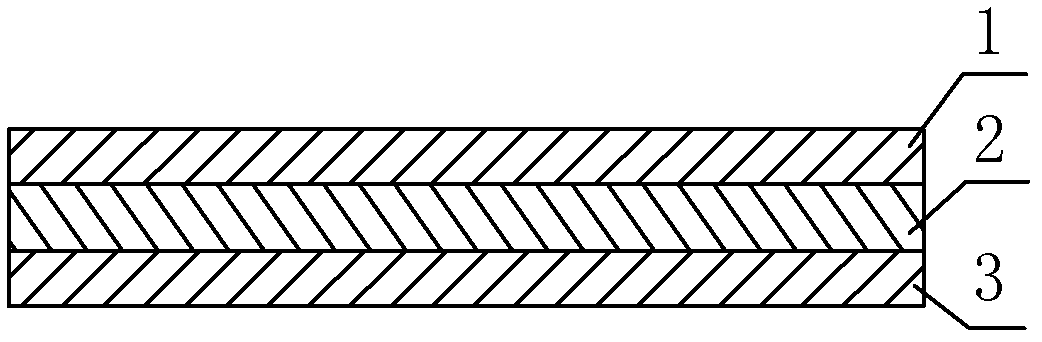

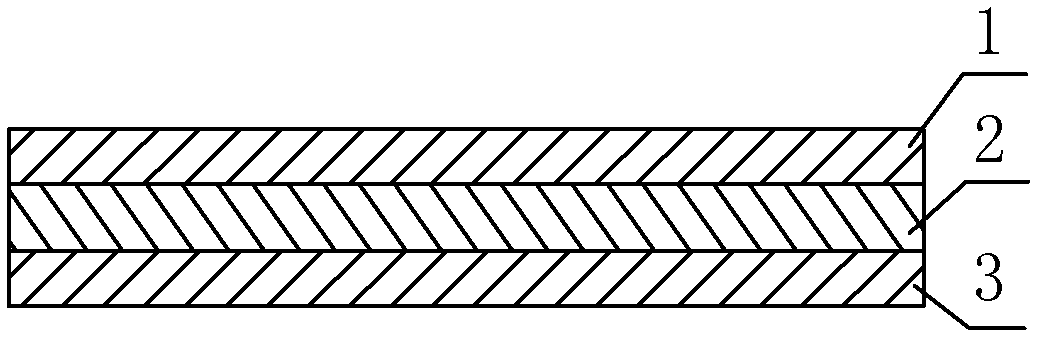

BOPE (biaxially-oriented polypropylene) coating mutt film

InactiveCN102602099AGood printabilityGood wipe resistanceSynthetic resin layered productsAntioxidantExtinction

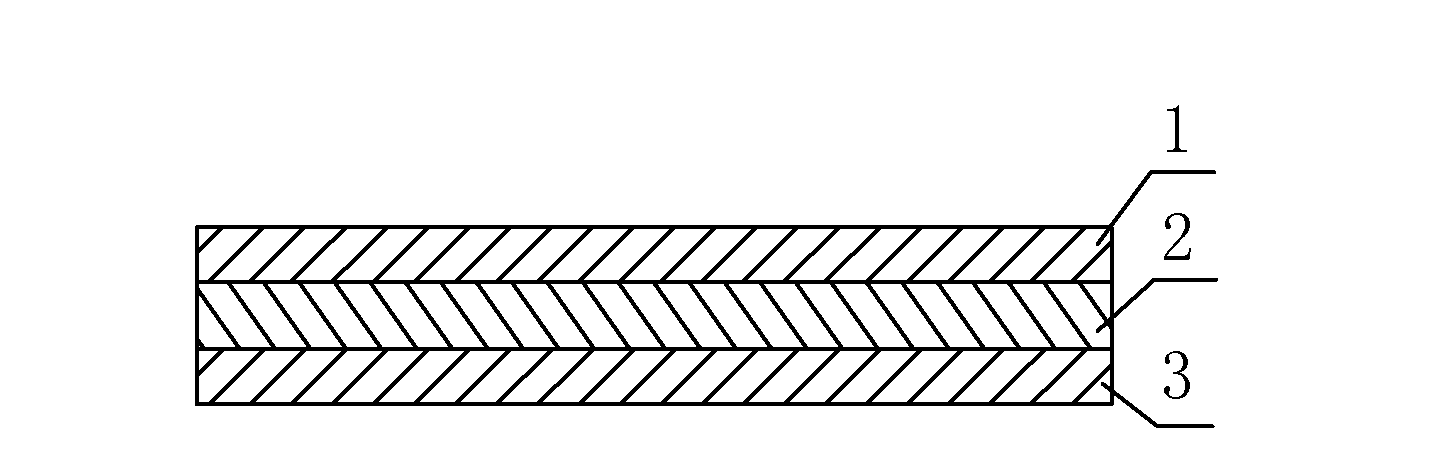

The invention belongs to the technical field of packaging materials, particularly relates to a coating film and discloses a BOPE (biaxially-oriented polypropylene) mutt coating film, which is characterized by comprising a function layer 1, a core layer 2 and an auxiliary function layer 3. The core layer is positioned between the function layer and the auxiliary function layer, the function layer, the core layer and the auxiliary function layer are integrated by means of biaxially stretching after being in coextrusion, the mass percent of the function layer ranges from 1% to 8%, the mass percent of the core layer ranges from 91% to 98%, the mass percent of the auxiliary function layer ranges from 1% to 5%, raw materials of the function layer includes, by mass percent, 55% of acetic ether, 10% of C9 hydrogenated petroleum resin, 18% of metallocene polyethylene, 13% of polyvinyl alcohol, 2% of sodium hydroxide, 1% of antioxidant and 1% of dispersing agent, the core layer is made of linear polyethylene, and components of the auxiliary function layer includes, by mass percent, 56% of high-density polyethylene, 40% of ethylene-propylene diene copolymer, 3% of SiO2 and 1% of antioxidant. The BOPE mutt coating film is fine in printing performance and has an extinction function.

Owner:HUBEI FIRSTA MATERIALS SCI & TECH GRP

Special ink jet printing machine ink for PE optical cables and cables and preparation method of special ink jet printing machine ink for PE optical cables and cables

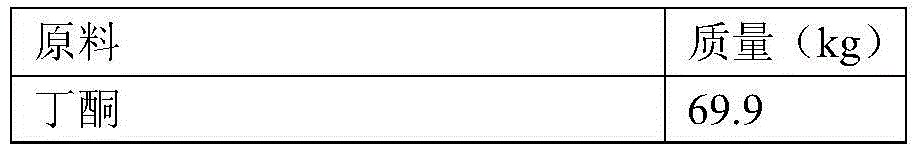

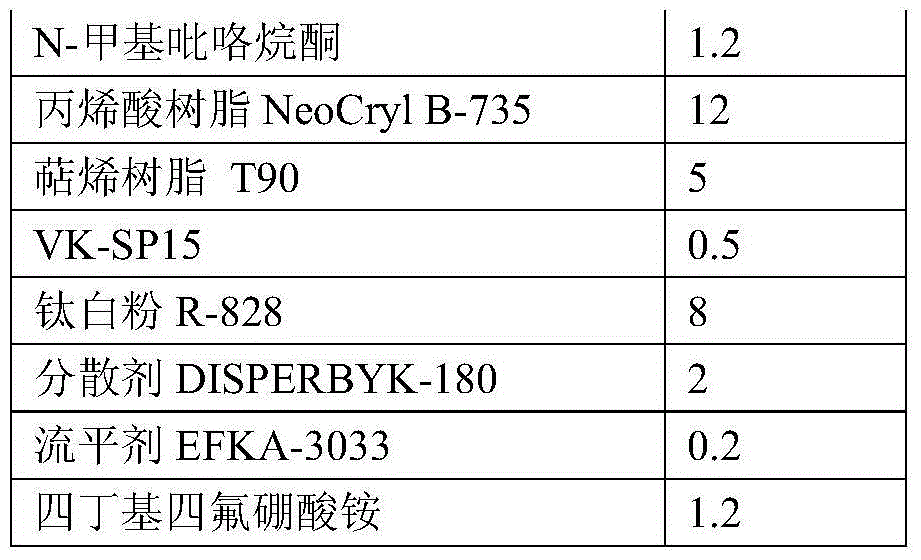

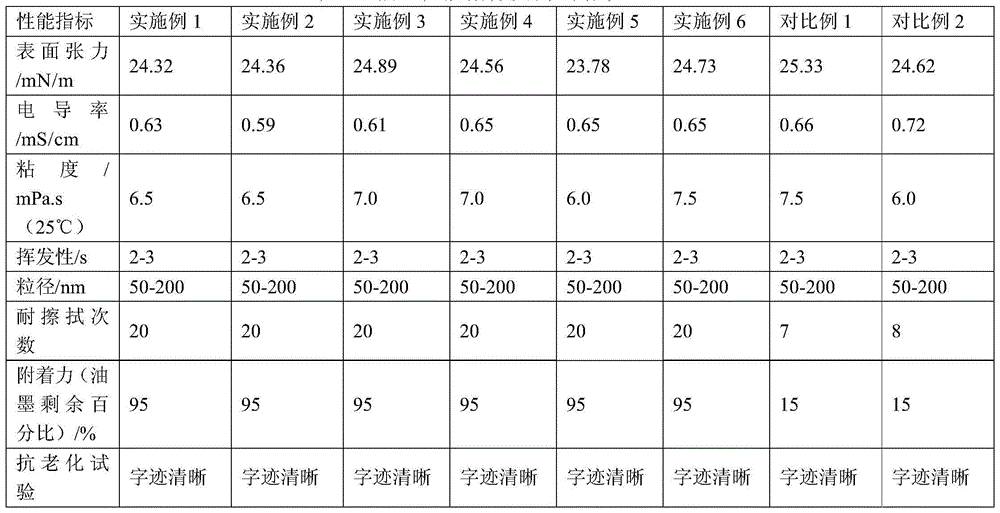

The invention provides special ink jet printing machine ink for PE optical cables and cables and a preparation method of the special ink jet printing machine ink for PE optical cables and cables. The ink jet printing machine ink is prepared from the following raw materials in parts by mass: 60-90 parts of organic solvent mixed solution, 2-15 parts of a colorant, 5-20 parts of vehicle resin, 1-15 parts of tackifying resin, 0.5-1.5 parts of a conductive agent, 0.5-5 parts of a wetting dispersant, 0.05-2 parts of a flatting agent and 0.0001-2 parts of an other adjuvant. The special ink jet printing machine ink for PE optical cables and cables not only has favorable performances such as stable storage and using performances, no ink accumulation at nozzles, cleaning simplicity, no blockage of spray heads, clear handwritings and good resolution ratio, but also has the characteristics of high adhesive force for the PE optical cables and cables and favorable scrubbing resistance.

Owner:HANGZHOU HIWETECH CHEM TECH CO LTD

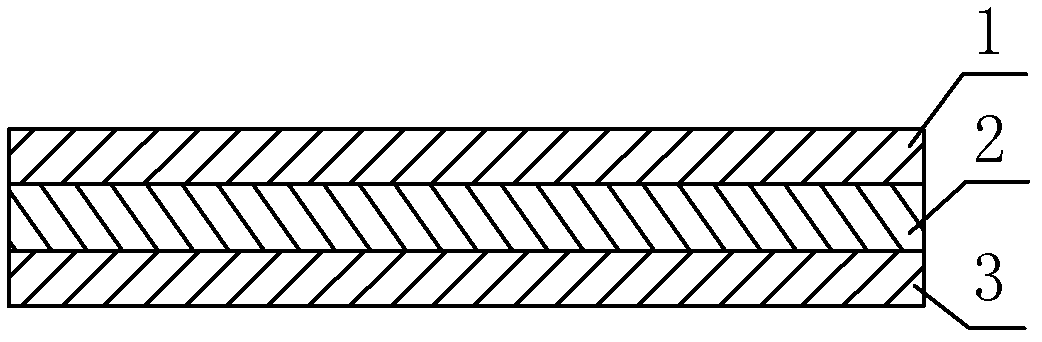

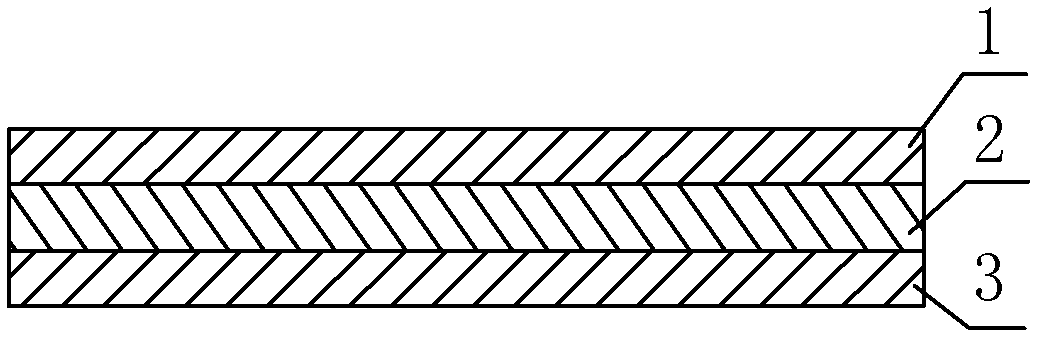

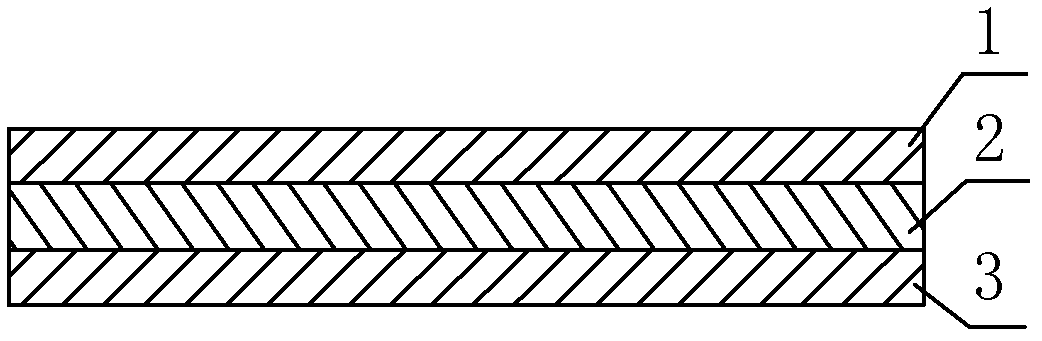

Biaxially-oriented polypropylene (BOPP) coated heat sealable film

ActiveCN102555381AGood printabilityGood wipe resistanceSynthetic resin layered productsAntioxidantMetallurgy

The invention belongs to the technical field of packaging materials and relates to a biaxially-oriented polypropylene (BOPP) coated heat sealable film, which is characterized by comprising a function layer, a core layer and a sub function layer, wherein the core layer is positioned between the function layer and the sub function layer, and the function layer, the core layer and the sub function layer are subjected to co-extrusion and biaxial tension to form a whole; the BOPP coated heat sealable film comprises 1 to 8 mass percent of function layer, 91 to 98 mass percent of core layer and 1 to 5 mass percent of sub function layer; the function layer is prepared from the following raw materials in percentage by mass: 55 percent of acetic ether, 10 percent of C9 hydrogenated petroleum resin, 18 percent of polypropylene, 13 percent of polyvinyl alcohol, 2 percent of sodium hydroxide, 1 percent of antioxidant and 1 percent of dispersing agent; the core layer is prepared from the following raw materials in percentage by mass: 73 to 82 percent of polypropylene, 10 to 15 percent of stiffening agent and 8 to 12 percent of anti-static slipping agent; and the sub function layer is prepared from the following raw materials in percentage by mass: 1 percent of SiO2 and 99 percent of propylene copolymer. The BOPP coated heat sealable film has the characteristics of good printing performance and low heat sealing temperature.

Owner:HUBEI FIRSTA MATERIALS SCI & TECH GRP

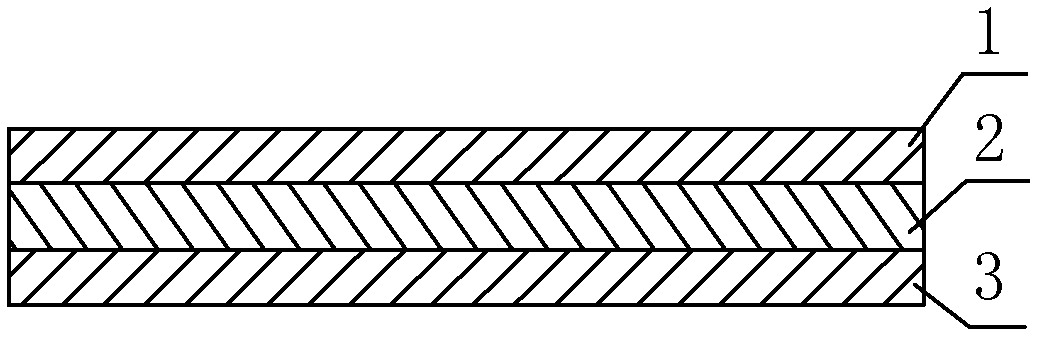

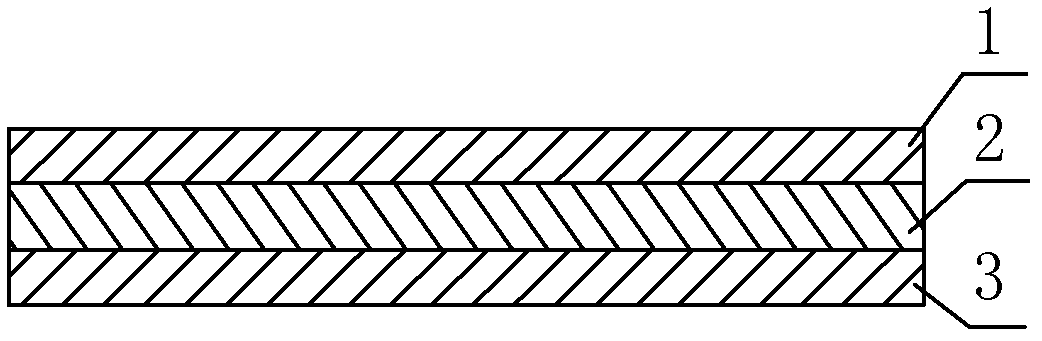

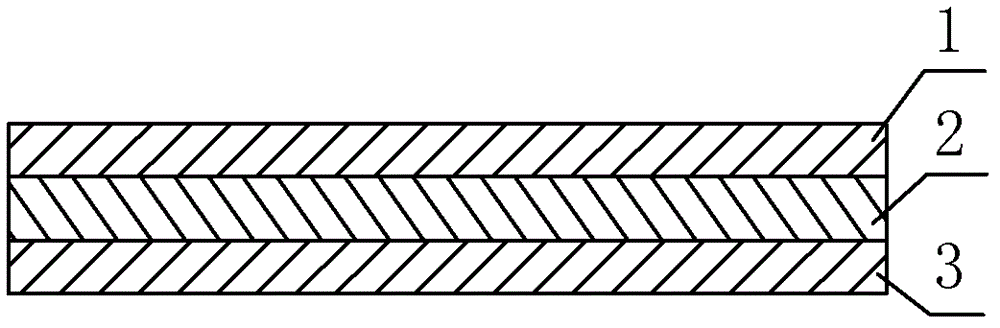

Biaxially oriented polyethylene (BOPE) coating print film

InactiveCN102529267AEnhanced printabilityGood printabilitySynthetic resin layered productsPolypropyleneEther

The invention belongs to the technical field of packing materials, and particularly relates to a coating film. A biaxially oriented polyethylene (BOPE) coating print film is characterized by comprising a functional layer, a core layer and a secondary functional layer; the core layer is positioned between the functional layer and the secondary functional layer; the functional layer, the core layer, and the secondary functional layer are subjected to coextrusion and then biaxial tension to be integrated; the BOPE coating print film comprises the following layers in percentage by mass: 1 to 8 percent of functional layer, 91 to 98 percent of core layer and 1 to 5 percent of secondary functional layer; the functional layer is prepared from the following raw materials in percentage by mass: 55 percent of acetic ether, 10 percent of C9 hydrogenated petroleum resin, 18 percent of metallocene polyethylene, 13 percent of polyvinyl alcohol, 2 percent of sodium hydroxide, 1 percent of antioxidant, and 1 percent of dispersing agent; the core layer is prepared from the following raw materials in percentage by mass: 73 to 82 percent of polyethylene, 10 to 15 percent of stiffening agent, and 8 to 12 percent of antistatic slipping agent; and the secondary functional layer is prepared from the following raw materials in percentage by mass: 5 percent of SiO2, and 95 percent of co-polypropylene. The BOPE coating print film has the characteristic of printing performance.

Owner:HUBEI FIRSTA MATERIALS SCI & TECH GRP

Fire-retarding thermal-shrinked indicated double pipe of radiant cross-linked and its preparation method

ActiveCN100387646CGood weather resistanceGood wipe resistanceTubular articlesCross-linkCarvacryl acetate

A radiant cross-linking fire-retardant and heat-shrinkage indicating double pipe and its production are disclosed. The process is carried out by taking ethane-vinyl acetate multi-polymer, ethane-ethyl acrylate multi-polymer, ethylene-propylene rubber, fire-retardant decabromodiphenyl ethane, antimonous oxide, surface-activated superfine-magnesium hydrate and auxiliary as raw material, mill granulating, extrude forming, radiant cross-linking, expand sizing, and finish treating. It has better weather-resisting, high and low-temperature-resisting, anti-corrosive and antibacterial performances and long-period storage. It can be used for military industry, aviation and aerospace, civil high-terminal electronic equipment and cable.

Owner:广州凯恒科塑有限公司

Self-cleaning waterproof coating

ActiveCN104119716AImprove thermal insulation performanceGood wipe resistanceCoatingsPhosphatePolypropylene

The invention discloses a self-cleaning waterproof coating which comprises the following raw materials in parts by weight: 62-70 parts of silicone acrylic emulsion, 1-2 parts of linseed oil, 1-2 parts of zinc dihydrogen phosphate, 1-2 parts of sodium lauroyl sarcosine, 2-3 parts of dimethyl glutarate, 2-3 parts of maleic anhydride grafted polypropylene, 1-2 parts of dimethyl diallyl ammonium chloride, 1-2 parts of tetrabutylammonium bromide, 1.2-2 parts of laurate dihydroxyethylamide, 1-2 parts of isopropanol, 3-5 parts of nano bauxite, 6-8.5 parts of vermiculite powder, 0.5-1 part of ascorbic acid, 6-8 parts of film-forming assistant and 10-17 parts of de-ionized water. The waterproof coating has a very good heat insulation effect, and has good wiping resistance, waterproofness, self-cleaning effect, adhesiveness, acid-base resistance, corrosion resistance and storage stability and long shelf life; the formed coating is stable.

Owner:ANHUI KUAILAI WATERPROOFING & ANTI CORROSION

BOPP (biaxially-oriented polypropylene) coating matt mould

ActiveCN102602102AGood printabilityGood wipe resistanceDuplicating/marking methodsSynthetic resin layered productsAntistatic agentPetroleum resin

The invention belongs to the technical field of packing materials, and particularly relates to a BOPP (biaxially-oriented polypropylene) coating matt mould, which is characterized in that the BOPP coating matt mould comprises a functional layer, a core layer and a secondary functional layer, the core layer is positioned between the functional layer and the secondary functional layer, the functional layer, the core layer and the secondary functional layer are coextruded and then bidirectionally stretched into a whole, the weight percents of the functional layer, the core layer and the secondary functional layer are 1-8%, 91-98% and 1-5% respectively, raw materials of the functional layer include, in weight percent, 55% of acetic ether, 10% of C9 hydrogenated petroleum resin, 18% of polypropylene, 13% of polyvinyl alcohol, 2% of sodium hydroxide, 1% of antioxidant and 1% of dispersing agent, raw materials of the core layer include, in weight percent, 92% of polypropylene, 5% of stiffening agent and 3% of antistatic agent, and raw materials of the secondary functional layer include, in weight percent, 48% of high-density polyethylene, 48% of polypropylene, 3% of SiO2 and 1% of antioxidant. The BOPP coating matt mould has a fine printing performance and has an extinction function.

Owner:HUBEI FIRSTA MATERIALS SCI & TECH GRP

BOPP (biaxially-oriented polypropylene) coating printing reinforcement film

ActiveCN102602098AEnhanced printabilityGood printabilityDuplicating/marking methodsSynthetic resin layered productsPolypropyleneEther

The invention belongs to the technical field of packaging materials, and particularly relates to a BOPP (biaxially-oriented polypropylene) coating printing reinforcement film, which is characterized by comprising a function layer, a core layer and an auxiliary function layer. The core layer is positioned between the function layer and the auxiliary function layer, the function layer, the core layer and the auxiliary function layer are integrated by means of biaxially stretching after being in coextrusion, the mass percent of the function layer ranges from 1% to 8%, the mass percent of the core layer ranges from 91% to 98%, the mass percent of the auxiliary function layer ranges from 1% to 5%, raw materials of the function layer include, by mass, 55% of acetic ether, 10% of C9 hydrogenated petroleum resin, 18% of polypropylene, 13% of polyvinyl alcohol, 2% of sodium hydroxide, 1% of antioxidant and 1% of dispersing agent, raw materials of the core layer include, by mass, from 73 to 82% of polypropylene, from 10 to 15% of stiffening agent and from 8 to 12% of antistatic smooth agent, and materials of the auxiliary function layer include, by mass, 5% of SiO2 and 95% of co-polypropylene. The BOPP coating printing reinforcement film has the advantage of fine printing performance.

Owner:HUBEI FIRSTA MATERIALS SCI & TECH GRP

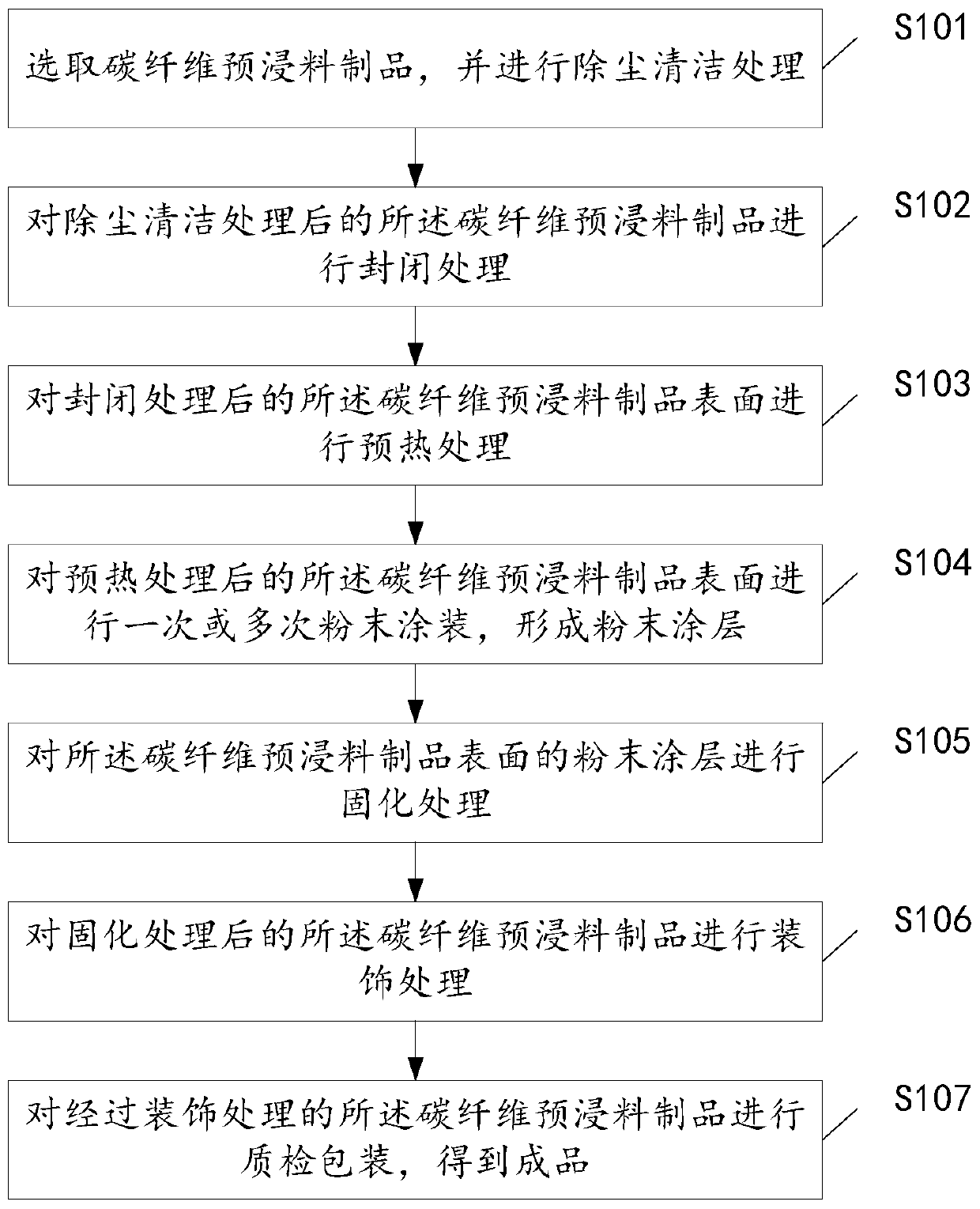

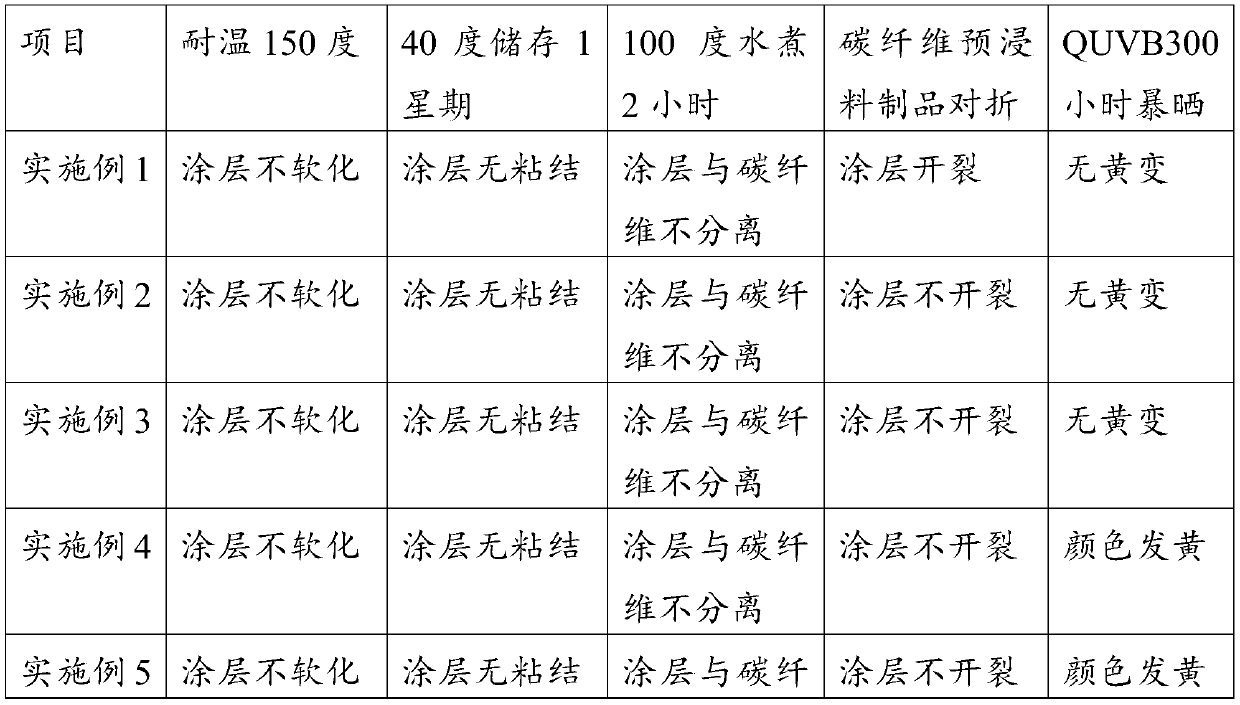

Carbon fiber prepreg product and coating method thereof

ActiveCN110628066AGloss can be adjusted freelyImprove the decorative effectPowdery paintsEpoxy resin coatingsFiberCarbon fibers

The invention discloses a coating method of a carbon fiber prepreg product. The coating method comprises the following steps: (1) selecting a carbon fiber prepreg product, and carrying out dust removal cleaning treatment; (2) carrying out sealing treatment on the carbon fiber prepreg product; (3) preheating the surface of a sealed carbon fiber prepreg product; (4) carrying out one time of a plurality of times of powder coating on the surface of the preheated carbon fiber prepreg product to form a powder coating layer; (5) carrying out curing treatment on the powder coating layer on the surfaceof the carbon fiber prepreg product; (6) carrying out decoration treatment on the cured carbon fiber prepreg product; and (7) carrying out quality inspection packaging on the decorated carbon fiber prepreg product to obtain a finished product. Correspondingly, the invention also provides the carbon fiber prepreg product prepared by the method. The method is simple, the process is controllable, nosolvent participates in the reaction, VOCs are not released, and no waste is generated.

Owner:FOSHAN YIKEJU NEW MATERIAL CO LTD

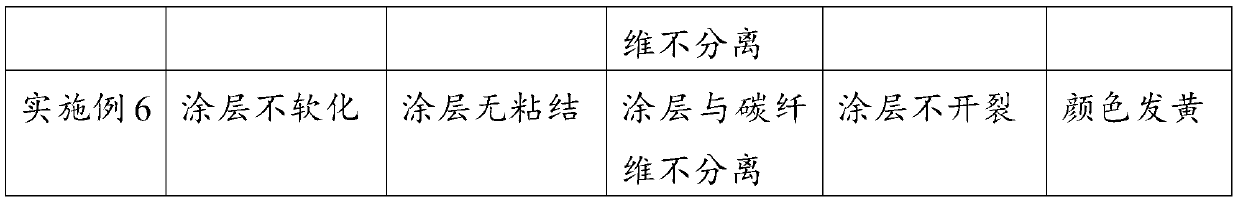

Heat-preserving and heat-insulating petroleum asphalt waterproof coating and preparation method thereof

InactiveCN105925192ALow thermal conductivityImprove thermal insulation performanceBituminous coatingsBetaineFatty acid

The invention discloses heat-preserving and heat-insulating petroleum asphalt waterproof coating and a preparation method thereof. The heat-preserving and heat-insulating petroleum asphalt waterproof coating is prepared by the following raw materials in parts by weight: 80-120 parts of a petroleum asphalt emulsion with a solid content of 48 percent , 1-2 parts of tallow amine polyoxyethylene ether, 5-9 parts of mountain sand, 4-8 parts of de-dusting ash, 6-10 parts of sulfurized lard, 7-9 parts of nano silicon dioxide aerogel, 2-3 parts of octadecyl hydroxypropyl sulfo betaine, 3-4 parts of sorbitol, 4-7 parts of cork powder, 5-8 parts of porous powder quartz, 2-4 parts of nano antimony tin oxide, 3-6 parts of nano tungsten oxide, 4-8 parts of 2-amino-2methyl-1-propyl alcohol, 1-2 parts of cetearyl glucoside, 1.5-2.5 parts of coco fatty acid diethanol amide, 25-35 parts of water, 5-10 parts of a sandstone and 7-13 parts of a pumice. The waterproof coating prepared by the preparation method is low in heat conductivity coefficient, good in heat-preserving and heat-insulating performances, high in mechanical strength, excellent in heat resistance, abrasion resistance, water resistance and weatherability, environmentally friendly, and convenient and safe to use.

Owner:ANHUI KUAILAI WATERPROOFING & ANTI CORROSION

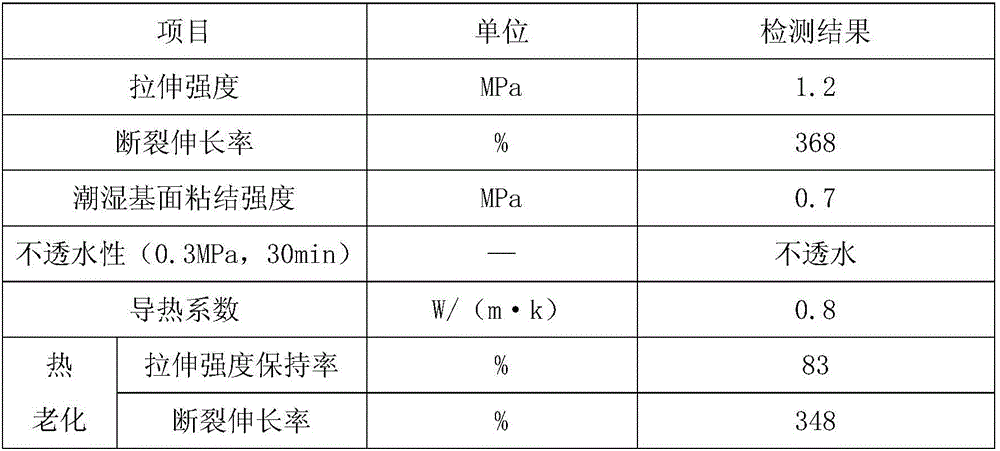

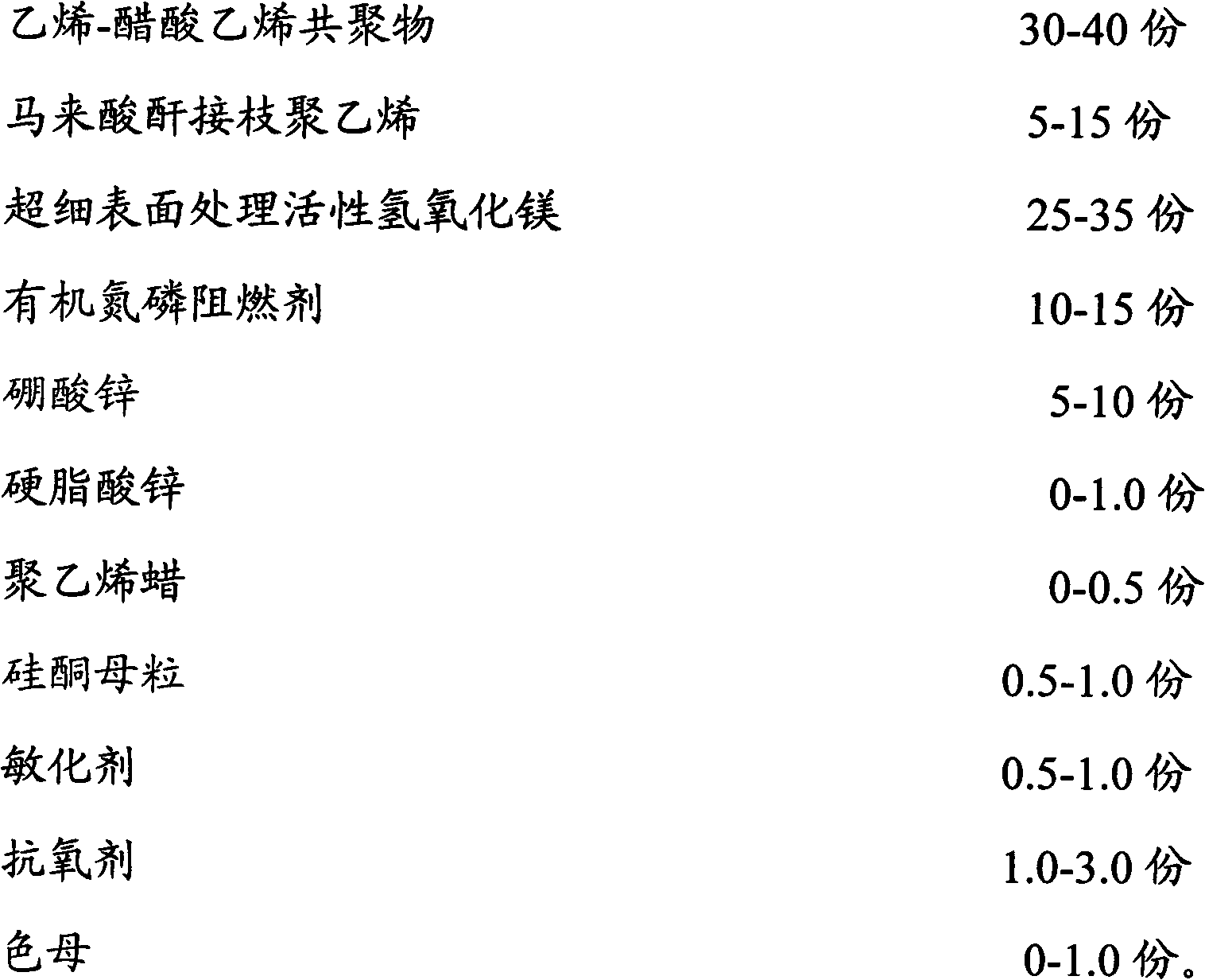

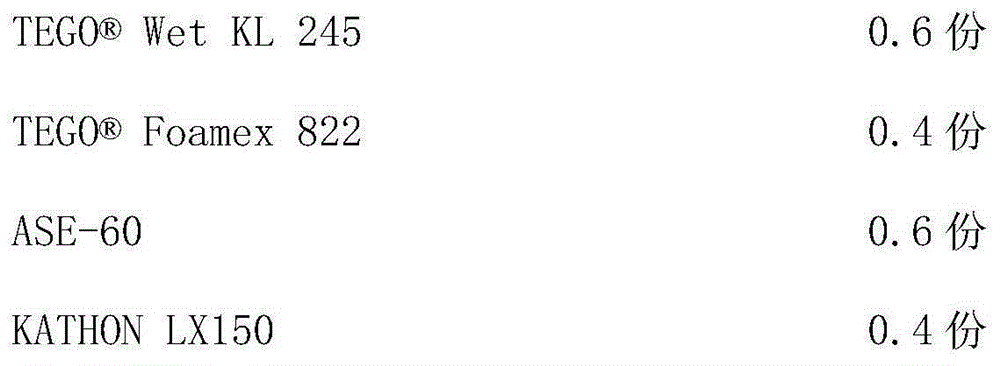

Halogen-free flame retardant mark sheet and preparation method

InactiveCN103183864AImprove flame retardant performanceHarm reductionStampsIdentification meansPolyethyleneMasterbatch

The invention provides a halogen-free flame retardant mark sheet and a preparation method, the halogen-free flame retardant mark sheet comprises the following components by weight: an ethylene-ethylene-vinyl acetate copolymer, maleic anhydride grafted polyethylene, super fine surface treatment activity magnesium hydroxide, an organic nitrogen and phosphorus fire retardant, zinc borate, zinc stearate, polyethylene wax, silicone masterbatch, a sensitizing agent, an antioxygen and color master. The halogen-free flame retardant mark sheet has the advantages of safety, environmental protection and durable performance.

Owner:HONGSHANG HEAT SHRINKABLE MATERIALS

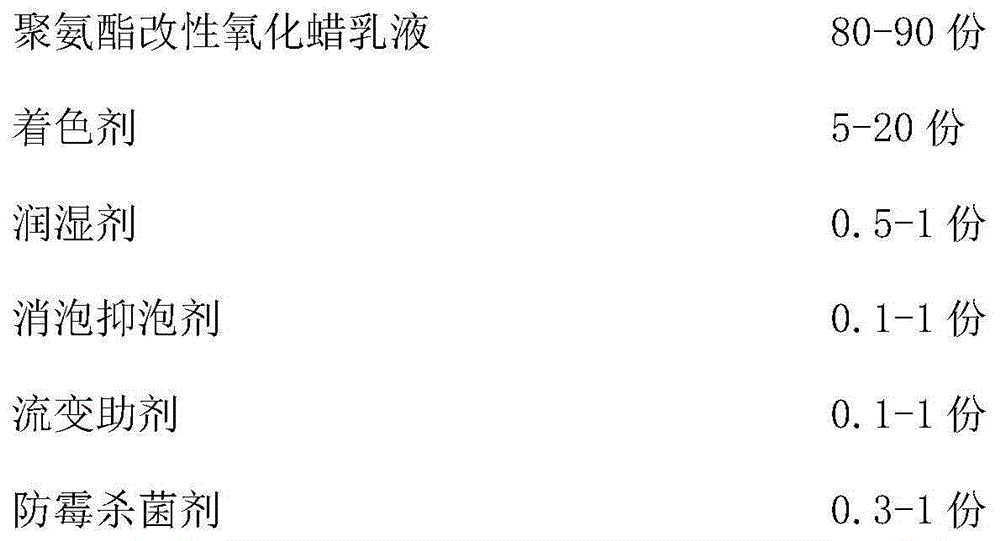

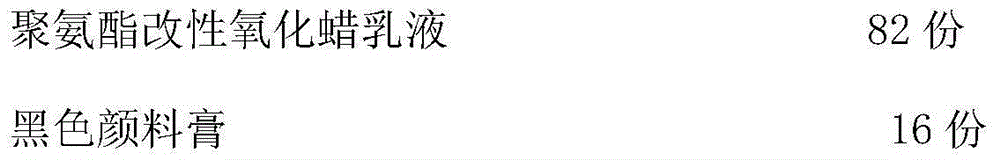

Water-borne wax-emulsion shoe polish finishing agent based on anionic polyurethane modified oxidized wax and preparation method of water-borne wax-emulsion shoe polish finishing agent

ActiveCN106281046AOutstanding and Beneficial Technical EffectsNon-toxicPolishing compositionsShoe polishPolymer chemistry

The invention relates to a water-borne wax-emulsion shoe polish finishing agent based on anionic polyurethane modified oxidized wax and a preparation method of the water-borne wax-emulsion shoe polish finishing agent. The water-borne wax-emulsion shoe polish finishing agent comprises polyurethane modified oxidized wax emulsion, coloring agent, wetting agent, defoaming foam inhibitor, rheological auxiliaries and anti-mildew bactericide. The preparation method includes: sufficiently grinding the coloring agent, the wetting agent and the polyurethane modified oxidized wax according to the mass of the components of the shoe polish finishing agent, stirring and dispersing for 10-40 minutes at the rotation speed of 2000-4000r / minute, lowering the rotation speed to 400-500r / minute, sequentially adding the defoaming foam inhibitor, the anti-mildew bactericide and the rheological auxiliaries, and continuing stirring for 10-20 minutes to obtain the water-borne wax-emulsion shoe polish finishing agent. The water-borne wax-emulsion shoe polish finishing agent is safe, environmentally friendly, nontoxic during use, free of pollution, less prone to combustion, free of offensive smell, good in storage stability, good in adhesive force, excellent in weather resistance and durability, excellent in scrub resistance and waterproof performance, widely applicable to the finishing and maintenance of leather shoes, leather bags, leather coats and the like, and extremely high in environment protection benefit, social benefit and economic benefit.

Owner:浙江芬尼斯工贸有限公司 +1

Dense anti-leakage waterproof coating

The invention discloses a dense anti-leakage waterproof coating. The coating comprises the following raw materials in parts by weight: 62-70 parts of a silicone acrylic emulsion, 2-3 parts of artemisia glue, 1-2 parts of epoxy chloropropane, 1-2 parts of polytetrafluoroethylene wax, 0.1-0.2 part of hexamethylphosphoric triamide, 1-2 parts of 2,2,4-trimethyl-1,3-pentanediolmono(2-methylpropanoate), 1-2 parts of sodium ethylenediamine tetramethylene phosphonate, 2-3 parts of ammonium metaborate, 2-3 parts of bi-dodecanol ester, 0.1-0.3 part of hexabromocyclododecane, 3-4 parts of aluminum nitride, 6-10 parts of bentonite, 0.3-1 part of aluminum dihydrogen phosphate, 5-8 parts of coalescing agent and 10-16 parts of deionized water. The waterproof coating prepared by the invention has the advantages of excellent flexibility, impermeability, weather resistance, heat resistance, good adhesion with the base layer, good flame-retardant effect, no toxicity, no environment pollution, high surface strength, uniform color, delicate hand feeling, strong scratch resistance and good abrasion resistance.

Owner:ANHUI KUAILAI WATERPROOFING & ANTI CORROSION

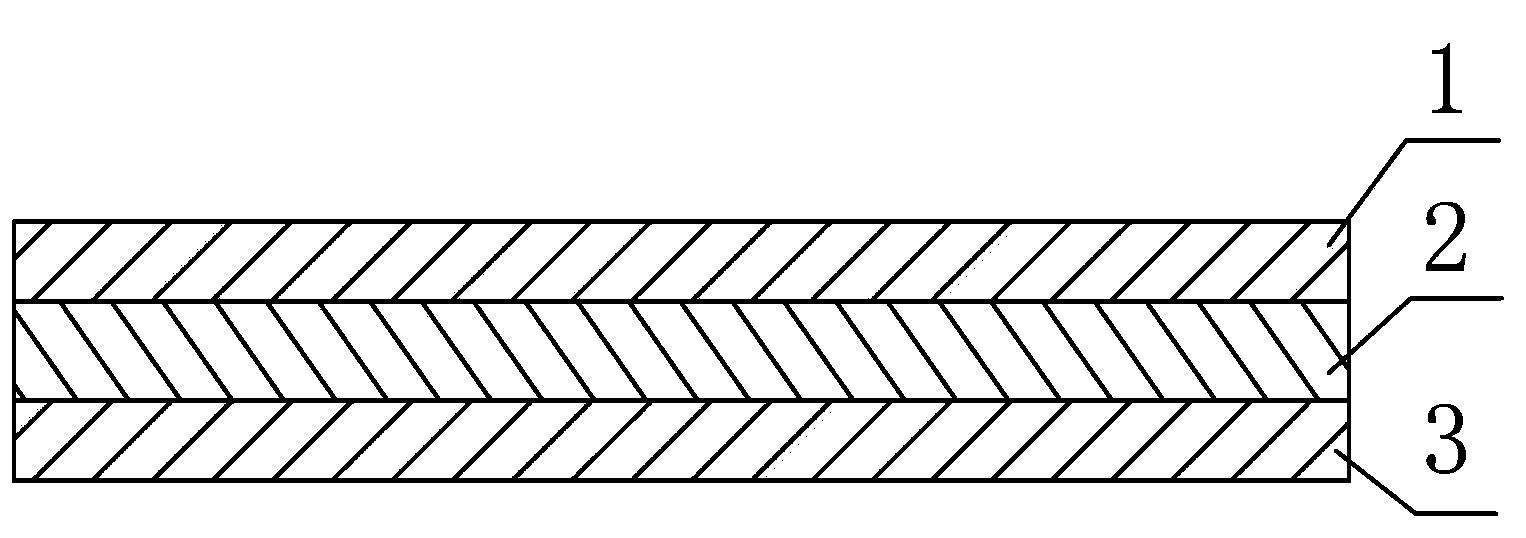

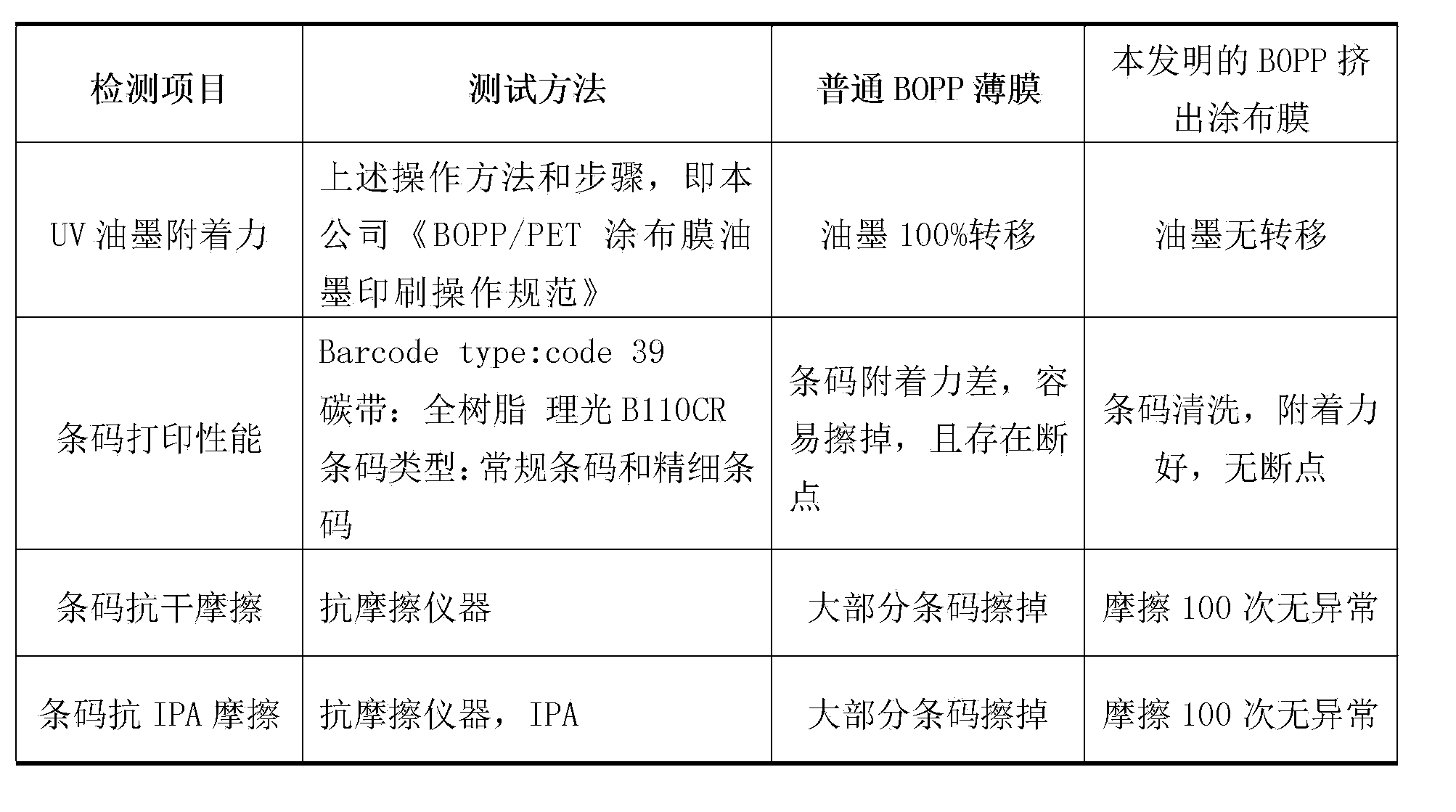

Bopp extruded coating film

InactiveUS20140017464A1Low costHigh printing fastnessSynthetic resin layered productsLabelsPolypropyleneAntioxidant

A coating film for labels of daily chemicals, beer, cosmetics, beverages, electronic products, and toys. A Biaxially Oriented Polypropylene (BOPP) extruded coating film includes a functional layer, a core layer, and a sub-functional layer. The core layer is located between the functional layer and the sub-functional layer. The functional layer, the core layer, and the sub-functional layer are co-extruded, and then biaxially stretched to form a unity. The weight percentages of the material of the functional layer, the material of the core layer, and the material of the sub-functional layer are 5-20%, 60-90%, and 5-20% respectively. The material of the functional layer is formed by mixing 30-60% of acrylic acid modified polyethylene, 30-45% of a polypropylene block copolymer, 7-20% of C9 hydrogenated petroleum resin, 1-3% of an antioxidant, and 1-2% of a dispersing agent.

Owner:HUBEI FIRSTA MATERIALS SCI & TECH GRP

Printing ink for label printing

The invention discloses printing ink for label printing. The printing ink is prepared from, by weight, 10-20 parts of acrylic acid resin, 4-8 parts of nitro-cotton, 10-15 parts of VAGH, 10-15 parts of CAB resin, 10-15 parts of EVA resin, 10-15 parts of hydrogenated rosin methyl ester, 5-15 parts of colorful pigment and 30-40 parts of diluent. By means of the printing ink for label printing, characters printed by the printing ink for label printing are clear in handwriting, edges of the characters are smooth, and wiping resistance is good.

Owner:广东紫泉标签有限公司

Multi-curing polyurethane latent curing agent and preparation method thereof

The invention relates to a multi-curing polyurethane latent curing agent. The multi-curing polyurethane latent curing agent is prepared from the following raw materials: diisocyanate, polymer polyol, a multi-hydroxyl monomer and hydroxyl-containing acrylate, the polyhydroxy small molecules are selected from one or more of trimethylolpropane, trimethylolethane, trimethylolmethane, 1,4-butanediol, 1,3-propylene glycol and 1,5-pentanediol. The invention also discloses a preparation method of the multi-curing polyurethane latent curing agent. The multi-curing polyurethane latent curing agent disclosed by the invention has relatively high hardness and chemical corrosion resistance after being cured, and has excellent water resistance, solvent corrosion resistance and wiping resistance.

Owner:韶关东森合成材料有限公司

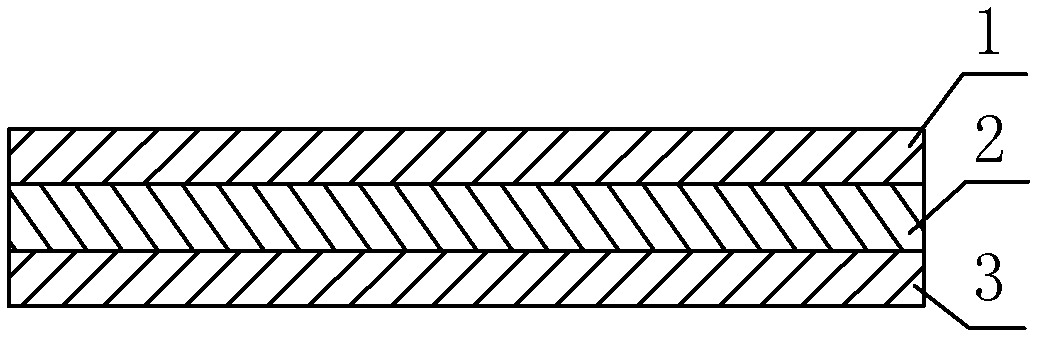

Biaxially-oriented polypropylene (BOPP) coated film

InactiveCN102555382AGood wipe resistanceImprove printabilitySynthetic resin layered productsEthyl acetatePolypropylene

The invention belongs to the technical field of packing materials, and particularly relates to a biaxially-oriented polypropylene (BOPP) coated film. The BOPP coated film is characterized by comprising 1 to 9 mass percent of functional layer, 91 to 98 mass percent of sandwich layer and 1 to 5 mass percent of secondary functional layer, wherein the sandwich layer is positioned between the functional layer and the secondary functional layer; the functional layer, the sandwich layer and the secondary functional layer are co-extruded and biaxially stretched to form a whole; the functional layer consists of the following raw materials in percentage by mass: 55 percent of ethyl acetate, 10 percent of C9 hydrogenated petroleum resin, 18 percent of polypropylene, 13 percent of polyvinyl alcohol, 2 percent of sodium hydroxide, 1 percent of antioxidant and 1 percent of dispersing agent; the sandwich layer is made from polypropylene; and the secondary functional layer comprises the following components in percentage by mass: 1 to 10 percent of SiO2 and 90 to 99 percent of polypropylene. The BOPP coated film has the characteristic of high wiping resistance property.

Owner:HUBEI FIRSTA MATERIALS SCI & TECH GRP

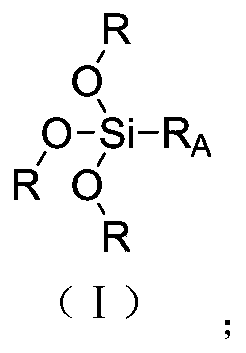

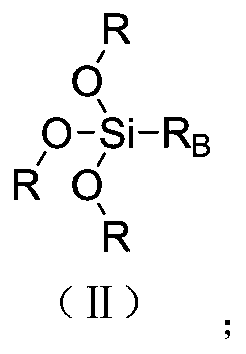

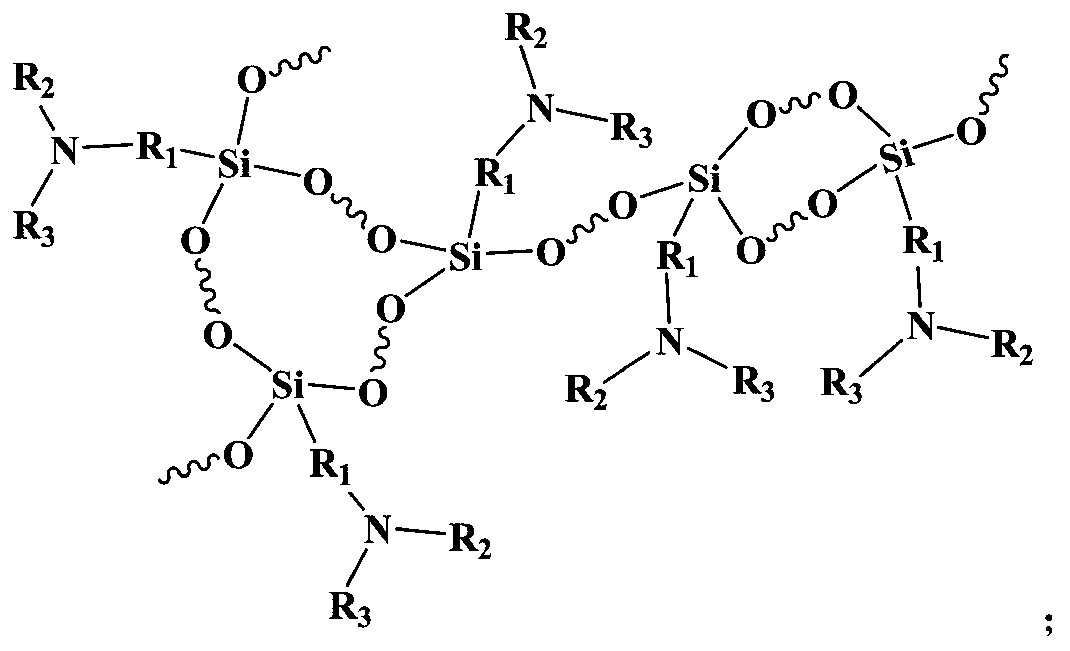

Crosslinked siloxane acrylate oligomer and photo-cured composition prepared from same

InactiveCN109749085AExcellent inhibition of oxygen polymerizationStrong antifoulingAntifouling/underwater paintsPaints with biocidesOxygen inhibitionPhoto curing

The invention discloses a crosslinked siloxane acrylate oligomer which is prepared by reaction crosslinking of a compound in a formula (I) and hydroxy-terminated polysiloxane. An RA group contains tertiary amine and an acrylate group, and R is alkyl with the carbon atom number of 1-8. The crosslinked siloxane acrylate oligomer is provided with a tertiary amine structure, the acrylate group and a crosslinked structure siloxane chain and has excellent oxygen inhibition suppression function. When a photo-cured composition prepared from the oligomer is photo-cured, the surface of the photo-cured composition is perfectly cured, curing speed is high, and firmness is improved. Moreover, the photo-cured composition has excellent antifouling capacity and wiping resistance.

Owner:新丰博兴聚合材料有限公司

BOPE (biaxially-oriented polypropylene) coating composite film

InactiveCN102602100AGood printabilityGood wipe resistanceDuplicating/marking methodsSynthetic resin layered productsComposite filmAntioxidant

The invention belongs to the technical field of packaging materials, particularly relates to a coating film and discloses a BOPE (biaxially-oriented polypropylene) coating composite film, which is characterized by comprising a function layer, a core layer and an auxiliary layer. The core layer is positioned between the function layer and the auxiliary function layer, the function layer, the core layer and the auxiliary function layer are integrated by means of biaxially stretching after being in coextrusion, the mass percent of the function layer ranges from 1% to 8%, the mass percent of the core layer ranges from 91% to 98%, the mass percent of the auxiliary function layer ranges from 1% to 5%, raw materials of the function layer include, by mass percent, 55% of acetic ether, 10% of C9 hydrogenated petroleum resin, 18% of metallocene polyethylene, 13% of polyvinyl alcohol, 2% of sodium hydroxide, 1% of antioxidant and 1% of dispersing agent, raw materials of the core layer include, by mass percent, 97.95% of linear polyethylene, 0.05% of nucleating agent and 2% of antioxidant 1076, components of the auxiliary function layer include, by mass percent, from 97 to 98% of metallocene polyethylene, from 1 to 2% of SiO2 and 1% of antioxidant 1076. The BOPE coating composite film has the advantages of fine printing performances and wiping resistance.

Owner:HUBEI FIRSTA MATERIALS SCI & TECH GRP

BOPE (biaxially-oriented polypropylene) coating composite film

InactiveCN102602100BGood printabilityGood wipe resistanceDuplicating/marking methodsSynthetic resin layered productsComposite filmAntioxidant

The invention belongs to the technical field of packaging materials, particularly relates to a coating film and discloses a BOPE (biaxially-oriented polypropylene) coating composite film, which is characterized by comprising a function layer, a core layer and an auxiliary layer. The core layer is positioned between the function layer and the auxiliary function layer, the function layer, the core layer and the auxiliary function layer are integrated by means of biaxially stretching after being in coextrusion, the mass percent of the function layer ranges from 1% to 8%, the mass percent of the core layer ranges from 91% to 98%, the mass percent of the auxiliary function layer ranges from 1% to 5%, raw materials of the function layer include, by mass percent, 55% of acetic ether, 10% of C9 hydrogenated petroleum resin, 18% of metallocene polyethylene, 13% of polyvinyl alcohol, 2% of sodium hydroxide, 1% of antioxidant and 1% of dispersing agent, raw materials of the core layer include, by mass percent, 97.95% of linear polyethylene, 0.05% of nucleating agent and 2% of antioxidant 1076, components of the auxiliary function layer include, by mass percent, from 97 to 98% of metallocene polyethylene, from 1 to 2% of SiO2 and 1% of antioxidant 1076. The BOPE coating composite film has the advantages of fine printing performances and wiping resistance.

Owner:HUBEI FIRSTA MATERIALS SCI & TECH GRP

B0PP (biaxially-oriented polypropylene) extrusion coating membrane

ActiveCN103538325AReduce lossLow costSynthetic resin layered productsLabelsPetroleum resinAntioxidant

The invention belongs to the technical field of label materials, and particularly relates to a coating membrane of labels for personal care products, beer, cosmetics, beverages, electronic products, toys and the like. A BOPP (biaxially-oriented polypropylene) extrusion coating membrane is characterized by comprising a functional layer, a core layer and a secondary functional layer; the core layer is positioned between the functional layer and the secondary functional layer; the functional layer, the core layer and the secondary functional layer are subjected to coextrusion, then are stretched bidirectionally, so as to form an integrated body; materials for preparing the functional layer, the core layer and the secondary functional layer respectively account for 5-20%of the total weight, 60-90%of the total weight, and 5-20% of the total weight; the materials for preparing the functional layer are prepared by mixing acrylic-modified polyethylene, blocked copolymerized polypropylene, C9 hydrogenated petroleum resin, an antioxidant and a dispersion agent; the acrylic modified polyethylene accounts for 30-60% of the total weight, the blocked copolymerized polypropylene accounts for 30-45% of the total weight, the C9 hydrogenated petroleum resin accounts for 7-20% of the total weight, the antioxidant accounts for1-3% of the total weight and the dispersion agent accounts for1-2%of the total weight. The BOPP extrusion coating membrane provided by the invention has the characteristics of low cost, good printing firmness and good wiping resistance.

Owner:HUBEI FIRSTA MATERIALS SCI & TECH GRP

BOPP (biaxially-oriented polypropylene) coating matt mould

ActiveCN102602102BGood printabilityGood wipe resistanceDuplicating/marking methodsSynthetic resin layered productsAntistatic agentPetroleum resin

The invention belongs to the technical field of packing materials, and particularly relates to a BOPP (biaxially-oriented polypropylene) coating matt mould, which is characterized in that the BOPP coating matt mould comprises a functional layer, a core layer and a secondary functional layer, the core layer is positioned between the functional layer and the secondary functional layer, the functional layer, the core layer and the secondary functional layer are coextruded and then bidirectionally stretched into a whole, the weight percents of the functional layer, the core layer and the secondary functional layer are 1-8%, 91-98% and 1-5% respectively, raw materials of the functional layer include, in weight percent, 55% of acetic ether, 10% of C9 hydrogenated petroleum resin, 18% of polypropylene, 13% of polyvinyl alcohol, 2% of sodium hydroxide, 1% of antioxidant and 1% of dispersing agent, raw materials of the core layer include, in weight percent, 92% of polypropylene, 5% of stiffening agent and 3% of antistatic agent, and raw materials of the secondary functional layer include, in weight percent, 48% of high-density polyethylene, 48% of polypropylene, 3% of SiO2 and 1% of antioxidant. The BOPP coating matt mould has a fine printing performance and has an extinction function.

Owner:HUBEI FIRSTA MATERIALS SCI & TECH GRP

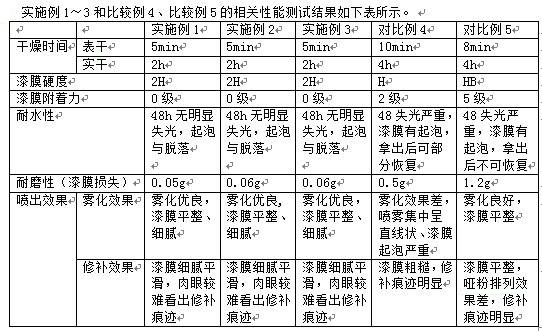

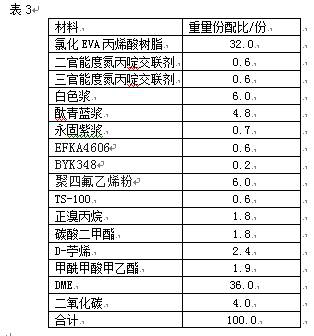

Aerosol paint and preparation method thereof

The aerosol paint is prepared from the following components in parts by weight: 25 to 35 parts of modified acrylic resin, 1 to 2 parts of a post-crosslinking agent, 7 to 13 parts of a coloring agent, 0.3 to 1.2 parts of a dispersing agent, 0.1 to 0.5 part of a flatting agent, 5 to 9 parts of wear-resistant filler, 0.5 to 1.5 parts of a reinforcing agent, 7 to 15 parts of an environment-friendly solvent and 35 to 45 parts of a propellant. The aerosol paint adopting the technical scheme has the following advantages: the aerosol paint has excellent adhesive force on the surfaces of plastic and polyolefin plastic; the paint has good compatibility with propellants, is excellent in spraying atomization, convenient to construct, smooth and fine in paint film and perfect in workpiece repairing effect, and repairing traces are difficult to perceive by naked eyes; a paint film is high in hardness, quick to dry and excellent in wear resistance. The invention also discloses a preparation method of the aerosol paint.

Owner:GUANGDONG SANVO CHEM IND TECH

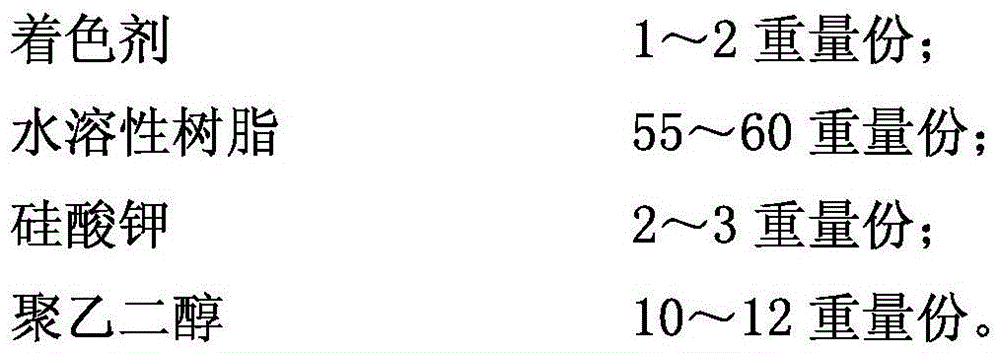

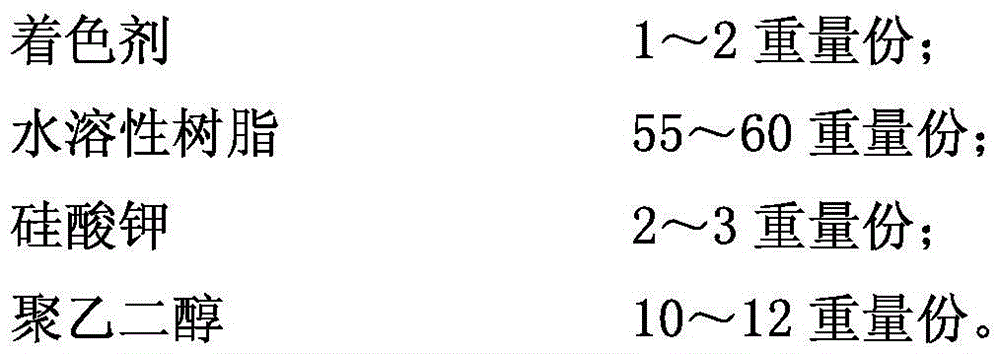

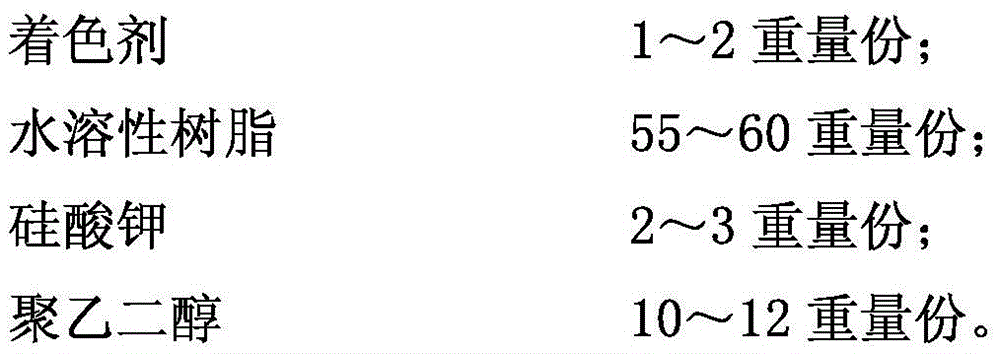

Toner for printer

InactiveCN105467787AImprove dispersion performanceGood glossDevelopersWater solublePolyethylene glycol

The invention relates to a toner for a printer. The toner for the printer comprises the following materials in parts by weight: 1-2 parts of a coloring agent, 55-60 parts of water-soluble resin, 2-3 parts of potassium metasilicate and 10-12 parts of polyethylene glycol. Through improvement and optimization of the formula of the toner, the dispersity of the toner is improved; and the toner has excellent glossiness, scrub resistance and color reproduction performance, has relatively high image density and fixing level and low waste powder amount, and is free of falling powder and free of viscosity to a drum or a fixing roller.

Owner:BEIHAI CHUANGSI ELECTRONICS TECH IND CO LTD

Flexible ink for white cover film of LED (Light Emitting Diode) soft light strip plate and preparation method of flexible ink

InactiveCN102532996BMeet the requirements of reflow soldering processImprove bending resistanceInksEngineeringTemperature resistance

Owner:四川日航电子科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com