Multi-curing polyurethane latent curing agent and preparation method thereof

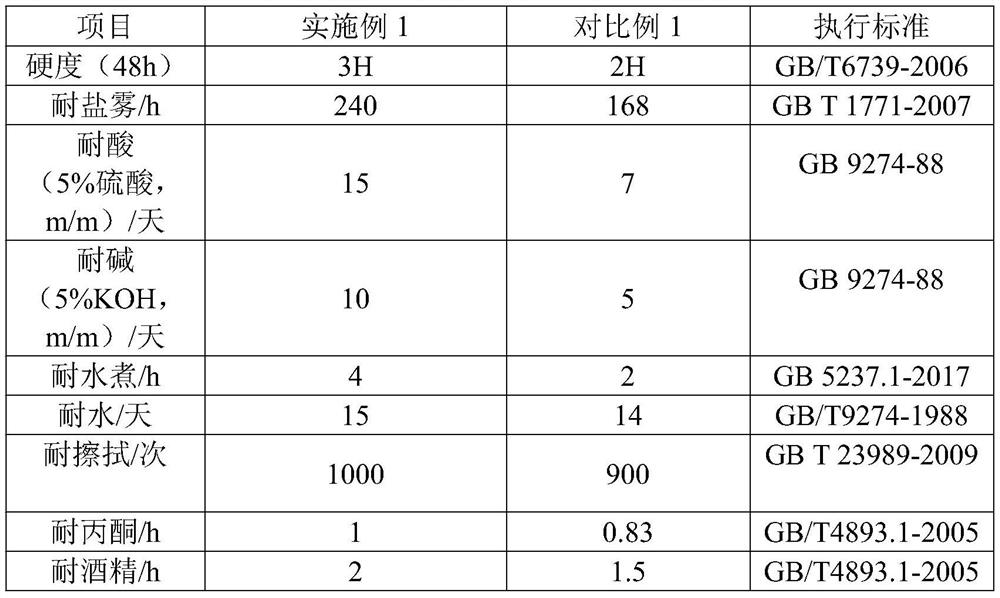

A latent curing agent and multiple curing technology, applied in the field of curing agent, can solve problems such as coating defects, coating hardness is not too high, too late to release, etc., to achieve high hardness and chemical corrosion resistance, excellent water resistance and solvent corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A multi-curing polyurethane latent curing agent, its raw materials include toluene diisocyanate, polyether polyol, polyester polyol, trimethylolpropane, and hydroxyethyl acrylate.

[0027] The preparation method of above-mentioned multiple curing polyurethane latent curing agent, comprises the steps:

[0028] S1. In parts by mass, 38 parts of toluene diisocyanate are dissolved in 25 parts of butyl acetate to form a mixture;

[0029] S2. Under the condition of 60°C, in parts by mass, 15 parts of polyether polyol and 12 parts of polyester polyol were added in batches to the mixture, reacted for 2 hours, and intermediate product 1 was obtained;

[0030] S3. Under the condition of 60°C, according to the number of parts by mass, 7.7 parts of trimethylolpropane were added in batches to the intermediate product 1, and reacted for 2 hours to obtain the intermediate product 2;

[0031] S4. Under the condition of 60°C, by mass parts, 2.5 parts of hydroxyethyl acrylate were added...

Embodiment 2

[0034] A multi-curing polyurethane latent curing agent, the raw materials of which include diphenylmethane diisocyanate, polyester polyol, trimethylol propane and hydroxyethyl methacrylate.

[0035] The preparation method of above-mentioned multiple curing polyurethane latent curing agent, comprises the steps:

[0036] S1. In parts by mass, 46 parts of diphenylmethane diisocyanate are dissolved in 30 parts of butyl acetate to form a mixture;

[0037] S2. Under the condition of 70° C., in parts by mass, 15 parts of polyester polyol was added in batches to the mixture, reacted for 2 hours, and intermediate product 1 was obtained;

[0038] S3. Under the condition of 70°C, according to the number of parts by mass, 6.2 parts of trimethylolpropane were added in batches to the intermediate product 1, and reacted for 2 hours to obtain the intermediate product 2;

[0039] S4. Under the condition of 70°C, according to the number of parts by mass, add 1 part of hydroxyethyl methacrylate...

Embodiment 3

[0042] A multi-curing polyurethane latent curing agent, the raw materials of which include toluene diisocyanate, polyether polyol, polyester polyol, trimethylolpropane, and hydroxypropyl acrylate.

[0043] The preparation method of above-mentioned multiple curing polyurethane latent curing agent, comprises the steps:

[0044] S1. In parts by mass, 40 parts of toluene diisocyanate is dissolved in 20 parts of butyl acetate to form a mixture;

[0045] S2. Under the condition of 65°C, in parts by mass, 13 parts of polyether polyol and 15 parts of polyester polyol were added in batches to the mixture, reacted for 2 hours, and intermediate product 1 was obtained;

[0046] S3. Under the condition of 65°C, in parts by mass, 2.3 parts of 1,4-butanediol were added in batches to the intermediate product 1, and reacted for 2 hours to obtain the intermediate product 2;

[0047] S4. Under the condition of 65° C., in parts by mass, 3 parts of hydroxypropyl acrylate were added to the interme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com